Abstract

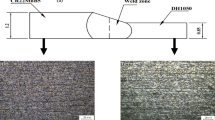

NiCrMoV steels used in nuclear rotor with heavy section were successfully fabricated by ultra-narrow gap submerged arc welding method. In this study, the mechanical properties including the tensile and impact toughness of the welded joints (WJs) with a wide temperature range were systematically investigated. Microstructural characterization indicated that the high-temperature tempered martensite and tempered bainite, as the main microstructure in WJ, were responsible for the improved comprehensive mechanical properties of the WJ. Microhardness across the WJ was measured as well, showing that the highest value of hardness occurred at the heat-affected zone which represents the appropriate lowest impact toughness of WJ. However, compared with the base metal, the ultimate tensile strength of the WJ displayed approximately equivalent values, while the yield strength was increased with increasing temperature. All the fracture of the WJ specimens occurred on the weld metal. In addition, the Charpy impact energy of weld metal was obtained at various temperatures, and the transition temperature (Tt) of welded metal was determined as 5 °C, which helps for the application design. The fractography indicated that the ductile fracture modes changed to quasi-cleavage ones gradually with decreasing temperature, and also the dimples became smaller and shallower.

Similar content being viewed by others

References

B. Staniša, Z. Schauperl, and K. Grilec: Erosion behaviour of turbine rotor blades installed in the Krsko nuclear power plant. Wear 254, 7 (2003).

L. Tan, J. Zhang, D. Zhuang, and C. Liu: Influences of lumped passes on welding residual stress of a thick-walled nuclear rotor steel pipe by multipass narrow gap welding. Nucl. Eng. Des. 273, 47–57 (2014).

L. Tan, L. Zhang, J. Zhang, and D. Zhuang: Effect of geometric construction on residual stress distribution in designing a nuclear rotor joined by multipass narrow gap welding. Fusion Eng. Des. 89, 4 (2014).

P. Liu, F. Lu, X. Liu, H. Ji, and Y. Gao: Study on fatigue property and microstructure characteristics of welded nuclear power rotor with heavy section. J. Alloys Compd. 584, 430–437 (2014).

M.L. Zhu, D.Q. Wang, and F.Z. Xuan: Effect of long-term aging on microstructure and local behavior in the heat-affected zone of a Ni–Cr–Mo–V steel welded joint. Mater. Charact. 87, 45–61 (2014).

N. Farabi, D.L. Chen, and Y. Zhou: Microstructure and mechanical properties of laser welded dissimilar DP600/DP980 dual-phase steel joints. J. Alloys Compd. 509, 982–989 (2011).

M.M.A. Khan, L. Romoli, M. Fiaschi, G. Dini, and F. Sarri: Laser beam welding of dissimilar stainless steels in a fillet joint configuration. J. Mater. Process. Technol. 212, 4 (2012).

I. Hajiannia, M. Shamanian, and M. Kasiri: Microstructure and mechanical properties of AISI 347 stainless steel/A335 low alloy steel dissimilar joint produced by gas tungsten arc welding. Mater. Des. 50, 566–573 (2013).

M.L. Zhu and F.Z. Xuan: Correlation between microstructure, hardness and strength in HAZ of dissimilar welds of rotor steels. Mater. Sci. Eng., A 527, 16 (2010).

N. Arivazhagan, S. Singh, S. Prakash, and G.M. Reddy: Investigation on AISI 304 austenitic stainless steel to AISI 4140 low alloy steel dissimilar joints by gas tungsten arc, electron beam and friction welding. Mater. Des. 32, 83–91 (2011).

T. Saeid, A. Abdollah-zadeh, H. Assadi, and F. Malek Ghaini: Effect of friction stir welding speed on the microstructure and mechanical properties of a duplex stainless steel. Mater. Sci. Eng., A 496, 1 (2008).

I. Bhamji, M. Preuss, P.L. Threadgill, R.J. Moat, A.C. Addison, and M.J. Peel: Linear friction welding of AISI 316L stainless steel. Mater. Sci. Eng., A 528, 2 (2010).

Y.D. Chung, H. Fujii, R. Ueji, and N. Tsuji: Friction stir welding of high carbon steel with excellent toughness and ductility. Scr. Mater. 63, 2 (2010).

J. Jeon, S. Mironov, Y.S. Sato, H. Kokawa, S.H.C. Park, and S. Hirano: Friction stir spot welding of single-crystal austenitic stainless steel. Acta Mater. 59, 20 (2011).

K. Hokamoto, K. Nakata, A. Mori, S. Tsuda, T. Tsumura, and A. Inoue: Dissimilar material welding of rapidly solidified foil and stainless steel plate using underwater explosive welding technique. J. Alloys Compd. 472, 507–511 (2009).

C.R. Das, A.K. Bhaduri, G. Srinivasan, V. Shankar, and S. Mathew: Selection of filler wire and effect of auto tempering on the mechanical properties of dissimilar metal joint between 403 and 304L(N) stainless steels. J. Mater. Process. Technol. 209, 3 (2009).

M.J. Torkamany, S. Tahamtan, and J. Sabbaghzadeh: Dissimilar welding of carbon steel to 5754 aluminum alloy by Nd:YAG pulsed laser. Mater. Des. 31, 458–465 (2010).

F. Malekghaini, M. Hamedi, M. Torkamany, and J. Sabbaghzadeh: Weld metal microstructural characteristics in pulsed Nd:YAG laser welding. Scr. Mater. 56, 11 (2007).

S. Mishra, T.J. Lienert, M.Q. Johnson, and T. DebRoy: An experimental and theoretical study of gas tungsten arc welding of stainless steel plates with different sulfur concentrations. Acta Mater. 56, 9 (2008).

B. Beidokhti, A.H. Kokabi, and A. Dolati: A comprehensive study on the microstructure of high strength low alloy pipeline welds. J. Alloys Compd. 597, 142–147 (2014).

B. Arivazhagan, S. Sundaresan, and M. Kamaraj: A study on influence of shielding gas composition on toughness of flux-cored arc weld of modified 9Cr–1Mo (P91) steel. J. Mater. Process. Technol. 209, 12 (2009).

V. Villaret, F. Deschaux-Beaume, C. Bordreuil, G. Fras, C. Chovet, B. Petit, and L. Faivre: Characterization of gas metal arc welding welds obtained with new high Cr–Mo ferritic stainless steel filler wires. Mater. Des. 51, 474–483 (2013).

V. Villaret, F. Deschaux-Beaume, C. Bordreuil, S. Rouquette, and C. Chovet: Influence of filler wire composition on weld microstructures of a 444 ferritic stainless steel grade. J. Mater. Process. Technol. 213, 9 (2013).

A.F. Mark, J.A. Francis, H. Dai, M. Turski, P.R. Hurrell, S.K. Bate, J.R. Kornmeier, and P.J. Withers: On the evolution of local material properties and residual stress in a three-pass SA508 steel weld. Acta Mater. 60, 8 (2012).

M. Ramakrishnan and V. Muthupandi: Application of submerged arc welding technology with cold wire addition for drum shell long seam butt welds of pressure vessel components. Int. J. Adv. Manuf. Technol. 65, 5–8 (2012).

E. Taban, E. Deleu, A. Dhooge, and E. Kaluc: Submerged arc welding of thick ferritic martensitic 12Cr stainless steel with a variety of consumables. Sci. Technol. Weld. Joining 13, 4 (2008).

V. Gunaraj and N. Murugan: Prediction of heat-affected zone characteristics in submerged arc welding of structural steel pipes. Weld. J. 81, 3 (2002).

N.A. McPherson, T.N. Baker, Y. Li, and J. Hoffmann: High dilution submerged arc welding of Cr-Ni-Mo austenitic stainless steel. Sci. Technol. Weld. Joining 5, 1 (2000).

J. Vannod, M. Bornert, J.E. Bidaux, L. Bataillard, A. Karimi, J.M. Drezet, M. Rappaz, and A. Hessler-Wyser: Mechanical and microstructural integrity of nickel–titanium and stainless steel laser joined wires. Acta Mater. 59, 17 (2011).

M.H. Avazkonandeh-Gharavol, M. Haddad-Sabzevar, and A. Haerian: Effect of chromium content on the microstructure and mechanical properties of multipass MMA, low alloy steel weld metal. J. Mater. Sci. 44, 1 (2008).

D.H. Kang and H.W. Lee: Effect of different chromium additions on the microstructure and mechanical properties of multipass weld joint of duplex stainless steel. Metall. Mater. Trans. A 43, 12 (2012).

A. Shekhter, S. Kim, D.G. Carr, A.B.L. Croker, and S.P. Ringer: Assessment of temper embrittlement in an ex-service 1Cr-1Mo-0.25V power generating rotor by Charpy V-Notch testing, KIc fracture toughness and small punch test. Int. J. Pressure Vessels Piping 79, 8–10 (2002).

M.L. Zhu and F.Z. Xuan: Effects of temperature on tensile and impact behavior of dissimilar welds of rotor steels. Mater. Des. 31, 3346–3352 (2010).

Q. Wu, F. Lu, H. Cui, X. Liu, P. Wang, and X. Tang: Role of butter layer in low-cycle fatigue behavior of modified 9Cr and CrMoV dissimilar rotor welded joint. Mater. Des. 59, 165–175 (2014).

Q. Wu, F. Lu, H. Cui, Y. Ding, X. Liu, and Y. Gao: Microstructure characteristics and temperature-dependent high cycle fatigue behavior of advanced 9% Cr/CrMoV dissimilarly welded joint. Mater. Sci. Eng., A 615, 98–106 (2014).

Y. Qi, H. Luo, S. Zheng, C. Chen, Z. Lv, and M. Xiong: Comparison of tensile and impact behavior of carbon steel in H2S environments. Mater. Des. 58, 234–241 (2014).

N. Farabi, D.L. Chen, J. Li, Y. Zhou, and S.J. Dong: Microstructure and mechanical properties of laser welded DP600 steel joints. Mater. Sci. Eng., A 527, 1215–1222 (2010).

W. Xu, D. Westerbaan, S.S. Nayak, D.L. Chen, F. Goodwin, E. Biro, and Y. Zhou: Microstructure and fatigue performance of single and multiple linear fiber laser welded DP980 dual-phase steel. Mater. Sci. Eng., A 553, 51–58 (2012).

M. Fattahi, N. Nabhani, M.R. Vaezi, and E. Rahimi: Improvement of impact toughness of AWS E6010 weld metal by adding TiO2 nanoparticles to the electrode coating. Mater. Sci. Eng., A 528, 8031–8039 (2011).

J. Hu, L.X. Du, J.J. Wang, H. Xie, C.R. Gao, and R.D.K. Misra: High toughness in the intercritically reheated coarse-grained (ICRCG) heat-affected zone (HAZ) of low carbon microalloyed steel. Mater. Sci. Eng., A 590, 323–328 (2014).

J. Hu, L.X. Du, J.J. Wang, and C.R. Gao: Effect of welding heat input on microstructures and toughness in simulated CGHAZ of V-N high strength steel. Mater. Sci. Eng., A 577, 161–168 (2013).

ACKNOWLEDGMENTS

The authors gratefully acknowledge the financial support by Shanghai Science and Technology Committee (Nos. 12DZ1101000, 13DZ1101504, and 13DZ1101502).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, F., Liu, X., Wang, P. et al. Microstructural characterization and wide temperature range mechanical properties of NiCrMoV steel welded joint with heavy section. Journal of Materials Research 30, 2108–2116 (2015). https://doi.org/10.1557/jmr.2015.162

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.162