Abstract

Background

2,4-Dichlorophenol (2,4-DCP) is a very toxic aromatic compound for humans and the environment and is highly resistant to degradation. Therefore, it is necessary to develop efficient remediation and cost-effective approaches to this pollutant. Microbial enzymes such as laccases can degrade phenols, but limited information is known about immobilized bacterial laccase and their reuse.

Methods

Immobilization of marine halophilic Bacillus subtilis AAK cultures via entrapment and adsorption techniques and degradation of different phenolic compounds by immobilized cells were estimated. Partial purification and immobilization of laccase enzymes were carried out. In addition, the biodegradation of 2,4-DCP and others contaminated by wastewater was investigated.

Results

Immobilization of cells and partially purified laccase enzymes by adsorption into 3% alginate increased 2,4-DCP biotransformation compared with free cells and free enzymes. In addition, the reuse of both the immobilized culture and laccase enzymes was evaluated. The highest removal of 2,4-DCP from pulp and paper wastewater samples inoculated by immobilized cells and the immobilized enzyme was 90% and 95%, respectively, at 50 h and 52 h of incubation, compared to free cells and free enzyme.

Conclusion

The results of this study have revealed the immobilization of a biocatalyst and its laccase enzyme as a promising technique for enhancing the degradation of 2,4-DCP and other toxic phenolic and aromatic compounds. The reuse of the biocatalyst and its laccase enzyme enabled the application of this cost-effective bioremediation strategy.

Similar content being viewed by others

Background

Chloro-phenolic compounds (CPs) are considered a vital type of xenobiotics due to their extensive use in many important chemical products such as herbicides, insecticides, wood preservatives, dyes, pharmaceuticals, and lubricant additives [1]. The process of chlorination can produce CPs as byproducts which can be used for wastewater disinfection. According to their persistence, CPs affect soil and water (ground and surface) and can be released into the environment for an extended period of time [2]. In addition, they are highly recalcitrant, carcinogenic, and toxic; hence, they are regarded as priority environmental pollutants by the United States Environmental Protection Agency (USEPA) [3]. Different approaches have been used to study the biodegradation of PCs from wastewaters, such as advanced oxidation, photo-catalytic removal, solvent extraction, and adsorption techniques [4]. The accumulation of toxic byproducts and low degradation efficiency are the primary characteristics of these removal techniques. Accordingly, economical and eco-friendly removal methods are preferred for the remediation of polluted toxic aromatic [5]. For process engineers and microbial ecologists, microbial enzymes and cell bioremediation of xenobiotic pollutants remain a significant challenge. Marine microbes are crucial to the biogeochemical cycling of marine ecosystems and marine food webs. Consequently, microbial enzymes produced from marine microorganisms have more advantages than their terrestrial homologs, including genetic manipulation, mass culture ability, biochemical variability, further catalytic activity, lower costs, and sustainability [6]. Recently, most enzymes used in biotechnological and industrial processes are hydrolytic and used to remove aromatic and phenolic compounds from water [7].

Laccases (benzenediol: oxygen oxidoreductase, EC 1.10.3.2) have a high potential for use in a variety of applications. They are multicopper oxidases and catalyze the oxidation of various PCs and some aromatic compounds [8]. Microorganisms can produce laccase enzymes such as fungi [9] and bacteria [10] that are produced by Bacillus and Streptomyces [11]. In contrast to other remediation techniques, the laccase enzyme does not produce harmful byproducts when removing environmental pollutants.

During the biodegradation process, enzyme and cell immobilization technology can increase microbial biomass and maintain its high activity rate. Furthermore, it has many advantages as the toxicity tolerance is high; the degradative enzyme activity is maintained without the need to extract enzymes from cells. The separation of products is easy, the reaction speed is fast, and the equipment is miniaturized [12].

In biotechnological applications, immobilized enzymes have many advantages: they become highly resistant to environmental conditions, they can be removed easily at the end of the reaction, the product is not contaminated with the enzyme, and enzymes can be reused easily. In addition, product formation can be done under control. They demonstrated greater activity than the free enzyme, and are more stable than the free enzyme [13].

Organic matter is typically classified as either a growth substrate or a non-growth substrate due to the complexity of the wastewater's components. The growth substrate acts as an energy and carbon source, supporting cell growth and increasing the non-growth substrate’s transformation rate. However, it is essential to investigate the ability of enzymes and microbial cultures to biotransform CPs in wastewater under these conditions.

Several Bacillus species are well known for the biodegradation of different phenolic compounds [14, 15]. Bacillus subtilis is an aerobic, endospore-forming, Gram-positive bacteria, opportunistic pathogen, and the virulence characteristics of the microorganism are low [16]. Several authors have investigated Bacillus subtilis cells ability to degrade the 2,4-DCP [17,18,19]

Therefore, the current work aimed at biotransformation of 2,4-DCP using immobilized safe Bacillus subtilis AAK cultures and immobilized its laccase enzyme. Moreover, wastewater management applying both immobilized bacterial cultures, and laccase enzymes will be investigated.

Methods

Microbial strain

Bacillus subtilis AAK strain, which was previously isolated, identified as a marine halophilic 2,4-DCP-degrading bacterial strain and kept in GenBank (accession No. MF 037698), was used in this study [19].

Assessment of hemolytic activity

The hemolytic activity of B. subtilis AAK strain was detected according to the method described by Brutscher et al. [20]. The cells were streaked onto blood agar plates to test their ability to lyse blood cells. The plates were incubated at 30 °C for 24 h. After incubation, the blood agar was inspected for an alpha, beta, or gamma-hemolysis. Alpha-hemolysis, or incomplete hemolysis, is indicated by a discolored, darkened, or green medium color after testing culture growth. Complete hemolysis, or beta-hemolysis, is referred to as a clear and colorless medium after growth. An indiscernible change in the color of the agar indicates that no hemolysis occurred (i.e., gamma-hemolysis).

Growth and culturing conditions

The bacterial isolate Bacillus subtilis AAK strain could use 2,4-DCP (300 mg/l) as the sole carbon and energy source. The minimal mineral synthetic (MMS) medium [19] was sterilized at 121 °C for 15–20 min by autoclaving, and sterilized 2,4-DCP (300 mg/l) was added to the medium after sterilization. Growth was carried out in 250 ml Erlenmeyer flasks containing 50 ml culture medium at 37 °C on an orbital shaker (160 rpm) for 72 h. Growth of bacteria was detected as optical density (OD) by spectrophotometer (600 nm). The resulted culture was used in subsequent experiments.

Determination of residual 2,4-DCP

Residual 2,4-DCP was measured through spectrophotometry using 4-aminoantipyrine solution and ferricyanide solution according to the method mentioned by Yang and Humphery [21] and Huang et al. [22]. The resulting color was measured at 510 nm, and the concentration of residual 2,4-DCP was calculated from the standard curve of different 2,4-DCP concentrations ranging from 10 to 100 mg/ml.

Laccase activity assay

Using ABTS (2, 2′-azino-bis (3-ethylbenzthiazoline-6-sulphonic acid) as a substrate, laccase activity assay was determined [23]. The mixture consisted of the enzyme solution, ABTS (0.01 M), and 50 mM phosphate buffer pH 6.5. The mixture was incubated for 15 min at 35 °C. After incubation, trichloroacetic acid (w/v) was added to stop the reaction. The laccase activity was calorimetrically estimated at 420 nm. Enzyme activity is the amount of enzyme that oxidizes one mol of substrate per ml (one unit).

Immobilization of B. subtilis AAK cultures

By entrapment

Liquid cultures (50 ml) were centrifuged for 30 min at 6000 rpm, and the clear supernatant was discarded. The cell pellets were suspended in a sterilized solution of Na alginate (3%) or k-carrageenan (3%). The mixture was added dropwise with a sterile syringe (20 ml) fitted with a wide bore needle (one mm diameter) into a sterilized 2% CaCl2 (for alginate) and 2% KCl (for k-carrageenan), and beads were formed immediately [24]. The beads were left for 2 h to harden before being filtered and harvested. The formed beads were collected and washed with 50 mM phosphate buffer (pH 7.5) to remove the excess Ca2+ or K+. The gel materials, including agarose and agar, were also used for the entrapment of cells. Each material (3% (wt/vol)) was mixed with cell suspension after cooling to about 45 °C. The mixture was poured into sterilized Petri dishes, allowed to solidify and cut into uniform-sized particles. Each biocatalyst was added to 50 ml of fresh, sterilized medium and incubated under shaking conditions at 37 °C. One ml of entrapped and free bacterial culture was withdrawn at different incubation times and analyzed for residual 2,4-DCP concentration.

Adsorption to solid supports

As solid supports for the adsorption of cells, polyurethane foam, stone particles, ceramic cubes, luffa pulp, nut particles, and charcoal cubes were used. Each solid support was added to 50 ml of B. subtilis AAK culture (OD600= 1.0) [25]. Afterward, the cultures were left for 4 h under shaking (80 rpm) at room temperature to allow good adsorption of bacterial cells to the carrier material (wet formulation). The support materials were removed from the flask and washed with sterile double distilled water to remove any cells that were not sufficiently adherent to the carrier material. Under optimal conditions, the sterilized medium and support materials were incubated. At different incubation periods, 1 ml of free and adsorbed culture was withdrawn and analyzed for residual 2,4-DCP concentration.

Reuse of immobilized B. subtilis AAK cells

The medium containing immobilized culture onto suitable material support was incubated at 37 °C. The immobilized cells were reused by removing the culture medium, a fresh, sterilized medium was added, and a new cycle was run. The process was repeated several times. At the end of each cycle, the rest of the 2,4-DCP concentration was estimated.

Scanning electron microscopy (SEM)

Scanning electron micrograph of the immobilized B. subtilis AAK cells was performed using SEM (JEOL JEM- 2100 F (JEOL Ltd, Japan).

Partial purification of laccase enzyme

Ammonium sulfate was added to the culture filtrate to obtain various fractions (35, 50, 65, 75, 85, and 95% saturation). Each precipitate was dissolved in 50 mM phosphate buffer (pH 7.5) and dialyzed against distilled water in a refrigerator overnight [26]. After dialysis, each fraction’s enzyme activity and protein content were determined.

Immobilization of laccase enzyme

Physical adsorption

Different carriers, such as silica gel and charcoal, were used for the adsorption of laccase enzymes. The carrier was incubated with the partially purified enzyme (159.4 U B. subtilis AAK laccase) dissolved in 50 mM phosphate buffer (pH 7.5) at 4 °C overnight. The enzyme activity and protein of unbound and immobilized enzymes were determined [27].

Ionic binding

Anion exchanger (DEAE-cellulose) equilibrated with phosphate buffer (0.05 mol/1, pH 7.5) was incubated with the partially purified enzyme (159.4 U B. subtilis AAK laccase) dissolved in the same buffer for 12 h at 4 °C. The protein content and enzyme activity of bound (immobilized) and unbound were estimated [27].

Entrapment

The partially purified enzyme (159.4.2 U of B. subtilis AAK laccase) was mixed with 5ml of Na-alginate of different concentrations (2, 3, and 5% (w/v)). The entrapment process was conducted by pouring the mixture into a sterilized 25 ml mol/1 CaCl2 solution. The resulting beads (1.5–2.0 mm diameter) were collected and washed with distilled water to remove the unbound enzyme [27].

Analysis of industrial effluent

The wastewater sample (effluent) was collected from the Rikta-Paper industry, Alexandria, Egypt. Different physicochemical properties of the collected effluent were analyzed (Table 1). Before and after degradation, the temperature, pH, chemical oxygen demand (COD), biological oxygen demand (BOD), and total organic compounds (TOC) analysis of the sample were performed [28].

2,4-DCP biotransformation experiment

The wastewater sample was sterilized by autoclaving for 15–20 min at 121 °C and left to cool. About 300 ml of sterilized wastewater sample and 60 pieces of luffa pulp-containing cells were placed in the air-bubble column. Subsequently, a second column was inoculated with immobilized B. subtilis AAK laccase. The wastewater samples were incubated under optimal conditions. Before and after incubation, a predetermined volume of samples was aseptically drawn at time intervals and analyzed for residual 2,4-DCP, TOC, BOD, and COD. Samples without the immobilized bacterial strain or enzyme were considered a control [23].

Statistical analysis

All experiments were performed in triplicate, and data were recorded as mean values ± standard deviation (SD).

Results

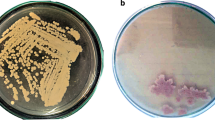

Blood hemolysis of B. subtilis AAK cells

B. subtilis AAK cells were streaked onto blood agar plates to characterize any potential hemolytic activity. The strain was γ-hemolytic (no clear halo around the bacterial colonies, Supplementary Fig. 1). The γ-hemolytic Bacillus subtilis AAK strain was selected as non-pathogenic.

Biotransformation of 2,4-DCP by cell immobilization

2,4-DCP biotransformation using different gel materials was investigated as graphically in Fig. 1. The biocatalyst formed by entrapment in alginate beads gave the maximum 2,4-DCP biotransformation rate (5.0 mg /l/h) and laccase activity (147.2 U/ml) which recorded 1.20-fold and 1.35-fold, respectively, increase compared to free cells. Immobilization by adsorption using different support materials (Fig. 2) was also studied. It is evident that luffa pulp and polyurethane foam revealed the maximum 2,4-DCP biotransformation rate (5.56 mg/l/h and 5.0 mg/l/h, respectively) and laccase activity (159.05 U/ml and 125.45 U/ml, respectively). Adsorbed cells on luffa pulp recorded higher 2,4-DCP biotransformation compared to free and entrapped cells, and the results are significant (P < 0.05). In addition, no decrease in 2,4-DCP concentration was detected when using support material without viable cells (biocatalysts) (data not shown), indicating that 2,4-DCP removal was due to biotransformation by bacterial cells and not due to adsorption or entrapment.

Biotransformation of different phenolic compounds (PCs) by free and immobilized B. subtilis AAK cells

Phenol, o-cresol, m-cresol, bromophenol, 2,4-DCP, and 2-CP were used as examples of PCs (300 mg/l) to model the PC treatment of wastewater. The results (Fig. 3B) revealed that the immobilized B. subtilis AAK culture could simultaneously degrade all the added PCs. Phenol, m-cresol, and o-cresol were depleted within 12 h, 18 h, and 22 h, respectively. In contrast, bromophenol, 2,4-DCP, 2-CP, and 4-CP were significantly prolonged (40 h, 54 h, 66 h, and 72 h, respectively). The maximum degradation by free cells (Fig. 3A) of phenol, o-cresol, m-cresol, bromophenol, 2,4-DCP, 2-CP, and 4-CP was detected at 18 h, 38 h, 36 h, 54 h, 80 h, and 96 h, respectively, which was higher than immobilized cultures and the results are significant (P < 0.05).

Partial purification and laccase immobilization

The partially purified B. subtilis AAK laccase enzyme was partially purified by fractional precipitation with ammonium sulfate (85%), yielding the highest laccase activity at about 3.01-fold purification. Additionally, immobilization of B. subtilis AAK laccase was conducted on different carriers, and its activity was estimated (Table 2). Enzyme immobilized in 3.0% alginate beads exhibited the highest activity (356.70 U/g of carriers) and the highest immobilization yield (93.64%). Therefore, alginate beads (3%) were determined to be the optimal carrier for future research.

Reuse of adsorbed B. subtilis AAK cells and laccase enzyme

The data (Fig. 4A, B) revealed that the biotransformation rate gradually increased by reusing immobilized cultures and enzymes, reaching a maximum value in the 6th and 4th reuse (for cells and enzyme, respectively), which were 1.49-fold and 1.59 -fold of the first run.

Removal of 2,4-DCP by immobilized laccase led to 100% removal of 2,4-DCP after 40 h of incubation. On the contrary, free laccase led to 100% 2,4-DCP removal after 48 h (data is not shown). By reusing immobilized cells and enzymes, the biotransformation rate decreased to 3.8 mg/l/h and 4.7 mg/l/h at the 11th cycle, respectively, with significant differences (P < 0.05).

The supporting material with attached bacterial cells was observed in the SEM. SEM analysis confirmed the successful cells of B. subtilis AAK to luffa pulp (Fig. 5), indicating the good adsorption of cells to the surface of supporting material.

The efficiency of immobilized B. subtilis AAK cultures and laccase enzyme for wastewater treatment

The reduction of contaminants in wastewater by using immobilized B. subtilis AAK culture and its laccase were estimated. Furthermore, BOD, COD, and TOC were detected before and after wastewater treatment. The maximum reduction efficiencies (Table 3) of BOD, COD, TOC, and 2,4-DCP were 92.05%, 90.11%, 75.88%, and 81.05%, respectively, after 52 h when using immobilized cells. However, the highest reduction efficiencies of BOD, COD, TOC, and 2,4-DCP were 90.12%, 82.66%, 68.9%, and 64.34%, respectively, after 56 h of incubation using free cells.

The maximum reduction efficiencies of BOD, COD, TOC, and 2,4-DCP were 95%, 93%, 90.11%, and 85.55%, respectively, after 48 h of incubation using an immobilized enzyme (Table 4). Moreover, the highest reduction efficiencies of BOD, COD, TOC, and 2,4-DCP were 92.11%, 82.0%, 88.67%, and 74.8%, respectively, after 54 h of incubation using a free enzyme.

Discussion

Classical methods for removing phenolic compounds have many disadvantages; therefore, biological methods are considered a good alternative. Bioremediation is a significant ecologic technology that uses microorganisms or microbial enzymes to degrade many environmental pollutants efficiently. The present study was carried out to optimize the 2,4-DCP biotransformation process by immobilizing cells and laccase enzymes, along with modeling bioremediation techniques for wastewaters.

In the biotransformation of 2,4-DCP, as an example of chlorophenols, various promising approaches are presented. Most magnitude utilize immobilized cells (B. subtilis AAK) and its laccase enzyme, with a higher rapid rate of 2,4-DCP biotransformation efficiency and performance of the process under aerobic conditions.

Few reports have thoroughly examined the biotransformation of 2,4-DCP by immobilized bacterial laccase. Entrapment and adsorption techniques were applied to approach the biotransformation of 2,4-DCP by immobilized B. subtilis AAK cells, and due to the increased availability of 2,4-DCP (substrate) to microbial cells, the results revealed that adsorption of cells detected a high biotransformation rate. On the contrary, the cells diffused in the Ca-alginate matrix led to slow diffusion of the substrate (2,4-DCP) and air into the polymer beads, which may decrease the 2,4-DCP biotransformation rate. Another study found that the efficiency of an immobilization process may depend on the support used [29]. Many authors reported enhanced biotransformation of different phenolic and aromatic compounds applying immobilized microbial cells [30,31,32].

The efficiency of immobilized B. subtilis AAK cultures in degrading different phenolic compounds was investigated. The results indicated that the biotransformation of phenol, o-cresol, m-cresol, bromophenol, 2,4-DCP, 2CP, and 4CP by immobilized cultures was higher than in free cultures. Our findings are in agreement with Yordanova et al. [33], who found that the degradation of phenol and 2,4-DCP by immobilized cultures was faster than 2-CP and 4-CP degradation. In addition, numerous reports demonstrated that the immobilized cultures process the highest removal potency for different CPs than free cultures [34,35,36].

Microbial laccases immobilization has recently increased the viability for their industrial uses such as reuse, easy recovery, and enhanced stability. Different carriers or supports for the immobilization of laccase have been reported [37, 38]. Several investigations covered the laccases produced by fungi (production, immobilization, and application) rather than bacterial laccases, which may be contributed to the highest potential for oxireduction of fungal laccases [9] compared to bacterial laccases. Therefore, this report may provide more information about immobilized bacterial laccase derived from marine halophilic B. subtilis AAK for efficient biotransformation of some phenolic compounds in a contaminated environment. Ammonium sulfate (85%) as a precipitant [39] and 3% alginate (356.70 U/g carrier) as an immobilization carrier were found to be the most favorable conditions for immobilizing B. subtilis AAK laccase. Due to its low cost and biodegradability, alginate was utilized as a common carrier for immobilizing many enzymes [40, 41].

Multiple batch fermentations were conducted to investigate the long-term stability of the catabolic process of 2,4-DCP biotransformation by immobilized cells and enzymes. The high efficiency of the immobilized enzyme, which may be attributable to Bacillus-produced laccases, is a component of their endospore coat, which protects cells from external stress and high concentrations of toxic substances [42]. The results of the present investigation also showed that the immobilized cultures and enzymes were relatively stable for a long time. The reused immobilized cultures and enzymes can be considered a crucial parameter in an industrial treatment, which determines the effectiveness of biotransformation over time [36]. Luffa pulp (as an adsorbed solid support) recorded lower cell leakage, maximum mechanical stability, and resistance to biological and chemical degradation, making it suitable for an extended period of repetition [43]. The obtained results partially agree with Bagewadi et al. [40] and Wen et al. [44].

In addition, the current work attempted to present a different perspective on the bioremediation of the phenolic contaminated environmental sites. The novelty of this method is confined to using immobilized cells and enzymes to direct bioremediation of 2,4-DCP under aerobic conditions at room temperature.

The production process of paper and pulp is a water-intensive process that generates a large amount of wastewater characterized by a high concentration of suspended solids (SS), COD, TOC, and BOD. The reduction efficiency of the examined parameters at room temperature may be considered economical, representing a low-energy biological technique compared to the classical techniques that need high energy and temperature levels.

The data revealed that the immobilized enzyme demonstrated an increased removal rate of 2,4-DCP than that of immobilized cells. Subsequently, immobilized enzyme techniques have more benefits than all microbial cell methods due to some enzyme characteristics such as easier handling, highest specificity, and its activity can be better standardized/optimized based on the environment [45]. Additionally, numerous studies focused on the increase of phenol biotransformation and its chlorinated derivatives by immobilized cells [46].

The higher biodegradation efficiency of 2,4-DCP in wastewater samples (Tables 3 and 4) was detected using immobilized enzymes than that of free enzymes and cells. These results are in line with Zhang et al. [47] and Chen et al. [48], who applied laccases immobilized in nanomaterials for the biodegradation of chlorophenol. Another study found that laccases (free or immobilized) demonstrated high biotransformation of 2,4-dinitrophenol in soil [8]. In the environment (soil and water), many studies used laccases for enzymatic biodegradation of different organic pollutants [49]. In addition, biodegradation of different PCs, pesticides, drugs, organic pollutants [50], synthetic dyes, and others in water and soil by immobilized and free laccases was investigated [44].

Conclusion

The present data support the potential of using immobilized safe marine halophilic B. subtilis AAK strain and its laccase enzyme as potential approaches for the 2,4-DCP removal. This method is a cost-effective alternative for large-scale wastewater treatment. Future prospective work would focus on determining the viability of applying the immobilized enzyme approach to biodegrade different phenolic compounds on a larger scale in different environments. Furthermore, cloning and over-expression of the gene responsible for 2,4-DCP biotransformation will also be addressed.

Availability of data and materials

All data generated or analyzed during this study are included in this published article.

Abbreviations

- 2,4-DCP:

-

2,4-Dichlorophenol

- BOD:

-

Biological oxygen demand

- COD:

-

Chemical oxygen demand

- MMS:

-

Minimal mineral synthetic

- mg/l/h:

-

Milligram per liter per hour

- OD:

-

Optical density

- ppm:

-

Part per million

- TOC:

-

Total organic compounds

- rpm:

-

Round per minute

- U/g:

-

Unit per gram

- wt/vol:

-

Weight per volume

References

Tobajas M, Monsalvo VM, Mohedano AF et al (2012) Enhancement of cometabolic biodegradation of 4-chlorophenol induced with phenol and glucose as carbon sources by Comamonas testosterone. Environ Manag 95:S116–S121

Li JW, Cai WJ, Zhu L (2011) The characteristics and enzyme activities of 4-chlorophenol biodegradation by Fusarium sp. Bioresour Technol 102(3):2985–2989

Gupta P, Sreekrishnan TR, Shaikh ZA (2018) Evaluating the effects on performance and biomass of hybrid anaerobic reactor while treating effluents having glucose with increasing concentrations of 4-chlorophenols. Environ Chem Eng 6(2):2643–2650

Ra JS, Oh SY, Lee BC, Kim SD (2008) The effect of suspended particles coated by humic acid on the toxicity of pharmaceuticals, estrogens and phenolic compounds. Environ Int 34:184–192

Geed SR, Kureel MK, Giri BS, Singh RS, Rai BN (2017) Performance evaluation of Malathion biodegradation in batch and continuous packed bed bioreactor (PBBR). Bioresour Technol 227:56–65

Barzkar N (2020) Marine microbial alkaline protease: an efficient and essential tool for various industrial applications. Int J Biol Macromol 161:1216–1229

Kurniawati S, Nicell JA (2008) Characterization of Trametes versicolor laccase for the transformation of aqueous phenol. Bioresour Technol 99:7825–7834

Georgieva S, Godjevargova T, Mita DG et al (2010) Non-isothermal bioremediation of waters polluted by phenol and some of its derivatives by laccase covalently immobilized on polypropylene membranes. J Mol Catal B Enzym 66:210–218

Rahmani H, Lakzian A, Karimi A, Halajnia A (2020) Efficient removal of 2,4-dinitrophenol from synthetic wastewater and contaminated soil samples using free and immobilized laccases. J Environ Manag 256:109740

Mot AC, Coman C, Hadade N et al (2020) Yellow laccase from Sclerotinia sclerotiorum is a blue laccase that enhances its substrate affinity by forming a reversible tyrosyl-product adduct. PLoS One 15:1–19

Janusz G, Pawlik A, Świderska-Burek U et al (2020) Laccase properties, physiological functions, and evolution. Int J Mol Sci 21(3):966

El-Naas MH, Al-Zuhair S, Alhaija MA (2010) Removal of phenol from petroleum refinery wastewater through adsorption on date-pit activated carbon. Chem Eng J 162:997–1005

Nadaroglu H, Sonmez Z (2016) Purification of an endo-beta 1,4-mannanase from Clitocybe geotropa and immobilization on chitosan-coated magnetite nanoparticles: Application for fruit juices. Digest J Nano Biostruct 11(2):685–697

Tallur P, Megadi V, Kamanavalli C, Ninnekar H (2006) Biodegradation of p-cresol by Bacillus sp. strain PHN 1. Curr Microbiol 53:529–533

Hasan SA, Jabeen S (2015) Degradation kinetics and pathway of phenol by Pseudomonas and Bacillus species. Biotechnol Biotechnol Equip 29:45–53

Boer AS, Diderichsen B (1991) On the safety of Bacillus subtilis and B. amyloliquefaciens: a review. Appl Microbiol Biotechnol 36:1–4

Hassan H, Schulte-Illingheim L, Jin B, Dai S (2016) Degradation of 2,4-dichlorophenol by Bacillus Subtilis with concurrent electricity generation in microbial fuel cell. Procedia Eng 148:370–377

Sandhibigraha S, Chakraborty S, Bandyopadhyay T, Bhunia B (2020) A kinetic study of 4-chlorophenol biodegradation by the novel isolated Bacillus subtilis in batch shake flask. Environ Eng Res 25(1):62–70

Farag AM, Fawzy A, El-Naggar MY, Ghanem KM (2021) Biodegradation and enhancement of 2,4-dichlorophenol by marine halophilic Bacillus subtilis AAK. Egy J Aquatic Res 47:117–123

Brutscher LM, Borgmeier C, Garvey SM, Spears JL (2022) Preclinical safety assessment of Bacillus subtilis BS50 for probiotic and food applications. Microorganisms 10:1038

Yang RD, Humphery AE (1975) Dynamic and steady sate studies of phenol biodegradation in pure and mixed cultures. Biotechnol Bioeng 17:1211–1235

Huang Y, Xi Y, Yang Y, Chen C (2014) Degradation of 2,4-dichlorophenol catalyzed by the immobilized laccase with the carrier of Fe3O4@MSS–NH2. Chin Sci Bull 59(5–6):509–520

Sarnthima R, Khammuang S (2007) Laccase from spent mushroom compost of Lentinus polychrous Lev. and its potential for remazol brilliant blue R decolourisation. Biotechnol 6:408–413

Mohanty SS, Jena HM (2017) Biodegradation of phenol by free and immobilized cells of a novel Pseudomonas sp. NBM11. Braz J Chem Eng 34(01):75–84

Farag AM, Hassan SW, Beltagy EA, El-Shenawy MA (2015) Optimization of production of anti-tumor L-asparaginase by free and immobilized marine Aspergillus terreus. Egy J Aquatic Res 41(4):259–302

Javed MR, Rashid MH, Nadeem HU, Riaz M, Perveen R (2009) Catalytic and thermodynamic characterization of endoglucanase (CMCase) from Aspergillus oryzae cmc-1. Appl Biochem Biotechnol 157:483–497

Farag AM, Hassan MA (2004) Purification, characterization and immobilization of a keratinase from Aspergillus oryzae. Enzym Microb Technol 34:85–93

APHA (American Public Health Association) (1992) Standard Methods for the Examination of Water and Wastewater. (18th ed.), Washington, DC

Musa N, Latip W, Abd Rahman RNZ, Salleh A, Ali MSM (2018) Immobilization of an antarctic Pseudomonas AMS8 lipase for low temperature ethyl hexanoate synthesis. Catalysts 8(6):234

Tosu P, Luepromchai E, Suttinun O (2015) Activation and immobilization of phenol degrading bacteria on oil palm residues for enhancing phenols degradation in treated palm oil mill effluent. Environ Eng Res 20(2):141–148

Gujjar P, Jain L (2018) Isolation of trinitrophenol (TNP) degraders and its application in bioremediation. Int J Pharm Bio Sci 8(3):223–227

Farsi RM, Alaidaroos BA, Alharbi NM, Basingab FS, Nass NM, Hassoubah SA et al (2021) Biodegradation of picric acid (2,4,6-trinitrophenol, TNP) by free and immobilized marine Enterococcus thailandicus isolated from the Red Sea, Saudi Arabia. Egy J Aquatic Res 47:307–312

Yordanova G, Godjevargova T, Nenkova R, Ivanova D (2013) Biodegradation of phenol and phenolic derivatives by a mixture of immobilized cells of Aspergillus Awamori and Trichosporon Cutaneum. Biotechnol Biotechnol Equip 27(2):3681–3688

Jiang B, Zhou Z, Dong Y et al (2015) Bioremediation of petrochemical wastewater containing BTEX compounds by a new immobilized bacterium Comamonas sp. JB in magnetic gellan gum. Appl Biochem Biotechnol 176(2):572–581

Hou J, Liu F, Wu N, Ju J, Yu B (2016) Efficient biodegradation of chlorophenols in aqueous phase by magnetically immobilized aniline degrading Rhodococcus rhodochrous strain. J Nanobiotechnol 14:5

Lin YH, Cheng YS (2020) Phenol degradation kinetics by free and immobilized Pseudomonas putida BCRC 14365 in batch and continuous-flow bioreactors. Processes 8:721

Daronch NA, Pereira CS et al (2020) Elucidating the choice fora precise matrix for laccase immobilization: a review. Chem Eng J 397:125506

Alvarado-Ramirez L, Kelbert M, Rostro-Alanis J, Rodriguez-Rodriguez et al (2021) Exploring current tendencies in techniques and materials for immobilization of laccases- a review. Int J Biol Macromol 181:683–696

Zerva A, Pentari C, Topakas E (2020) Crosslinked enzyme aggregates (CLEAs) of laccases from Pleurotus citrinopileatus induced in olive oil mill wastewater (OOMW). Molecules 25:7–9

Bagewadi ZK, Mulla SI, Ninnekar HZ (2017) Purification and immobilization of laccase from Trichoderma harzianum strain HZN10 and its application in dye decolorization. J Genet Eng Biotechnol 15:139–150

Olajuyigbe FM, Adetuyi OY, Fatokun CO (2019) Characterization of free and immobilized laccase from Cyberlindnera fabianii and application in degradation of bisphenol A. Int J Biol Macromol 125:856–864

Wu J, Yu HQ (2007) Biosorption of 2,4-dichlorophenol by immobilized white rot fungus Phanerochaete chrysosporium from aqueous solutions. Bioresour Technol 98(2):253–259

Martins LO, Durao P, Brissos V, Lindley PF (2015) Laccases of prokaryotic origin: enzymes at the interface of protein science and protein technology. Cell Mol Life Sci 72:911–922

Wen X, Zeng Z, Du C et al (2019) Immobilized laccase on bentonite-derived mesoporous materials for removal of tetracycline. Chemosphere 222:865–871

Bilal M, Adeel M, Rasheed T et al (2019) Emerging contaminants of high concern and their enzyme-assisted biodegradation-a review. Environ Int 124:336–353

Kumar S, Neeraj VK, Karn SK (2018) Biodegradation of phenol by free and immobilized Candida tropicalis NPD1401. Afri J Biotech 17(3):57–64

Zhang K, Yang W, Liu Y et al (2020) Laccase immobilized on chitosan-coated Fe3O4 nanoparticles as reusable biocatalyst for degradation of chlorophenol. J Mol Struct 1220:128769

Chen Z, Yao J, Ma B, Liu B, Kim J, Li H, Zhu X, Zhao C, Amde M (2021) A robust biocatalyst based on laccase immobilized superparamagnetic Fe 3 O 4@SiO 2-NH 2 nanoparticles and its application for degradation of chlorophenols. Chemosphere 291(Pt 1):132727

Brugnari T, Contato AG, Pereira MG et al (2021) Characterisation of free and immobilized laccases from Ganoderma lucidum: application on bisphenol a degradation. Biocatalysis Biotransformation 39(1):71–80

Bala JD, Lalung J, Smail N (2014) Biodegradation of palm oil mill effluent (POME) by bacteria. Int J Sci Res 4:1–10

Acknowledgements

Not applicable.

Author information

Authors and Affiliations

Contributions

Aida M. Farag made all the practical work. Aida M. Farag; Khaled M. Ghanem, and Moustafa Y. El-Naggar collected and reversed the data. Aida M. Farag wrote the manuscript. All authors read, reversed, and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1: Supplementary Figure 1.

Gamma hemolysis of Bacillus subtilis AAK (did not shown any hemolytic activity) against blood in the blood agar medium.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Farag, A.M., El-Naggar, M.Y. & Ghanem, K.M. 2,4-Dichlorophenol biotransformation using immobilized marine halophilic Bacillus subtilis culture and laccase enzyme: application in wastewater treatment. J Genet Eng Biotechnol 20, 134 (2022). https://doi.org/10.1186/s43141-022-00417-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s43141-022-00417-1