Abstract

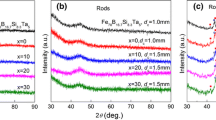

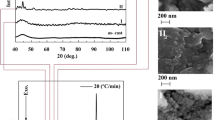

It is widely accepted that oxygen will severely deteriorate the glass-forming ability (GFA) of an alloy. In this work, we report that the GFA of a Fe76Si9B10P5 glassy alloy can be significantly improved (the critical diameter for fully glass formation is increased from 1 to 3 mm) under oxygen casting atmosphere. Furthermore, the pressure of oxygen atmosphere gives an obvious enhancement in the critical diameter of Fe76Si9B10P5 glassy alloy. A dependence of GFA on casting atmosphere species (argon, nitrogen, air, and oxygen) is also observed for this glassy alloy, and its critical diameter is 1, 1.5, 2.5, and 3 mm, respectively. In addition, the Fe-based glassy alloy exhibits excellent soft magnetic properties regardless of the applied casting atmosphere. The mechanism for such an unusual oxygen effect on the GFA of Fe76Si9B10P5 glassy alloy is attributed to the reduced nucleation rate caused by the enhancement of surface tension of the alloy melt.

Similar content being viewed by others

References

W.H. Wang, C. Dong, and C.H. Shek: Bulk metallic glasses. Mater. Sci. Eng., R 44 (2–3), 45 (2004).

E. Axinte: Metallic glasses from “alchemy” to pure science: Present and future of design, processing and applications of glassy metals. Mater. Des. 35, 518 (2012).

A. Inoue and A. Takeuchi: Recent development and application products of bulk glassy alloys. Acta Mater. 59 (6), 2243 (2011).

T.D. Shen and R.B. Schwarz: Bulk ferromagnetic glasses prepared by flux melting and water quenching. Appl. Phys. Lett. 75 (1), 49 (1999).

Z.P. Lu, C.T. Liu, and W.D. Porter: Role of yttrium in glass formation of Fe-based bulk metallic glasses. Appl. Phys. Lett. 83 (13), 2581 (2003).

Z.P. Lu, C.T. Liu, J.R. Thompson, and W.D. Porter: Structural amorphous steels. Phys. Rev. Lett. 92 (24), 245503 (2004).

V. Ponnambalam, S.J. Poon, and G.J. Shiflet: Fe-based bulk metallic glasses with diameter thickness larger than one centimeter. J. Mater. Res. 19 (05), 1320 (2004).

V. Ponnambalam, S.J. Poon, and G.J. Shiflet: Fe-Mn-Cr-Mo-(Y, Ln)-CB (Ln = Lanthanides) bulk metallic glasses as formable amorphous steel alloys. J. Mater. Res. 19 (10), 3046 (2004).

W.H. Wang, M. Pan, D. Zhao, Y. Hu, and H. Bai: Enhancement of the soft magnetic properties of FeCoZrMoWB bulk metallic glass by microalloying. J. Phys. Condens. Matter 16 (21), 3719 (2004).

T. Bitoh, A. Makino, A. Inoue, and A.L. Greer: Large bulk soft magnetic [(Fe0.5Co0.5)0.75]B0.20Si0.05]96Nb4 glassy alloy prepared by B2O3 flux melting and water quenching. Appl. Phys. Lett. 88 (18), 182510 (2006).

W.H. Wang: Roles of minor additions in formation and properties of bulk metallic glasses. Prog. Mater. Sci. 52 (4), 540 (2007).

H. Jian, W. Luo, S. Tao, and M. Yan: Mechanical and magnetic properties of (Fe72Mo4B24)100−xTbx (x = 4, 5, 6, 7 at.%) bulk glassy alloys. J. Alloys Compd. 505 (1), 315 (2010).

S.L. Lin, S.F. Chen, J.K. Chen, and Y.L. Lin: Formation and magnetic properties of Fe–Si–B–Dy amorphous alloy. Intermetallics 18 (10), 1826 (2010).

A. Chrobak, V. Nosenko, G. Haneczok, L. Boichyshyn, B. Kotur, A. Bajorek, O. Zivotsky, and A. Hendrych: Effect of rare earth additions on magnetic properties of Fe82Nb2B14RE2 (RE = Y, Gd, Tb and Dy) amorphous alloys. Mater. Chem. Phys. 130 (1–2), 603 (2011).

M. Stoica, S. Roth, J. Eckert, L. Schultz, and M. Baro: Bulk amorphous FeCrMoGaPCB: Preparation and magnetic properties. J. Magn. Magn. Mater. 290, 1480 (2005).

J. Park, G. Wang, R. Li, N. Mattern, J. Eckert, and D. Kim: Enhancement of plastic deformability in Fe–Ni–Nb–B bulk glassy alloys by controlling the Ni-to-Fe concentration ratio. Appl. Phys. Lett. 96 (3), 031905 (2010).

K. Qiu, J. Pang, Y. Ren, H. Zhang, C. Ma, and T. Zhang: Fe-based bulk metallic glasses with a larger supercooled liquid region and high ductility. Mater. Sci. Eng., A 498 (1), 464 (2008).

S. Yoon, J. Kim, G. Bae, B. Kim, and C. Lee: Formation of coating and tribological behavior of kinetic sprayed Fe-based bulk metallic glass. J. Alloys Compd. 509 (2), 347 (2011).

Y. Lu, Y. Huang, W. Zheng, and J. Shen: Free volume and viscosity of Fe–Co–Cr–Mo–C–B–Y bulk metallic glasses and their correlation with glass-forming ability. J. Non-Cryst. Solids 358 (10), 1274 (2012).

X. Huang, C. Chang, Z. Chang, A. Inoue, and J. Jiang: Glass forming ability, mechanical and magnetic properties in Fe–W–Y–B alloys. Mater. Sci. Eng., A 527 (7), 1952 (2010).

S.P. Harimkar, S.R. Paital, A. Singh, R. Aalund, and N.B. Dahotre: Microstructure and properties of spark plasma sintered Fe–Cr–Mo–Y–B–C bulk metallic glass. J. Non-Cryst. Solids 355 (43), 2179 (2009).

S. Guo, Z. Wu, and L. Liu: Preparation and magnetic properties of FeCoHfMoBY bulk metallic glasses. J. Alloys Compd. 468 (1), 54 (2009).

J.W. Li, H. Men, and B.L. Shen: Soft-ferromagnetic bulk glassy alloys with large magnetostriction and high glass-forming ability. AIP Adv. 1 (4), 042110 (2011).

A. Inoue, B. Shen, and C. Chang: Super-high strength of over 4000 MPa for Fe-based bulk glassy alloys in [(Fe1−xCox)0.75B0. 2Si0. 05]96Nb4 system. Acta Mater. 52 (14), 4093 (2004).

A.D. Setyawan, H. Kato, J. Saida, and A. Inoue: Origin of the effect of the gas atmosphere during mold-casting Zr65Al7.5Ni10Pd17.5 bulk glassy or nano-quasicrystal-forming alloy. Mater. Trans. 48 (6), 1266 (2007).

A.D. Setyawan, H. Kato, J. Saida, and A. Inoue: Glass formation dependence on casting-atmosphere pressure in Zr65Al7.5Ni10Cu17.5−xPdx(x = 0–17.5) alloy system: A resultant effect of quasicrystalline phase transformation and cooling mechanism during mold-casting process. J. Appl. Phys. 103 (4), 044907 (2008).

Y. Ito, O. Ueki, and S. Nakamura: Determination of colloidal iron in water by laser-induced breakdown spectroscopy. Anal. Chim. Acta 299 (3), 401 (1995).

Z.P. Lu and C.T. Liu: Role of minor alloying additions in formation of bulk metallic glasses: A review. J. Mater. Sci. 39 (12), 3965 (2004).

Y.X. Wang, H. Yang, G. Lim, and Y. Li: Glass formation enhanced by oxygen in binary Zr-Cu system. Scr. Mater. 62 (9), 682 (2010).

H.X. Li, J.E. Gao, Z.B. Jiao, Y. Wu, and Z.P. Lu: Glass-forming ability enhanced by proper additions of oxygen in a Fe-based bulk metallic glass. Appl. Phys. Lett. 95 (16), 014202 (2009).

L.L. Meng, X.Y. Li, J. Pang, L. Wang, B. An, L.J. Yin, K.K. Song, and W.M. Wang: Casting atmosphere effects on the precipitates, magnetism, and corrosion resistance of Fe78Si9B13 glassy alloys. Metall. Mater. Trans. A 44A (11), 5122 (2013).

W.M. Wang, J.T. Zhang, A. Gebert, S. Roth, and L. Schultz: Casting vacuum effects on the precipitates and magnetic properties of Fe-based glassy alloys. J. Non-Cryst. Solids 357 (7), 1657 (2011).

D. Tumbull and J.C. Fisher: Rate of nucleation in condensed systems. J. Chem. Phys. 17, 71 (1949).

D. Turnbull: Formation of crystal nuclei in liquid metal. J. Appl. Phys. 21, 1022 (1950).

M. Nastar and E. Clouet: Mean field theories for the description of diffusion and phase transformations controlled by diffusion. Phys. Chem. Chem. Phys. 6 (13), 3611 (2004).

X.M. Xue, H.G. Jiang, Z.T. Sui, B.Z. Ding, and Z.Q. Hu: Influence of phosphorus addition on the surface tension of liquid iron and segregation of phosphorus on the surface of Fe-P alloy. Metall. Mater. Trans. B 27 (1), 71 (1996).

G.C. Lavorato, G. Fiore, P. Tiberto, M. Baricco, H. Sirkin, and J.A. Moya: Structural and magnetic properties of Fe76P5(Si0.3B0.5C0.2)19 amorphous alloy. J. Alloys Compd. 536, S319 (2012).

ACKNOWLEDGMENTS

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51201174 and 51377113) and the Qualified Personnel Foundation of Taiyuan University of Technology (QPFT) (No: tyutrc-201370a).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Chang, C., Zhang, J., Shen, B. et al. Pronounced enhancement of glass-forming ability of Fe-Si-B-P bulk metallic glass in oxygen atmosphere. Journal of Materials Research 29, 1217–1222 (2014). https://doi.org/10.1557/jmr.2014.96

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.96