Abstract

Background

Bioremediation is one of the indispensable features of Pseudomonas putida. The use of Pseudomonas has been proved to be an effective treatment of tannery released chromium (VI). The current study is the first attempt for the optimization of chromate reduction by Pseudomonas putida strain APRRJVITS11 in an optimized bench-scale bioreactor with successful thermo-pressure elimination of the strain thereby eliminating the health risk caused by antibiotic resistant genes (ARGs).

Results

The growth media, modified with optimized 1.0% nitrogen, 0.5% yeast extract and 0.3% sodium, showed enhanced bacterial growth for 72 h of incubation. The optimization of aeration (1.0 vvm) and agitation (150 rpm) rates enhanced the chromate reduction by about 40% at 72 h fermentation. Thermo-pressure pathogenic DNA degradation was achieved at 90 °C and 5868 Pa for 10 min.

Conclusions

Successful chromium reduction and total elimination of ARGs from effluent. A two-step treatment train was proposed for chromium reduction in the environment, which should be incorporated by the existing leather industries running on conventional treatment units.

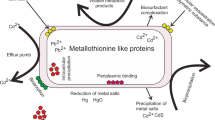

Graphical Abstract

Similar content being viewed by others

1 Background

Global industrialization is the major contributor to environmental pollution [12]. Industrial runoffs consisting of increased concentrations of heavy metals when released without proper pre-treatment vastly contaminate the soil and freshwater bodies [15]. Among all industries, the leather industry is the most responsible for chromium emissions into the environment. Globally, an estimated 40 million litres of chromate-infused wastewater are discharged each year [23].

As Cr(VI) is persistent, bioaccumulative and toxic to human health, living resources and the ecological system, alternative treatment methods for the removal of Cr(VI) are needed. Cr(VI) causes severe skin and respiratory tract conditions and has been linked to kidney and liver failure, with the worst-case scenario being skin and lung cancer [17].

The use of bacteria for cleaning pollution sites, specifically for chromium removal has been proved with the use of different genera viz. Geotrichum, Bacillus, Escherichia, Leucobacter, Ochrobactrum, Streptomyces, Amycolatopsis, Aeromonas, Agrobacterium, Aereobacterium and Xanthobacter [4, 7, 8, 11, 27, 30]. The application of bacteria in chromate wastewater treatment systems is environmentally friendly [6]. Biofilters with simple construction and embedded with bacteria capable of reducing chromate have been studied [5].

To satisfy the rising demand for leather products while remaining cost-effective, tanneries must be remodeled with more environmentally friendly plants and processes [35]. Nitrogen inputs, growth promoters, organic compounds and metal ions for osmotic equilibrium are all-important nutritional factors influencing chromium reductase production [24]. Physical parameters such as aeration and agitation rates, pH and temperature, as well as incubation time, are also significant [38]. As a result, improving nutritional and physical parameters for optimum chromate reductase efficiency is critical for making the industrial process commercially sustainable [25].

The factors are optimized in the “one-factor-at-a-time” technique by adjusting one aspect at a time while leaving other aspects stable [20]. This method is the quickest to adopt and particularly aids in the identification of important factors influencing culture growth, thereby increasing enzyme yield [29].

An additional problem is the genes of highly resistant mutated strains used in the bioremediation process [31]. Antimicrobial resistance (AMR) has recently been linked to tolerance to heavy metals, both naturally occurring and anthropogenic, and chromium has also been confirmed to co-select such AMR [3]. The hazardous effects of a chromium-treated isolate can result in strains containing these genes (in plasmids) which commonly exist in runoff water from the tanneries and facilitate the transmission of these genes reaching higher food chains [14].

The objective of the present research work was to optimize a bench-scale bioreactor for chromate reduction by Pseudomonas putida strain APRRJVITS11. Followed by total incineration of the bacterial strain DNA in the water.

2 Methods

In this current study, two-unit operations (Fig. 1) were evaluated independently, which is a standard technique to determine the viability of linking and scaling them up in a concept.

2.1 Procurement and stock solution

The novel strain Pseudomonas putida APRRJVITS11 (Accession No. MN453582) was procured from the laboratory TT635 of Vellore Institute of Technology, Vellore, Tamil Nadu, India. In a 500 ml conical flask, 250 ml sterile modified Luria–Bertani (MLB) broth of pH 6.0 was inoculated with 2.0% (v/v) mother culture of 0.8 OD, containing 2.8 × 108 colony forming units (CFU/ml) and incubated at 37 °C in a shaker incubator (150 rpm). The broth (5.0 ml) was collected aseptically regularly, and the bacterial growth was measured by turbidity at 620 nm [32].

2.2 One-factor-at-a-time optimization of nutritional and physical parameters

The scaling-up technique was used to improve different nutritional and physical parameters by keeping all variables constant in the basal medium except the one undergoing consideration. After taking into consideration the previously optimized component(s), each following factor was evaluated [36]. Peptone in MLB broth was replaced separately by NH4Cl and urea to test the effect of different nitrogen sources. Yeast extract was replaced by (NH4)2SO4 and tryptone. NaCl was replaced by MgCl2 and CaCl2. After which the selected alternative’s concentration was optimized following the optimization of K2Cr2O7 concentration. The physical parameters of pH (4.0–11.0) and temperature (40–55 °C) were optimized keeping a shaking speed of 150 rpm. The bacterial growth was studied at an absorbance of 620 nm using a spectrophotometer [34].

2.3 Bench-scale bioreactor level optimization

Fermentation was performed in a stirred tank bioreactor (Hygene Plus Glass Bioreactor, Lark Innovation Fine Technology, India) of 3–7 L capacity (Fig. 1). The fermentor included a direct drive twin Rushton type impeller, PID temperature and agitation control, pH probes and a pH controller [34]. For chromium reduction activity, fermentation was carried out in 5 L LB broth under previously optimized nutritional (glucose 1.25%, gelatin 2%, yeast extract 0.5%, Mg2+ 0.01%) and physical (pH 7.0 and 37 °C) conditions. The bioreactor solution was injected with a 2.0% mother culture of Pseudomonas putida APRRJVITS11 (0.8 OD, A660; 2.8 × 108 CFU/ ml). Aeration of culture broth was altered at various rates (0.5, 1.0 and 1.5 vvm), and samples (5.0 ml) were taken every 24 h for three days. Turbidity at 660 nm was screened to detect bacterial proliferation. After centrifuging the samples at 12,000 rpm (4 °C) for 10 min, the cell-free supernatant was utilised to assess chromate removal efficiency using flame atomic absorption spectroscopy (AAS) and diphenylcarbazide (DPC) [13, 28].

2.4 Statistical analysis

Hexavalent chromium was assessed by its capability to react with the S-diphenylcarbazide (DPC) reagent [33]. All the statistical calculations were done on the Microsoft Excel 2019 edition software and all sampling analyses were done in triplicates and were performed with a confidence of 95% at p < 0.05 [9, 30].

2.5 Thermo-pressure degradation of gDNA

Reported data suggests that the thermal genomic DNA (gDNA) degradation under dry conditions happens at > 190 °C, while a complete gDNA degradation occurs somewhere between 100 and 110 °C in wet sterilization conditions [18]. Pseudomonas putida APRRJVIYS11 gDNA was extracted with an E.Z.N.A.® Water DNA Kit using the following protocol—The samples were filtered using microporous filter paper (0.22 μm or 0.45 μm). The filter from the adapter was removed and cut into four pieces, and placed in a clean 50 ml centrifuge tube. 3 ml of SLX-Mlus buffer and 500 mg glass beads X were added. Vortexed at for 10 min. 1 mL of DS buffer was added and incubated at 70 °C for 10 min. 1 ml of P2 buffer was added and vortexed for 30 s. Kept on ice for 5 min. Centrifuged at 4000×g for 10 min at room temperature. Transferred the cleared supernatant to a new 50 ml centrifuge tube. Added 0.7 volumes of isopropanol and mixed thoroughly. Again, centrifuged at 4000×g for 10 min at room temperature. The supernatant was discarded. To the DNA pellet, 400 μl of elution buffer was added and vortexed to mix thoroughly. Then incubated at 65 °C for 10 min to dissolve the DNA. The sample was transferred to a new 1.5 ml microcentrifuge tube. To that, 100 μl of cHTR Reagent was added and vortexed. Then centrifuged at 14,000×g for 3 min. The supernatant was transferred to a new 1.5 ml microcentrifuge tube and added equal volume XP1 buffer. Vortexed to mix thoroughly. Transferred the entire sample to the HiBind® DNA Mini Column and centrifuged at 10,000×g for 1 min at room temperature. The filtrate was discarded and to the pellet 300 μl of XP1 buffer was added. Centrifuged at 10,000×g for 1 min at room temperature. Discarded the filtrate and transferred the HiBind® DNA Mini Column to a new 2 ml collection tube. Added 750 μl of DNA wash buffer. Centrifuged again at 10,000×g for 1 min. Discarded the filtrate. Centrifuged the empty HiBind® DNA Mini Column for 2 min at maximum speed to dry the column matrix. Transferred the HiBind® DNA Mini Column to a clean 1.5 ml microcentrifuge tube. To that added 50 μl of sterile deionized water directly to the centre of the column membrane. Incubated at 65 °C for 5 min. Centrifuged finally at 10,000×g for 1 min. Stored the DNA at − 20 °C.

Approximately 0.75 mg of gDNA was used for each thermo-pressure subjection (n = 3) [14]. A solar-powered CO2 conversion device, which uses CO2 produced from the aerobic wastewater treatment unit, can provide more sustainable temperature and pressure conditions [2].

The gDNA samples were taken in low-iron content borosilicate glass tubes containing 1.0 ml of Milli-Q water and sealed using rubber plugs. The test tubes were subjected to temperatures of 40, 60, 80, 90, 100, 120 and 150 °C, and pressure was recorded using a data logger (ALMEMO® 2690-8A). The degradation of the gDNA was observed by subjecting the DNA sample through 1 h of gel electrophoresis at 70 V and using a 1.0% agarose. An ultra-violet (UV) transilluminator was used to see the DNA bands.

3 Results

3.1 One-factor-at-a-time (OFAT) optimization of nutritional and physical parameters

3.1.1 Nitrogen source

Each organic and inorganic nitrogen source employed supported bacterial growth and chromium reductase production. However, maximum growth was observed with ammonium chloride (inorganic source) (Additional file 1: Table S1). Ammonium chloride at 1.0% (w/v) plus yeast extract (0.7%, w/v) were most suitable for maximum bacterial growth (Additional file 1: Table S1).

3.1.2 Metal ions

The use of sodium ions enhanced bacterial growth (Additional file 1: Table S1). Whereas the other metal ions (Mg2+ and Ca2+) resulted in reduced bacterial growth. Among different levels of sodium (Na+) employed, 0.3% (w/v) was the most effective [1].

3.1.3 Initial pH

The organism was able to grow in the selected pH range (7.0–11.0), but optimum bacterial growth was restricted to a pH range of 6.0 to 7.0. At pH 6.0 ± 0.1, maximum growth was observed under optimized nutritional conditions (Additional file 1: Table S2).

3.1.4 Heavy metal

Although the organism has shown a high chromate tolerance (1250 ppm) [16], the best growth results in the current bench-scale bioreactor (5 L) level study was observed at 100 ppm (Additional file 1: Table S1).

3.1.5 Temperature

Pseudomonas putida APRRJVITS11 was able to grow and produce chromium reductase in a temperature range of 10–55 °C, with maximum production at an optimum 37 °C. Temperature higher than 40 °C or lower than 37 °C, reduced the bacterial growth (Additional file 1: Table S2).

3.1.6 Incubation time

The bacterial growth and chromium reduction activity were in harmony up to 72 h under optimized nutritional and physical conditions.

3.2 Bench-scale bioreactor optimization

3.2.1 Effect of aeration

The chromium(VI) reduction was analyzed in this portion of the experiment at a fixed agitation speed of 150 rpm and varied aeration rates of 0.5, 1.0 and 1.5 vvm (Additional file 1: Table S3). The chromium(VI) reduction was a little low at an aeration rate of 0.5 vvm (51.3% at 72 h) and that of 1.5 vvm (53.1% at 72 h). The aeration rate of 1.0 vvm showed slightly better results with chromium(VI) reduction of 53.4% at 72 h (Fig. 2).

3.2.2 Effect of agitation at optimized aeration

After optimization of suitable aeration rate (1.0 vvm), agitation speed was optimized (100–200 rpm) for studying its effect on chromium(VI) reduction (Additional file 1: Table S3). The chromium(VI) reduction rate increased with an increase in agitation rate from 150 rpm, which was maximum at 200 rpm within 72 h of incubation. However, a decrease in agitation speed from 150 rpm reduced the efficiency to 53.1% at 72 h incubation (Fig. 3). At an optimized fixed aeration rate of 1.0 vvm and 200 rpm agitation, the efficiency was enhanced to 56.6% at 72 h at bench-scale bioreactor level compared to the conventional flask level optimization (51.9%) demonstrated in the previous work [16].

3.3 Thermo-pressure degradation of DNA

The genomic DNA from Pseudomonas putida strain APRRJVITS11 were found to be degraded at 90 °C and above (5868 Pa gauge of pressure) when exposed for 10 min (Fig. 4).

4 Discussion

Maximum growth was observed with ammonium chloride (inorganic source) (Additional file 1: Table S1). Other organic nitrogen sources showed less bacterial culture growth. Complex nitrogen sources are generally required for enzyme production; however, the requirement of a specific nitrogen source varies from organism to organism [22]. In the present study, ammonium chloride and yeast extract were most suitable for maximum bacterial growth (Additional file 1: Table S1). Yeast extract is shown to be an effective organic nitrogen source for bacterial cell growth stimulus and improved hydrogen production [10]. Singh et al. [34] found 2.0% (w/v) of gelatin (nitrogen source) with 0.5% (w/v) yeast extract most suitable for maximum protease production by Pseudomonas putida SKG-1.

The acidic pH optimum reveals a slightly acidophilic nature of strain Pseudomonas putida APRRJVITS11 [16]. Likewise, Karpouzas and Walker reported Pseudomonas putida (epI and epII) strains were able to grow well in the pH range 5.0–7.0 [19].

In any bioprocess, specific temperature requirement and their regulation are some of the most critical parameters. The bacterial strain was able to grow efficiently at a temperature range of 10–55 °C, with optimum activity at 37 °C, as reported by others working with the Pseudomonas strains [21, 26].

Bacterial growth was in the exponential phase up to 72 h. Our findings are per the results of Nowak et al. [26]. Whereas, Zeng et al. has recorded maximum growth beyond 72 h [37].

The reducing efficiency was compared with the use of fresh media (FM) and was observed that there was around a 40% increase in the efficiency when the optimized modified media (MM) was used. The findings show that optimal agitation of fermenting broth is required for efficient oxygen transport to bacterial cells. A suitable agitation/aeration ratio is required for optimum oxygen delivery to the bacterial cell, as well as to limit the shearing impact by the impeller for optimum growth and chromium(VI) reduction efficiency of this obligate aerobic bacteria.

The genomic DNA from Pseudomonas putida strain APRRJVITS11 exhibited total thermo-pressure degradation of gDNA in water when exposed to 90 °C and 5868 Pa gauge of pressure for 10 min (Fig. 4). No growth was observed for the Pseudomonas putida APRRJVITS11 beyond this temperature and pressure in a solid or broth medium. Thereby proving as an essential condition for sustainable remediation of pathogenic DNA in water sources.

5 Conclusions

The bioreactor level optimization of chromium(VI) reduction efficiency from Pseudomonas putida APRRJVITS11 is being informed by a quick one-factor-at-a-time methodology. Increase in the bacterial growth was evident with optimized nutritional (nitrogen 1%, yeast extract 0.5%, Na+ 0.3%) and physical (pH 7.0, 37 °C, 200 rpm) conditions during 72 h fermentation. Further optimization of aeration (1.0 vvm) and agitation (150 rpm) rates enhanced the chromate reduction by about 40% at 72 h fermentation (Additional file 1). Whole DNA degradation at 90 °C efficiently eliminated ARGs, limiting the harmful effect of chromium-treated isolates. The leather industries should consider adapting the train of operations (Fig. 1) described in this work, to their existing wastewater treatment units.

Furthermore, this is the first attempt at an effective reduction of chromate by Pseudomonas putida strain APRRJVITS11 in an optimized bench-scale bioreactor and successful thermo-pressure elimination of the strain thereby eliminating the health risk caused by ARGs.

Availability of data and materials

Not applicable.

Abbreviations

- AAS:

-

Atomic absorption spectroscopy

- AMR:

-

Antimicrobial resistance

- ARGs:

-

Antibiotic resistant genes

- CFU:

-

Colony forming unit

- DNA:

-

Deoxyribonucleic acid

- DPC:

-

Diphenylcarbazide

- gDNA:

-

Genomic DNA

- LB:

-

Luria–Bertani

- MLB:

-

Modified Luria–Bertani

- OD:

-

Optical density

- OFAT:

-

One-factor-at-a-time

- PID:

-

Proportional–integral–derivative

- rpm:

-

Revolutions per minute

- UV:

-

Ultraviolet

- vvm:

-

Vessel volumes per minute

References

Aina AT (2017) Effect of sodium chloride (NaCl) on the growth of pediococcus acidilactici used for the improvement of nutritional and microbial quality of Tsire: a Nigerian grilled meat product. J Nutr Food Sci 07:1–4. https://doi.org/10.4172/2155-9600.1000614

Chen B, Alto P (2016) Solar powered carbon dioxide (CO2) conversion. US 9528192 B1

Cheng G, Ning J, Ahmed S, Huang J, Ullah R, An B, Hao H, Dai M, Huang L, Wang X, Yuan Z (2019) Selection and dissemination of antimicrobial resistance in agri-food production. Antimicrob Resist Infect Control 8:1–13. https://doi.org/10.1186/s13756-019-0623-2

Conceição D, Jacques R, Bento F, Simonetti A, Selbach P, Camargo F (2007) Redução de cromo hexavalente por bactérias isoladas de solos contaminados com cromo. Ciência Rural 37:1661–1667. https://doi.org/10.1590/S0103-84782007000600024

Dalcin MG, Pirete MM, Lemos DA, Ribeiro EJ, Cardoso VL, De Resende MM (2011) Evaluation of hexavalent chromium removal in a continuous biological filter with the use of central composite design (CCD). J Environ Manag 92:1165–1173. https://doi.org/10.1016/j.jenvman.2010.11.022

Dias RM, Silva JG, Cardoso VL, de Resende MM (2020) Removal and desorption of chromium in synthetic effluent by a mixed culture in a bioreactor with a magnetic field. J Environ Sci (China) 91:151–159. https://doi.org/10.1016/j.jes.2020.01.026

Elahi A, Rehman A (2019) Comparative behavior of two gram positive Cr6+ resistant bacterial strains Bacillus aerius S1 and Brevibacterium iodinum S2 under hexavalent chromium stress. Biotechnol Rep 21:e00307. https://doi.org/10.1016/J.BTRE.2019.E00307

Ge S, Zheng W, Dong X, Zhou M, Zhou J, Ge S (2014) Distributions of soluble hexavalent chromate reductase from Leucobacter sp. G161 with high reducing ability and thermostability. J Pure Appl Microbiol 8:1893–1900

Ghosh A, Dastidar MG, Sreekrishnan TR (2017) Bioremediation of chromium complex dyes and treatment of sludge generated during the process. Int Biodeterior Biodegrad 119:448–460. https://doi.org/10.1016/j.ibiod.2016.08.013

Hakobyan L, Gabrielyan L, Trchounian A (2012) Yeast extract as an effective nitrogen source stimulating cell growth and enhancing hydrogen photoproduction by Rhodobacter sphaeroides strains from mineral springs. Int J Hydrog Energy 37:6519–6526. https://doi.org/10.1016/j.ijhydene.2012.01.077

Hora A, Shetty VK (2015) Partial purification and characterization of chromate reductase of a novel Ochrobactrum sp. strain Cr-B4. Prep Biochem Biotechnol 45:769–784. https://doi.org/10.1080/10826068.2014.952385

Huang H, Wu K, Khan A, Jiang Y, Ling Z, Liu P, Chen Y, Tao X, Li X (2016) A novel Pseudomonas gessardii strain LZ-E simultaneously degrades naphthalene and reduces hexavalent chromium. Bioresour Technol 207:370–378. https://doi.org/10.1016/j.biortech.2016.02.015

Huang XN, Min D, Liu DF, Cheng L, Qian C, Li WW, Yu HQ (2019) Formation mechanism of organo-chromium (III)complexes from bioreduction of chromium (VI)by Aeromonas hydrophila. Environ Int 129:86–94. https://doi.org/10.1016/j.envint.2019.05.016

Islas-Espinoza M, Aydin S, Heras A, Ceron CA, Martínez SG, Vázquez-Chagoyán JC (2018) Sustainable bioremediation of antibacterials, metals and pathogenic DNA in water. J Clean Prod 183:112–120. https://doi.org/10.1016/j.jclepro.2018.02.068

John R, Rajan AP (2021) Effective sequestration of chromium by bacterial biosorption: a review. Prep Biochem Biotechnol 51:738–748. https://doi.org/10.1080/10826068.2020.1861010

John R, Rajan AP (2021) Pseudomonas putida APRRJVITS11 as a potent tool in chromium (VI) removal from effluent wastewater. Prep Biochem Biotechnol. https://doi.org/10.1080/10826068.2021.1922918

Kamarudheen N, Chacko SP, George CA, Chettiparambil Somachandran R, Rao KVB (2020) An ex-situ and in vitro approach towards the bioremediation of carcinogenic hexavalent chromium. Prep Biochem Biotechnol 50:842–848. https://doi.org/10.1080/10826068.2020.1755868

Karni M, Zidon D, Polak P, Zalevsky Z, Shefi O (2013) Thermal degradation of DNA. DNA Cell Biol 32(6):298–301. https://doi.org/10.1089/dna.2013.2056 (Epub 2013 Apr 27 PMID: 23621849)

Karpouzas DG, Walker A (2000) Factors influencing the ability of Pseudomonas putida strains epI and II to degrade the organophosphate ethoprophos. J Appl Microbiol 89:40–48. https://doi.org/10.1046/j.1365-2672.2000.01080.x

Kheiralla ZH, El-Gendy NS, Ahmed HA, Shaltout TH, Hussein MMD (2018) One-factor-at-a-time (OFAT) optimization of hemicellulases production from Fusarium moniliforme in submerged fermentation. Energy Sour Part A Recover Util Environ Eff 40:1877–1885. https://doi.org/10.1080/15567036.2018.1487485

Kondakova T, Cronan JE (2019) Transcriptional regulation of fatty acid cis–trans isomerization in the solvent-tolerant soil bacterium, Pseudomonas putida F1. Environ Microbiol 21:1659–1676. https://doi.org/10.1111/1462-2920.14546

Kumar CG, Takagi H (1999) Microbial alkaline proteases: from a bioindustrial viewpoint. Biotechnol Adv 17:561–594. https://doi.org/10.1016/S0734-9750(99)00027-0

Kumaresan Sarankumar R, Arulprakash A, Devanesan S, Selvi A, AlSalhi MS, Rajasekar A, Ahamed A (2020) Bioreduction of hexavalent chromium by chromium resistant alkalophilic bacteria isolated from tannery effluent. J King Saud Univ Sci 32:1969–1977. https://doi.org/10.1016/j.jksus.2020.02.010

Malaviya P, Singh A (2016) Bioremediation of chromium solutions and chromium containing wastewaters. Crit Rev Microbiol. https://doi.org/10.3109/1040841X.2014.974501

Manikandan M, Gopal J, Kumaran RS, Kannan V, Chun S (2016) Purification and characterization of a highly active chromate reductase from endophytic Bacillus sp. DGV19 of Albizzia lebbeck (L.) Benth. actively involved in phytoremediation of tannery effluent-contaminated sites. Prep Biochem Biotechnol 46:192–199. https://doi.org/10.1080/10826068.2015.1068803

Nowak A, Żur-Pińska J, Piński A, Pacek G, Mrozik A (2021) Adaptation of phenol-degrading Pseudomonas putida KB3 to suboptimal growth condition: a focus on degradative rate, membrane properties and expression of xylE and cfaB genes. Ecotoxicol Environ Saf 221:112431. https://doi.org/10.1016/j.ecoenv.2021.112431

Polti MA, Aparicio JD, Benimeli CS, Amoroso MJ (2014) Simultaneous bioremediation of Cr(VI) and lindane in soil by actinobacteria. Int Biodeterior Biodegrad 88:48–55. https://doi.org/10.1016/j.ibiod.2013.12.004

Rath BP, Das S, Mohapatra PKD, Thatoi H (2014) Optimization of extracellular chromate reductase production by Bacillus amyloliquefaciens (CSB 9) isolated from chromite mine environment. Biocatal Agric Biotechnol 3:35–41. https://doi.org/10.1016/j.bcab.2014.01.004

Saha SP, Mazumdar D (2019) Optimization of process parameter for alpha-amylase produced by Bacillus cereus amy3 using one factor at a time (OFAT) and central composite rotatable (CCRD) design based response surface methodology (RSM). Biocatal Agric Biotechnol 19:101168. https://doi.org/10.1016/j.bcab.2019.101168

Sandana Mala JG, Sujatha D, Rose C (2015) Inducible chromate reductase exhibiting extracellular activity in Bacillus methylotrophicus for chromium bioremediation. Microbiol Res 170:235–241. https://doi.org/10.1016/j.micres.2014.06.001

Santona A, Taviani E, Hoang HM, Fiamma M, Deligios M, Ngo TVQ, Van Le A, Cappuccinelli P, Rubino S, Paglietti B (2018) Emergence of unusual vanA/vanB 2 genotype in a highly mutated vanB 2—vancomycin-resistant hospital-associated E. faecium background in Vietnam. Int J Antimicrob Agents 52:586–592. https://doi.org/10.1016/j.ijantimicag.2018.07.006

Saumya S, Akansha S, Rinaldo J, Jayasri MA, Suthindhiran K (2015) Construction and evaluation of prototype subsurface flow wetland planted with Heliconia angusta for the treatment of synthetic greywater. J Clean Prod 91:235–240. https://doi.org/10.1016/j.jclepro.2014.12.019

Shukla VY, Tipre DR, Dave SR (2014) Optimization of chromium(VI) detoxification by pseudomonas aeruginosa and its application for treatment of industrial waste and contaminated soil. Bioremediat J 18:128–135. https://doi.org/10.1080/10889868.2013.834872

Singh SK, Singh SK, Tripathi VR, Khare SK, Garg SK (2011) Comparative one-factor-at-a-time, response surface (statistical) and bench-scale bioreactor level optimization of thermoalkaline protease production from a psychrotrophic Pseudomonas putida SKG-1 isolate. Microb Cell Fact 10:1–13. https://doi.org/10.1186/1475-2859-10-114

Tao F, Wang Y, Zhao Z, Liu X, Zhang G, Li C, Wang Z, Huo Q (2020) Effective removal of Cr(VI) in aqueous solutions using Caulis lonicerae residue fermented by Phanerochaete chrysosporium. Prep Biochem Biotechnol. https://doi.org/10.1080/10826068.2020.1805623

Vishwanatha KS, Rao AGA, Singh SA (2010) Acid protease production by solid-state fermentation using Aspergillus oryzae MTCC 5341: optimization of process parameters. J Ind Microbiol Biotechnol 37:129–138. https://doi.org/10.1007/s10295-009-0654-4

Zeng R, Zhang R, Zhao J, Lin N (2003) Cold-active serine alkaline protease from the psychrophilic bacterium Pseudomonas strain DY-A: enzyme purification and characterization. Extremophiles 7:335–337. https://doi.org/10.1007/s00792-003-0323-x

Zhou L, Zhang Z, Xia S (2016) Characteristics of dissolved organic matters in submerged membrane bioreactor with low-concentration Cr(VI). Desalin Water Treat 57:8927–8934. https://doi.org/10.1080/19443994.2015.1025434

Acknowledgements

The authors are thankful to the management, Vellore Institute of Technology (VIT), Vellore, for providing the essential amenities. The authors would also like to thank the Almighty God for everything.

Funding

This work was supported by the VIT SEED Grant (SEED-2576), provided by the Vellore Institute of Technology (VIT), Vellore.

Author information

Authors and Affiliations

Contributions

RJ conducted methodology, software running, formal analysis, investigation, data curation, original draft preparation, and final paper’s visualization. APR provided resources and conducted validation, reviewing the draft, and supervised the work. Both RJ and APR contributed to the final paper’s visualization. Both the authors read and approved the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

All the authors, declare that they have no financial or non-financial conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1.

Supplementary Table 1. Effect of different nutritional factors on the growth of Pseudomonas putida APRRJVITS11 at pH 7.0, 37°C and 150 rpm during 72 h incubation. Supplementary Table 2. Effect of different physical factors on the growth of Pseudomonas putida APRRJVITS11 in nutritionally optimized media at 150 rpm during 72 h incubation. Supplementary Table 3. Effect of different aeration and agitation on the growth of Pseudomonas putida APRRJVITS11 in nutritionally optimized media at 37˚C and 7.0 pH during 72 h incubation.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

John, R., Rajan, A.P. Bioreactor level optimization of chromium(VI) reduction through Pseudomonas putida APRRJVITS11 and sustainable remediation of pathogenic DNA in water. Beni-Suef Univ J Basic Appl Sci 11, 13 (2022). https://doi.org/10.1186/s43088-021-00183-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s43088-021-00183-y