Abstract

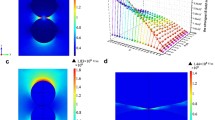

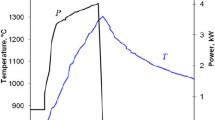

Microwave sintering is a novel and efficient technology for the rapid preparation of metallic materials. In this paper, an investigation has been performed on the distribution of microwave electromagnetic fields in a metallic particle system and its influence on sintering behavior. The results show that the microstructure of the “metallic-void” will induce a nonuniform distribution and focusing effect of electromagnetic fields during microwave processing, which may accelerate the sintering process. However, further study shows that the focusing effect will decline as the neck grows larger, and will also decline from outside to inside within the loosely packed powder system, which will result in the slowdown of the sintering rate. These results were supported by the synchrotron radiation computed tomography experimental observation of the microstructure evolution of metallic powders during an entire uninterrupted microwave sintering process.

Similar content being viewed by others

References

P. Yadoji, R. Peelamedu, D. Agrawal, and R. Roy: Microwave sintering of Ni-Zn ferrites: Comparison with conventional sintering. Mater. Sci. Eng., B 98, 269 (2003).

D. Agrawal: Latest global developments in microwave materials processing. Mater. Res. Innovations 14(1), 3 (2010).

D.E. Clark, D.C. Folz, and J.K. West: Processing materials with microwave energy. Mater. Sci. Eng., A 287, 153 (2000).

M. Oghbaei and O. Mirzaee: Microwave versus conventional sintering: A review of fundamentals, advantages and applications. J. Alloys Compd. 494, 175 (2010).

R.R. Menezes, P.M. Souto, and R.H.G.A. Kiminami: Microwave hybrid fast sintering of porcelain bodies. J. Mater. Process. Technol. 190, 223 (2007).

J. Cheng, D. Agrawal, Y. Zhang, and R. Roy: Microwave sintering of transparent alumina. Mater. Lett. 56, 587 (2002).

R. Roy, D. Agrawal, J. Cheng, and Sh. Gedevanishvili: Full sintering of powdered-metal bodies in a microwave field. Nature 339, 668 (1999).

B.A. Wilson, K.Y. Lee, and E.D. Case: Diffusive crack-healing behavior in polycrystalline alumina: A comparison between microwave annealing and conventional annealing. Mater. Res. Bull. 32(12), 1607 (1997).

M.A. Janney, H.D. Kimrey, M.A. Schmidt, and J.O. Kiggans: Grain growth in microwave-annealed alumina. J. Am. Ceram. Soc. 74(7), 1675 (1991).

M.A. Janney, H.D. Kimrey, W.R. Allen, and J.O. Kiggans: Enhanced diffusion in sapphire during microwave heating. J. Mater. Sci. 32, 1347 (1997).

D. Demirskyi, D. Agrawal, and A. Ragulya: Neck growth kinetics during microwave sintering of nickel powder. J. Alloys Compd. 509(5), 1790 (2011).

N. Yoshikawa: Fundamentals and applications of microwave heating of metals. J. Microwave Power Electromagn. Energy 44(1), 4 (2010).

D. Demirskyi, D. Agrawal, and A. Ragulya: Neck growth kinetics during microwave sintering of copper. Scr. Mater. 62, 552 (2010).

D. Demirskyi, D. Agrawal, and A. Ragulya: Neck formation between copper spherical particles under single-mode and multimode microwave sintering. Mater. Sci. Eng., A 527, 2142 (2010).

T. Saji: Microwave Sintering of Large Products. In Microwave Processing of Materials V, M.F. Iskander, J.O. Kiggins, Jr., and J.C. Bolomey eds.; Materials Research Society: Pittsburgh, PA, 1996.

A. Birnboim, J.P. Calame, and Y. Carmel: Microfocusing and polarization effects in spherical neck ceramic microstructures during microwave. J. Appl. Phys. 85, 478 (1999).

J. Ma, J.F. Diehl, E.J. Johnson, K.R. Martin, N.M. Miskovsky, C.T. Smith, G.J. Weisel, B.L. Weiss, and D.T. Zimmerman: Systematic study of microwave absorption, heating and microstructure evolution of porous copper powder metal compacts. J. Appl. Phys. 101, 074906 (2007).

T. Galek, K. Porath, E. Burkel, and U. van Rienen: Extraction of effective permittivity and permeability of metallic powders in the microwave range. Modell. Simul. Mater. Sci. Eng. 18, 025015 (2010).

J. Cheng, R. Roy, and D. Agrawal: Radically different effects on materials by separated microwave electric and magnetic fields. Mater. Res. Innovations 5, 170 (2002).

K.I. Rybakov, V.E. Semenov, S.V. Egorov, A.G. Eremeev, I.V. Plotnikov, and Yu.V. Bykov: Microwave heating of conductive powder materials. J. Appl. Phys. 99, 023506 (2006).

R. Roy, P.D. Peelamedu, L. Hurtt, J.P. Cheng, and D. Agrawal: Definitive experimental evidence for microwave effects: Radically new effects of separated E and H fields, such as decrystallization of oxides in seconds. Mater. Res. Innovations 6, 128 (2002).

F. Xu, Y. Li, X. Hu, Y. Niu, J. Zhao, and Z. Zhang: In situ investigation of metal’s microwave sintering. Mater. Lett. 67, 162 (2012).

X. Li and X.F. Hu: Synchrotron radiation tomography for reconstruction of layer structures and internal damage of composite material. Chin. J. Lasers, B B8(6), 503 (1999).

K.I. Rybakov, E.A. Olevsky, and E.V. Krikun: Microwave sintering: Fundamentals and modeling. J. Am. Ceram. Soc. 96(4), 1003 (2013).

ACKNOWLEDGMENT

This work was supported by National Nature Science Foundation of China under the Contract Nos. 11272305, 11402160 and 11390362. The authors warmly thank Niu Yu, Hongyan Qu and Kang Dan for the assistance in conducting the experiment.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Y., Xu, F., Hu, X. et al. Focusing effect of electromagnetic fields and its influence on sintering during the microwave processing of metallic particles. Journal of Materials Research 30, 3663–3670 (2015). https://doi.org/10.1557/jmr.2015.344

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.344