Abstract

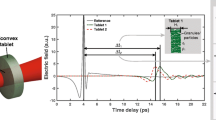

“Sticking” during tablet manufacture is the term used to describe the accumulation of adhered tablet material on the punch over the course of several compaction cycles. The occurrence of sticking can affect tablet weight, image, and structural integrity and halt manufacturing operations. The earlier the risk of sticking is detected during R&D, the more options are available for mitigation and the less potential there is for significant delays and costs. The detection osf sticking, however, during the early stages of drug development is challenging due to the limitations of available material quantity. In this work, single tablet multi-compaction (STMC) and a highly sensitive laser reflection sensor are used to detect the propensity of sticking with ibuprofen powder blends. STMC can differentiate the various formulations and replicates the trends of sticking at different punch speeds. The results demonstrate the potential for STMC to be used as an extremely material sparing (requiring very few tablets) methodology for the assessment of sticking during early-stage development.

Graphical Abstract

Similar content being viewed by others

References

Thomas JV. Evaluation and study on the adhesion of powder onto punch faces during tablet compaction. Drexel University; 2015.

Danjo K, Kojima S, Chen CY, Sunada H, Otsuka A. Effect of water content on sticking during compression. Chem Pharm Bull. 1997;45(4):706–9.

Wang JJ, Li T, Bateman SD, Erck R, Morris KR. Modeling of adhesion in tablet compression-I. Atomic force microscopy and molecular simulation. J Pharm Sci. 2003;92(4):798–814. https://doi.org/10.1002/jps.10339.

Waknis V, Chu E, Schlam R, Sidorenko A, Badawy S, Yin S, et al. Molecular basis of crystal morphology-dependent adhesion behavior of mefenamic acid during tableting. PharmRes. 2014;31:160–72. https://doi.org/10.1007/s11095-013-1149-6.

Wang JJ, Guillot MA, Bateman SD, Morris KR. Modeling of adhesion in tablet compression II Compaction studies using a compaction simulator and an instrumented tablet press. J Pharm Sci. 2004;93(2):407–17. https://doi.org/10.1002/jps.10553.

Sendall FEJ, Staniforth JN. A study of powder adhesion to metal surfaces during compression of effervescent pharmaceutical tablets. J Pharm Pharm. 1986;38(7):489–93. https://doi.org/10.1111/j.2042-7158.1986.tb04620.x.

McDermott TS, Farrenkopf J, Hlinak A, Neilly JP, Sauer D. A material sparing method for quantitatively measuring tablet sticking. Powder Technol. 2011;212(1):240–52. https://doi.org/10.1016/j.powtec.2011.05.023.

Roberts M, Ford JL, MacLeod GS, Fell JT, Smith GW, Rowe PH, et al. Effect of lubricant type and concentration on the punch tip adherence of model ibuprofen formulations. J Pharm Pharmacol. 2004;56(3):299–305. https://doi.org/10.1211/0022357022827.

Mullarney MP, MacDonald BC, Hutchins A. Assessing tablet-sticking propensity by weighing accumulated powder on a removable punch tip. Pharm Technol. 2012;36(1):57–62.

Bejugam NK, Mutyam SK, Shankar GN. Tablet formulation of an active pharmaceutical ingredient with a sticking and filming problem: direct compression and dry granulation evaluations. Drug Dev Ind Pharm. 2013;41(2):333–41. https://doi.org/10.3109/03639045.2013.859266.

Roberts M, Ford JL, MacLeod GS, Fell JT, Smith GW, Rowe PH. Effects of surface roughness and chrome plating of punch tips on the sticking tendencies of model ibuprofen formulations. J Pharm Pharm. 2003;55(9):1223–8. https://doi.org/10.1211/0022357021684.

Schumann S, Searle GD. The effects of chromium nitride ion bombardment treatment of tablet tooling on tablet adherence. Drug Dev Ind Pharm. 1992;18(10):1037–61. https://doi.org/10.3109/03639049209069314.

Uchimoto T, Iwao Y, Yamamoto T, Sawaguchi K, Moriuchi T, Noguchi S, et al. Newly developed surface modification punches treated with alloying techniques reduce sticking during the manufacture of ibuprofen tablets. Int J Pharm. 2013;441(1–2):128–34. https://doi.org/10.1016/j.ijpharm.2012.12.006.

Bunker M, Zhang J, Blanchard R, Roberts CJ. Characterising the surface adhesive behavior of tablet tooling components by atomic force microscopy. Drug Dev Ind Pharm. 2011;37(8):875–85. https://doi.org/10.3109/03639045.2010.546402.

Podczeck F. Investigations into the reduction of powder adhesion to stainless steel surfaces by surface modification to aid capsule filling. Int J Pharm. 1999;178(1):93–100. https://doi.org/10.1016/S0378-5173(98)00363-9.

Roberts M, Ford JL, MacLeod GS, Fell JT, Smith GW, Rowe PH, et al. Effect of punch tip geometry and embossment on the punch tip adherence of a model ibuprofen formulation. J Pharm Pharmacol. 2004;56(7):947–50. https://doi.org/10.1211/0022357023736.

Aoki S, Danjo K. Effect of tableting conditions on the sticking of tablet using ibuprofen. Yakugaku Zasshi. 1998;118(11):511–8.

Simmons DM, Gierer DS. A material sparing test to predict punch sticking during formulation development. Drug Dev Ind Pharm. 2012;38(9):1054–60. https://doi.org/10.3109/03639045.2011.637933.

Högdin A: Drug substances: scale-up challenges. https://www.contractpharma.com/issues/2019-09-01/view_features/drug-substances-scale-up-challenges/ (2019). Accessed 7 Sep 2023.

Alsirawan MB, Mohammad MA, Alkasmi B, Alhareth K, El-Hammadi M. Development and validation of a simple HPLC method for the determination of ibuprofen sticking onto punch faces. Int J Pharm Pharm Sci. 2013;5(SUPPL.4):227–31.

Wang Z, Shah UV, Olusanmi D, Narang AS, Hussain MA, Gamble JF, et al. Measuring the sticking of mefenamic acid powders on stainless steel surface. Int J Pharm. 2015;496(2):407–13. https://doi.org/10.1016/j.ijpharm.2015.09.067.

Al-Karawi C, Leopold CS. A comparative study on the sticking tendency of ibuprofen and ibuprofen sodium dihydrate to differently coated tablet punches. Eur J Pharm Biopharm. 2018;128:107–18. https://doi.org/10.1016/j.ejpb.2018.04.004.

Al-Karawi C, Kaiser T, Leopold CS. A novel technique for the visualization of tablet punch surfaces: characterization of surface modification, wear and sticking. Int J Pharm. 2017;530(1–2):440–54.

Paul S, Taylor LJ, Murphy B, Krzyzaniak J, Dawson N, Mullarney MP, et al. Mechanism and Kinetics of punch sticking of pharmaceuticals. J Pharm Sci. 2017;106(1):151–8. https://doi.org/10.1016/j.xphs.2016.07.015.

Paul S, Sun CC. Modulating sticking propensity of pharmaceuticals through excipient selection in a direct compression tablet formulation. Pharm Res. 2018;35(6):1–10. https://doi.org/10.1007/s11095-018-2396-3.

Paul S, Taylor LJ, Murphy B, Krzyzaniak JF, Dawson N, Mullarney MP, et al. Powder properties and compaction parameters that influence punch sticking propensity of pharmaceuticals. Int J Pharm. 2017;521(1–2):374–83. https://doi.org/10.1016/j.ijpharm.2017.02.053.

Paul S, Wang C, Wang K, Sun CC. Reduced punch sticking propensity of acesulfame by salt formation: role of crystal mechanical property and surface chemistry. Mol Pharm. 2019;16(6):2700–7. https://doi.org/10.1021/acs.molpharmaceut.9b00247.

Gunawardana CA, Kong A, Wanapun D, Blackwood DO, Travis Powell C, Krzyzaniak JF, et al. Understanding the role of magnesium stearate in lowering punch sticking propensity of drugs during compression. Int J Pharm. 2023;640:123016. https://doi.org/10.1016/j.ijpharm.2023.123016.

Samiei L, Kelly K, Taylor L, Forbes B, Collins E, Rowland M. The influence of electrostatic properties on the punch sticking propensity of pharmaceutical blends. Powder Technol. 2017;305:509–17. https://doi.org/10.1016/j.powtec.2016.10.018.

Capece M. The role of particle surface area and adhesion force in the sticking behavior of pharmaceutical powders. J Pharm Sci. 2019;108(12):3803–13. https://doi.org/10.1016/j.xphs.2019.08.019.

Thomas J, Zavaliangos A. An in-line, high sensitivity, non-contact sensor for the detection of initiation of sticking. J Pharm Innov. 2020;15(1):66–72. https://doi.org/10.1007/s12247-018-9367-4.

Tsosie H, Thomas J, Strong J, Zavaliangos A. Scanning electron microscope observations of powder sticking on punches during a limited number (N<5) of compactions of acetylsalicylic acid. Pharm Res. 2017;34(10):2012–24. https://doi.org/10.1007/s11095-017-2186-3.

Mollereau G, Mazel V, Busignies V, Tchoreloff P, Mouveaux F, Rivière P. Image analysis quantification of sticking and picking events of pharmaceutical powders compressed on a rotary tablet press simulator. Pharm Res. 2013;30(9):2303–14. https://doi.org/10.1007/s11095-013-1074-8.

Neilly J, Vogt A, Dziki W. Characterization of sticking residue on tablet punch faces by scanning electron microscopy and X-ray mapping. Microsc Microanal. 2009;15(S2):18–9. https://doi.org/10.1017/S1431927609097165.

Swaminathan S, Ramey B, Hilden J, Wassgren C. Characterizing the powder punch-face adhesive interaction during the unloading phase of powder compaction. Powder Technol. 2017;315:410–21. https://doi.org/10.1016/j.powtec.2017.04.003.

Shunichi N, Masui K, Shiraki T. Prediction of tableting problems such as capping and sticking: theoretical calculations. J Pharm Sci. 1977;66(2):254–9. https://doi.org/10.1002/jps.2600660229.

Goodhart FW, Mayorga G, Ninger FC. Measurement of lower punch pulldown force and its significance. J Pharm Sci. 1969;58(2):248–51. https://doi.org/10.1002/jps.2600580226.

Waimer F, Krumme M, Danz P, Tenter U, Schmidt PC. A novel method for the detection of sticking of tablets. Pharm Dev Technol. 1999;4(3):359–67. https://doi.org/10.1081/PDT-100101371.

Lam KK, Newton JM. Influence of particle size on the adhesion behaviour of powders, after application of an initial press-on force. Powder Technol. 1992;73(2):117–25. https://doi.org/10.1016/0032-5910(92)80072-5.

Kakimi K, Niwa T, Danjo K. Influence of compression pressure and velocity on tablet sticking. Chem Pharm Bull. 2010;58(12):1565–8.

Mitrovej A, Augsburger LL. Adhesion of tablets in a rotary tablet press I. Instrumentation and preliminary study of variables affecting adhesion. Drug Dev Ind Pharm. 1980;6(4):331–77. https://doi.org/10.3109/03639048009068709.

Danjo K, Kamiya K, Otsuka A. Effect of temperature on the sticking of low melting point materials. Chem Pharm Bull. 1993;41(8):1423–7. https://doi.org/10.1248/cpb.41.1423.

Parekh BV, Saddik JS, Patel DB, Dave RH. Evaluating the effect of glidants on tablet sticking propensity of ketoprofen using powder rheology. Int J Pharm. 2023;635:122710. https://doi.org/10.1016/j.ijpharm.2023.122710.

Nakamura S, Otsuka N, Yoshino Y, Sakamoto T, Yuasa H. Predicting the occurrence of sticking during tablet production by shear testing of a pharmaceutical powder. Chem Pharm Bull. 2016;64(5):512–6. https://doi.org/10.1248/cpb.c15-00992.

Toyoshima K, Yasumura M, Ohnishi N, Ueda Y. Quantitative evaluation of tablet sticking by surface roughness measurement. Int J Pharm. 1988;46(3):211–5. https://doi.org/10.1016/0378-5173(88)90080-4.

Saniocki I, Sakmann A, Leopold CS. How suitable is the measurement of take-off forces for detection of sticking during direct compression of various ibuprofen tablet formulations? Pharm Dev Technol. 2013;18(1):257–65. https://doi.org/10.3109/10837450.2012.712538.

Hertz H. Ueber die Berührung fester elastischer Körper. Journal Für Die Reine und Angewandte Mathematik. 1882;1882(92):156–71. https://doi.org/10.1515/crll.1882.92.156.

Tablet Breaking Force <1217>. United States Pharmacopea and National Formulary (USP37–NF32). United State Pharmacopea Convention; 2015. p 1146-8.

Fell JT, Newton JM. Determination of tablet strength by the diametral-compression test. J Pharm Sci. 1970;59(5):688–91. https://doi.org/10.1002/jps.2600590523.

Zavaliangos A, Laptev A. The densification of powder mixtures containing soft and hard components under static and cyclic pressure. Acta Materialia. 2000;48(10):2565–70. https://doi.org/10.1016/S1359-6454(00)00066-5.

Huang C-Y, Daehn GS. Densification of composite powder compacts in pressure cycling. Acta Materialia. 1996;44(3):1035–45. https://doi.org/10.1016/1359-6454(95)00230-8.

Sawicki A, Swidzinski W. Cyclic compaction of soils, grains and powders. Powder Technol. 1995;85(2):97–104. https://doi.org/10.1016/0032-5910(95)03013-Y.

Jiang G, Wu W, Daehn GS, Wagoner RH. Experimental and numerical investigation of idealized consolidation: part II: cyclic compaction. Acta Materialia. 2000;48(17):4331–5. https://doi.org/10.1016/S1359-6454(00)00207-X.

Jiang G, Daehn GS, Lannutti JJ, Fu Y, Wagoner RH. Effects of lubrication and aspect ratio on the consolidation of metal matrix composites under cyclic pressure. Acta Materialia. 2001;49(8):1471–7. https://doi.org/10.1016/S1359-6454(01)00026-X.

Bechard SR, Down GRB. Infrared imaging of pharmaceutical materials undergoing compaction. Pharm Res. 1992;9(4):521–8. https://doi.org/10.1023/A:1015896414765.

Zavaliangos A, Galen S, Cunningham J, Winstead D. Temperature evolution during compaction of pharmaceutical powders. J Pharm Sci. 2008;97(8):3291–304. https://doi.org/10.1002/jps.21229.

Klinzing GR, Zavaliangos A, Cunningham J, Mascaro T, Winstead D. Temperature and density evolution during compaction of a capsule shaped tablet. Comput Chem Eng. 2010;34(7):1082–91. https://doi.org/10.1016/j.compchemeng.2010.04.012.

Narurkar AN, Purkaystha AR, Sheen P-C. Effect of various factors on the corrosion and rusting of tooling material used for tablet manufacturing. Drug Dev Ind Pharm. 1985;11(8):1487–95. https://doi.org/10.3109/03639048509057681.

Acknowledgements

The authors would like to thank Elizabeth Moroz from GlaxoSmithKline for help with this project and the Material Science Department at GlaxoSmithKline for access to instrumentation.

Funding

The authors would like to thank GlaxoSmithKline for their financial support on this project. Phuong Bui was also partially funded by the Department of Education scholarship under award number P200A150240.

Author information

Authors and Affiliations

Contributions

J.T. designed the custom components that enabled the STMC with rotation mechanism and executed the experiments. P.B. executed initial experiments for proof of concept including the effect of punch rotation. J.T. and A.Z. were responsible for the conceptual idea of the technique. A.Z. was responsible for the planning for the work and the discussion of mechanism.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Thomas, J., Bui, P. & Zavaliangos, A. Sticking Detection by Repeated Compactions on a Single Tablet. AAPS PharmSciTech 24, 237 (2023). https://doi.org/10.1208/s12249-023-02694-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-023-02694-6