Abstract

Background

Process intensification is a major hurdle in pharmaceutical process scale-up. Solvent removal strategies have limited the effectiveness of the overall stability of pharmaceutical formulations. The main aim of present review article is to focus on the use of the freeze-drying process in pharmaceuticals, biopharmaceuticals and nanoderived therapeutics and their translation into commercial viable products. Unwavering efforts of scientists in the process intensification of lyophilization promote unique features of products for commercialization. Regulatory agencies are promoting the utilization of a quality-by-design approach to improve product characteristics. Among 300 FDA-approved pharmaceutical industries, 50% of products are freeze-dried. The freeze-drying process is costlier and requires more time than other drying methodologies. Unstable pharmaceutical dispersions and solutions can be preferably stabilized by using the freeze-drying method.

Main text

This review highlights the utilization of critical quality attributes and process parameters for the freeze-drying process, which helps to improve the integrity and stability of the formulation. The quality-by-design approach possibly cuts the cost of the process and saves money, time, and laborious work. The present review focuses preliminarily on the applications of freeze-drying in the development of biopharmaceuticals, including vaccines, proteins and peptides, and injectable products. In addition, a separate section demonstrating the potential of freeze-drying in nanoderived therapeutics has been illustrated briefly. The present clinical scenario of freeze-dried pharmaceuticals and biopharmaceuticals has also been described in later sections of the review.

Conclusions

This review underscores the value of integrating Quality by Design into the development of lyophilization processes for pharmaceutical and biopharmaceutical products. By identifying critical process parameters, delineating a design space, and leveraging advanced monitoring techniques, manufacturers can effectively address the intricacies of lyophilization. This approach empowers them to produce stable, superior quality products with confidence and consistency.

Graphical abstract

Similar content being viewed by others

Background

Most of the time, formulation scientists select lyophilization or freeze-drying technology as the first preferable method during formulation development [1]. Depending on the route of administration, the formulator must consider different formulation attributes, such as volume for intravenous, intramuscular, or subcutaneous administration through reconstituted dispersion [2]. For intramuscular or subcutaneous administration, the quantity of formulation required is 2 or 10 mL, and the methodology is also distinct because the isotonicity and pH of the dispersion did not promote irritation at the site of intravenous injection. Very few therapeutics are stable in a liquid state and are miscible in unusual pH ranges, such as glucagon at pH 3, and some are stable at extremely high pH ranges [3]. However, apart from the administration route, pharmaceuticals can be stabilized during the freeze-drying process. Because of its distinct advantages, freeze-drying is an extensive manufacturing method used for improving the stability of medicaments, such as nanoparticles (NPs). The methodology used is relatively simple, easy to scale up and specifically applicable for small volume products [4]. Freeze-drying involves a dehydration process at a lower temperature that involves transitioning from a solid into a gas phase without converting into a liquid phase [5]. It is made up of three steps: freezing, primary drying, and secondary drying. Water is eventually removed from the ice by the process of sublimation at reduced temperature and pressure underneath the triple point of water [6]. Considering the process tactics, freeze-dried products are relatively easy to handle, package and transport [7]. The highly concentrated liquid suspensions are converted to powdered form, where the powder characteristics are similar to other solid powder formulations and can be blended into pills, tablets, pellets or easily filled it into capsules [8].

Furthermore, biopharmaceuticals products have several benefits over conventional therapeutics and are transiently useful to treat numerous ailments, such as hepatitis B virus, arthritis, psoriasis, and multiple types of cancer [9]. Other factors that led to the development of biopharmaceuticals and biosimilar products are target-based selectivity towards diseases due to the presence of anchored substrates such as monoclonal antibodies (mAbs), proteins, peptides, and amino acids. The engineered particles promote an increase in the blood circulation time and reduced protein binding. The reduction in the frequency of dosage helps to improve patient compliance.

Proteins and peptide-based formulations are multifaceted and challenging compounds that necessitate unique industrial operations and handling conditions throughout their production, which is attributed to the rising cost of these biosimilar formulations [1, 10]. Biological macromolecules have a high molecular weight and are unsuitable for parenteral administration due to aggregation and unstable formulation characteristics. The majority of biopharmaceutical formulations are available as dilute or concentrated solutions, suspensions, and dispersions. Protein-based drug delivery systems are developed for administration through different routes, such as pulmonary [10], oral, intranasal [11], and transdermal routes [12], that have been extensively researched. Protein-derived formulations have low stability in biological environments and low physicochemical stability [13]. Protein stability is a major concern that restricts the development of biopharmaceuticals. Protein stability can be addressed during the preformulation and product development stages. The particle engineering approach has been utilized to improve the in vivo effectiveness of biosimilar formulations [14, 15].

The mAb-based formulations are typically developed as aqueous dispersions for parenteral administration. Liquid dispersions are unstable and prone to degradation with relative environmental factors. Additionally, the mobility of particles creates a more unstable formulation. However, convertible solid components avoid degradation and possess limited protein mobility. Conversion of liquid formulations into stable solid components was accelerated by use of the freeze-drying process. Freeze-drying is the preferred method mostly in the manufacturing process of stable biopharmaceutical drug products like proteins that are unstable in an aqueous system. Lyophilized forms have been used for approximately 50% of newly approved biological products, and this figure is likely to increase further [16].

Main text

Basics of freeze-drying

Water can be categorized into three forms: solid as ice, liquid or gas (in the form of vapours) [1]. Freeze-drying employs the sublimation effect, in which solid ice is converted directly into a vapour phase without passing through the liquid phase [2]. Looking at the water phase diagram (Fig. 1a), at low temperature and variable pressure, water behaves as solid ice. Water is available as a liquid at higher temperatures and pressures and as a gas in the form of vapour at even higher temperatures and pressures [17]. The sublimation process is slightly opposite, while during the lyophilization process, sublimation occurs and vapour is sublimed into the condenser. The process of sublimation occurs below the triple point of water. The freeze-drying process optimization is set to complete below the triple point of water, which can be facilitated at controlled temperature and pressure. During lyophilization, a significant amount of energy is required to convert ice into vapour under very-low-temperature conditions. To convert 1 gm of ice into water vapour, 2800 J of energy is needed, which is six times more than the energy required for the simple evaporation process required to convert liquid into gas [17, 18].

a Water's triple point at 0.01 °C and 0.00603 atm is depicted in a phase diagram. Freeze-drying is performed under the triple point to convert ice to vapour without entering the liquid phase. [Reproduced from Assegehegn et al. [17] with kind permission of the copyright holder, Elsevier, Amsterdam] b State diagram showing Tm, onset of ice melting; Tm′, onset of ice melting in a maximally freeze-concentrated solute matrix; Tg, glass transition temperature; Tg′, glass transition temperature of the maximally freeze-concentrated solute matrix; Tgw, glass transition of water, and Tc, collapsed temperature. Tc approximate to Tg′ and increases in the presence of cells. The shaded area shows a temperature range for maximum ice formation for the solute concentration Cg′. The glass line indicates the glass transition temperature at various solute concentrations [Reproduced from Santivarangkna et al. [31] with kind permission of the copyright holder, Wiley]

Effect of pressure

The most important parameter in freeze-drying process is pressure. The pressure in the system is kept low to facilitate effective sample temperature during the freeze-drying process [19]. In a pure solvent (aqueous) without an admixture, the temperature of the sample will be zero degrees Celsius (0 °C) if the pressure is set at 6.11 mbar, which is near to the triple point of water. Currently, freeze-drying does not use pure water for freezing and mostly involves an aqueous system with the required amount of solid content, excipients, cryoprotectants, and so on. The composition reduces the melting temperature of the mixture, and therefore, freeze-drying works at lower pressure, typically at 1 mbar or below. A pressure of 1 mbar corresponds to a temperature of approximately reaching to -20 °C [5, 6]. Even at low pressure, the temperature of the material drastically decreases at lower level. The minimum pressure achievable in freeze-drying is approximately 0.03 mbar, which corresponds to a temperature of approximately -50 to -60 °C. As a result, pressure is critical and typically used in the range of 1 mbar down to 0.03 mbar based on the sample temperature [17, 20].

Effect of temperature

The temperature of the sample is also essential since the temperature gradient between the condenser of the freeze dryer and the sample temperature is driven by sublimation [21, 22]. The sample location in the freeze dryer varies based on manufacturer specifications in the general case; sample is placed at top of the freeze dryer. In other cases, chamber is provided for sample placement or attached as a manifold. The manufacturer designs the sample compartment based on type of sample, volume of sample and composition. During freeze-drying, the vapours formed at the top move down to the condenser and are collected in the receiver. A small temperature difference is required between the sample temperature and condenser temperature, which helps to accelerate the process [18, 23, 24]. The small temperature difference and applied vacuum help to move the vapour downwards to the condenser and condensate. In general, the faster the temperature difference is, the faster the drying process, but the temperature difference should not be more than 15 – 20 °C.

A very common misunderstanding in freeze-drying is that at lower pressure, the freeze-drying process becomes faster. However, the actual process parameter defines that at lower pressure, the sample temperature is also reduced and affects the overall lyophilization process. The temperature of the samples does not go below -50 to -60 °C. If the pressure falls below the desired level, the temperature also falls and deteriorates the freezing process. During the lyophilization process, the pressure should be maintained at a desirable set point where the sample remains in the frozen state and helps to accelerate the process as presented in Fig. 2 [20, 24, 25].

Effect of heat transfer

The sublimation process consumes much energy, as discussed earlier, and is considered to be an important viewpoint in the freeze-drying process. Two types of freezing processes are represented: shelf freeze drying and manifold applications [26]. In the first type, shelves are created for vials, while stress is applied during the freeze-drying process. The shelves are used with or without heat transfer mechanisms, preferably conduction or radiation [27]. Conduction utilizes the direct transfer of heat energy from shelves, while the radiation mechanism transfers heat from the top in the downwards direction. At the same time, convection was initiated, which exchanges heat energy from outside to inside shelves. The overall process balances heat transfers across all the shelves and regulates the drying process. The balancing mechanism improves the drying characteristics and accelerates the rate of drying. Recent reports highlight the importance of heat transfer during the freeze-drying process: an increase in the heat transfer process by 1 °C can shorten the freezing time of the sample by 13%. In short, a 5 °C increase in temperature can fruitfully reduce drying time to half [23, 24].

There are some systems available without heatable shelves. In this case, the process takes a much longer time to dry because the energy available will be delivered by convection only. In the second type, one end of the manifold is attached to the valve, and the other end is attached to the freeze dryer [28]. The second type utilizes heat from the environment, which initiates the exchange of heat energy directly from the external environment. The sample vessel is encapsulated completely, while a larger area is exposed to the external environment. The higher exposure surface can accelerate the freezing process. At ambient temperature conditions where laboratories are not completely air-conditioned it utilizes manifold devices for freeze-drying applications. The rate of freezing using a manifold device can also be improved on warm days [24, 29].

Freezing is very important consideration in the case of crystalline and amorphous samples. It is often misunderstood that once the sample reaches the freezing point, it becomes completely frozen, which is not correct. The sample is cooled to zero degrees, is not yet frozen and goes to the level called supercooling, so it cools below the freezing point and forms ice crystals. The entire sample crystallizes, and the sample achieves a frozen state at 0 °C. However, at this stage, the sample is not completely frozen, as it contains a portion of the solution and a portion of ice [24, 29, 30]. To achieve complete solidification of the sample, we need to achieve a temperature that is below the freezing temperature, also known as the eutectic temperature or collapse temperature, as shown in Fig. 1b [31]. Similarly, for amorphous samples, freezing temperature should only have a solid and rubbery state that can achieve at lower temperature. For achieving a glassy state, there is a need to go below the glass transition temperature or collapse temperature, which is typically even lower than the eutectic temperature of crystalline samples. Therefore, amorphous samples typically need to be freeze-dried at lower temperatures or pressures than crystalline samples [32]. If the sample goes above the critical solution temperature, one can see a collapse in the sample. In general, the solid sample is surrounded by ice, and it turns into a gas (vapour) and left the solid at the bottom. In the case where the sample goes above the collapse temperature, part of the sample starts melting, some of the solvents become liquid again and start to redissolve. After melting, the solvent starts to sublimed and convert it into spongy hard material instead of conversion into fluffy cake. The hard spongy material may create a problem in the final application [30, 32, 33]. To avoid collapse of material and hardening of sample, few commercial manufacturers provide automatic monitoring of collapse temperature measurement. Where it ensures and avoids conversion into hard spongy material. The recent advancements in the design of freeze dryers allow the measurement of sample temperature and ensure that it will remain below the collapsed temperature. A temperature sensor placed on each central vial at the bottom of each shelf makes the freeze-drying process highly efficient and reproducible [24, 34].

Implementation of quality by design (QbD) in freeze-dried product development

Quality by design (QbD) is a method of choice in formulation development to obtain robust and quality products followed by continuous improvement [35]. QbD is an organized approach preferably select predefined parameters with major objective to screen the product or process. The QbD considered fundamental consideration and select process control tactics as quality control parameters. Additionally QbD promotes quality risk management workflow to eliminate the associated errors [36]. QbD is particularly helpful in designing robust processes with well-understood operational limits and their significance. Implementation of QbD is complex and challenging work in the pharmaceutical industry. The use of QbD in formulation development minimizes the trial cost of validation batches. Therefore, implementation of QbD principles, developing a better understanding, and possibly designing simple templates for the development of complex formulations is the current need.

From an operational standpoint, freeze-drying is an expensive and time-consuming process. As a result, the process must be brief, repeatable and robust. To design a freeze-drying method, one must first define the essential formulation parameters and control them in the process design. The temperature of the heating fluid, pressure in the drying chamber, and timeframe of both drying stages throughout primary and secondary drying are some of the freeze-drying process parameters that have a major impact on the quality of finished products [21]. If such variables are not controlled, they can cause product denaturation, melting, or collapse of the dried cake. Therefore, systematic development of the freeze-dried product by the implementation of QbD is required to obtain a quality product. According to ICH Q8 (R2), different effective QbD tools can be used for the development of robust quality formulations (Fig. 3).

Quality target product profile (QTPP)

QTPP is an outline of expected product characteristics and is used to design quality into the product and process. QTPP embodies the overall objectives of the quality of the drug product development program. Strategies, prior knowledge, and experience of a process or availability of equipment and facilities could influence the choice of QTPP. QTPP is a knowledge-based system, so it should be utilized in the identification of drug product characteristics of freeze-dried products. Some probable QTPP elements of freeze-dried products are represented in Fig. 4.

Critical material attributes (CMAs), critical material parameters (CPPs), and critical quality attributes (CQAs)

The desired quality of the material for use in freeze-drying must be determined by taking into account its use as well as knowledge and understanding of its physicochemical, biological, and microbiological characteristics, which can impact product characteristics. As a result, before beginning the development cycle, CMAs should be identified. A CPP is one whose variability has an effect on a CQA and should thus be checked or controlled to ensure that the system achieves the best quality. The freeze-drying process consists of a series of unit operations and need to rectify each steps/stages.

The CQAs have physicochemical, biological, or microbiological attributes or characteristics that must fall within a specific range. The freeze-dried product's CQAs are usually those factors that impact product quality, safety, efficacy, purity, strength, drug release, stability, and so on. CQAs are normally linked with the active substance, additives, intermediates (in-process steps) and drug products in freeze-drying. The possible CMAs, CPPs and CQAs for the freeze-dried product are depicted in Table 1.

Risk assessment of the freeze-drying process

Risk assessment is a valued science-based method used for quality risk management by identifying the potential impact of CMAs and CPPs on drug product CQAs (3). Different models have been used previously for risk assessment, such as risk ranking, fishbone diagrams, and failure mode effects analysis (FMEA) [37, 38]. The risk assessment of the freeze-dried products is carried out by linking input and process variables to CQA. The relative risk that each variable presents was ranked as high, medium, or low based on their criticality. Attributes that could have a high or medium impact on the CQA of freeze-dried products will be selected for further investigation. No further action is required for low-impact attributes [39].

Design of experiment (DOE) and design space

In DOE, inputs (variables) and output (response) form a complicated matrix in which the input variables may be interlinked or independent of each other. It is challenging to understand all potential variations and their impact on the quality of a drug product. DOE tools help scientifically collate most variations in a minimum number of experiments. Some possible input variables are the concentration of a solution, amount of excipients, freezing rate, annealing temperature, secondary drying temperature, etc. [40]. The ultimate goal of the DOE in the freeze-dried product is to optimize critical parameters identified in risk assessment and to achieve the desired quality product. Two types of designs can be used in DOE, i.e. screening design and optimization design. The purpose of using a screening design is to test pairs of combinations in only a few experimental runs, thereby saving time and resources. Some commonly used screening designs are fractional factorial design, Plackett‒Burman design and Taguchi design. The critical variables identified in the screening design will be further developed by optimization design. Some commonly used optimization designs are full factorial design, Box‒Behnken design and central composite design.

The linkage between input, process and output was described in the design space. The operating ranges of CMAs and CPPs can be defined by knowledge obtained through risk assessment and the design of experiments for their effects on CQA [41]. The effect of each parameter on freeze-dried products was estimated, and operating ranges for each parameter were selected as the design space to obtain a robust formulation. ANOVA, response surface diagrams (RSDs), contour plots, interaction plots, main effects and other statistical tools were used to establish the design space. It was considered that the process within the design space will result in a product meeting defined quality.

Control strategy for the preparation of freeze-dried products

The control strategy is a planned set of controls that comprises process monitoring, practical controls, lot release testing, in-process controls, comparability testing, characterization testing and stability testing. Control strategy development requires an organized process involving a team of experts, linkage of the development of a product to the manufacturing process and process equipment controls. An example of a control strategy for the freeze-dried product is depicted in Table 2, which is built upon the outcome of extensive product and process understanding studies [42].

Selection of lyoprotectants and their impact on stability

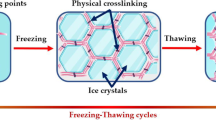

Lyophilization is an industrial process that converts an aqueous nanoparticle suspension into an amorphous-crystalline solid by freezing, primary drying and secondary drying [43]. These processes generate mechanical stress on the nanoparticles, causing aggregation and reducing nanoparticle stability [44]. Lyoprotectants are inert excipients introduced exclusively into the aqueous suspension before lyophilization to provide physical and chemical stability to the nanoparticles as presented in Fig. 5 [45]. It reduces the mechanical stress during freezing and drying steps and improves the stability of nanoparticles [46]. Bulking agents (mannitol, glycine, sucrose), buffers (Tris HCl, histidine, and phosphate), structure modifiers, tonicity adjusters (salts), stabilizers (glucose, dextran, sucrose, trehalose, lactose, mannitol and alanine) and collapse inhibitors (glucose, dextran, maltose, maltotriose, maltopentose and maltoheptose) are the most commonly used inert excipients as lyoprotectants and cryoprotectants in the freeze-drying process [45]. Moreover, lyoprotectants also act as cryoprotectants and vice versa [44]. The details of commonly used excipients as lyoprotectants in nanoformulations are tabulated in Table 3.

Romeo and colleagues prepared and assessed the effect of lyophilized ferulic acid-loaded polymeric nanoparticles for ocular drug delivery. Ferulic acid (FA) is a well-known antioxidant that has low bioavailability due to low aqueous solubility. Biodegradable polymers, such as poly(lactic acid) (PLA) and poly(lactic-co-glycolic acid) (PLGA), were used to prepare ferulic acid-loaded and unloaded polymeric nanoparticles (FA-NPA and FA-NPB) using the nanoprecipitation method. The nanoparticles were lyophilized using hydroxypropyl-β-cyclodextrin (HP-β-CD) lyoprotectant and evaluated for stability studies. Final reports showed that unloaded NPA and NPB carriers at a concentration range of 0.25–1 mg/mL and 0.25–2.5 mg/mL produced no cytotoxicity in endothelial and pericyte cell lines as a part of the retinal vascular system due to their biodegradability and biocompatibility characteristics. Lyophilization of FA-NPA and FA-NPB polymeric nanosuspensions using HP-β-CD at 5% w/v resulted in particle sizes in the range of ~ 150–200 nm, PDI values of ~ < 0.2 and zeta potential values of > − 20 mV. It was indicated that lyoprotectant could inhibit particle aggregation following rehydration and provide long-term stability. The presence of HP-β-CD on the surface of nanoparticles promotes easy absorption and reconstitution in aqueous media. The strong hydrogen bonding between the nanoparticles and cryoprotectant reduces the collapse temperature of the final formulation. The strong hydrogen bonding shifts the glass transition temperature to a slightly lower value. This causes a reduction in the primary drying step in the lyophilization process. The developed amorphous powder reduces the aggregation potential and enhances the stability of both nanoparticles. Hence, HP-β-CD is considered an efficient lyoprotectant and assists in enhancing the long-term stability of polymeric nanoparticles targeted for ocular delivery [66].

In another study, Telange and coworkers studied the effect of five lyoprotectants on the particle size and polydispersity index (PDI) value of mangiferin phospholipid complex-loaded phytosomal soft nanoparticles. These nanoparticles, after lyophilization, showed a smaller particle size and PDI. In this study, glucose, fructose (monosaccharides) and trehalose, maltose, and sucrose (disaccharides) were used as lyoprotectants at 0.5%, 1%, 2% and 5% w/w, respectively. The findings of the study revealed that glucose and fructose at 2% and 5% w/w concentrations reduced the particle size and PDI values to ~ 936.39 nm and ~ 0.68 of soft nanoparticles compared to their lower concentrations. This significant effect of both monosaccharides showed that the formation of weak interactions with soft nanoparticles reduced aggregation. Likewise, trehalose and maltose at 2% and 5% w/w reduced the particle size and PDI value to ~ 931.50 nm and 0.62, respectively, compared to their lower concentrations. It was suggested that the solid form of these excipients during lyophilization improved the alliance with nanoparticles and reduced their particle size and PDI more significantly. Compared to 5% w/w, sucrose at 2% w/w reduced the particle size and PDI by ~ 906.69 nm and 0.50, respectively, due to its amorphous nature and easy interaction with nanoparticles, which improved the stability of the soft nanoparticles. The study confirms that sucrose enhances redispersibility and long-term stability at a low concentration acts as a superior cryoprotectant and enhanced the nanoparticle's redispersibility and long-term stability via the formation of hydrogen bonding interactions with nanoparticles surfaces [67].

Veilleux and colleagues prepared lyophilized highly concentrated chitosan/deoxyribonucleic acid (DNA) nanoparticle formulations for gene delivery at clinically relevant dosages. Chitosan (degree of deacetylation ~ 92–93.7%) and plasmid EGFPLuc were used to prepare chitosan/DNA nanoparticles. These nanoparticles were freeze-thawed to select the optimal concentration of lyoprotectants from mannitol, sucrose, dextran (5 kDa) and trehalose. The histidine buffer is used during dispersion and further lyophilized to get the free flowing powder. The chitosan/DNA nanoparticles shows particle size > 100 nm in the presence of mannitol (0.1–0.3% w/v) with polydispersity index value > 0.1. The particle size increases may be due to the crystallization of mannitol causing particle aggregation. In comparison with mannitol, other cryoprotectants like sucrose, trehalose and dextran (0.5% w/v) demonstrate effective reduction of particle size ~ 80–100 nm and PDI ~ 0.19–0.24. The reduction in particle size ascribed the amorphization of lyophilized formulation, while 0.5% w/v concentration of cryoprotectant can effectively stabilize the particles as shown in Fig. 6a–d.

Evaluation of potential lyoprotectants for CS/DNA polyplexes using freeze–thaw (FT). Prior to (fresh) and after a freeze–thaw cycle, Z-average diameter and PDI, or intensity mean diameter, of polyplexes formulated with up to 3% w/v mannitol (a), sucrose (b), dextran 5 kDa (c) or trehalose (d) (1FT). Histidine concentration optimization for lyophilization of CS/DNA polyplexes (e). SEM images of CS/DNA polyplexes formulated without or with excipients (f) [Reproduced from Veilleux et al. [57] with kind permission of the copyright holder, Elsevier, Amsterdam]

The low dispersibility of nanoparticles following rehydration and hydrolysis of chitosan-induced severe aggregation leads to increase its particle size and PDI value by ~ 1900 nm and 0.9, respectively. Histidine buffer (pH 6.5) lowered the particle size (< 200 nm), and PDI (~ 0.32) value may be due to H-bonding and cation-π interactions between chitosan and histidine. The presence of lyoprotectant and histidine buffer (pH 6.5) at ~ 0.5% w/v and ~ 3.5 mM could be useful for improving the stability (Fig. 6e) and gene delivery of chitosan/DNA nanoparticles [57]. Furthermore, the SEM study also revealed aggregation of nanoparticles (Fig. 6f-a) in the absence of excipients, whereas distinct nanosized spherical particles are formed (Fig. 6f-b) in the presence of lyoprotectants.

Chow and coworkers fabricated lyophilized curcumin-loaded polyethylene glycol (PEG)-PLA nanoparticles using flash nanoprecipitation technology and studied its effects on the long-term stability of curcumin nanoparticles. Curcumin is a highly lipophilic compound. Its nanoparticles association with a copolymer stabilizer exhibited low stability that may be due to weak binding interaction with the hydrophobic cores. The prepared nanosuspension was lyophilized using kleptose lyoprotectant. The study demonstrated that variable factors, i.e. mixing rate, the molecular weight of PEG-PLA, and the drug-to-stabilizer ratio, influenced the curcumin particle size and its distribution to a great extent. The mixing rate and molecular weight of PEG-PLA at ~ 4500 and 2–5 k generated particle sizes of ~ 70–75 nm, indicating that mass transportation from water to the organic phase followed by supersaturation and nucleation reduced the particle size of curcumin nanoparticles. However, after preparation the curcumin nanoparticle suspension showed a cloudy nature with the appearance of recrystallized curcumin. The recrystallization leads to high molecular mobility of PEG-PLA. The stability issue was addressed by use of polyvinyl pyrrolidone (PVP) as a costabilizer. Compared to PVP K-30, polyvinyl alcohol (PVA), D-α-tocopheryl polyethylene glycol 1000 succinate (TPGS), Pluronic F68, and leucine at 0.5% w/v offer excellent stability. The enhanced stability may be due to hydrogen-bonded interaction between PVP and the PEG block copolymer. The interaction also prevents drug leakage during long-term storage. Lyophilization of the curcumin nanosuspension with lactose, trehalose, mannitol and glucose at a 10% w/v concentration produced a higher glass transition temperature of approximately − 28 °C and − 43 °C and particle size was enlarged to approximately 275 to 512 nm. The ratio of particle size after lyophilization to initial particle size (i.e. Sf/Si) was approximately 3.05: 5.67, respectively, and the higher ratio contributes to precipitation that appears after redispersion. This indicates that these lyophiloprotectants failed to preserve the curcumin nanoparticles. In contrast, kleptose (HP-β-CD), a collapse temperature modifier at a 1.25% w/v concentration, produced a low Sf/Si ratio of ~ 1.22 and resulted in a transparent solution following redispersion. The presence of kleptose and its amorphous characteristics enhances the stability of the curcumin nanoparticles and avoids aggregation. The presence of the lyoprotectant kleptose promotes the long-term stability of curcumin nanoparticles at the lowest concentration in support with stabilizer and costabilizer through its amorphous nature [68].

Chitkara and colleagues developed a lyophilized core–shell nanoparticle preparation using gemcitabine and assessed its stability, in vitro and in vivo cytotoxicity studies on MCF-7 cell line and dimethyl benz [α] anthracene (DMBA)-induced breast cancer models. Hydrophilic bovine serum albumin and hydrophobic PLGA were used as core and shell materials, respectively. The core–shell formulation loaded with gemcitabine was lyophilized using different lyoprotectants, such as inulin, lactose, mannitol, sorbitol, sucrose, and trehalose, at 5 and 10% w/v concentrations. The findings indicated that trehalose at 5% w/v increased the reconstitution of the formulation in the water compared to other lyoprotectants. Sucrose produces reconstitution solution at similar concentration using vial inversion method. The trehalose (5% w/v) and sucrose (10% w/v) show a significant reduction in particle size ratio to ~ 0.99: ~ 1.05. Trehalose (5% w/v) considered as a suitable lyoprotectant based on reconstitution time and avoids aggregation during lyophilization process. Lyophilized gemcitabine core shell nanoparticles possess high encapsulation efficiency (~ 40.5% w/w), small particle size (243 nm) and PDI (0.16). The presence of albumin on the core shell nanoparticles improves update efficiency to 91% MCF-7 cell line comparatively higher than GEMCITE® marketed formulation (~ 51%). The IC50 value was calculated on third day of study and was found to be 16 µM. The process of lyophilization significantly improves the stability, encapsulation and cytotoxicity potential of gemcitabine [69].

Lyophilized drug product development

Development of an oral drug delivery system

Since its inception, the oral route is considered as the best route for the delivery of many drugs or active molecules [70]. From the component of patient conformity, the oral route is much more justifiable [71]. It can be used for systematic as well as local drug delivery applications. Principally, it provides an abundance of merits, including non-invasiveness, ease of use and simplicity for self-administration [71]. The limitations of oral drug delivery system include the process factors, drug release, content analysis and stability. The formulation scientist focuses on imparting better drug release characteristics to oral formulations. The process factors include uneven particle size, low flowability, less surface interaction or formation of complex due to ionic species available. There is constant need to alleviate the processing factors in designing solid dosage forms, and freeze-drying technique may be helpful for such improvements.

Presently, the involvement of freeze-drying is immensely important, with an ongoing quest on the development for the oral drug delivery systems [72]. The earlier reports suggest that lyophilization is known as the desiccation process wherein favourable component prosperities are ascribed to the freeze-drying that helps in the preparation of stable pharmaceutical products [73]. The multiple parameters affect the product stability in solid state such as flow characteristics, moisture content and processability with additional emphasis on process-related and formulation-related variables [74]. For introducing new products for the oral administration, it is interesting to know the detailed process and principles of freeze-drying [73]. In recent decades, numerous types of lyophilized products have been developed for the delivery of drug molecules via the oral route [75]. In 2020, Al-Amodi and coauthors developed febuxostat-loaded self-nanoemulsifying delivery systems (FSNEDS) followed by the preparation of lyophilized tablets for transmucosal delivery applications. The lyophilization of FSNEDS provides a porous structure and fluffy matrix that help to reduce the disintegration time of tablets as well as maximum drug release. As a result, it increased the oral bioavailability of febuxostat up to 146.4%. The lyophilization process helps to enhance the bioavailability and pharmacokinetic parameter of poorly soluble drug candidate [76]. Salama and coauthors designed an oral disintegrating tablet (ODT) using the atorvastatin calcium-based dry emulsion technique followed by lyophilization. In brief, gelatin has been used as a binder for lyophilized ODT and as a matrix former, whereas sugar alcohol plays the role of cement for the porous structure of the lyophilized matrix. In addition, it provides excellent disintegration and a good release profile for ODT that results in the enhancement of oral bioavailability [77]. Gulsun and coauthors reported terbutaline sulphate ODTs by freeze-drying method and comparative evaluation of directly compressed tablets. The lyophilized ODT demonstrates a low disintegration time (11 s) and quicker dissolution profile in compared to the directly compressed tablet (11 min). Overall, it will help to improve patient compliance and can be a suitable substitute for conventional oral dosage forms [78]. Huanbutta and colleagues developed the tamarind seed gum-based ODT of diclofenac sodium using the freeze-drying method. It shows a low disintegration time (less than 1.5 min) and enhanced dissolution rates of ODT. Moreover, it provides 100% drug release within 6 min. Hence, the use of the lyophilization method for the development of gum-based ODTs will open a new path for oral drug delivery applications [79]. A similar line of work reported by Bae et al. explored hepato-peptide-loaded ODT formulations developed for the treatment of neurogenic bladder dysfunction prepared using lyophilization method. It shows an extremely low disintegration time (30 s) and rapid release of peptides (almost 97%) within 15 min. Additionally, it shows good stability in different stability zones for 30 days. The use of sorbitol avoids structural collapse or shrinkage of the lyophilized tablet during the lyophilization process [80]. In another study, deferasirox-based directly compressed and lyophilized fast disintegrating tablets were prepared. Notably, the lyophilized tablet shows a low disintegration time (5 s) and a faster dissolution rate in comparison with the compressed form of the tablet. The lyophilization process embeds high porous structure in the tablet matrix, which was absent in the case of compared with the directly compressed tablet. Accordingly, it resulted in enhancement of bioavailability as well as rapid onset of action. Overall, it could be a better dosage form to improve patient compliance compared to the currently engaged dosage forms for the treatment of geriatric, paediatric populations [81]. Ahmed and coworkers report rosuvastatin-loaded pullulan-based tablets prepared using lyophilization process. The drug-loaded chitosomes help to improved bioavailability as well as anti-hyperlipidaemic and antioxidant activity. The tablet rapidly disintegrates within 1.48 min because of the distinct porous surface (Fig. 7a) and sponge-like inner structure of the freeze-dried tablet (Fig. 7c), whereas the marketed directly compressed tablet formulation exhibits a smooth surface (Fig. 7b) and compact inner structure (Fig. 7d), as confirmed by scanning electron microscopy. In the future, the lyophilization technique can be used as a suitable alternative for the development of fast dissolving tablets along with improvement of oral bioavailability and pharmacodynamics as well as pharmacokinetic activity [82]. Hosny and coauthors reported the preparation of sildenafil citrate-loaded self-nanoemulsifying system-based oral lyophilized flash tablets. A mixture of clove oil/oleic acid (10%) was selected as the oil base, whereas Tween 20 (60%) and propylene glycol (30%) were selected as the surfactant and cosurfactant that forms nanoemulsion (65 nm). The flash tablet was prepared using fumed silica, hydroxyl propyl methylcellulose (HPMC) and sodium starch glycolate (SSG) followed by freezing of the mixture. Freeze-drying was carried out at − 45 °C for 24 h, which resulted in the formulation of patch-like structures. The porous powder formed was compressed into tablets by adding a suitable amount of diluents and disintegrating agent. The disintegration time was decreased to 3 s, while flash tablet releases 68% of sildenafil within the first 1 h. The study suggests that the bioavailability of sildenafil was improved after lyophilization process in comparison with marketed tablet. In summary, it can be used as an outstanding approach for enhancing the bioavailability of water-insoluble drugs [83].

Scanning electron microscope (SEM) images for the surface (a) and inner structure (c) of the chitosomes freeze-dried tablets and marketed drug product (b and d), respectively [Reproduced from Ahmed et al. [82] with kind permission of the copyright holder, Elsevier, Amsterdam]

Powar and Hajare developed a lyophilized nanosuspension of ethinyl estradiol using a quality-by-design approach. An ethinyl estradiol containing nanosuspension was prepared by using a high-pressure homogenizer followed by freeze-drying with mannitol act as cryoprotectant. Significantly, it provides a porous drug-loaded lyophilized nanosuspension that enhances the stability and relative bioavailability by twofold [84]. Ibrahim and coauthors developed silymarin-containing lyophilized nanosuspension-based tablets for immediate release applications. The use of mannitol provides the formation of a lyophilized cake with a porous structure, which results in effortless conversion into suspension and preserves the actual nanosized particle size distribution of the nanosuspension. The highly porous structure of the lyophilized nanosuspension matrix resulted in rapid disintegration as well as dissolution enhancement [85]. Sharma and colleagues report the curcumin-loaded lipid nanoparticles for oral delivery prepared using lyophilization method. The lyophilization of the formulation was accelerated in the presence of 10% w/w trehalose. Mainly, trehalose has been used as a good cryoprotectant due to its high glass transition temperature, lack of chemical reactivity, poor hygroscopicity, etc. Trehalose imparts good physical and chemical stability to formulations [86]. Li and coauthors reported the preparation of curcumin-HP-β-CD inclusion complexes using a cosolvency method followed by lyophilization. As a result, HP-β-CD improves the oral bioavailability of curcumin by 2.77-fold. Therefore, the preparation of inclusion complexes at an industrial scale can be feasible using the simple cosolvency and lyophilization method. In addition, this method can be more suitable for solubility enhancement and improving the oral bioavailability of poorly soluble candidates [87]. In another study, cosolvency-lyophilization method-based encapsulation of thiostrepton (hydrophobic antibiotic) was stabilized via steric micellar aggregates. Esparaza and coauthors reported that phosphate-buffered saline (PBS) salts improved cake porosity, accelerated the reconstitution time of lyophilized cakes and allowed efficient thiostrepton encapsulation [88]. Routray and colleagues prepared lyophilized cinnacalcet hydrochloride-loaded solid lipid nanoparticles using mannitol (100% w/w) as a matrix former. The particles with a lower size (less than 200 nm) give a high surface area and offer faster dissolution. In addition, lyophilization of solid lipid nanoparticles provides good redispersibility and an enhanced dissolution rate. As a result, lyophilized solid lipid nanoparticles improve the pharmacokinetic parameters and oral bioavailability of cinnacalcet hydrochloride compared to the pure drug and optimized solid lipid nanoparticles [89].

Textural effect of freeze-dried formulation was assessed using image processing and artificial intelligence. Following freeze-dried carrot was taken as case study to understand the use of AI in freeze-drying process. The digital camera images of carrot and freeze-dried carrot was extracted and converted to colour channel L, a, b, R, G, B, X, Y and Z creates 181 channels for assessment. Machine learning algorithms find 20 effective textural parameters for each model. The Trees, Rules, Meta, Lazy and functional groups classify the models and provide highest accuracy for the determination of difference between carrot and freeze-dried carrot [90].

Residual moisture (RM) content is an important tool in assessment of freeze-dried product. Machine learning and NIR spectroscopy were used to evaluate the level of RM as quantitative value. The linear regression and neural network model were used to predict the RM with creation of architectural categorization. The learning step uses root-mean-square error for calculating RM with supportive parity and absolute error plot use to visualize the effect. The effect of sucrose concentration (3, 6 9%) on lyophilization was observed with comparative evaluation of trehalose on arginine mixture. The 6% sucrose model provides consistent effect for prediction of RM [91].

The lyophilization process offers many merits, such as rapid disintegration time, flow characteristics, improved dissolution rate, faster drug release, high stability and bioavailability. Moreover, the physicochemical characteristics of drugs and excipients can be modified by the use of lyophilization process. Additionally, the finished dosage form characteristics can be changed by use of modified process tactics such as use of lyophilization process. Owing to this, lyophilization holds new positions in the field of oral drug delivery systems. The improving applicability of lyophilization process in designing oral drug delivery is pertinent and appealing with the introduction of the latest new dosage forms.

Freeze-dried biopharmaceuticals

Biopharmaceuticals are organic entities that are popularly recognized as biological drugs that are derived from a biological organism by recombinant DNA technology or biotechnology and intended for the treatment and prevention of diseases [14]. At present, biopharmaceuticals have been highly valued as therapeutic agents that include peptides, enzymes, monoclonal antibodies, oligonucleotides, nucleic acid derivatives, DNA preparations, antibody‒drug conjugates, vaccines, immunosera, hormones, therapeutic proteins, etc. [2, 92]. These biotherapeutic agents possess better specificity and potency than small molecules but offer many challenges, such as stabilization of their highly labile, delicate, unstable, sensitive structures. In intent to provide stable biopharmaceutical formulations, low-temperature lyophilization or cryodesiccation is the most popular processing technique in practice. The technique improves stability along with thermolabile, and sensitive biopharmaceuticals to manufacture and serve stabilized biotherapeutic products for the betterment of mankind as presented in Fig. 8 [15]. Freeze-drying or lyophilization is recognized as a gentle process to concentrate or dry biologically active substances.

Cryodesiccated biotherapeutic products provide several benefits, such as ease of handling and storage, reduction in transportation costs, and improved stability without damaging physical structure with retained potency. Freeze-dried biopharmaceuticals may be reconstituted very quickly and easily, which is particularly feasible for vaccines and antibodies and mostly supportive in the case of a medical emergency where quick administration of medication is a need. The extensive demand and usage of freeze-dried biopharmaceuticals have made it a potential candidate likely to take over the dominant position in the global market. Biopharmaceuticals are one of the fastest-growing sectors in the pharmaceutical industry and are evidenced by the current scenario of several lyophilized biopharmaceuticals available in the global pharma market. Examples of some blockbuster freeze-dried biopharmaceuticals are trastuzumab (Genentech), etanercept (Amgen), rituximab (Biogen Idec), and infliximab (Janssen Biotech) [93]. Designing a protocol for the development of stable liquid prototype formulations is mostly the first step for the development of novel biopharmaceuticals; moreover, this approach has been carefully studied and consistently practiced for the development of biopharmaceuticals in the biopharmaceutical industry [94, 95]. Figure 9 illustrates the routine process associated with the manufacturing of biopharmaceuticals.

The production of typical biopharmaceuticals prominently involves upstream and downstream processes. Upstream process (step 2) signifies the method, which involves the microbes or mammalian cells to cultivate, harvest, and produce the desired substance or other biomolecules associated with necessary steps such as choice of a cell line, selection of culture media, regulation of growth parameters and process parameter optimization to execute optimal conditions for the growth of cell culture in a well-controlled condition. The major objective of the upstream process is the transformation of starting material into the required metabolic product. The downstream process (step 3) elaborates the separation and purification process of the biological product from the substrate to a desired final product. Each step involved in the purification is adequate to remove various types of impurities [96]. Downstream processing generally encompasses steps such as extraction or isolation, purification and polishing (removal of particular contaminants and unwanted target biomolecules that may have been generated during the process of isolation and purification). The primary objective behind carrying out the downstream process is to produce the purest product with maximum yield in a short period at an efficient cost. Step 4 represents the obtained purified biological product that can be preserved as frozen liquid, crystallized solid and ready-to-fill formulated liquid. Additionally, the consequential process may result in a fill-finish operation that elaborates the development of freeze-dried biotherapeutics [97, 98].

Many biopharmaceuticals are not satisfactorily providing stability over 2-year period, drastically decreasing shelf life in a liquid state. Currently, more than 50% of marketed biopharmaceuticals, such as monoclonal antibodies, vaccines, therapeutic proteins and plasma products, are available as lyophilized formulations. Lyophilized marketed biopharmaceuticals have several advantages over liquid formulations, including enhanced long-term storage/shelf life and superior stability during transportation and storage. Moreover, the improved stability of lyophilized biopharmaceuticals often avoids the emergence of stability concerns during development or at the commercial stage. These elements make lyophilized formulations an outstanding commercial candidate [99, 100]. Since unstable therapeutic proteins, such as interferon or haemophilia factors, are lyophilized, which retains therapeutic potency after lyophilization and allow to store at ambient temperature. The use of lyophilization improves ease of storage, handling, shipping, transportation, administration and distribution of the biopharmaceutical product, which makes the methodology more convenient for underdeveloped countries or regions where the cold chain has yet to be established [101]. Lyophilization of biopharmaceuticals is a well-established process and is commonly used in the pharmaceutical industry for stabilizing high-cost, sensitive, and labile bioproducts. A few important lyophilized bioproducts are discussed below, such as vaccines and proteins.

Vaccines

The development of the freeze-dried vaccine started in the nineteenth century. In 1909, the first freeze-dried smallpox vaccine formulation was reported. Thereafter, a multidose dried powder formulation of Bacillus Calmette–Guérin (BCG) and the smallpox vaccine was developed for immunization. Later, in 1940, the "Dry Vax" smallpox vaccine was introduced in several countries for mass immunization. In addition, in 1960, a lyophilized rabies vaccine was successfully launched that extended the shelf life of the vaccine and made a vital impact on providing postexposure protection in rabies outbreaks [102]. There are several freeze-dried vaccines available in the global pharma market that possess the potential to trigger the required immune response. Some blockbuster marketed freeze-dried biotherapeutic vaccines are listed in Table 4.

Generally, cryodesiccated live attenuated viruses frequently need a complex formulation that involves various excipients [104]. Such lyophilized vaccines consist of multiple antigens, a bulking agent to produce product appearance up to the mark, a buffer to set a pH at a required value, tonicity modifiers, and stabilizers to impart the required protection to the viruses against chemical and physical degradation throughout manufacturing and storage [104, 108]. The freeze-drying process mainly accomplishes the generation and extension of the stability of the vaccine, yet freezing and the low-temperature dehydration operation themselves are very stressful processes for product development [109, 110]. To minimize the negative impact produced by the procedure, the well-designed optimized formulation and steps play a crucial role. Optimization of the formulation suggests a method for establishing the best combination of excipients by studying various permutations and combinations that will have a specific role concerned either with the process or with the protection of the key component during and subsequent lyophilization [25, 111, 112]. Several optimization protocols and stabilizing agents play a vital role in the stabilization of the freeze-dried live, attenuated vaccine manufacturing process.

Proteins

Over the past two decades, outstanding growth has been marked in the development of therapeutic proteins, while recombinant DNA and hybridoma techniques play a crucial role in the advancement of such biopharmaceuticals. In 1982, the first approved recombinant protein was insulin, and sequential biotherapeutic growth hormone and blood-clotting factor VIII were also reported. Presently, almost 30% of therapeutic protein products share the lyophilized biopharmaceutical market [113], which covers various types of antibodies (e.g. monoclonal, fused, domain), small therapeutic proteins (e.g. enzymes, hormones, cytokines), and complex biologicals (e.g. pegylated proteins, antibody‒drug conjugate). The large structure, delicate nature and different physical and chemical properties of therapeutic proteins usually result in poor stability in aqueous solution and thus create a challenge to make formulations stable [114, 115]. Lyophilization is the best-known method for the stabilization of unstable liquid protein biopharmaceuticals into a solid-state dosage form. The lyophilization process relies greatly on the protein moiety and excipients used in the formulation. Admitting protein formulations developed in assorted forms to continue stability. Certainly, the nature of proteins is affected by different degradation pathways during the freeze-drying process, which may be due to stress encountered by the respective method that affects the quality of therapeutic proteins [116]. Due to chemical degradation, protein products come across the destruction of covalent bonds and undergo hydrolysis and oxidation reactions [117, 118]. The list of commonly experienced chemical instabilities includes disulphide exchange, elimination, etc. Particularly physical instabilities include denaturation, aggregation (association of native monomers, surface-induced aggregation, etc.), precipitation (haziness or cloudiness), and surface adsorption (adsorption of native or partially unfolded protein) [119,120,121]. All the physicochemical stress factors revamp the final product as well if an indigenous structure is not preserved, which then leads to an emulated ambiguous finish product. However, due to the defined stability of proteins, freeze-drying results in protein unfolding and subsequent destabilization. However, one of the most compelling properties of proteins is the three-dimensional conformation of biological activity. This involves complexity and is oftentimes associated with weak forces [122,123,124]. The freeze-drying process imparts beneficial properties and promotes stability. The stability of a protein is an imperative characteristic and is subjected to assorted designs of other stress elements, such as pH, temperature, light and organic solvents. The aggregation and degradation of protein due to the stress effect were set to appear in the final formulation, while efficacy was analysed after delivery [125, 126]. Moreover, all these stresses often correlate with degradation and make them a favourable barometer of the instability and quality of a finished product. The instability of proteins has also been analysed via intermolecular bonds, morphology and hydrophobicity, but the process is very complex [126, 127]. If the process is not controlled, it leads to a difference in integrity, which appears to curtail therapeutic competence and activate immunogenic reactions in patients and hence necessitates amalgamation of the distinct analytical technique. As proteins undergo numerous instabilities, the delivery system selected must magnify the storage stability and perpetuate in vivo efficacy. Hence, for the design and expansion of therapeutic proteins, stability is of major concern and is given definite relevance in the preformulation studies [128].

The freeze-drying process prevails over the long-term stability argument and is beneficial for shipping when correlated to liquid protein therapeutic products. The factors elaborated above are based on the type of excipient composition used during preparation, and pertinent operational process parameters are important considerations when dealing with the stability of protein-based products [129]. Depletion of water content and molecular potency during lyophilization may shorten as the physicochemical properties of proteins may be altered during storage [130]. Following regulatory guidelines, the list of excipient use for parenteral application must be of supreme quality, sterile and stable during the product life cycle. The right choice of excipient and most ideal storage conditions is recommended for long-term stability purposes [131].

Regular excipients with distinct properties that impart more than one property are selected during preparation. Excipients such as buffers help to balance the variation in pH, surfactants can manage stress-induced aggregation and are used as bulking agents, oxidation is prevented using antioxidants, low molecular weight carbohydrates are used to maintain physiological osmolality, etc. Many others are used to improve stability along with cryoprotective action [132, 133]. The stability assessment of dried formulations is also investigated using product residue content as an alternative measure for understanding physical factors [134]. At the global level, the International Pharmaceutical Excipient Council (IPEC) provides goods manufacturing practices and good distribution measures. The IPEC regulates the number, concentration and types of excipients used during the process of manufacturing. The excipient concentration in protein-based formulations was slightly higher than in other formulations. The choice of excipients in protein-based formulations is dependent on the type of dosage form, route of administration, content and clinical acceptance [135].

Various types of stress conditions are applied during the drying process and lead to changes in the integrity of the formulation. The conformation changes in the polymer structure during drying lead to destabilization of particulate matter. Destabilization can be avoided by studying process factors, or the use of single or combinations of stabilizers may be considered a suitable alternative to alleviate stress [136]. The stabilizer can protect the protein through a distinct mechanism out of these two major mechanisms of vitrification and water replacement. Vitrification involves inactive forms of protein matrix composed of stabilizer, which counters the structural changes. Water replacement centred on the construction of hydrogen bonds between the hydroxyl group of the stabilizer and the polar group of the protein. The change in hydrogen-bonded interactions helps to maintain the structure of the protein and thereby stabilize it in the environment [117, 137]. Vitrification theory mainly exhibits kinetic stabilization, although water replacement serves a thermodynamic part. Kinetic stabilization is firmly associated with Tg, which is necessary for convenient storage and transport conditions [138].

In the solid state, a glass matrix containing excipients and proteins is analysed for thermomechanical analysis. The Tg value suggests a reduction in the rate of degradation of proteins in the presence of excipients. The protective action of the excipient is dependent on the concentration of the excipient used for encapsulation [139, 140].

There are distinctive illustrations of the stabilization of proteins in aqueous environments. The molecular states of proteins in solid forms explore the functional properties of formulations. In biopharmaceuticals, notably, the secondary and tertiary structures of the protein can be identified through methods that build on structural characterization in solid forms of protein in the interim of formulation development. Hence, significant formulation protects the solid states of the native structure of a protein. The adaptation of a proportionate path can direct the solid state of the protein and eliminate inadequate formulations for stability studies [141, 142]. The development and formulation of stable biotherapeutics require more intellectual effort than the conventional method of small molecule formulation. A great deal of research concerning the delicate, labile, complex, large, and unstable structure of biopharmaceuticals evidenced the development of freeze-dried biopharmaceuticals. Lyophilization, a quickly growing technique, has a high potential to provide stability and retain the therapeutic efficacy of sensitive biopharmaceutical products. The pace of freeze-dried biopharmaceutical development has opened the doors to accepting new opportunities and challenges to stabilize and make better biotherapeutics. The proficiency to govern and operate during the lyophilization process will benefit the establishment of competent biopharmaceutical products with ameliorating stability.

Freeze-dried injectables

Freeze-drying grew from a research laboratory to a well-established technology for the protection of biopharmaceutical molecules. The technology was established in the twentieth century [143, 144]. Fundamental principles in formulation development, as well as process design, are being introduced throughout this era. Even though we are now in the twenty-first century, lyophilization remains the preferred method for a diverse variety of pharmaceutical applications, and it is still undergoing continuous improvement and extension [145]. Several difficulties have arisen, and even well-accepted orthodoxy has been called into question [144]. The growing use of complex structures of bioactive compounds (e.g. recombinant proteins, peptides, polynucleotides), as well as supramolecular drug carriers (e.g. liposomes) in pharmaceuticals, highlights the importance of preparations that enable products to be stored and distributed while maintaining their standard functionality [114, 146, 147]. Even at chilled temperatures (2–8 °C), several protein medicines have a significant proclivity for physical and chemical deterioration in aqueous systems and are therefore not stable enough just to withstand preservation for the 1–3 years required for commercial goods. When compared to alternative formulations, freeze-drying is by far the most efficient way to maintain the therapeutic efficiency of protein medicines [101].

Lyophilization is thought to be a pleasant way to concentrate or dry pharmacologically important chemicals. For more than 40 years, enzymologists have used it as a normal practice, and pharmaceutical companies have followed suit. This is because enzyme/protein/peptide-based medications are much more durable in solid form (as opposed to solution). As a result, freeze-dried particles have benefits in terms of preservation and transportation. They also extend the shelf life of the product at the endless mode. Sublimation and desorption remove water from such a frozen sample during freeze-drying (lyophilization). It is a three-step procedure that includes chilling, initial drying, and secondary drying. Although cryoprotectants can preserve proteins against denaturation even during the early phases of their development, lyophiloprotectants are required to avoid protein deactivation during the drying [114, 145, 148,149,150]. By turning the mixture of volatile particles into solid powder as well as cake by the sublimation process, lyophilization or freeze-drying is the preferred method for improving the long-term durability of small-molecule [39, 151,152,153,154]. The majority of the literature on pharmaceutical lyophilization focuses on the drying of medicinal proteins. Furthermore, research into the utilization of lyophilization for a variety of additional medicinal purposes has begun [144].

In another study, the researcher reported lyophilization of a parenteral rhEGF (recombinant human epidermal growth factor) formulation. Excipients were screened using both unannealed and annealed drying procedures. Excipients and formulations were chosen based on freeze-dry microscopy, which was also utilized to define freeze-drying parameters. The chemical stability, protein structure, and bioactivity of excipients were assessed utilizing a comprehensive range of analytical procedures to assess their effect on freeze-drying recovery and dried product stability at 50 °C. The inclusion of sucrose or trehalose increased the durability of rhEGF after freeze-drying. The maximum stability was attained by adding dextran, sucrose, trehalose, or raffinose to the dry sample after it had been stored at 50 °C. Mostly during freeze-drying as well as delivery processes, the chosen composition blend of sucrose and dextran may avoid protein degradation. In dried formulations, the degradation rate measured by RP-HPLC may be reduced by 100 times at 37 °C and 70 times at 50 °C when compared to the liquid formulation. These findings suggest that the freeze-dried product is a suitable alternative for rhEGF stabilization [146].

Nanomaterials composed of human serum albumin (HSA) were freeze-dried in the presence of several cryoprotective compounds, and their physicochemical features were studied following reconstitution. The variable concentrations of cryoprotectants like sucrose, trehalose and mannitol were used during the process. The cryoprotectants avoids aggregation of PEGylated nanoparticles via freeze-drying approach. Particle development was detected throughout all freeze-dried compositions in the presence of cryoprotectants. Clustering of HSA nanomaterials during the freeze-drying technique was inhibited in the presence of sucrose, mannitol, and trehalose. Even though all of the additives were found to be appropriate stabilizers for freeze-drying HSA nanomaterials, sucrose and trehalose outperformed in terms of long-term storage stability [150].

A group of researchers developed a parenteral dosage form for EO9-encoded experimental cytotoxic medication. The solubility and stability of EO9 in water were significantly improved using freeze-drying. Quality control of the lyophilized formulation revealed that the fabrication process did not affect the integrity of EO9. Whenever stored at + 4 °C in a dark setting, the preparation is stable for one year, according to accelerated stability test data [155].

Ayen and colleagues developed doxorubicin-loaded (PEG)3–PLA nanopolymersomes. Nanopolymersomes were made using the nanoprecipitation method and lyophilized in the presence of several lyophiloprotectants before being assessed for physicochemical qualities. Finally, the findings reveal that doxorubicin-loaded micropolymersomes can be lyophilized using inulin (5% w/v) without losing their physicochemical features and can be preserved at 2–8 °C for more than a year [145]. Butreddy et al. (2020) provided a broad overview of the lyophilization process and examined various critical concerns and product development features, such as formulation, process optimization, container closing systems, scale-up principles and medicinal product quality [151]. Mockus and coworkers show that the effect of QbD method could be used in the process parameter development of a small molecule freeze-dried injectable medication. The model ingredient was sodium ethacrynate. The main breakdown products of sodium ethacrynate are dimers formed by Diels–Alder condensation in the freeze-dried solid-state and hydrolysis of the unsaturated ketone in an aqueous solution [39].

In another study, Franzé and coauthors examine the key production parameters that can ensure an output with desirable properties while also increasing the production process effectiveness [153].

Prolonged reconstitution durations for lyophilized biomaterials with protein-rich concentrations can be inconvenient for the end user. Luoma and coauthors outlined two strategies for reducing the reconstitution period: (1) tert-butyl alcohol (TBA) was included in the prelyophilization composition and (2) the headspace pressure in the final lyophilized container was reduced. The physical properties of cakes formed from prelyophilization products containing a range of TBA concentrations were studied. Under stress conditions, the stability of antibodies containing TBA in liquid and lyophilized forms was assessed. At a TBA content of 5% w/v, reconstitution time was reduced by more than half (> 50%). A headspace pressure was less than 50 Torr in the lyophilized vial resulted in a 50-per cent reduction in reconstitution time [156]. The list of commonly used additives in freeze-dried formulations has been described in detail by Mehmood et al. [157].

Lyophilization of nanoderived therapeutics

Nanoderived therapeutic agents have a better compliance structure than the conventional therapeutics available [158]. The multiple number of nanoderived therapeutics or in a simple term referred to as nanomedicine [159]. Nanoderived therapeutics have the capability to work as theranostics and can have dual functionality as diagnostics and therapeutics for specific disease types. Designing nanomedicine while understanding their physicochemical characteristics and maintaining their integrity throughout the formulation cycle is a challenging task for formulation scientists. The major step in commercialization is the formulation cycle, which is considered a benchmark. The interaction of nanocarriers at the biointerface is also an important component in formulation development, and recent studies have defined computational strategies to comply with the selectivity of polymers. Most of the nanoderived formulations are available as dispersions, or during formulation development, liquid suspensions are prepared [160].

The dispersion systems are extremely unstable and deteriorate the encapsulated actives [161]. The dispersed phase particles aggregate due to charged species, hydrolysis, uneven particle distribution of particles, and denaturation in the presence of solvent, which may possibly result in premature drug leakage. The instability may be harmful, as it leads to toxic effects after ingestion. The alternative approach to improve the stability of dispersed nanomedicine is conversion into a dry solid component by removing, extracting or evaporating solvents by various particle engineering approaches, such as spray drying, freeze drying, spray freeze drying, tray drying, and vacuum drying. Freeze drying is one of the most promising methods to improve the integrity of particulate matter and stabilize particles in the solid state. The removal of solvent in the sublimation state (in the vapour state) and via desorption is also called the lyophilization process and includes primary and secondary drying, respectively. The method has been extensively used in pharmaceuticals and the food industry. Lyophilization improves the stability of nanoderived therapeutic agents and improves the shelf life of encapsulated actives [162]. Major limitations of nanodervied therapeutic are aggregation of colloidal mass, and formation complex may diminish the therapeutic potential of loaded actives. The presence of organic solvent may interfere in the drug content analysis as traces of solvent decrease the total concentration of actives upon storage like in the case of liposome presence of chloroform decrease the active concentration of bioactives upon storage. Other drying methods like surface drying, spray drying, tray drying, air drying, etc., drastically modify the morphological characteristics of nanomedicine, which hamper the release mechanism. Additionally surface-anchored material may degraded in case of alternative processing steps used for targeted nanomedicine and decrease the stability and performance characteristics. The lyophilized method has considerable importance in the development of nanomedicine, which preserves and protects the actives encapsulated inside polymeric matrices. Along with morphological characteristics was retained at controlled temperature processing.

Targetability and cryoprotectant ability of hyaluronic acid (HA) were analysed on PLGA nanoparticles and liposome formulation. The HA increases interaction at the polymeric and lipid surfaces and improves redispersion characteristics after lyophilization process. Classical saccharides require 10–20% of lyoportectant, while HA concentration was lesser. High hydrophilic HA having variable molecular weight (4.8 kDa and 14.8 kDa) provides strong interaction with phospholipids. The high molecular weight HA shows least particle size less than 300 nm and less variability (less than 20%) before and after lyophilization. The HA considered as promising targeting as well as cryopreservation characteristics [163].

Targeting to ocular inflammation is a difficult task for the formulation scientist as multiple layers of barrier avoid the transportation of therapeutically active agent. The Licochalcon A (Lico A)-loaded PLGA NPs transported across ocular barrier using cell penetrating peptides B6 and Tet-1 prepared using lyophilization process. To mitigate physical stress, different grades of lyoprotectants were used such as disaccharides, alcohol and sugar alcohol. The prepared nanoparticles converted to semisolid state at physiological condition due to the presence of temperature-sensitive polymer poloxamer 407. The functionalized PLGA NPs support biocompatibility in Caco-2 cell studies, while RAW 264.7 cells show strong anti-inflammatory response [164].

Isradipine-based PLGA nanoparticles were prepared using the QbD approach and provide improved kinetics and stability to designed drug delivery system. Mannitol was used as cryoprotectant, which retains the spherical-shaped prepared nanoparticles effective for storage with improved release characteristics [165].

Biological actives such as messenger RNA (mRNA) require deep freezing temperature to stabilize the formulations like vaccine. Maintaining deep freezing temperature is challenging task as it creates complications during storage, distribution and increase cost of accessibility in low-income countries. The lipid-encapsulated mRNA nanoparticles (mRLNPs) were prepared using spin freezing technique to provide continuous manufacturing modalities. The high ionizable weight ratios between lipid and mRNA prevent premature release of bioactives. The phosphates and Tris buffer were used during lyophilization to maintain the stability. The transfection properties of mRLNP were increased after lyophilization and maintained the integrity of formulation up to 12 weeks [166].

Patents and clinical status

Cryogenic modifications are relatively important in the development of drug delivery systems. It improvises the storage, transportation and handling of pharmaceuticals. Freeze drying was adopted to enhance the product characteristics. For the past few years, freeze-drying techniques were used in addition to conventional techniques for tableting. Freeze-drying methodologies are robust and dissolve unique features of materials. The technique helps to explore the material characteristics in solid‒solid as well as solute-solid interactions. The freeze-dried formulations patented by the world-renowned manufacturer are highlighted in Table 5.

Clinical investigation of freeze-dried formulations was better than other conventional dosage forms. Bavarian Nordic scheduled a clinical phase II study to identify the bioequivalence between liquid frozen and freeze-dried formulations containing a smallpox vaccine. The trial was conducted for immunogenicity and safety against two comparative formulations. A similar comparative evaluation updated in Table 6 provides the safety and efficacy of freeze-dried formulations against conventional formulations containing biologicals.

Conclusion