Abstract

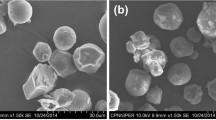

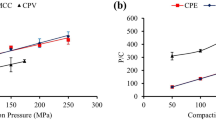

Particle engineering of excipients, at sub-particulate level using co-processing, can provide high functionality excipients. NanoCrySP technology has been recently explored as a novel approach for the generation of nanocrystalline solid dispersion of poorly soluble drugs, using spray drying process. The purpose of the present study was to generate co-processed mannitol and sorbitol (SD-CSM) using NanoCrySP technology having similar composition to commercial co-processed excipient (Compressol® SM, CP). The characterization of excipients was performed to evaluate their various physicomechanical properties. The sub-micron crystallite size of sorbitol in the matrix of mannitol was determined using the Williamson-Hall equation and Halder-Wagner equation. The reduction in crystallite size of sorbitol and mannitol, lower melting point, and lower heat of fusion of SD-CSM could be responsible for excellent compactibility, better tabletability, and comparable compressibility with respect to CP. This was confirmed by the compressibility-tabletability-compactibility (CTC) profile and Heckel plot analysis. Overall, SD-CSM generated using NanoCrySP technology improved functionalities of excipients over CP and would be useful for direct compression application.

Graphical abstract

Similar content being viewed by others

References

Abrantes CG, Duarte D, Reis CP. An overview of pharmaceutical excipients: safe or not safe? J Pharm Sci. 2016;105(7):2019–26. https://doi.org/10.1016/j.xphs.2016.03.019.

Koo OMY. Application challenges and examples of new excipients in advanced drug delivery systems. 2011. https://www.americanpharmaceuticalreview.com/Featured-Articles/36925-Application-Challenges-and-Examples-of-New-Excipients-in-Advanced-Drug-Delivery-Systems/. Accessed 25 Apr 2019.

Parmar PK, Rao SG, Bansal AK. Co-processing of small molecule excipients with polymers to improve functionality. Expert Opin Drug Deliv. 2021:1–22. https://doi.org/10.1080/17425247.2021.1873946.

Gupta P, Nachaegari SK, Bansal AK. Improved excipient functionality by coprocessing. In: Katdare A, Chaubal M, editors. Excipient development for pharmaceutical, biotechnology, and drug delivery systems. New York: Informa Healthcare; 2006. p. 129–46.

Bhattacharyya L, Schuber S, Sheehan C, William R. Excipients: background/introduction. In: Katdare A, Chaubal M, editors. Excipient development for pharmaceutical, biotechnology, and drug delivery systems. New York: Informa Healthcare; 2006. p. 21–2.

Nachaegari SK, Bansal AK. Coprocessed excipients for solid dosage forms. Pharm Technol. 2004;28(1):52–65.

Binab KA, Gaurav A, Mandal UK. A review on co-processed excipients: current and future trend of excipient technology. Int J Pharm Pharm Sci. 2019;11(1):1–9. https://doi.org/10.22159/ijpps.2019v11i1.29265.

Saha S, Shahiwala AF. Multifunctional coprocessed excipients for improved tabletting performance. Expert Opin Drug Deliv. 2009;6(2):197–208. https://doi.org/10.1517/17425240802708978.

Shete G, Bansal AK. NanoCrySP technology for generation of drug nanocrystals: translational aspects and business potential. Drug Deliv Transl Res. 2016;6(4):392–8. https://doi.org/10.1007/s13346-016-0286-y.

Kaur A, Parmar PK, Bansal AK. Evaluation of different techniques for size determination of drug nanocrystals: a case study of celecoxib nanocrystalline solid dispersion. Pharmaceutics. 2019;11(10):516. https://doi.org/10.3390/pharmaceutics11100516.

SPIPharma. Compressol® SM-Co-Processed Polyol. 2019. https://www.spipharma.com/downloads/Products/Excipients/Compressol_S/CompressolSTech.pdf. Accessed 20 Jun 2019.

Ebatco. X-ray diffraction. 2020. http://www.ebatco.com/laboratory-services/x-ray-diffraction/. Accessed 29 Jun 2020.

Sen SK, Paul TC, Dutta S, Hossain M, Mia M. XRD peak profile and optical properties analysis of Ag-doped h-MoO 3 nanorods synthesized via hydrothermal method. J Mater Sci Mater Electron. 2020;31(2):1768–86. https://doi.org/10.1007/s10854-019-02694-y.

Wiranwetchayan O, Promnopat S, Thongtem T, Chaipanich A, Thongtem S. Effect of polymeric precursors on the properties of TiO2 films prepared by sol-gel method. Mater Chem Phys. 2020;240:1–8. https://doi.org/10.1016/j.matchemphys.2019.122219.

Zak AK, Majid WA, Abrishami ME, Yousefi R. X-ray analysis of ZnO nanoparticles by Williamson–Hall and size–strain plot methods. Solid State Sci. 2011;13(1):251–6. https://doi.org/10.1016/j.solidstatesciences.2010.11.024.

Phadke C, Sharma J, Sharma K, Bansal AK. Effect of variability of physical properties of povidone K30 on crystallization and drug–polymer miscibility of celecoxib–povidone K30 amorphous solid dispersions. Mol Pharm. 2019;16(10):4139–48. https://doi.org/10.1021/acs.molpharmaceut.9b00452.

USP. 〈616〉 Bulk density and tapped density of powders. The United States Pharmacopeial Convention. 2015. https://www.usp.org/sites/default/files/usp/document/harmonization/gen-chapter/bulk_density.pdf. Accessed 10 Jul 2019.

Chawla G, Bansal AK. Effect of processing on celecoxib and its solvates. Pharm Dev Technol. 2005;9(4):419–33. https://doi.org/10.1081/PDT-200035800.

Jetzer W, Leuenberger H, Sucker H. The compressibility and compactibility of pharmaceutical powders. Pharm Technol. 1983;7(33):36–9.

Singh S, Nwabor OF, Ontong JC, Voravuthikunchai SP. Characterization and assessment of compression and compactibility of novel spray-dried, co-processed bio-based polymer. J Drug Deliv Sci Tec. 2020;56:1–28. https://doi.org/10.1016/j.jddst.2020.101526.

Denny P. Compaction equations: a comparison of the Heckel and Kawakita equations. Powder Technol. 2002;127(2):162–72. https://doi.org/10.1016/S0032-5910(02)00111-0.

Khomane KS, More PK, Raghavendra G, Bansal AK. Molecular understanding of the compaction behavior of indomethacin polymorphs. Mol Pharm. 2013;10(2):631–9. https://doi.org/10.1021/mp300390m.

Joshi AB, Patel S, Kaushal AM, Bansal AK. Compaction studies of alternate solid forms of celecoxib. Adv Powder Technol. 2010;21(4):452–60. https://doi.org/10.1016/j.apt.2010.01.006.

Patel RD, Raval MK, Bagathariya AA, Sheth NR. Functionality improvement of nimesulide by eutectic formation with nicotinamide: exploration using temperature-composition phase diagram. Adv Powder Technol. 2019;30(5):961–73. https://doi.org/10.1016/j.apt.2019.02.010.

Raval MK, Sorathiya KR, Chauhan NP, Patel JM, Parikh RK, Sheth NR. Influence of polymers/excipients on development of agglomerated crystals of secnidazole by crystallo-co-agglomeration technique to improve processability. Drug Dev Ind Pharm. 2013;39(3):437–46. https://doi.org/10.3109/03639045.2012.662508.

Callahan J, Cleary G, Elefant M, Kaplan G, Kensler T, Nash R. Equilibrium moisture content of pharmaceutical excipients. Drug Dev Ind Pharm. 1982;8(3):355–69. https://doi.org/10.3109/03639048209022105.

Burger A, Henck JO, Hetz S, Rollinger JM, Weissnicht AA, Stöttner H. Energy/temperature diagram and compression behavior of the polymorphs of D-mannitol. J Pharm Sci. 2000;89(4):457–68. https://doi.org/10.1002/(SICI)1520-6017(200004)89:4%3C457::AID-JPS3%3E3.0.CO;2-G.

Nezzal A, Aerts L, Verspaille M, Henderickx G, Redl A. Polymorphism of sorbitol. J Cryst Growth. 2009;311(15):3863–70. https://doi.org/10.1016/j.jcrysgro.2009.06.003.

Nath D, Singh F, Das R. X-ray diffraction analysis by Williamson-Hall, Halder-Wagner and size-strain plot methods of CdSe nanoparticles-a comparative study. Mater Chem Phys. 2020;239:1–9. https://doi.org/10.1016/j.matchemphys.2019.122021.

Kumar S, Chawla G, Bansal AK. Spherical crystallization of mebendazole to improve processability. Pharm Dev Technol. 2008;13(6):559–68. https://doi.org/10.1080/10837450802310180.

Mohammed G, Puri V, Bansal AK. Coprocessing of nevirapine and stavudine by spray drying. Pharm Dev Technol. 2008;13(4):299–310. https://doi.org/10.1080/10837450802089164.

Sun CC. Decoding powder tabletability: roles of particle adhesion and plasticity. J Adhes Sci Technol. 2011;25(4-5):483–99. https://doi.org/10.1163/016942410X525678.

Kale DP, Puri V, Kumar A, Kumar N, Bansal AK. The role of cocrystallization-mediated altered crystallographic properties on the tabletability of rivaroxaban and malonic acid. Pharmaceutics. 2020;12(6):546. https://doi.org/10.3390/pharmaceutics12060546.

Patel S, Kaushal AM, Bansal AK. Compression physics in the formulation development of tablets. Crit Rev Ther Drug. 2006;23(1):1–65. https://doi.org/10.1615/critrevtherdrugcarriersyst.v23.i1.10.

Bolhuis GK, Rexwinkel EG, Zuurman K. Polyols as filler-binders for disintegrating tablets prepared by direct compaction. Drug Dev Ind Pharm. 2009;35(6):671–7. https://doi.org/10.1080/03639040802587799.

Khomane KS, More PK, Bansal AK. Counterintuitive compaction behavior of clopidogrel bisulfate polymorphs. J Pharm Sci. 2012;101(7):2408–16. https://doi.org/10.1002/jps.23148.

Ramberger R, Burger A. On the application of the Heckel and Kawakita equations to powder compaction. Powder Technol. 1985;43(1):1–9. https://doi.org/10.1016/0032-5910(85)80073-5.

Patel S, Kaushal AM, Bansal AK. Effect of particle size and compression force on compaction behavior and derived mathematical parameters of compressibility. Pharm Res. 2007;24(1):111–24. https://doi.org/10.1007/s11095-006-9129-8.

Patel S, Kaushal AM, Bansal AK. Compaction behavior of roller compacted ibuprofen. Eur J Pharm Biopharm. 2008;69(2):743–9. https://doi.org/10.1016/j.ejpb.2008.01.005.

Adeoye O, Alebiowu G. Flow, packing and compaction properties of novel coprocessed multifunctional directly compressible excipients prepared from tapioca starch and mannitol. Pharm Dev Technol. 2014;19(8):901–10. https://doi.org/10.3109/10837450.2013.840843.

Ginty M, Munters. The significance of humidity control in GMP compliant production. 2018. https://www.pharmaceuticalprocessingworld.com/the-significance-of-humidity-control-in-gmp-compliant-production/. Accessed 31 Oct 2019.

Khomane KS, Bansal AK. Effect of particle size on in-die and out-of-die compaction behavior of ranitidine hydrochloride polymorphs. AAPS PharmSciTech. 2013;14(3):1169–77. https://doi.org/10.1208/s12249-013-0008-4.

Bacher C, Olsen P, Bertelsen P, Sonnergaard J. Compressibility and compactibility of granules produced by wet and dry granulation. Int J Pharm. 2008;358(1-2):69–74. https://doi.org/10.1016/j.ijpharm.2008.02.013.

Kelemen A, Szalay A, Sovány T, Pintye-Hódi K. Role of the particle size of sorbitol during the compression of common tablets and prediction of mini-tablet compression parameters. Chem Eng Res Des. 2015;104:814–8. https://doi.org/10.1016/j.cherd.2015.10.028.

Bučar DK, Elliott JA, Eddleston MD, Cockcroft JK, Jones W. Sonocrystallization yields monoclinic paracetamol with significantly improved compaction behavior. Angew Chem Int Ed. 2015;54(1):249–53. https://doi.org/10.1002/anie.201408894.

Awad ME, López-Galindo A, Medarević D, Đuriš J, El-Rahmany MM, Ibrić S, et al. Flow and tableting behaviors of some egyptian kaolin powders as potential pharmaceutical excipients. Minerals. 2020;10(1):1–23. https://doi.org/10.3390/min10010023.

ElShaer A, Al-Khattawi A, Mohammed AR, Warzecha M, Lamprou DA, Hassanin H. Understanding the compaction behaviour of low-substituted HPC: macro, micro, and nano-metric evaluations. Pharm Dev Technol. 2018;23(5):442–53. https://doi.org/10.1080/10837450.2017.1363775.

Acknowledgments

Srilaxmi G. Rao would like to gratefully acknowledge SPI Pharma, United States, for providing gift samples of Compressol® SM. Srilaxmi G. Rao and Prashantkumar K. Parmar would like to thank Dnyaneshwar P. Kale and Sneha Sheokand for their support and help during this project. The authors would like to acknowledge NIPER-S.A.S. Nagar for providing the necessary facilities for this project.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

Srilaxmi G. Rao: conceptualization, methodology, investigation, formal analysis, software, data curation, and writing—original draft. Prashantkumar K. Parmar: conceptualization, investigation, formal analysis, data curation, and writing—review and editing. Katangur Vishruth Reddy: conceptualization, methodology, formal analysis, and data curation. Arvind K. Bansal: conceptualization, writing—review and editing, and supervision. All persons mentioned above have made substantial contributions to the work in the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rao, S.G., Parmar, P.K., Reddy, K.V. et al. Preparation and Characterization of Co-Processed Mannitol and Sorbitol Using NanoCrySP Technology. AAPS PharmSciTech 22, 201 (2021). https://doi.org/10.1208/s12249-021-02071-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-021-02071-1