Abstract

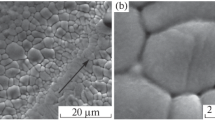

The martensitic transformation of Fe–22 wt% Ni austenite was investigated by high-resolution dilatometry as well as differential thermal analysis. Macroscopically discontinuous formation of lath martensite was observed, manifested in a train of transformation-rate maxima. It is proposed that the modulation of the transformation rate is caused by simultaneous formation of blocks in different martensite packages. The origin of simultaneity is ascribed to the interplay of chemical driving force, developing strain energy, and its relaxation upon sufficiently slow cooling. The transformation-rate maxima become more distinct with decreasing cooling rate (CR), clearly indicating the involvement of a thermally activated process in martensite formation. Quantitative analysis of the microstructure of differently cooled specimens revealed smaller martensite block sizes for higher CRs. All observations are compatible with athermal nucleation and thermally activated growth. (Local) strain relaxation in the austenite was identified as the involved thermally activated mechanism.

Similar content being viewed by others

References

Z. Nishiyama: Martensitic Transformation, M.E. Fine, M. Meshii, and C.M. Wayman eds.; Academic Press: New York, 1978.

E.S. Machlin and M. Cohen: Burst phenomenon in martensitic transformation. Trans AIME 191, 746 (1951).

R. Brook and A. Entwisle: Kinetics of burst transformation to martensite. J. Iron Steel Inst. 203, 905 (1965).

A. Amengual, L. Manosa, F. Marco, C. Picornell, C. Segui, and V. Torra: Systematic study of the martensitic transformation in a Cu-Zn-Al alloy. Reversibility versus irreversibility via acoustic emission. Thermochim. Acta 116, 195 (1987).

E.K.H. Salje, J. Koppensteiner, M. Reinecker, W. Schranz, and A. Planes: Jerky elasticity: Avalanches and the martensitic transition in Cu74.08Al23.13Be2.79 shape-memory alloy. Appl. Phys. Lett. 95, 231908 (2009).

M.C. Gallardo, J. Manchado, F.J. Romero, J. del Cerro, E.K.H. Salje, A. Planes, E. Vives, R. Romero, and M. Stipcich: Avalanche criticality in the martensitic transition of Cu67.64Zn16.71Al15.65 shape-memory alloy: A calorimetric and acoustic emission study. Phys. Rev. B 81, 174102 (2010).

R. Niemann, J. Kopeček, O. Heczko, J. Romberg, L. Schultz, S. Fähler, E. Vives, L. Mañosa, and A. Planes: Localizing sources of acoustic emission during the martensitic transformation. Phys. Rev. B 89, 214118 (2014).

E.J. Mittemeijer: Fundamentals of Materials Science (Springer, Berlin-Heidelberg, 2011).

S. Loewy, B. Rheingans, S.R. Meka, and E.J. Mittemeijer: Unusual martensite-formation kinetics in steels: Observation of discontinuous transformation rates. Acta Mater. 64, 93 (2014).

M. Villa, K. Pantleon, M. Reich, O. Kessler, and M.A.J. Somers: Kinetics of anomalous multi-step formation of lath martensite in steel. Acta Mater. 80, 468 (2014).

M. Villa, M.F. Hansen, K. Pantleon, and M.A.J. Somers: Anomalous kinetics of lath martensite formation in stainless steel. Mater. Sci. Technol. (2014). DOI: 10.1179/1743284714Y.0000000709.

L. Kaufman and M. Cohen: The martensitic transformation in the iron-nickel system. Trans AIME 206, 1393 (1956).

J.A. Klostermann and W.G. Burgers: Surface martensite in iron-nickel. Acta Metall. 12, 355 (1964).

J. Marder and A. Marder: The morphology of iron-nickel massive martensite. Trans. ASM 62, 1 (1969).

S. Floreen: The physical metallurgy of maraging steels. Int. Mater. Rev. 13, 115 (1968).

K. Tsuzaki, T. Maki, and I. Tamura: Isothermal character and cooling rate dependence of lath martensitic transformation in Fe-15% Ni alloy. Scr. Metall. 21, 1693 (1987).

K. Tsuzaki, T. Fukiage, T. Maki, and I. Tamura: The effect of Ni content on the isothermal character of lath martensitic transformation in Fe-Ni alloys. Mater. Sci. Forum 56–58, 229 (1990).

E.A. Wilson, S. Allen, and J. Butler: γ→α-transformation on Fe-15Ni. Met. Sci. 16, 539 (1982).

E.A. Wilson, D.V. Shtansky, and Y. Ohmori: A kinetic and electronmicroscopic study of transformations in continuously cooled Fe-15% Ni alloys. ISIJ Int. 41, 866 (2001).

Y. Liu, L. Zhang, F. Sommer, and E.J. Mittemeijer: Kinetics of martensite formation in substitutional Fe-Al alloys; dilatometric analysis. Metall. Mater. Trans. A 44, 1430 (2013).

Y.C. Liu, F. Sommer, and E.J. Mittemeijer: Calibration of the differential dilatometric measurement signal upon heating and cooling; thermal expansion of pure iron. Thermochim. Acta 413, 215 (2004).

W. Baumann, A. Leineweber, and E.J. Mittemeijer: Calibration and desmearing of a differential thermal analysis measurement signal — Upon heating and cooling — In the high-temperature region. Thermochim. Acta 472, 50 (2008).

A.T.W. Kempen, F. Sommer, and E.J. Mittemeijer: Calibration and desmearing of a differential thermal analysis measurement signal upon heating and cooling. Thermochim. Acta 383, 21 (2002).

H. Kitahara, R. Ueji, N. Tsuji, and Y. Minamino: Crystallographic features of lath martensite in low-carbon steel. Acta Mater. 54, 1279 (2006).

S. Morito, X. Huang, T. Furuhara, T. Maki, and N. Hansen: The morphology and crystallography of lath martensite in alloy steels. Acta Mater. 54, 5323 (2006).

N. Thadhani and A. Meyers: Kinetics of isothermal martensitic transformation. Prog. Mater. Sci. 30, 1 (1986).

S. Morito, R. Igarashi, K. Kamiya, T. Ohba, and T. Maki: Effect of cooling rate on morphology and crystallography of lath martensite in Fe-Ni alloys. Mater. Sci. Forum 638–642, 1459 (2010).

K. Tsuzaki and T. Maki: The effect of cooling rate on the morphology of lath martensite in Fe-Ni alloys. J. Japan Inst. Met. 45, 126 (1981).

R.E. Cech and D. Turnbull: Heterogeneous nucleation of martensite transformation. Trans AIME 206, 124 (1956).

J. Fisher: Application of nucleation theory to isothermal martensite. Acta Metall. 1, 1 (1953).

S.R. Pati and M. Cohen: Kinetics of isothermal martensitic transformations in an iron-nickel-manganese alloy. Acta Metall. 19, 1327 (1971).

V. Raghavan and M. Cohen: Measurement and interpretation of isothermal martensitic kinetics. Metall. Mater. Trans. B 2, 2409 (1971).

G. Ghosh and G.B. Olson: Kinetics of fcc→bcc heterogeneous martensitic nucleation-II. Thermal activation. Acta Metall. Mater. 42 (10), 3371 (1994).

D. Kim, S-J. Lee, and B.C. de Cooman: Microstructure of low C steel isothermally transformed in the Ms to Mf temperature range. Metall. Mater. Trans. A 43, 4967 (2012).

M. Villa, M.F. Hansen, K. Pantleon, and M.A.J. Somers: Thermally activated growth of lath martensite in Fe–Cr–Ni–Al precipitation hardenable stainless steel. Mater. Sci. Technol. 31, 115 (2015).

Y.C. Liu, F. Sommer, and E.J. Mittemeijer: Abnormal austenite-ferrite transformation behaviour in substitutional Fe-based alloys. Acta Mater. 51, 507 (2003).

Y.C. Liu, F. Sommer, and E.J. Mittemeijer: Abnormal austenite–ferrite transformation behaviour of pure iron. Philos. Mag. 84, 1853 (2004).

ACKNOWLEDGMENTS

The authors thank Dr. M. Villa (Technical University of Denmark) for critical reading of the manuscript and helpful discussions and Dr. E. Bischoff (Max Planck Institute for Intelligent Systems) for performing the EBSD (electron backscatter diffraction) measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Loewy, S., Rheingans, B., Meka, S.R. et al. Modulated martensite formation behavior in Fe–Ni-based alloys; athermal and thermally activated mechanisms. Journal of Materials Research 30, 2101–2107 (2015). https://doi.org/10.1557/jmr.2015.175

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.175