Abstract

Describing the elastic deformation of single-crystal molecular solids under stress requires a comprehensive determination of the fourth-rank stiffness tensor (Cijkl). Single crystals are, however, rarely utilized in industrial applications, and thus averaging techniques (e.g., the Voigt or Reuss approach) are employed to reduce the Cijkl (or its inverse Sijkl) to polycrystalline aggregate mechanical moduli. With increasing elastic anisotropy, the Voigt and Reuss-averaged aggregate moduli can diverge dramatically and, provided that drug molecules almost exclusively crystallize into low-symmetry space groups, warrants a significant need for accurate aggregate mechanical moduli. This elasticity data, which currently is largely absent for pharmaceutical materials, is expected to aid understanding how materials respond to direct compression and tablet formation. Powder Brillouin light scattering (p-BLS) has recently demonstrated facile access to porosity-independent, aggregate mechanical moduli. In this study, we extend our previous p-BLS model for obtaining mechanical properties and validate our approach against a broad library of molecular solids with diverse intermolecular interaction topologies and with previously determined Cijkl which permits benchmarking our results. Our Young’s and shear moduli determined with p-BLS strongly correlate, with limited bias (i.e., a near 1:1 relation), with the Voigt-averaged Young’s and shear moduli determined using the Cijkl. Through follow-on tabletability studies, we introduce initial classifications of tabletability behavior based on the results of our p-BLS studies and the apparent elastic anisotropy. With further development, this approach represents a robust and novel method to potentially identify materials for optimum tabletability at early developmental stages.

Similar content being viewed by others

References

Duncan-Hewitt WC, Weatherly GC. Evaluating the hardness, Young’s modulus and fracture toughness of some pharmaceutical crystals using microindentation techniques. J Mater Sci Lett. 1989;8(11):1350–2.

Katz JM, Buckner IS. Characterization of strain rate sensitivity in pharmaceutical materials using indentation creep analysis. Int J Pharm. 2013;442(1–2):13–9.

Egart M, Ilić I, Janković B, Lah N, Srčič S. Compaction properties of crystalline pharmaceutical ingredients according to the Walker model and nanomechanical attributes. Int J Pharm. 2014;472(1–2):347–55.

Price CP, Grzesiak AL, Matzger AJ. Crystalline polymorph selection and discovery with polymer heteronuclei. J Amer Chem Soc. 2005;127(15):5512–7.

Reddy CM, Basavoju S, Desiraju GR. Sorting of polymorphs based on mechanical properties. Trimorphs of 6-chloro-2, 4-dinitroaniline. Chem Commun. 2005;(19):2439–41.

Khomane KS, More PK, Raghavendra G, Bansal AK. Molecular understanding of the compaction behavior of indomethacin polymorphs. Mol Pharm. 2013;10(2):631–9.

Hiestand EN. Mechanical properties of compacts and particles that control tableting success. J Pharm Sci. 1997;86(9):985–90.

Heckel R. Density-pressure relationships in powder compaction. Trans Metall Soc AIME. 1961;221(4):671–5.

Çelik M, Marshall K. Use of a compaction simulator system in tabletting research. Drug Dev Ind Pharm. 1989;15(5):759–800.

Duberg M, Nyström C. Studies on direct compression of tablets XVII. Porosity—pressure curves for the characterization of volume reduction mechanisms in powder compression. Powder Technol. 1986;46(1):67–75.

Ilkka J, Paronen P. Prediction of the compression behaviour of powder mixtures by the Heckel equation. Int J Pharm. 1993;94(1–3):181–7.

Ilic M, Galiana F, Fink L. Power systems restructuring: engineering and economics: Springer Science & Business Media, Boston, MA; 2013.

Khomane KS, More PK, Bansal AK. Counterintuitive compaction behavior of clopidogrel bisulfate polymorphs. J Pharm Sci. 2012;101(7):2408–16.

Sonnergaard JM. Quantification of the compactibility of pharmaceutical powders. Eur J Pharm Biopharm. 2006;63(3):270–7.

Rasenack N, Müller BW. Dissolution rate enhancement by in situ micronization of poorly water-soluble drugs. Pharm Res. 2002;19(12):1894–900.

Shariare MH, Leusen FJ, de Matas M, York P, Anwar J. Prediction of the mechanical behaviour of crystalline solids. Pharm Res. 2012;29(1):319–31.

Sun CC. Decoding powder tabletability: roles of particle adhesion and plasticity. J Adhes Sci Technol. 2011;25(4–5):483–99.

Egart M, Janković B, Srčič S. Application of instrumented nanoindentation in preformulation studies of pharmaceutical active ingredients and excipients. Acta Pharma. 2016;66(3):303–30.

Roberts RJ. Particulate analysis–mechanical properties. Solid State Characterization of Pharmaceuticals. 2011:357–386.

Nordström J, Klevan I, Alderborn G. A protocol for the classification of powder compression characteristics. Eur J Pharm Biopharm. 2012;80(1):209–16.

Roberts R, Rowe R, York P. The relationship between the fracture properties, tensile strength and critical stress intensity factor of organic solids and their molecular structure. Int J Pharm. 1995;125(1):157–62.

Jain S. Mechanical properties of powders for compaction and tableting: an overview. Pharm Sci Technolo Today. 1999;2(1):20–31.

Amidon GE, Secreast PJ, Mudie D. Particle, powder, and compact characterization. In: Developing solid oral dosage forms: Elsevier; 2009. p. 163–86.

Sun C, Grant DJ. Influence of crystal structure on the tableting properties of sulfamerazine polymorphs. Pharm Res. 2001;18(3):274–80.

Taylor L, Papadopoulos D, Dunn P, Bentham A, Mitchell J, Snowden M. Mechanical characterisation of powders using nanoindentation. Powder Technol. 2004;143:179–85.

Davidge R, Tappin G. The effective surface energy of brittle materials. J Mater Sci. 1968;3(2):165–73.

Meier M, John E, Wieckhusen D, Wirth W, Peukert W. Influence of mechanical properties on impact fracture: prediction of the milling behaviour of pharmaceutical powders by nanoindentation. Powder Technol. 2009;188(3):301–13.

Govedarica B, Ilić I, Srčič S. The use of single particle mechanical properties for predicting the compressibility of pharmaceutical materials. Powder Technol. 2012;225:43–51.

Brillouin L, editor Diffusion de la lumière et des rayons X par un corps transparent homogène-Influence de l’agitation thermique. Ann Phy; 1922: EDP Sciences.

Borovik-Romanov A, Kreines NM. Brillouin-Mandelstam scattering from thermal and excited magnons. Phys Rep. 1982;81(5):351–408.

Dil J. Brillouin scattering in condensed matter. Rep Prog Phys. 1982;45(3):285–334.

Krüger J, Marx A, Peetz L, Roberts R, Unruh H-G. Simultaneous determination of elastic and optical properties of polymers by high performance Brillouin spectroscopy using different scattering geometries. Colloid Polym Sci. 1986;264(5):403–14.

Speziale S, Marquardt H, Duffy TS. Brillouin scattering and its application in geosciences. Rev Mineral Geochem. 2014;78(1):543–603.

Singaraju AB, Nguyen K, Jain A, Haware RV, Stevens LL. Aggregate elasticity, crystal structure, and tableting performance for p-aminobenzoic acid and a series of its benzoate esters. Mol Pharm. 2016;13(11):3794–806.

Hernandez J, Li G, Cummins HZ, Callender RH, Pick RM. Low-frequency light-scattering spectroscopy of powders. JOSA B. 1996;13(6):1130–4.

Newton J, Rowley G, Fell J, Peacock D, Ridgway K. Computer analysis of the relation between tablet strength and compaction pressure. J Pharm Pharmacol. 1971;23(S1):195S–201S.

Haussühl S. Elastic and thermoelastic properties of selected organic crystals: acenaphthene, trans-azobenzene, benzophenone, tolane, trans-stilbene, dibenzyl, diphenyl sulfone, 2, 2′-biphenol, urea, melamine, hexogen, succinimide, pentaerythritol, urotropine, malonic acid, dimethyl malonic acid, maleic acid, hippuric acid, aluminium acetylacetonate, iron acetylacetonate, and tetraphenyl silicon. Z Kristallogr Cryst Mater. 2001;216(6):339–53.

Dye R, Eckhardt CJ. A complete set of elastic constants of crystalline anthracene by Brillouin scattering. J Chem Phys. 1989;90(4):2090–6.

Mohapatra H, Eckhardt CJ. Elastic constants and related mechanical properties of the monoclinic polymorph of the carbamazepine molecular crystal. J Phys Chem B. 2008;112(8):2293–8.

Bauer JD, Haussühl E, Br W, Arbeck D, Milman V, Robertson S. Elastic properties, thermal expansion, and polymorphism of acetylsalicylic acid. Cryst Growth Des. 2010;10(7):3132–40.

Armstrong N, Haines-Nutt R. Elastic recovery and surface area changes in compacted powder systems. J Pharm Pharmacol. 1972;24:Suppl: 135P.

Kerridge J, Newton J. The determination of the compressive Young’s modulus of pharmaceutical materials. J Pharm Pharmacol. 1986;38(S12):79P.

Church M, Kennerley J. A comparison of the mechanical properties of pharmaceutical materials obtained by the flexure testing of compacted rectangular beams. J Pharm Pharmacol. 1983;35:43P.

Mashadi AB, Newton J. The characterization of the mechanical properties of microcrystalline cellulose: a fracture mechanics approach. J Pharm Pharmacol. 1987;39(12):961–5.

Bassam F, York P, Rowe R, Roberts R. Young’s modulus of powders used as pharmaceutical excipients. Int J Pharm. 1990;64(1):55–60.

Akseli I, Becker DC, Cetinkaya C. Ultrasonic determination of Young’s moduli of the coat and core materials of a drug tablet. Int J Pharm. 2009;370(1–2):17–25.

Lee J-U, Yoon D, Cheong H. Estimation of Young’s modulus of graphene by Raman spectroscopy. Nano Lett. 2012;12(9):4444–8.

Peiponen K-E, Bawuah P, Chakraborty M, Juuti M, Zeitler JA, Ketolainen J. Estimation of Young’s modulus of pharmaceutical tablet obtained by terahertz time-delay measurement. Int J Pharm. 2015;489(1–2):100–5.

Ketolainen J, Oksanen M, Rantala J, Stor-Pellinen J, Luukkala M, Paronen P. Photoacoustic evaluation of elasticity and integrity of pharmaceutical tablets. Int J Pharm. 1995;125(1):45–53.

Gupta A, Peck GE, Miller RW, Morris KR. Real-time near-infrared monitoring of content uniformity, moisture content, compact density, tensile strength, and Young’s modulus of roller compacted powder blends. J Pharm Sci. 2005;94(7):1589–97.

Busignies V, Tchoreloff P, Leclerc B, Hersen C, Keller G, Couarraze G. Compaction of crystallographic forms of pharmaceutical granular lactoses. II. Compacts mechanical properties. Eur J Pharm Biopharm. 2004;58(3):577–86.

Ryshkewitch E. Compression strength of porous sintered alumina and zirconia. J Am Ceram Soc. 1953;36(2):65–8.

Newton J, Mashadi A, Podczeck F. The mechanical-properties of an homologous series of benzoic-acid esters. Eur J Pharm Biopharm. 1993;39(4):153–7.

Krycer I, Pope DG, Hersey JA. An evaluation of the techniques employed to investigate powder compaction behaviour. Int J Pharm. 1982;12(2–3):113–34.

Spriggs R. Expression for effect of porosity on elastic modulus of polycrystalline refractory materials, particularly aluminum oxide. J Am Ceram Soc. 1961;44(12):628–9.

Leuenberger H. The compressibility and compactibility of powder systems. Int J Pharm. 1982;12(1):41–55.

Pharr G. Measurement of mechanical properties by ultra-low load indentation. Mater Sci Eng A. 1998;253(1–2):151–9.

Khossravi D, Morehead WT. Consolidation mechanisms of pharmaceutical solids: a multi-compression cycle approach. Pharm Res. 1997;14(8):1039–45.

Newnham RE. Properties of materials: anisotropy, symmetry, structure: Oxford University Press on Demand; 2005.

Nye JF. Physical properties of crystals: their representation by tensors and matrices: Oxford University Press; 1985.

Crosson RS, Lin JW. Voigt and Reuss prediction of anisotropic elasticity of dunite. J Geophys Res. 1971;76(2):570–8.

Ranganathan SI, Ostoja-Starzewski M. Universal elastic anisotropy index. Phys Rev Lett. 2008;101(5):055504.

Kube CM. Elastic anisotropy of crystals. AIP Adv. 2016;6(9):095209.

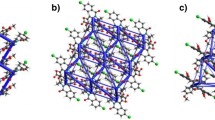

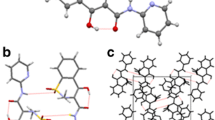

Singaraju AB, Iyer M, Haware RV, Stevens LL. Caffeine co-crystal mechanics evaluated with a combined structural and spectroscopic approach. Cryst Growth Des. 2016;16(8):4383–91.

Singaraju AB, Nguyen K, Gawedzki P, Herald F, Meyer G, Wentworth D, et al. Combining crystal structure and interaction topology for interpreting functional molecular solids: a study of theophylline cocrystals. Cryst Growth Des. 2017;17(12):6741–51.

Author information

Authors and Affiliations

Corresponding author

Additional information

Guest Editors: William C. Stagner and Rahul V. Haware

Electronic Supplementary Material

ESM 1

(DOCX 905 kb)

Rights and permissions

About this article

Cite this article

Bahl, D., Singaraju, A.B. & Stevens, L.L. Aggregate Elasticity and Tabletability of Molecular Solids: a Validation and Application of Powder Brillouin Light Scattering. AAPS PharmSciTech 19, 3430–3439 (2018). https://doi.org/10.1208/s12249-018-1194-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-018-1194-x