Abstract

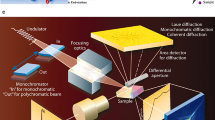

High performance materials that can withstand radiation, heat, multiaxial stresses, and corrosive environment are necessary for the deployment of advanced nuclear energy systems. Nondestructive in situ experimental techniques utilizing high energy x-rays from synchrotron sources can be an attractive set of tools for engineers and scientists to investigate the structure–processing–property relationship systematically at smaller length scales and help build better material models. In this study, two unique and interconnected experimental techniques, namely, simultaneous small-angle/wide-angle x-ray scattering (SAXS/WAXS) and far-field high-energy diffraction microscopy (FF-HEDM) are presented. The changes in material state as Fe-based alloys are heated to high temperatures or subject to irradiation are examined using these techniques.

Similar content being viewed by others

References

S.J. Zinkle and B.N. Singh: Microstructure of neutron-irradiated iron before and after tensile deformation. J. Nucl. Mater. 351(1–3), 269 (2006).

B.N. Singh and J.H. Evans: Significant differences in defect accumulation behavior between FCC and BCC crystals under cascade damage conditions. J. Nucl. Mater. 226(3), 277 (1995).

H. Trinkaus, B.N. Singh, and A.J.E. Foreman: Glide of interstitial loops produced under cascade damage conditions: Possible effects on void formation. J. Nucl. Mater. 199(1), 1 (1992).

H. Wollenberger: Phase-transformations under irradiation. J. Nucl. Mater. 216, 63 (1994).

S.J. Zinkle and J.T. Busby: Structural materials for fission & fusion energy. Mater. Today 12(11), 12 (2009).

D.R. Haeffner, J.D. Almer, and U. Lienert: The use of high energy X-rays for the advanced photon source to study stresses in materials. Mater. Sci. Eng., A 399(1), 120–127 (2005).

M.R. Daymond, M.L. Young, J.D. Almer, and D.C. Dunand: Strain and texture evolution during mechanical loading of a crack tip in martensitic shape-memory NiTi. Acta Mater. 55(11), 3929 (2007).

A. King, G. Johnson, D. Engelberg, W. Ludwig, and J. Marrow: Observations of intergranular stress corrosion cracking in a grain-mapped polycrystal. Science 321(5887), 382 (2008).

H.F. Poulsen: Three-Dimensional X-Ray Diffraction Microscopy: Mapping Polycrystals and their Dynamics. Springer Tracts in Modern Physics Vol. 205; Springer-Verlag: Germany.

R. Suter, D. Hennessy, C. Xiao, and U. Lienert: Forward modelling method for microstructure reconstruction using x-ray diffraction microscopy: Single-crystal verification. Rev. Sci. Instrum. 77, 123905, 2006.

D.T. Hoelzer, K.A. Unocic, E.T. Manneschmidt, and M.A. Sokolov: Reference Characterization of the Advanced ODS 14YWT-SM12 Heat Used in HFIR JP30/31 Neutron Irradiation Experiment, Fusion Reactor Materials Program DOE/ER-0313-0352, Vol. 52, 2012.

S.D. Shastri, J. Almer, C. Ribbing, and B. Cederstrom: High-energy X-ray optics with silicon saw-tooth refractive lenses. J. Synchrotron Radiat. 14, 204 (2007).

National Institute of Standards and Technology: X-Ray Powder Diffraction Intensity Set (Quantitative Powder Diffraction Standard), USA, 2012. https://www-s.nist.gov/srmors/view_detail.cfm?srm=674B.

F. Zhang, J. Ilavsky, G.G. Long, J.P.G. Quintana, A.J. Allen, and P.R. Jemian: Glassy carbon as an absolute intensity calibration standard for small-angle scattering. Metall. Mater. Trans. A 41A(5), 1151 (2010).

L.Y. Wang, M.M. Li, and J. Almer: In situ characterization of Grade 92 steel during tensile deformation using concurrent high energy X-ray diffraction and small angle X-ray scattering. J. Nucl. Mater. 440(1–3), 81 (2013).

J.T. Busby: Advanced materials for nuclear reactor systems: Alloys by design to overcome past limitations. In International Conference on Fast Reactors and Related Fuel Cycles (FR09): Challenges and Opportunities, Japan, 2009.

National Institute of Standards and Technology: Single Crystal Diffractometer Alignment Standard–Ruby Sphere, USA, 2001. https://www-s.nist.gov/srmors/view_detail.cfm?srm=1990.

H. Sharma, R.M. Huizenga, and S.E. Offerman: A fast methodology to determine the characteristics of thousands of grains using three-dimensional X-ray diffraction. I. Overlapping diffraction peaks and parameters of the experimental setup. J. Appl. Crystallogr. 45, 693 (2012).

H. Sharma, R.M. Huizenga, and S.E. Offerman: A fast methodology to determine the characteristics of thousands of grains using three-dimensional X-ray diffraction. II. Volume, centre-of-mass position, crystallographic orientation and strain state of grains. J. Appl. Crystallogr. 45, 705 (2012).

J. Ilavsky and P.R. Jemian: Irena: Tool suite for modeling and analysis of small-angle scattering. J. Appl. Crystallogr. 42, 347 (2009).

S.E. Offerman and H. Sharma: Grain nucleation and growth of individual austenite and ferrite grains studied by 3DXRD microscopy at the ESRF. In In-situ Studies with Photons, Neutrons and Electrons Scattering, T. Kannengiesser, S.S. Babu, Y. Komizo, and A.J. Ramirez eds.; Springer-Verlag: Berlin, 2010; p. 41.

U.F. Kocks, C.N. Tomé, H.-R. Wenk, and H. Mecking: Texture and Anisotropy: Preferred Orientations in Polycrystals and Their Effect on Materials Properties (Cambridge University Press, UK, 2000).

C. Mieszczynski, G. Kuri, C. Degueldre, M. Martin, J. Bertsch, C.N. Borca, D. Grolimund, C. Delafoy, and E. Simoni: Irradiation effects and micro-structural changes in large grain uranium dioxide fuel investigated by micro-beam X-ray diffraction. J. Nucl. Mater. 444(1–3), 274 (2014).

E.D. Specht, F.J. Walker, and W.J. Liu: X-ray microdiffraction analysis of radiation-induced defects in single grains of polycrystalline Fe. J. Synchrotron Radiat. 17, 250 (2010).

H. Peisl: Defect properties from x-ray scattering experiments. J. Phys. Colloques. 37(C7), 47–53 (1976).

D. Grasse, B. Vonguerard, and J. Peisl: Interstitial clustering in cascades in fast-neutron irradiated aluminum by diffuse-x-ray scattering. J. Nucl. Mater. 108(1–2), 169 (1982).

R.I. Barabash, G.E. Ice, and F.J. Walker: Quantitative microdiffraction from deformed crystals with unpaired dislocations and dislocation walls. J. Appl. Phys. 93(3), 1457 (2003).

F. Hofmann, S. Keegan, and A.M. Korsunsky: Diffraction post-processing of 3D dislocation dynamics simulations for direct comparison with micro-beam Laue experiments. Mater. Lett. 89, 66 (2012).

W.V. Vaidya and K. Ehrlich: Radiation-induced recrystallization, its cause and consequences in heavy-ion irradiated 20-percent cold-drawn steels of type 1.4970. J. Nucl. Mater. 113(2–3), 149 (1983).

J. Rest: Derivation of analytical expressions for the network dislocation density, change in lattice parameter, and for the recrystallized grain size in nuclear fuels. J. Nucl. Mater. 349(1–2), 150 (2006).

A.R. Stokes and A.J.C. Wilson: The diffraction of X rays by distorted crystal aggregates–I. Proc. Phys. Soc. 56, 174 (1944).

L. Hsiung, S. Tumey, M. Fluss, Y. Serruys, and F. Willaime: HRTEM study of the role of nanoparticles in ODS ferritic steel. Presented at the 2010 MRS Fall Meeting, USA, 2010.

X. Pan, X. Wu, K. Mo, X. Chen, J. Almer, J. Ilavsky, D.R. Haeffner, and J.F. Stubbins: Lattice strain and damage evolution of 9–12%Cr ferritic/martensitic steel during in situ tensile test by X-ray diffraction and small angle scattering. J. Nucl. Mater. 407(1), 10 (2010).

L. Wang, M. Li, and J. Almer: Investigation of deformation and microstructural evolution in Grade 91 ferritic-martensitic steel by in situ high-energy X-rays. Acta Mater. 62, 239 (2014).

S.L. Wong and P.R. Dawson: Influence of directional strength-to-stiffness on the elastic–plastic transition of fcc polycrystals under uniaxial tensile loading. Acta Mater. 58(5), 1658–1678 (2010), ISSN 1359-6454. https://doi.org/10.1016/j.actamat.2009.11.009.

U.F. Kocks: The relation between polycrystal deformation and single-crystal deformation. Metall. Mater. Trans. B 1(5), 1121–1143 (1970).

U.F. Kocks, G.R. Canova, and J.J. Jonas: Yield vectors in F.C.C. crystals. Acta Metall. 31(8), 1243–1252 (1983).

H. Ritz, P. Dawson, and T. Marin: Analyzing the orientation dependence of stresses in polycrystals using vertices of the single crystal yield surface and crystallographic fibers of orientation space. J. Mech. Phys. Solids 58(1), 54–72 (2010), ISSN 0022-5096. https://doi.org/10.1016/j.jmps.2009.08.007.

R.E. Stoller, F.J. Walker, E.D. Specht, D.M. Nicholson, R.I. Barabash, P. Zschack, and G.E. Ice: Diffuse X-ray scattering measurements of point defects and clusters in iron. J. Nucl. Mater. 367, 269 (2007).

M.A. Krivoglaz: X-ray and Neutron Diffraction in Nonideal Crystals (Springer Verlag, Germany, 1996).

J. Spino and D. Papaioannou: Lattice parameter changes associated with the rim-structure formation in high burn-up UO2 fuels by micro X-ray diffraction. J. Nucl. Mater. 281(2–3), 146 (2000).

M. Song, Y.D. Wu, D. Chen, X.M. Wang, C. Sun, K.Y. Yu, Y. Chen, L. Shao, Y. Yang, K.T. Hartwig, and X. Zhang: Response of equal channel angular extrusion processed ultrafine-grained T91 steel subjected to high temperature heavy ion irradiation. Acta Mater. 74, 285 (2014).

K.G. Field, L.M. Barnard, C.M. Parish, J.T. Busby, D. Morgan, and T.R. Allen: Dependence on grain boundary structure of radiation induced segregation in a 9 wt.% Cr model ferritic/martensitic steel. J. Nucl. Mater. 435(1–3), 172 (2013).

A. Alsabbagh, R.Z. Valiev, and K.L. Murty: Influence of grain size on radiation effects in a low carbon steel. J. Nucl. Mater. 443(1–3), 302 (2013).

W. Han, M.J. Demkowicz, N.A. Mara, E. Fu, S. Sinha, A.D. Rollett, Y. Wang, J.S. Carpenter, I.J. Beyerlein, and A. Misra: Design of radiation tolerant materials via interface engineering. Adv. Mater. 25(48), 6975 (2013).

G.K. Williamson and W.H. Hall: X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1(1), 22–31 (1953), ISSN 0001-6160. https://doi.org/10.1016/0001-6160(53http://dx.doi.org/10.1016/0001-6160(53)90006-6.

B.E. Warren and B.L. Averbach: The effect of cold-work distortion on X-ray patterns. J. Appl. Phys. 21, 595–599 (1950). DOI:https://doi.org/10.1063/1.1699713.

T. Ungár and A. Borbély: The effect of dislocation contrast on x-ray line broadening: A new approach to line profile analysis. Appl. Phys. Lett. 69, 3173 (1996). (doi: https://doi.org/10.1063/1.117951).

S.L. Wong, J-S. Park, M.P. Miller, and P.R. Dawson: A framework for generating synthetic diffraction images from deforming polycrystals using crystal-based finite element formulations. Comput. Mater. Sci. 77, 456–466 (2013), ISSN 0927-0256. https://doi.org/10.1016/j.commatsci.2013.03.019.

M. Obstalecki, S.L. Wong, P.R. Dawson, and M.P. Miller: Quantitative analysis of crystal scale deformation heterogeneity during cyclic plasticity using high-energy X-ray diffraction and finite-element simulation. Acta Mater. 75, 259–272 (2014), ISSN 1359-6454. https://doi.org/10.1016/j.actamat.2014.04.059.

N.R. Barton, A. Arsenlis, and J. Marian: A polycrystal plasticity model of strain localization in irradiated iron. J. Mech. Phys. Solids 61(2), 341–351 (2013), ISSN 0022-5096, https://doi.org/10.1016/j.jmps.2012.10.009.

R.A. Lebensohn and C.N. Tomé: A self-consistent anisotropic approach for the simulation of plastic deformation and texture development of polycrystals: Application to zirconium alloys. Acta Metall. Mater. 41(9), 2611–2624 (1993), ISSN 0956-7151. http:/dx./doi.org/10.1016/0956-7151(93http://dx.doi.org/10.1016/0956-7151(93)90130-K.

P. Dawson, M. Miller, T-S. Han, and J. Bernier: An accelerated methodology for the evaluation of critical properties in polyphase alloys. Metall. Mater. Trans. A 36(7), 1627–1641 (2005).

C. Efstathiou, D.E. Boyce, J-S. Park, U. Lienert, P.R. Dawson, and M.P. Miller: A method for measuring single-crystal elastic moduli using high-energy X-ray diffraction and a crystal-based finite element model. Acta Mater. 58(17), 5806–5819 (2010), ISSN 1359-6454. https://doi.org/10.1016/j.actamat.2010.06.056.

ACKNOWLEDGMENTS

The research was sponsored by the U.S. Department of Energy, Office of Nuclear Energy, for the Nuclear Energy Enabling Technology (NEET) Program under Contract No. DE-AC02-06CH11357. This research used resources of the Advanced Photon Source, a U.S. Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357. Neutron-irradiated specimens were provided by the ATR National Scientific User Facility (NSUF) at the Idaho National Laboratory (INL). The authors would like to thank Collin Knight, Brandon Miller, and James Cole at the ATR NSUF, INL. The authors also would like to thank Loren A. Knoblich, Jakub P. Dobrzynski, Yiren Chen at the Irradiated Materials Laboratory, Brent A. Finney at Special Materials, John Vacca at Health Physics, Environment, Safety, and Quality Assurance, APS Radioactive Sample Safety Review Committee at ANL. Erika Benda and Ali Mashayekhi at the APS, ANL are thanked for designing and fabricating the specimen holders for the irradiated TEM specimen.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, JS., Zhang, X., Sharma, H. et al. High-energy synchrotron x-ray techniques for studying irradiated materials. Journal of Materials Research 30, 1380–1391 (2015). https://doi.org/10.1557/jmr.2015.50

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.50