Abstract

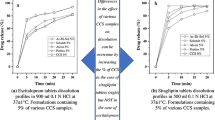

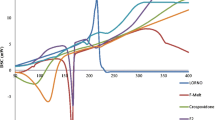

The development of suitable dosage forms is essential for an effective pharmacological treatment in children. Orally disintegrating tablets (ODTs) are attractive dosage forms that avoid swallowing problems, ensure dosage accuracy and are easy to administer as they disintegrate in the oral cavity. This study aimed to develop ODTs containing losartan potassium (LP) for the treatment of arterial hypertension in children. The ODTs, produced by the cost-effective manufacturing process of direct compression, consisted of a mixture of diluent, superdisintegrant, glidant and lubricant. Five superdisintegrants (croscarmellose sodium, two grades of crospovidone, sodium starch glycolate and pregelatinized starch) were tested (at two concentrations), and combined with three diluents (mannitol, lactose and sorbitol). Thus, thirty formulations were evaluated based on disintegration time, hardness and friability. Two formulations, exhibiting the best results concerning disintegration time (< 30 s), hardness and friability (≤ 1.0%), were selected as the most promising ones for further evaluation. These ODTs presented favourable drug-excipient compatibility, tabletability and flow properties. The in vitro dissolution studies demonstrated ‘very rapid’ drug release. Preliminary stability studies highlighted the requirement of a protective packaging. All quality properties retained appropriate results after 12 months of storage in airtight containers. In conclusion, the ODTs were successfully developed and characterised, suggesting a potential means to accomplish a final prototype that enables an improvement in childhood arterial hypertension treatment.

Graphical Abstract

Similar content being viewed by others

References

Burrello J, Erhardt EM, Saint-Hilary G, Veglio F, Rabbia F, Mulatero P, et al. Pharmacological treatment of arterial hypertension in children and adolescents: A network meta-analysis. Hypertension. 2018;72(2):306–13. https://doi.org/10.1161/hypertensionaha.118.10862.

Bell CS, Samuel JP, Samuels JA. Prevalence of hypertension in children. Hypertension. 2019;73(1):148–52. https://doi.org/10.1161/hypertensionaha.118.11673.

Pearson K, Halbach SM. Continuing medical education pediatric hypertension: An update on the American Academy of Pediatrics clinical practice guidelines. J Pediatr Health Care. 2023;37(4):447–54. https://doi.org/10.1016/j.pedhc.2023.03.004.

Díaz A, Calandra L. Presión arterial elevada en niños y adolescentes escolarizados de Argentina en los últimos 25 años: revisión sistemática de estudios observacionales. Arch Argent Pediatr. 2017;115(1):5–11. https://doi.org/10.5546/aap.2017.5.

Simsolo R. Hipertensión arterial en niños y adolescentes. In: Sociedad Argentina de Hipertensión Arterial (SAHA). 2016; 4–9. https://areaclinicapediatrica.files.wordpress.com/2016. Accessed 14 Sep 2023.

Flynn JT, Kaelber DC, Baker-Smith CM, Blowey D, Carroll AE, Daniels SR, et al. Clinical practice guideline for screening and management of high blood pressure in children and adolescents. Pediatrics. 2017;140(3):1–72. https://doi.org/10.1542/peds.2017-1904.

Al-Majed ARA, Assiri E, Khalil NY, Abdel-Aziz HA. Losartan: Comprehensive profile. In: Brittain HG, editor. Profiles of drug substances, excipients and related methodology. New Jersey: Elsevier Inc; 2015. p. 159–94. https://doi.org/10.1016/bs.podrm.2015.02.003. Accessed 16 Sep 2023.

Goa KL, Wagstaff AJ. Losartan potassium: A review of its pharmacology, clinical efficacy and tolerability in the management of hypertension. Drugs. 1996;51(5):820–45. https://doi.org/10.2165/00003495-199651050-00008.

Pediamécum. Asociación Española de Pediatría, Comité de Medicamentos. España. 2015. https://www.aeped.es/comite-medicamentos/pediamecum/losartan. Accessed 2 Aug 2023.

Webb NJA, Wells TG, Shahinfar S, Massaad R, Dankner WM, Lam C, et al. A randomized, open-label, dose-response study of losartan in hypertensive children. Clin J Am Soc Nephrol. 2014;9(8):1441–8. https://doi.org/10.2215/CJN.11111113.

Mercovich N, Kyle GJ, Naunton M. Safe to crush? A pilot study into solid dosage form modification in aged care. Australas J Ageing. 2014;33(3):180–4. https://doi.org/10.1111/ajag.12037.

Nguyen D, Secretan PH, Auvity S, Vidal F, Postaire M, Cisternino S, et al. Assessment of practices for suspended oral drugs by tablet crushing in pediatric units. Eur J Pharm Biopharm. 2020;157:175–82. https://doi.org/10.1016/j.ejpb.2020.10.013.

European Medicines Agency (EMA). Guideline on pharmaceutical development of medicines for paediatric use. EMA/CHMP/QWP/805880/2012 Rev. 2. London. 2013. https://www.ema.europa.eu/en/documents/scientific-guideline/guideline-pharmaceutical-development-medicines-paediatric-use_en.pdf. Accessed 10 Sep 2023.

Van der Veken M, Brouwers J, Budts V, Lauwerys L, Pathak SM, Batchelor H, et al. Practical and operational considerations related to paediatric oral drug formulation: An industry survey. Int J Pharm. 2022;618: 121670. https://doi.org/10.1016/j.ijpharm.2022.121670.

Almukainzi M, Araujo GLB, Löbenberg R. Orally disintegrating dosage forms. J Pharm Investig. 2019;49(2):229–43. https://doi.org/10.1007/s40005-018-0408-2.

Chinwala M. Recent Formulation advances and therapeutic usefulness of orally disintegrating tablets (ODTs). Pharmacy. 2020;8:186. https://doi.org/10.3390/pharmacy8040186.

Food and Drug Administration (FDA). Guidance for industry: Orally disintegrating tablets. Silver Spring USA. 2008. https://www.fda.gov/media/70877/download. Accessed 7 Sep 2023.

Aghera NJ, Shah SD, Vadalia KR. Formulation and evaluation of sublingual tablets of losartan potassium. Asian Pac J Trop Dis. 2012;2(1):130–5. https://doi.org/10.1016/S2222-1808(12)60138-8.

Bhanja S, Hardel S, Sudhakar M. Mouth dissolving tablets of losartan potassium: Formulation and evaluation. Int J Pharm Sci Res. 2012;3(09):3444–53.

Chaturvedi S, Agrawal VK, Singh S. Impact of superdisintegrants on the release of oro-dispersible tablets of losartan potassium: A comparative analysis. Der Pharm Lett. 2012;4(6):1768–76.

Goyal R, Nagpal M, Arora S, Dhingra GA. Development and optimization of fast dissolving tablets of losartan potassium using natural gum mucilage. J Pharm Technol Res Manag. 2023;1(2):153–69. https://doi.org/10.15415/jptrm.2013.12009.

Shailaja CJ, Karwa Preeti, Nargund LVG, Laxman SV. Development of fast dissolving tablets of losartan potassium using Kollidon CL-SF. J Chem Pharm Res. 2013;5(5):119–27.

Freerks L, Sommerfeldt J, Löper PC, Klein S. Safe, swallowable and palatable paediatric mini-tablet formulations for a WHO model list of essential medicines for children compound—a promising starting point for future PUMA applications. Eur J Pharm Biopharm. 2020;156:11–9. https://doi.org/10.1016/j.ejpb.2020.08.014.

Rouaz K, Chiclana-Rodríguez B, Nardi-Ricart A, Suñé-Pou M, Mercadé-Frutos D, Suñé-Negre JM, et al. Excipients in the paediatric population: A review. Pharmaceutics. 2021;13(3):387. https://doi.org/10.3390/pharmaceutics13030387.

Jagadale SK, Patil Pradeep S, Rajini N. Formulation development and evaluation of orally disintegrating tablets of losartan potassium by direct compression method. Res J Pharm Biol Chem Sci. 2013;4(4):127–35.

Reddy BV, Navaneetha K, Ramana Reddy KV, Reddy PP, Reddy PU, Lavanya T, et al. Formulation and evaluation of fast dissolving tablets of losartan potassium. Indo Am J Pharm Res. 2014;4(05):2573-84.

Rowe R, Sheskey PJ, Quinn ME, editors. Handbook of Pharmaceutical Excipients. 6th ed. London: Pharmaceutical Press. 2009.

Berardi A, Bisharat L, Quodbach J, Abdel Rahim S, Perinelli DR, Cespi M. Advancing the understanding of the tablet disintegration phenomenon—an update on recent studies. Int J Pharm. 2021;598: 120390. https://doi.org/10.1016/j.ijpharm.2021.120390.

Mostafa M, Gardouh AR, Abogresha NM, Gad S. Factorial design, formulation, in vitro and in vivo evaluation of rapid orally disintegrating tablets prepared by sublimation technique using captopril as a model drug. J Drug Deliv Sci Technol. 2020;57: 101635. https://doi.org/10.1016/j.jddst.2020.101635.

Desai PM, Liew CV, Heng PWS. Review of disintegrants and the disintegration phenomena. J Pharm Sci. 2016;105(9):2545–55. https://doi.org/10.1016/j.xphs.2015.12.019.

Goel H, Rai P, Rana V, Tiwary A. Orally disintegrating systems: Innovations in formulation and technology. Recent Pat Drug Deliv Formul. 2008;2(3):258–74. https://doi.org/10.2174/187221108786241660.

Kalyankar P, Panzade P, Lahoti S. Formulation design and optimization of orodispersible tablets of quetiapine fumarate by sublimation method. Indian J Pharm Sci. 2015;77(3):267–73. https://doi.org/10.4103/0250-474x.159605.

Al-Dhahir RK, Al-Kotaji M. Formulation of orally disintegrating tablets of cinnarizine by using direct compression method. Int J Appl Pharm. 2019;11(1):117–23. https://doi.org/10.22159/ijap.2019v11i1.29599.

Siemiradzka W, Szulc-Musiol B, Bulas L, Jankowski A. Effect of selected excipients and the preparation method on the parameters of orally disintegrating tablets containing ondansetron. Acta Pol Pharm Drug Res. 2018;75:733–40.

Aodah AH, Fayed MH, Alalaiwe A, Alsulays BB, Aldawsari MF, Khafagy ES. Design, optimization, and correlation of in vitro/in vivo disintegration of novel fast orally disintegrating tablet of high dose metformin hydrochloride using moisture activated dry granulation process and quality by design approach. Pharmaceutics. 2020;12(7):1–20. https://doi.org/10.3390/pharmaceutics12070598.

Mahrous GM, Ibrahim MA, Mostafa HF, Elzayat EM. Application of a quality-by-design approach for utilizing sodium stearyl fumarate as a taste-masking agent in dextromethorphan hydrobromide orally disintegrating tablets. Pharm Dev Technol. 2019;24(6):711–9. https://doi.org/10.1080/10837450.2019.1579228.

Alyami H, Dahmash E, Bowen J, Mohammed AR. An investigation into the effects of excipient particle size, blending techniques & processing parameters on the homogeneity & content uniformity of a blend containing low-dose model drug. PLoS ONE. 2017;12(6):1–19. https://doi.org/10.1371/journal.pone.0178772.

Chadha R, Bhandari S. Drug-excipient compatibility screening—role of thermoanalytical and spectroscopic techniques. J Pharm Biomed Anal. 2014Jan;87:82–97. https://doi.org/10.1016/j.jpba.2013.06.016.

Gallo L, Ramírez-Rigo MV, Piña J, Bucalá V. A comparative study of spray-dried medicinal plant aqueous extracts. Drying performance and product quality. Chem Eng Res Des. 2015;104:681–94. https://doi.org/10.1016/j.cherd.2015.10.009.

USP USP 44 - NF 39. Rockville: US Pharmacopeial Convention; 2021.

Hooper P, Lasher J, Alexander KS, Baki G. A new modified wetting test and an alternative disintegration test for orally disintegrating tablets. J Pharm Biomed Anal. 2016;120:391–6. https://doi.org/10.1016/j.jpba.2015.12.046.

Conceição J, Adeoye O, Cabral-Marques H, Concheiro A, Alvarez-Lorenzo C, Sousa Lobo JM. Orodispersible carbamazepine/hydroxypropyl-β-cyclodextrin tablets obtained by direct compression with five-in-one co-processed excipients. AAPS PharmSciTech. 2020;21(2):1–10. https://doi.org/10.1208/s12249-019-1579-5.

Tashan E, Karakucuk A, Celebi N. Development of nanocrystal ziprasidone orally disintegrating tablets: Optimization by using design of experiment and in vitro evaluation. AAPS PharmSciTech. 2020;21(3):115. https://doi.org/10.1208/s12249-020-01653-9.

Assaf S, Qandil A, Al-Ani E. Fast and pH-dependent release of domperidone from orally disintegrating tablets. Pharm Dev Technol. 2013;18(4):897–905. https://doi.org/10.3109/10837450.2011.583925.

Juan C, Rodriguez D, Ceballos L, Lanusse C, Gallo L, Gonzalez VN. Development of ivermectin orally disintegrating tablets using factorial design: In-vitro evaluation and in vivo absorption pattern in rats. J Drug Deliv Sci Technol. 2023;87: 104757. https://doi.org/10.1016/j.jddst.2023.104757.

Türkmen Ö, Ay Şenyiğit Z, Baloğlu E. Formulation and evaluation of fexofenadine hydrochloride orally disintegrating tablets for pediatric use. J Drug Deliv Sci Technol. 2018;43:201–10. https://doi.org/10.1016/j.jddst.2017.10.008.

ICH. ICH Harmonised Tripartite Guideline. Validation of analytical procedures: text and methodology Q2(R1). In: International conference on harmonisation of technical requirements for registration of pharmaceuticals for human use, Geneva; 2005. pp. 1–13.

Ruhil S, Dahiya M, Kaur H, Singh J. New insights into the disintegration mechanism and disintegration profiling of rapidly disintegrating tablets (RDTs) by thermal imaging. Int J Pharm. 2022;5:611. https://doi.org/10.1016/j.ijpharm.2021.121283.

Pabari R, Ramtoola Z. Effect of a disintegration mechanism on wetting, water absorption, and disintegration time of orodispersible tablets. J Young Pharm. 2012Jul;4(3):157–63. https://doi.org/10.4103/0975-1483.100021.

Tranová T, Loskot J, Navrátil O, Brniak W, Mužíková J. Effect of co-processed excipient type on properties of orodispersible tablets containing captopril, tramadol, and domperidone. Int J Pharm. 2023;636:122838. https://doi.org/10.1016/j.ijpharm.2023.122838.

Khan KA. The concept of dissolution efficiency. J Pharm Pharmacol. 1975;27(1):48–9. https://doi.org/10.1111/j.2042-7158.1975.tb09378.x.

ICH. ICH Harmonised Tripartite Guideline. Stability testing of new drug substances and products, Q1A (R2). In: International Conference on harmonisation of technical requirements for registration of pharmaceuticals for human use. Geneva; 2003. pp 1–24.

Alalaiwe A, Fayed MH, Alshahrani SM, Alsulays BB, Alshetaili AS, Tawfeek HM, et al. Application of design of experiment approach for investigating the effect of partially pre-gelatinized starch on critical quality attributes of rapid orally disintegrating tablets. J Drug Deliv Sci Technol. 2019;49:227–34. https://doi.org/10.1016/j.jddst.2018.11.018.

Majzoobi M, Kaveh Z, Blanchard CL, Farahnaky A. Physical properties of pregelatinized and granular cold water swelling maize starches in presence of acetic acid. Food Hydrocoll. 2015;51:375–82. https://doi.org/10.1016/j.foodhyd.2015.06.002.

Rojas J, Uribe Y, Zuluaga A. Powder and compaction characteristics of pregelatinized starches. Pharmazie. 2012;67(6):513–7.

Ojogbo E, Ogunsona EO, Mekonnen TH. Chemical and physical modifications of starch for renewable polymeric materials. Mater Today Sustain. 2020;7–8: 100028. https://doi.org/10.1016/j.mtsust.2019.100028.

Singh GP, Bangar SP, Yang T, Trif M, Kumar V, Kumar D. Effect on the properties of edible starch-based films by the incorporation of additives: A review. Polymers. 2022;14(10):1–20. https://doi.org/10.3390/polym14101987.

Di Martino P, Martelli S, Wehrlé P. Evaluation of different fast melting disintegrants by means of a central composite design. Drug Dev Ind Pharm. 2005;31(1):109–21. https://doi.org/10.1081/ddc-44233.

Gryczke A, Schminke S, Maniruzzaman M, Beck J, Douroumis D. Development and evaluation of orally disintegrating tablets (ODTs) containing Ibuprofen granules prepared by hot melt extrusion. Colloids Surf B. 2011;86(2):275–84. https://doi.org/10.1016/j.colsurfb.2011.04.007.

Amelian A, Przybyslawska M, Wilczewska AZ, Basa A, Winnicka K. Preparation and characterization of orally disintegrating loratadine tablets manufactured with co-processed mixtures. Acta Pol Pharm Drug Res. 2016;73:453–60.

Yıldız S, Aytekin E, Yavuz B, Pehlivan SB, Ünlü N. Formulation studies for mirtazapine orally disintegrating tablets. Drug Dev Ind Pharm. 2016;42(6):1008–17. https://doi.org/10.3109/03639045.2015.1104345.

Desai PM, Liew CV, Heng PWS. Understanding disintegrant action by visualization. J Pharm Sci. 2012;101:2155–64. https://doi.org/10.1002/jps.23119.

Berardi A, Janssen PHM, Dickhoff BHJ. Technical insight into potential functional-related characteristics (FRCs) of sodium starch glycolate, croscarmellose sodium and crospovidone. J Drug Deliv Sci Technol. 2022;70: 103261. https://doi.org/10.1016/j.jddst.2022.103.

Eisa AM, El-Megrab NA, El-Nahas HM. Formulation and evaluation of fast dissolving tablets of haloperidol solid dispersion. Saudi Pharm J. 2022;30(11):1589–602. https://doi.org/10.1016/j.jsps.2022.09.002.

Johnson JR, Wang LH, Gordon MS, Chowhan ZT. Effect of formulation solubility and hygroscopicity on disintegrant efficiency in tablets prepared by wet granulation, in terms of dissolution. J Pharm Sci. 1991;80(5):469–71. https://doi.org/10.1002/jps.2600800514.

Juvonen H, Antikainen O, Lemmens M, Ehlers H, Juppo A. The effect of relative humidity and formulation variables on chewable xylitol-sorbitol tablets. Int J Pharm. 2021;601: 120573. https://doi.org/10.1016/j.ijpharm.2021.120573.

Mishra SM, Rohera BD. An integrated, quality by design (QbD) approach for design, development and optimization of orally disintegrating tablet formulation of carbamazepine. Pharm Dev Technol. 2017;22(7):889–903. https://doi.org/10.1080/10837450.2016.1199566.

Rowley G, Mackin LA. The effect of moisture sorption on electrostatic charging of selected pharmaceutical excipient powders. Powder Technol. 2003;135–136:50–8. https://doi.org/10.1016/j.powtec.2003.08.003.

Batra A, Desai D, Serajuddin ATM. Conversion of α-lactose monohydrate to anhydrous form with superior tabletability by twin-screw extrusion at elevated temperature. Int J Pharm. 2020;588: 119790. https://doi.org/10.1016/j.ijpharm.2020.119790.

Lou Y, Zuo L. Quantification of losartan potassium polymorphs using powder X-ray diffraction. J AOAC Int. 2021;104(3):579–84. https://doi.org/10.1093/jaoacint/qsaa166.

Ponnaiah R, Desai S, Rathod D, Parikh C. Alembic limited. A process for preparation of losartan potassium form I. Patent WO 2010/046804 A2. 29 April 2010.

Wu LS, Gerard C, Hussain MA. Thermal analysis and solution calorimetry studies on losartan polymorphs. Pharm Res. 1993;10:1793–5. https://doi.org/10.1023/A:1018942718941.

Vidyadhara S, Babu JR, Balakrishna T, Trilochani P, Kumar MP. Design and evaluation of controlled release losartan potassium microcapsules. J Pharm Res. 2013;6(4):470–5. https://doi.org/10.1016/j.jopr.2013.04.015.

Raghavan K, Dwivedi A, Campbell GC Jr, Johnston E, Levorse D, McCauley J, et al. A spectroscopic investigation of losartan polymorphs. Pharm Res. 1993;10:900–4. https://doi.org/10.1023/A:1018973530443.

Ejsmont A, Stasiłowicz-Krzemień A, Ludowicz D, Cielecka-Piontek J, Goscianska J. Synthesis and characterization of nanoporous carbon carriers for Losartan potassium delivery. Materials. 2021;14(23):7345. https://doi.org/10.3390/ma14237345.

Birajdar SM, Bhusnure OG, Mulaje SS. Formulation and evaluation of fast disintegrating losartan potassium tablets by formal experimental design. Int J Drug Regul Aff. 2014;2(2):61–77. https://doi.org/10.22270/ijdra.v2i2.132.

Chopra S, Patil GV, Motwani SK. Release modulating hydrophilic matrix systems of losartan potassium: Optimization of formulation using statistical experimental design. Eur J Pharm Biopharm. 2007;66(1):73–82. https://doi.org/10.1016/j.ejpb.2006.09.001.

Devi D, Ghosh A, Mandal UK. Sustained release matrix tablet of 100 mg losartan potassium: Formulation development and in vitro characterization. Braz J of Pharm Sci. 2022;58:1–16. https://doi.org/10.1590/s2175-97902022e20079.

Krishna YP, Chowdary YA, Rao MVB. Drug-excipient compatibility studies for losartan potassium pulsatile dosage form. Int J Res Anal Rev. 2018;5(4):501–6.

Maddiboyina B, Hanumanaik M, Nakkala RK, Jhawat V, Rawat P, Alam A, et al. Formulation and evaluation of gastro-retentive floating bilayer tablet for the treatment of hypertension. Heliyon. 2020;6(11):e05459. https://doi.org/10.1016/j.heliyon.2020.e05459.

Saisivam S, Rahamath Ulla M, Shakeel F. Development of floating matrix tablets of losartan potassium: In vitro and in vivo evaluation. J Drug Deliv Sci Technol. 2013;23(6):611–7. https://doi.org/10.1016/S1773-2247(13)50093-1.

Shinde AKJ, Patil NS, Jadhav TS, More HN. Design and development of floating pulsatile drug delivery of losartan potassium. Int J Appl Pharm. 2020;12(4):218–27. https://doi.org/10.22159/ijap.2020v12i4.37607.

Singh S, Shyale SS, Jadhav A. Formulation and evaluation of buccoadhesive tablets of losartan potassium. Int J Pharm Sci Nanotech. 2015;8(4):3045–52. https://doi.org/10.37285/ijpsn.2015.8.4.8.

Yamini SG, Sri Naga Varun M, Sunil Kumar KT, MohanVarma M. Formulation and evaluation of sublingual tablets of losartan potassium by using natural and synthetic super disintegrants. JOPIR. 2023;1(2):145–53. https://doi.org/10.5281/zenodo.10255436.

Balaci T, Velescu B, Karampelas O, Musuc AM, Nițulescu GM, Ozon EA, et al. Physico-chemical and pharmaco-technical characterization of inclusion complexes formed by rutoside with β-cyclodextrin and hydroxypropyl-β-cyclodextrin used to develop solid dosage forms. Processes. 2021;9(1):1–25. https://doi.org/10.3390/pr9010026.

Kudo Y, Yasuda M, Matsusaka S. Effect of particle size distribution on flowability of granulated lactose. Adv Powder Technol. 2020;31(1):121–7. https://doi.org/10.1016/j.apt.2019.10.004.

Muselík J, Franc A, Doležel P, Goněc R, Krondlová A, Lukášová I. Influence of process parameters on content uniformity of a low dose active pharmaceutical ingredient in a tablet formulation according to GMP. Acta Pharm. 2014;64(3):355–67. https://doi.org/10.2478/acph-2014-0022.

Shah RB, Tawakkul MA, Khan MA. Comparative evaluation of flow for pharmaceutical powders and granules. AAPS PharmSciTech. 2008;9(1):250–8. https://doi.org/10.1208/s12249-008-9046-8.

Comoglu T, Ozyilmaz ED. Orally disintegrating tablets and orally disintegrating mini tablets—novel dosage forms for pediatric use. Pharm Dev Technol. 2019;24(7):902–14. https://doi.org/10.1080/10837450.2019.1615090.

Markl D, Maclean N, Mann J, Williams H, Abbott A, Mead H, et al. Tablet disintegration performance: Effect of compression pressure and storage conditions on surface liquid absorption and swelling kinetics. Int J Pharm. 2021;601:120382. https://doi.org/10.1016/j.ijpharm.2021.120382.

Abdelbary A, Elshafeey AH, Zidan G. Comparative effects of different cellulosic-based directly compressed orodispersable tablets on oral bioavailability of famotidine. Carbohydr Polym. 2009;77(4):799–806. https://doi.org/10.1016/j.carbpol.2009.02.030.

European Medicines Agency (EMA). Guideline on the Investigation of Bioequivalence, CPMP/EWP/QWP/1401/98 Rev. 1. London; 2008. https://www.ema.europa.eu/en/documents/scientific-guideline/guideline-investigation-bioequivalence-rev1_en.pdf. Accessed 20 Sep 2023.

Acknowledgements

The authors wish to thank Chutrau (Argentina) and DFE Pharma (Germany) for the kind donation of lactose SuperTab®50 ODT and Rumapel (Argentina) for donation of crospovidone (Kollidon® CL and CL-SF). Furthermore, the authors wish to acknowledge Luciano Benedini for his technical assistance. Candela Juan is grateful to Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET) and Agencia Nacional de Laboratorios Públicos (ANLAP) for the PhD fellowship.

Funding

This work was supported by Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET) (grant number PIBAA 28720210100113CO), ANLAP (grant number EX-2020–50428127-APN-ANLAP#MS), Agencia Nacional de Promoción Científica y Tecnológica (ANPCyT) (grant number PICT-2021-GRT-TI-00524) and Universidad Nacional del Sur (UNS) (grant number PGI 24/B306).

Author information

Authors and Affiliations

Contributions

All authors contributed to the design of the study, interpretation of outcomes, writing, editing and revision of the manuscript. In detail, CJ executed the experiments and wrote the original draft; both LG and NGV were responsible for the project design and administration and the acquisition and management of funding resources.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Juan, C., Gallo, L. & Gonzalez Vidal, N. Development of Losartan Orally Disintegrating Tablets by Direct Compression: a Cost-Effective Approach to Improve Paediatric Patient’s Compliance. AAPS PharmSciTech 25, 79 (2024). https://doi.org/10.1208/s12249-024-02796-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-024-02796-9