Abstract

Background

The development of chromatographic method and the validation of a sensitive, simple, efficient, and reversed-phase high-performance liquid chromatography (RP-HPLC) approach were adopted for the drug flurbiprofen (FBP) in nanoparticles formulation by using a design of experiment (DoE). The critical method variables (CMVs) were screened using a statistical two-level fractional factorial design (FFD) followed by optimization of the selected CMVs that influence the analytical responses (ARs) of the RP-HPLC process by using two-level full factorial design.

Results

Statistical models are used to investigate the effects of system factors including column temperature, flow rate, and methanol in orthophosphoric acid (OPA) on the dependent responses, retention time, peak area, tailing factor, and theoretical plates in HPLC. The ideal column temperature (25 °C), flow rate (1 ml/min), and mobile phase (methanol 85 percent v/v in 0.05 percent OPA in water) were selected independently from the response surface at three levels (1, + 1, and 0) for further validation at constant solvent pH 2.75. Optimized method in the RP-HPLC resulted a retention time of 4.75 min, a peak area of 3975.12, a tailing factor of 0.73, and a total of 9697.7 theoretical plates followed by validation in accordance with the current ICH recommendations Q2 (R1). Linearity, precision, accuracy, assay, limit of detection (LOD), limit of quantification (LOQ), and robustness were all included in validation. The calibration curve was linear (r2 = 0.9997, slope = 70.72) for the concentration of 10 to 50 µg/ml, with a limit of detection of 0.14 µg/ml. Furthermore, stability-indicating methods demonstrate that drug degradation is highest in the presence of basic circumstances (about 96.49%), followed by oxidation (about 76.41%), and acidic conditions (about 48.12%), whereas drug is stable in some extent under neutral, photo (sunlight), and dry heat conditions.

Conclusions

Effect of independent variables on dependent responses was screened and optimized by using statistical software design. A method for drug development could be successfully implemented for the estimation of drug in nanoparticles formulation as well as for the routine analysis in bulk and pharmaceutical formulations. The high recovery and low relative standard deviation support the suitability of proposed method that could be employed.

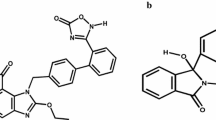

Graphical Abstract

Similar content being viewed by others

Background

Flurbiprofen (FBP) is a significant non-steroidal calming, pain-relieving drug and is regularly suggested for rheumatoid joint inflammation, osteoarthritis, ankylosing spondylitis, and gout patients [1]. Many times it is prescribed for the diagnosis of vernal kerato conjunctivitis ocular gingivitis [2] and postoperative care, ophthalmic inflammations [3,4,5]. The analytical method is the sole accurate method for FBP estimation; however, it has several drawbacks due to the laborious, difficult extraction procedures, numerous and lengthy steps to develop method, very time-consuming procedure. In most of published articles of FBP which follow HPLC–UV methods, it was found that due to the complex combinations of mobile phase composition there was a lack of stability-indicating ability, extended retention time, and limited use [6, 7]. Analytical methods are essential components in product due to their significance in contributing with process development and product quality control. Inaccurate data from poor analytical techniques can produce inaccurate information that may be detrimental to the drug development program. For the development of any pharmaceutical substance, traditional liquid chromatographic methods are generally used on trial-and-error process; likewise, it varied one aspect at a time and watched at the resolution of the outcome until the ideal method was discovered. The process took a long time and involved a lot of manual data analysis. Additionally, the capabilities and robustness of a method are only partially understood through this form of method development. Furthermore, until now, the development of a scientific and risk-based Analytical Quality by Design (AQbD)-oriented reversed-phase HPLC (RP-HPLC) method for FBP has not received. To solve the issues, there is a need for the development of a reliable, easy, and highly sensitive HPLC technique FBP based on AQbD principles. The ultimate objective of this research work was to produce an easy, quick, sensitive, robust, effective, and reliable stability-indicating HPLC approach by applying AQbD principles and methodology for assessment of FBP in bulk and pharmaceutical formulation product [8].

The drug's solubility, chemical stability, and photosensitivity concerns will be improved because of the new nano-formulation. This research includes screening for critical analytical variables that affect ARs and the FBP analytical method optimization using fractional factorial and full factorial, respectively. DoE is a method of systematic development beginning with screening of parameters and process which highlights the development of a process and parameters that has been optimized. The application of the DoE method results in the identification of critical method variables (CMVs) that has major impact on RP-HPLC method analytical responses (ARs). Optimization by DoE technique helps for the development of the best experimental designs for greatest method performance [9].

The selected mobile phase, flow rate, column temperature, and pH are the most significant variables in HPLC examination which affect response 1: RT (retention time), Response 2: PA (peak area), Response 3: TF (tailing factor), and Response 4: TP (theoretical plate) [10,11,12].

Materials and methods

Pure drug flurbiprofen was purchased from Yarrow Chem Products, Mumbai, India, and has been claimed to contain 99.980 percent (w / w). HPLC analytical-grade methanol was procured from Merck Life Science Pvt. Ltd., Mumbai, India. HPLC-grade water procured from Rankem, India, and orthophosphoric acid was purchased from Merck Life Science Pvt. Ltd., Mumbai, India. The HPLC system was used as an Agilent 1220 Infinity LC system with auto sampler. The column was used Nucleosil C-18 segment (4.6 mm I.D × 250 mm) with UV detector.

Defining of method—design of experiment (DoE)

"The design of experiments" is a well-structured and well-organized process strategy for identifying the association between elements, having an impact on a process and its output. DoE is a fantastic approach that allows pharmaceutical person to modify parameters in a systematic manner according to a pre-determined design to obtain best suited results [13,14,15].

-

a) Screening design of variables

-

The CMVs that have a substantial impact on ARs, retention time, peak area, and theoretical plate number, and tailing factor are all factors to consider in the HPLC technique and were identified in a screening analysis utilizing fractional factorial design (FFD). The dependent variables include the composition of MeOH in the mobile phase, flow rate, temperature of HPLC column, wavelength, and pH; two levels of change were made to the dependent variables with + 1 and -1 denoting levels high and low, respectively (Table 1). The Design-Expert® Software version 11 recommended a total of 16 experiments. All the 16 experiments were carried out to identify CMVs that have a considerable impact on the ARs of the HPLC method.

-

As shown in Fig. 1, Pareto plots suggest that the factors had a significant influence, i.e., MeOH volume (A), flow rate (B), and pH (E), on all ARs i.e., retention time (Fig. 1a), peak area (Fig. 1b), tailing factor (Fig. 1c), and number of theoretical plates (Fig. 1d). In the Pareto charts, all responses showed statistical significance having larger than the t-value limit and the Bonferroni limit. Also, all three variables, i.e., MeOH percentage (A), pH (E), and flow rate (B), had a negative impact on retention time (Fig. 1a) and theoretical plate number (Fig. 1d). These three parameters were chosen as CMVs for FFD method optimization because they were found to have a significant impact on ARs.

-

b) Optimization design

-

According to the screening investigation, parameters that have a significant impact on the responses were chosen, and further study was carried out using 32 full factorial designs. MeOH concentration (85% v/v in 0.05 percent OPA), flow rate, and column temperature for some instances were proved to affect the CMVs. For this, there are two types of optimizations; one is graphical and other is numerical optimization if there are more than three responses. The STATISTICA program was used to plot the response surface. The obtained data were subjected into various models, but the final model was chosen for future experiments based on the highest F-value, P-value, and R2, and highest desirability found was selected as optimized batch (Tables 2 & 3).

Standard and sample solution preparation and calibration curve

A standard flurbiprofen (FBP) solution was set by taking accurate amount of FBP in methanol for final concentration 100 µg/ml to obtain the calibration graph, 5 fixations (20 µl loop) of concentration 10–50 µg/ml injected into system, and the graph between peak area and concentrations was plotted. A 30-min time fragment was kept in between each run [16]. For the determination of FBP drug content from FBP nanoparticles (Nps), an appropriate quantity of solid NPs was dissolved in the minimum quantity of dichloromethane to form polymer precipitate [17]. After mixing the solution carefully, it was centrifuged for 15 min at 4000 rpm and filtered through 0.22-μ PVDF membrane, and the collected supernatant was made up with the mobile phase to obtain a sample solution containing 100 µg/ml. The assay was carried out with the resulting solution of FBP [18,19,20,21].

Development of method and validation process

The optimized chromatographic process for the determination of FBP was validated as per the ICH guidelines Q2 (R1) for linearity, accuracy, intra-day and inter-day precision, limit of quantification and limit of detection, repeatability, robustness, and assay study.

Both intra-day precision and inter-day precision were performed at six replicates of concentration levels. The % RSD measured for inter-day compared to intra-day accuracy is high due to the high-end stability of the solvent. Assay of FBP was performed. The accuracy has been determined by the actual sample concentration (40 µg/ml), and % RSD was calculated. In standard graph of calibration, the value of drug content was calculated through regression equations.

The robustness is the capacity to remain unaffected where any small change in process parameters do not lead to any change in its reliability during the day-to-day usage. The method was investigated by intentionally altering the process, such as by changing the mobile phase's pH, its percentage of organic content, or its wavelength [22].

System suitability

The system suitability test verifies that the HPLC is sufficiently precise, most specific, and repeatable for the analytical estimations. The tests were carried out by injecting any sample six times in a row. Peak area, theoretical plate, retention time, and tailing factor are the system suitability parameters and are represented as an %RSD.

Response surface methodology analysis and optimization model validation

An aggregate of twenty-seven runs for factor optimization were done by employing 32 full factorial design, and the impact of three independent variables was analyzed using factorial structure based on the dependent variables (responses, Table 3). The following equation is standard equation showing the correlation of critical factors and the analytical responses.

Y is the expected outcome value for the polynomial model and β represents the regression coefficients 1 to k for each degree and β0 is the Y intercept. The model is only a general linear regression model with k predictors raised to the power of i where i = 1 to k. A quadratic expression follows second-order (k = 2) polynomial forms. X1, X2, X3 are the critical factors which are depending on the correlation of factors and responses [23,24,25].

Force degradation study

To check the stability and the purity of the drug solution, a forced degradation analysis is required in which methanol (100 μg/ml) is used and the precise outcomes are obtained after the 6 replications. Studies on force degradation were conducted out from the following stress conditions by treating the sample. The drug shows more stability in solution up to a month, according to a stability study of FBP under various conditions. For the quantification of FBP, the established approach was proven to be specific, in the presence of formulation excipients, and then used to estimate drug content in solid powder of nanoparticle formulation [26,27,28,29].

Oxidation degradation

To obtain chromatograms from the solution of H2O2, a desired solution was prepared using 1% of 2 ml H2O2 mixed with 2 ml of drug content at standard atmospheric conditions. The water was added after half an hour to obtain the desired solution of 40 μg / ml concentration. Then, the solution was analyzed in HPLC.

Acid degradation

To obtain chromatograms from the solution of hydrochloric acid (HCL), a desire solution was prepared using 1% of 2 ml HCl mixed with 2 ml of drug content at standard atmospheric conditions. Water was added after 15 min to obtain the desired solution of 40 μg / ml concentration. Then, the solution was analyzed in HPLC.

Base degradation

To obtain chromatograms from the solution of NaOH, a desire solution was prepared using 1% of 2 ml NaOH was mixed with 2 ml of drug content at standard atmospheric conditions. The water is added after 15 min to obtain the desired solution of 40 μg / ml concentration. Then, the solution was analyzed in HPLC.

Neutral degradation

To obtain chromatograms from the solution, a desired solution was prepared using 100 mg of drug content mixed with water at 70 0C for approximately 3 h. Finally, water was added to get 40 µg/ml in the solution. Then, the solution was analyzed in HPLC.

Photo (sunlight) degradation

To obtain chromatograms from the solution, a desired solution was prepared using 1% of 1000 µg/ml drug content. The prepared solution is applied on the wooden blank and kept in direct sun rays for approximately 1 day. Finally, water was added to get 40 µg/ml solutions. Then, the solution was analyzed in HPLC.

Dry heat (thermal) degradation

A chromatogram is obtained after dry heat treatment. Dried drug sample of about 100 mg of was kept in the oven at 80 0C with for 6 h. Finally, 40 µg/ml concentration solution was prepared of the heated sample. Then, the solution was analyzed in HPLC.

Results

All the analyses were conducted at a concentration of 40 µg/ml. STATISTICA software was used to analyze the results. The polynomial model of the second-order coefficients was determined by regression equation. For each response, the model was found to be significant when adjusted R value is near to predicted R value. Based on Eq. 1, Y1 is the suitable response for retention time and Y2 is for peak area, Y3 for tailing factor, and Y4 for theoretical plate. X1, X2 are the flow rate of mobile phase represented in ml/min, X2 is the internal temperature of column, and X3 is the degree of methanol in the design. In terms of coded factors, the model equation for responses (Y1-Y4) are as follows:

Variables effect on retention time (Y1)

Figures 2 and 3 (A1-A3 and B1-B3) graph shows the effect of independent factors (X1, X2 and X3) over dependent response retention time (Y1).

Final equation in terms of coded factors

Equation 2 shows the inverse relationship of RT and the functional parameters, i.e., flow rate of mobile phase (X1) and concentration of MeOH (X3). The solid positive relapse coefficient demonstrates a sharp increment in retention time, with equal a higher rate of flow and MeOH conc. To minimize the retention time, the flow rate can be increased. We can likewise accelerate the partition and lessen mobile phase thickness by expanding the temperature, in this way limiting backpressure. To expand the mobile phase variable i.e., methanol, the retention time will diminish, and every single other response will increase. This might be because of the mobile phase's expanded extremity, making a quicker analyte balance among stationary phase and the mobile phase.

Variables effect on peak area (Y2)

Figures 4 and 5 (C1–C3 and D1-D3) show linear correlation plot for the response Y2 among true as well as measured values and the corresponding remaining graphs. Increase in flow rate makes the pinnacle zone (Area under curve) rise. Likewise, the peak area is additionally increased by increment in column temperature and amount of methanol in the mobile phase. Equation 3 shows impact of flow rate, column temperature and methanol concentration on peak area.

Final equation in terms of coded factors

Variables effect on tailing factor

Figures 6 and 7 (E1–E3 and F1-F3) show linear correlation plot for the response Y3 among true as well as measured values and the corresponding graphs.

Final Equation in Terms of Coded Factors

This equation shows the positive impact of flow rate (X1) so whenever increase in flow rate there will be elevation of TF value and negative impact of column temperature (X2). The increase in temperature value decreases the tailing factor.

Variables effect on theoretical plate

This equation expressed to predict values of response for coded variables. The response on theoretical plate is affected by flow rate (X1), temperature of column (X2), and methanol concentration in mobile phase (X3).

Figures 8 and 9 (G1-G3 and H1-H3) indicate linear correlation plot for the response Y4 among true as well as measured values and the corresponding graphs.

Final equation in terms of coded factors

Statistics of response

All the dependent critical analytical responses are analyzed statistically, i.e., RT, PA, TP, and TF. (Table 4).

Analysis of variance for the responses (Y1-Y4)

Tables 5 , 6 , 7 and 8 show the ANOVA tables for various responses (RT, PA, TF, and TP).

Graphical and numerical optimization

Figure 10 shows the overlay plots showing relationship of factor and responses for graphical optimization, whereas Figs. 11 and 12 show numerical optimized method having highest desirability of 0.918.

Calibration curves

The span of the linearity can be analyzed by the standard solution of 10–50 µg/ml (r2 = 0.9997, slope = 70.72) (Fig. 13).

Validation

During validation, all the graphs were clear, sharp, and very well without any impurities. Results for precision, the RSD percentage were less than 2. A recovery study is well utilized to determine the accuracy and the response of the peak area. The ICH limit decides different parameters of linearity with the system variables. In FLP, the linearity test was executed at 5 separate levels. The suggested approach shows a great linearity span of 10, 20, 30, 40, 50 μg/ml (r2 = 0.9997).

Intra-day and inter-day precision (n = 6).

This method is used to determine the precision values of inter-day and intra-day. % RSD was found 0.48 for inter-day and 0.081 for intra-day. The outcome (Table 9) has almost no effect on the parameters due to any little variation.

Repeatability

Repeatability study was conducted and % RSD was found 0.05.

Robustness

The process parameters were checked for robustness study; it is found acceptable % RSD value less than 2 percent within the limits. The fact that there were no obvious alterations in the chromatograms suggested that the HPLC procedures that have been developed are robust (Table 10).

Limit of quantification (LOQ), limit of detection (LOD)

LOD and LOQ values determine the sensitivity of method. The lowest concentration can be detected by system is LOD, whereas LOQ is lowest concentration in analytes in stated sample determined under acceptable precision values. To obtain LOQ & LOD, actual drug concentration in linear range and calibration curve were used for 6 repetition assessments. LOD and LOQ values were 0.14 μg / ml and 0.42 μg / ml. (Table 11).

Analysis of the nanoparticles formulation and recovery study

The chromatogram of drug content from nanoparticles was obtained. A peak at RT 4.42 min was obtained with (% RSD 0.01). The formulation's average recovery was discovered to be 101.28% with % RSD 0.08 (Tables 11 and 12).

Forced degradation analysis (stability-indicating methods)

Studies on force degradation were conducted out and the following results obtained (Table 13, Fig. 14).

Oxidation degradation

FBP found to be extremely susceptible to degradation in the oxidation analysis. At RT values of 2.24, 2.34, 2.60, and 4.77, the FBP showed four additional degradation peaks.

Acid degradation

FBP very easily undergoes acid degradation; degradation graph showed 3 peaks more having values for RT of 2.27, 2.68, and 7.06 when solution was reacted with HCL for 15 min.

Basic degradation

FBP is found to undergo degradation very quickly in the base-induced degradation analysis. An additional 6 peak values are obtained in the drug content of 2.06, 2.42, 2.68, 2.77, 2.99, and 4.07.

Neutral degradation

No degradation peak observed in neutral degradation.

Photo degradation

At RT 3.16 min, the drug showed additional peaks.

Dry heat degradation

Just 6.32 percent of the medication was depleted under this condition. At RT values of 2.23 min and 3.13 min, the drug showed two additional peaks.

Discussion

The screening and optimizations are successfully done by novel statistical designing approaches. In this study, the HPLC was used to perform and produce an effective resolution of FBP from nanoparticles formulated previously; as a result, the suggested study had several advantages over the previous one. Most quality issues originate from the way a pharmaceutical product was designed. As per the survey of this research, no adequate validated analytical approach for the simultaneous quantitative determination of flurbiprofen in the loaded polymer-mediated nano-formulations has been published. As a result, proposed research is about method development and validating a RP-HPLC for simultaneous FBP analysis in polymer-based nano-formulations by employing the DoE approach. The prior approach employed was pricey, because of use of acetonitrile as the solvent, and the mobile phase of system in combination of acetonitrile and ammonium acetate, and buffer. However, new method appears as a cost effective as we have used methanol and water as the mobile phase. At 247 nm wavelength, the retention duration was less 4.75 min, compared to 8.94 min (previous) for the previous approach. Also, no significant difference found in LOD and LOQs in proposed method with 0.14 µg/ml and 0.42 µg/ml with highest recovery. A stability-indicating study was carried out, on applying varying stress conditions over the sample. During the forced degradation experiment, roughly 76.41 percent of the substance deteriorated under oxidation. Under the acidic conditions, the drug was degraded by approximately 48.12 percent.

In basic condition, the drug was degraded about 96.49 percent. The neutral degradation condition exists without drug degradation. Less than 1 percent of the drug was degraded in the photo and dry heat degradation state.

We discovered that FBP degradation was highest in basic conditions, followed by oxidation and acidic conditions, whereas drug is stable, i.e., did not degrade any further under neutral, very less degradation in photo (sunlight), and dry heat conditions. During the robustness investigation, all responses RT, PA, TP, and TF were confirmed within considerable limits.

Conclusions

Based on the study, it can be concluded that screening and optimization of analytical-dependant and independent factors and responses by using statistical designs and screened best factors affecting the process of optimization, developing, and validation of method. A new precise, reliable, quick, simple, analytical method can be developed and validated for determination of the flurbiprofen in nanoparticle formulation, FBP. The use of the DoE approach for parameter screening aids in identifying crucial parameters that influence ARs of HPLC method for FBP. The DoE software optimization design aids in optimizing the precise circumstances needed to build a most accurate and precise analytical method for FBP. Quantification of FBP was carried out with precision, methanol in 0.05% OPA in water as mobile phase, pH 2.75 having flow rate 1 ml/min, and RT of 4.75 min. The new approach was proved to be capable of accurately measuring FBP in nanoparticle formulations.

Availability of data and materials

The data that support the findings of this study are available from the corresponding author, upon reasonable request.

Abbreviations

- FBP::

-

Flurbiprofen

- API::

-

Active pharmaceutical ingredients

- RP-HPLC::

-

Reverse-phase high-pressure/performance liquid chromatography

- OPA::

-

Ortho phosphoric acid

- DoE::

-

Design of experiments

- FFD::

-

Fractional factorial design

- CMV::

-

Critical method variables

- AR::

-

Analytical responses

- HPTLC::

-

High-pressure/performance thin layer chromatography

- PVDF::

-

Polyvinylidene fluoride

- ICH::

-

The International Conference on Harmonization

- LOD::

-

Limits of detection

- LOQ::

-

Limits of quantification

- RSD::

-

Relative standard deviation

- SIM::

-

Stability indicator method

- UV::

-

Ultraviolet

References

Brooks PM, Day RO (1991) Nonsteroidal anti-inflammatory drugs–differences and similarities. N Engl J Med 324(24):1716–1725. https://doi.org/10.1056/NEJM199106133242407

Sud RN, Greval RS, Bajwa RS (1995) Topical flurbiprofen therapy in vernal kerato conjunctivitis. Indian J Med Sci 49(9):205–209

Akhlaq M, Khan GM, Wahab A, Khan A, Hussain A, Nawaz A, Abdelkader H (2011) A simple high-performance liquid chromatographic practical approach for determination of flurbiprofen. J Adv Pharmaceut Technol Res 2(3):151–155. https://doi.org/10.4103/2231-4040.85529

Colin J (2007) The role of NSAIDs in the management of postoperative ophthalmic inflammation. Drugs 67:1291–1308. https://doi.org/10.2165/00003495-200767090-00004

Galasko DR, Graff-Radford N, May S, Hendrix S, Cottrell BA, Sagi SA (2007) Safety, tolerability, pharmacokinetics, and Abeta levels after short-term administration of R-flurbiprofen in healthy elderly individuals. Alzheimer Dis Assoc Disord 21:292–299

Lee HI, Choi CI, Byeon JY, Lee JE, Park SY, Kim YH, Kim SH, Lee YJ, Jang CG, Lee SY (2014) Simultaneous determination of flurbiprofen and its hydroxy metabolite in human plasma by liquid chromatography-tandem mass spectrometry for clinical application. J Chromatograph B, Anal Technol Biomed life sci 971:58–63. https://doi.org/10.1016/j.jchromb.2014.09.00

Foda NH, Al Gohary OM (1994) High performance liquid chromatographic determination of flurbiprofen in pharmaceutical dosage forms. Anal Lett 27(13):2523–2534. https://doi.org/10.1080/00032719408002659

Yu LX, Amidon G, Khan MA, Hoag SW, Polli J, Raju GK, Woodcock J (2014) Understanding pharmaceutical quality by design. AAPS J 16(4):771–783. https://doi.org/10.1208/s12248-014-9598-3

Sandhu PS, Beg S, Katare OP, Singh B (2016) QbD-driven development and validation of a HPLC method for estimation of tamoxifen citrate with improved performance. J Chromatogr Sci 54(8):1373–1384

Manwar JV, Vispute SS, Kumbhar DD, Manmode RS, Bakal RL, Jadhao RG, Jogdand SD (2017) Response surface based optimization of system variables for liquid chromatographic analysis of candesartan cilexetil. Integrative Med Res 11(1):159–172. https://doi.org/10.1016/j.jtusci.2016.02.004

Saha P, Pandey MM (2021) Design of experiment (DoE)-approach based RP-HPLC analytical method development and validation for estimation of efavirenz in bulk and formulations. J Chromatogr Sci 2021:1–10. https://doi.org/10.1093/chromsci/bmab029

Ghica MV, Albu MG, Leca M, Popa L, Moisescu ST (2011) – “Design and optimization of some collagen-minocycline based hydrogels potentially applicable for the treatment of cutaneous wound infections.” Die Pharmazie-An Int J Pharmaceut Sci 66(11):853–861

A C, Atkinson, A N & Donev, (1992) Optimum experimental designs. Oxford Stat Sci Series 8(13):9780198522546

Lewis GA, Mathieu D, Phan-Tan-Luu R (1998) Pharmaceutical experimental design. CRC Press. https://doi.org/10.1201/9780203508688

Bas D, Boyaci IH (2007) Modeling and optimization I: usability of response surface methodology. J Food Eng 78:836–845. https://doi.org/10.1016/j.jfoodeng.2005.11.024

Waghulde M, Naik J (2018) Development and validation of analytical method for vildagliptin encapsulated poly- ε -caprolactone microparticles. Mater Today: Proc 5(1):958–964. https://doi.org/10.1016/j.matpr.2017.11.171

Kazusaki M, Ueda S, Takeuchi N, Ohgami Y (2012) Validation of analytical procedures by high−performance liquid chromatography for pharmaceutical analysis. CHROMATOGRAPHY 33(2):65–73. https://doi.org/10.15583/jpchrom.2012.005

ICH, Q2A, (1994) – “International conference on harmonization”, Geneva, 1994, October.

ICH, (2002) - “International convention on quality for the pharmaceutical industry”. Toronto, Canada, 2002, September.

United states pharmacopeia (USP 30) (2007) The United States pharmacopeia convention. Rockville, USA

Bushra Tuwfeeq Alquadeib (2019) Development and validation of a new HPLC analytical method for the determination of diclofenac in tablets. Saudi Pharmaceutical J 27(1):66–70

Suryawanshi D, Jha DK, Shinde U, Amin PD (2019) Development and validation of a stability-indicating RP-HPLC method of cholecalciferol in bulk and pharmaceutical formulations: analytical quality by design approach. J Appl Pharm Sci 9(06):021–032

Armitage P, Berry G (1994) Statistical methods in medical research. Blackwell, USA

David G, Kleinbaum Lawrence L. Kupper, Keith E. Muller, Azhar Nizam., (1998) Applied regression analysis and other multivariable methods (3rd edition). Duxbury Press 1998.

Mandpe SR, Parate VR, Naik JB (2021) (2021), Method optimization and analysis of flurbiprofen loaded Eudragit L100 nanoparticles using RP-HPLC technique: a central composite design approach. Mater Today: Proc 45(P6):4777–4786. https://doi.org/10.1016/j.matpr.2021.01.210

Maheswaran R (2012) FDA perspectives: scientific considerations of forced degradation studies in ANDA submissions. Pharm Technol 36(5):73–80

Nirav S (2018) Stability indicating analytical methods (SIAMS), 1st edition. Scholars' Press, India, pp 1–72

Blessy M, Ruchi D, Patel PN, Prajapati YKA (2014) Development of forced degradation and stability indicating studies of drugs—a review. J Pharmaceut Anal 4(3):159–165. https://doi.org/10.1016/j.jpha.2013.09.003

Reynolds DW, Facchine KL, Mullaney JF, Alsante KM, Hatajik TD, Motto MG (2002) Conducting forced degradation studies. Pharm Technol 26(2):48–56

Acknowledgements

Authors like to thank Technical Education Quality Improvement Program (TEQIP-III), World Bank and MHRD, New Delhi, for providing financial assistance to carry out this research work.

Funding

Technical Education Quality Improvement Programme-III (TEQIP-III), World Bank and Ministry of Human Resource Development, New Delhi, India.

Author information

Authors and Affiliations

Contributions

Shilpa R. Mandpe has contributed to design and performed experimentation as well as prepared draft manuscript. Jitendra B Naik has contributed to design experimentation and edited manuscript. Vishal R Parate has contributed to edit manuscript. All authors are read and approved by the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

The authors declare no conflict of interest.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mandpe, S.R., Parate, V.R. & Naik, J.B. Experimental design approach, screening and optimization of system variables, analytical method development of flurbiprofen in nanoparticles and stability-indicating methods for high-pressure liquid chromatography. Futur J Pharm Sci 8, 38 (2022). https://doi.org/10.1186/s43094-022-00426-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s43094-022-00426-4