Abstract

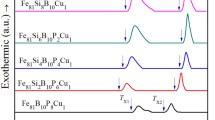

Amorphous ferromagnetic alloy with the composition Fe56Co24Nb4B13Si2Cu1 was obtained by rapid quenching from the melt. Samples cut from the ribbons were annealed at 450, 550, 650 and 750 °C in a vacuum furnace. 57Fe Mössbauer spectroscopy was used to identify the phases formed based on the refined values of the hyperfine parameters. The as-quenched specimen was analyzed with a hyperfine magnetic field distribution and corresponded to an in-plane orientation of the magnetic moment directions. The sample annealed at 450 °C was found to be in a nanocrystalline state due to observation of the (FeCo)-Si alloy with the DO3 structure. The balance of the composition was represented by a metalloid-enriched amorphous grain boundary phase. In contradistinction to this, the samples annealed at 550–750 °C were totally crystallized and the new phases formed were α-(FeCo), (FeCo)2(BSi) and (FeCo)3(BSi). These findings suggest that nanocrystallization is obtained only at select processing temperatures. A new set of Mössbauer spectra was obtained by recording simultaneously the intensity transmitted by a sandwich of the sample with the stainless steel etalon, based on the dual absorber method recently introduced by us. The values of the recoilless fraction can be derived from the relative spectral areas. The f factor value dropped from 0.6 to 0.37 for the sample annealed at 450 °C, consistent with the onset of nanocrystallization in the system. For the completely crystallized specimens, the f factor maintained values close to 0.5. This indicates that the presence of quenched-in stresses may play a role in the ability of samples to undergo recoilless emission and absorption of gamma rays.

Similar content being viewed by others

References

P. Duhaj, I. Matko, P. Svec, J. Sitek, D. Janickovic, Mater. Sci. Eng. B, 39, 208 (1996).

N. Clavaguera, T. Pradell, Z. Jie, M.T. Clavaguera-Mora, Nanostruct. Mater., 6, 453 (1995).

H.R. Lashgari, D. Chu, S. Xie, H. Sun, M. Ferry, S. Li, J. Non-Cryst. Solids, 391, 4161 (2014).

S.M. Hoque, M.A. Hakim, F.A. Khan, N. Chau, Mater. Chem. Phys., 101, 112 (2007).

X.D. Li, W.Z. Yuan, Z.J. Zhao, X.Z. Wang, J.Z. Ruan, X.L. Yang, J. Magn. Magn. Mater., 279, 429 (2004).

M.A. Hakim, S.M. Hoque, J. Magn. Magn. Mater., 284, 395 (2004).

M. Sorescu, T. Xu, S. Herchko, J. Magn. Magn. Mater., 323, 2859 (2011).

P. Gorria, V.M. Prida, M. Tejedor, B. Hernando, M.L. Sanchez, Phys. B, 299, 215 (2001).

P. Duhaj, P. Svec, J. Sitek, D. Janickovic, Mater. Sci. Eng. A, 304–306, 178 (2001).

F. Zhou, K.Y. He, K. Lu, Nanostruct. Mater., 9, 535 (1997).

M. Sorescu, E.T. Knobbe, Phys. Rev. B, 52, 16086 (1995).

M. Sorescu, E.T. Knobbe, D. Barb, J. Phys. Chem. Solids, 56, 79 (1995).

M. Sorescu, Mater. Lett., 54, 256 (2002).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sorescu, M., Limongelli, J., Stroh, C. et al. Crystallization Behavior and Recoilless Fraction Determination of Amorphous and Nanocrystalline Fe56Co24Nb4B13Si2Cu1 System. MRS Advances 2, 1435–1440 (2017). https://doi.org/10.1557/adv.2017.234

Published:

Issue Date:

DOI: https://doi.org/10.1557/adv.2017.234