Abstract

The use of flours or phenolic extracts obtained from non-traditional sources or agri-food industry by-products has been a strategy used to formulate new bakery products with characteristics of a functional food. However, phenolic compounds present great structural diversity, as well as the ability to interact in a complex way with the macromolecules that constitute the bread matrix. Therefore, the addition of these flours, extracts or pure compounds produces various effects on the microstructure of bread, and several of its sensory properties. This is mainly due to interactions between phenolic compounds and gluten proteins. The objective of this review is to analyze some of the most recent published works on the addition of phenolic compounds in wheat bread to identify the type of positive and negative effects that have been observed and how they can be related to the physicochemical interactions between phenolic compounds and the macromolecules that constitute the food matrix, mainly gluten. The effect of monomeric and polymeric phenolic compounds on the strength of these interactions and on the properties of dough and bread are discussed.

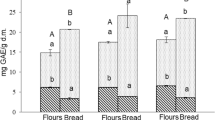

Graphical Abstract

Similar content being viewed by others

Background

Cereals and cereal-based products are among the most abundant components of the human diet, being wheat and rice the most used for human consumption products. Nutritionally, they are an important source of dietary protein, carbohydrates, vitamin B, vitamin E, iron, trace minerals and fibers. Cereals have a wide variety of uses in the food area, being wheat characterized because of its extensive use for the elaboration of a diverse range of bakery products. To date, bread and cereal-based products constitute the base of the food pyramid and it has been estimated that the contribution of wheat to the daily intake is 20 % of the energy and protein recommended in the human diet (Rosell 2011). However, traditionally bread elaboration is carried out with white wheat flour, which is obtained after removing the wheat bran and germ where fiber, phytochemicals and important essential nutrients are usually found. Consequently, the final product contains less dietary fiber and phenolic compounds (Xu et al. 2019). To compensate for this loss of nutrients and other bioactive compounds, it has been sought to elaborate foods enriched with natural antioxidant compounds, such as phenolic compounds, to improve their healthy properties. These foods are known as functional foods, which, when consumed as part of the normal diet, provide biologically active ingredients that confer specific health benefits (McIntosh et al. 1998).

Phenolic compounds are a broad group of phytochemicals generated by plants as secondary metabolites, which are involved in functions such as defense against predators, protection against UV light damage and environmental stress (Martínez-González et al. 2017). These compounds have been used to improve bread antioxidant properties, through the addition of different by-products of plant extracts/flours such as green tea, black tea, grape seeds, quinoa, to name a few (Xu et al. 2019). These compounds have been investigated due to their health benefits to humans, in addition, phenolic compounds can form different types of interactions, such as hydrogen bonds, ionic bonds and hydrophobic interactions, with the components of the food matrix, therefore, it has been sought to optimize the production of phenolic compounds-enriched foods without altering its organoleptic and structural characteristics. For example, the addition of phenolic compounds to a food can help reduce the risk of suffering diseases caused by free radicals, however, its characteristics can be affected, causing a macroscopic change, either in texture, taste, or odor, which can be desirable or undesirable. Because of this, it is important to know the interactions that phenolic compounds have with macromolecules present in the food, in order to prevent or minimize negative effects on the structure of the food, and the sensory acceptance of the product (Dziki et al. 2014). Sensory requirements are an important factor in food quality as they are determinant for the acceptance of the product by the consumer (Peri 2006). Recently, our research group published a review on the interaction of phenolic compounds with dietary fiber obtained from agri-food industrial by-products, and their effect on bakery products (Subiría-Cueto et al. 2021).

The objective of this review was to analyze some of the most recently published works on the addition of phenolic compounds in wheat bakery products to identify the type of positive and negative effects that have been observed and how they can be related to the physicochemical interactions between phenolic compounds and the macromolecules (mainly proteins) that constitute the food matrix.

Classification of phenolic compounds

Phenolic compounds are secondary metabolites synthesized by plants, they are essential for the plant´s biological functions, defense mechanisms against environmental stress, among others (de la Rosa et al. 2019). These compounds are widely distributed in plant foods such as fruits, cereals, and vegetables, in addition, they are especially abundant in non-edible parts of plants that are considered as food by-products (peel, seeds, etc.). The occurrence of phenolic compounds in plants and their by-products, has recently been reviewed (de Camargo et al. 2018; Shahidi et al. 2019). Some examples of products rich in phenolic compounds are grape seed, which possess flavan-3-ols such as catechin, epicatechin, epicatechin gallate, and procyanidins (Manach et al. 2004), strawberries that contain hydroxybenzoic acids and anthocyanins, red wine, which is rich in flavonoids such as anthocyanins, quercetin, kaempferol, catechin and epicatechin (Hasna 2009), blueberry that possesses anthocyanins, quercetin, myricetin, kaempferol and flavan-3-ols (White et al. 2010) and wheat that has phenolic acids such as ferulic acid and glycosylated flavonoids, isoflavones and stilbenes. These compounds are also important due to the organoleptic properties they provide to foods, as discussed by de Camargo and Schwember (2019). For example, anthocyanins are responsible for the red, blue, and violet colors of many fruits such as strawberries, plums, grapes, radishes, among others. Flavanones provide a bitter taste as in the case of olives, proanthocyanidins give astringency to foods as in the case of wine, and simple phenols provide aromas as in the case of eugenol to bananas (Manach et al. 2004).

They have been studied for their health benefits, such as its antioxidant, antiallergic, antiviral, anti-inflammatory and antimutagenic capacity (Peng et al. 2010a, b). However, due to their complexity and structural diversity, these compounds can also present adverse health effects such as interference in protein absorption (Velickovic and Stanic-Vucinic 2018) and, in high amounts, pro-oxidant effect (Vázquez-Flores et al. 2012).

It has been shown that different subgroups within phenolic compounds differ significantly in their stability, bioavailability, and physiological functions related to health benefits (Tsao 2010). One of the ways to classify the subgroups is depending on the number of phenolic rings it contains, as well as the structural elements that link one ring with another (Hasna 2009).

Phenolic compounds are classified into two major groups, flavonoids and non-flavonoids. Flavonoid compounds share a base structure composed of two phenyl rings (A and B) linked through a heterocyclic pyran ring (C) (Fig. 1) (de la Rosa et al. 2019). More than 5,000 different compounds are known from this group alone, which are subdivided into 13 groups (Ou et al. 2019) including anthocyanins, flavonols, flavanones, flavones, chalcones, dihydrochalcones, isoflavones and flavan-3-ols (Barberan and Andrés-Lacueva 2012). While non-flavonoid compounds present the phenolic ring, with at least one hydroxyl group, that may or may not be linked to two to four carbon skeletons, among them are hydroxybenzoic acids, hydroxycinnamic acids, and stilbenes (Vázquez-Flores et al. 2012).

Phenolic compounds also include tannins, which are defined as water-soluble phenolic compounds with a molecular weight between 500 and 3000 D. These compounds present multiple hydroxyl groups in their structure that can form covalent and non-covalent bonds with proteins and other macromolecules (Chung et al. 1998). They can also be also defined as the only group of high molecular weight phenolic metabolites capable of forming strong complexes with carbohydrates and proteins. Tannins are present in many plant foods such as bananas, spinach, grapes, wine, coffee, and cocoa (Wang et al. 2014).

Tannins are divided in hydrolysable and condensed tannins. Hydrolysable tannins are derived from non-flavonoid compounds (mainly gallic and ellagic acids), while condensed tannins are derived from flavan-3-ols. Hydrolysable tannins (mainly gallotanins and ellagitanins) are found in berries, pomegranate, nuts and wine, among other vegetable foods (Shahidi et al. 2019). Condensed tannins also called proanthocyanidins (PAC) are found in different foods and their content varies depending on the part of the plant that is analyzed, being usually more abundant in the skin and seeds of fruits such as grapes and apples, and in the skins of nuts and peanuts (de Camargo et al. 2017; Shahidi et al. 2019). Some of the fruits with the highest content of PAC are wild forest berries, followed by blueberries. Regarding nuts, hazelnuts and pecans have been found to have the highest content of PAC (Vázquez-Flores et al. 2012). PAC are a subclass of polymeric phenolic compounds composed of flavan-3-ol units, mainly catechin and epicatechin. They can bind through A–type bonds, which consist of two bonds: C4 → C8 and O7 → C2, while B-type bonds consist only of one bond in position C4 → C8 (Fig. 2) or C4 → C6 (Kimura et al. 2011). PAC type, polarity and solubility are characteristics that can modify their interaction with proteins and therefore alter their biological activity and their effects when incorporated into foods in the design of new functional foods (Aron and Kennedy 2008). It has been reported that condensed tannins have a great impact over the sensory properties of foods, mainly by increasing their astringent and bitter properties. Astringency refers to the drying sensation in the mouth, due to the interaction between condensed tannins and salivary proteins, which leads to the aggregation and precipitation of the protein-tannin complex, resulting in a loss of mouth lubrication (Versari et al. 2013).

Structure and characteristic of wheat bread

Bread is one of the most common staple foods. The type of flour used for bread production varies around the world, however, in North America it is traditionally baked with white wheat flour, which is obtained by removing fiber and germ fractions from the wheat kernel, together with most of the phenolic compounds found in wheat. Therefore, white bread presents low content of phenolic compounds (150–167 mg/kg in fresh weight) compared to whole wheat bread (1342 mg/kg in fresh weight) (Xu et al. 2019). Due to this characteristic, studies have been developed that add phenolic compounds to bread, to compensate for the loss of fiber and germ and increase the antioxidant activity present in bakery products. However, several authors have found that the addition of these compounds produces relevant changes in the structure and sensory characteristics of bread (Xu et al. 2019, Subiría-Cueto et al. 2021), as will be discussed in the following sections.

Bread making process consists in mixing wheat flour, water, salt, sugar, and yeast. These ingredients are kneaded to form a viscoelastic dough which is then subjected to a leavening process and finally is baked. Each of these steps has unique importance for the final product. In the mixing and kneading of the ingredients, the structure of the dough itself is formed, since the viscoelastic properties are developed by incorporating hydrated gluten proteins and starch, as well as air which, thanks to the structure of the wheat proteins, is retained in the food matrix. In the leavening process, the air integrated in the mixing process expands within the mesh formed by the proteins, thus determining the final volume and texture of the final product, this expansion limit will be closely related to the stability of the dough (Dobraszczyk and Morgenstern 2003). Finally, during baking, the combination of heat, humidity and baking time allows the starch to swell and gelatinize (Goesaert et al. 2005).

The structure of dough and bread depends mainly on proteins, which confer unique viscoelastic properties that give the necessary quality characteristics to the final product; therefore, it is important to identify these proteins and the role that they play within the food matrix. The structural characteristics of a food depend on the physical characteristics of each constituent, and are related to the deformation, disintegration, and flow in response to the application of a force. The understanding of food properties is fundamental for the development of new products and the improvement of processes, these properties are closely related to the physicochemical and functional properties of each ingredient in the food (Rodríguez Sandoval et al. 2005). Structurally, wheat dough is a complex system formed by hydrated proteins, a starch matrix and protein-starch interactions that will influence the rheological properties of the dough (Islas et al. 2005). Food rheology is a branch of physics, which is defined as the study of the deformation and flow of raw materials, intermediate products and finished products in the food industry. Textural and rheological information is important in the design of food transformation processes, in the determination of the functionality of ingredients for product development, quality control of intermediate and final products, evaluations of textural properties related to sensory tests, among others.

The proteins present in wheat flour are albumins, globulins, prolamins (or gliadins) and glutelins, the latter two being the proteins that form gluten when hydrated (Islas et al. 2005). Gluten proteins interact with each other via disulfide bonds, hydrogen bonds and hydrophobic crosslinks, which will be the basis for the formation of the mesh that will allow gas retention in the wheat flour dough (Rodríguez Sandoval et al. 2005). Gluten proteins can also be classified as monomeric and polymeric. Monomeric gluten proteins are gliadins that are associated to the matrix by hydrogen bonds or hydrophobic interactions, while glutelins are polymeric proteins covalently linked to each other by disulfide bonds. Within these two proteins there is a subclassification (Fig. 3). Gliadins are divided into three groups according to their primary structure and the abundance of sulfhydryl groups: ω-gliadins (low sulfhydryl prolamins), γ-gliadins and α/β gliadins (high sulfhydryl prolamins). Glutelins are divided into high molecular weight (HMW) and low molecular weight (LMW) fractions (Tatham et al. 1985).

(adapted from Shewry and Tatham 1997)

Classification of gluten proteins by type of protein and content of sulfhydryl groups.

All gluten fractions are important as they contribute to the rheological properties of the dough, gliadins, due to their monomeric structure, provide viscosity and extensibility, while the glutenins are polymers responsible for the strength and elasticity (Wieser 2007). When the dough is mixed, both proteins hydrate and interact, transforming into a continuous, cohesive, and viscoelastic matrix stabilized mainly by disulfide bridges (Zhang et al. 2010). However, there are factors that can affect gluten structure, such as the distribution of the polymers, the density of covalent and non-covalent bonds, the number of disulfide bridges between proteins, or whether polymers are linear or strongly linked to an individual protein, a complex, or between polymers (Shewry and Tatham 1997).

Another biopolymer that plays an important role in the structure of wheat dough and bread is starch, which makes up about 63 to 72 % of flour and is constituted by amylose and amylopectin (Sivam et al. 2012), which are glucose polymers (Fig. 4). Amylose is a linear molecule which consists of α-(1,4)-linked glucoses with an average degree of polymerization of 500–600 glucose residues, while amylopectin is a branched molecule consisting of α-(1,6) and α-(1,4)-linkages, possessing a degree of polymerization around 3 × 105 − 3 × 106 glucose units (Goesaert et al. 2005). This biopolymer provides fermentable sugars to the yeast present in the bread dough and has a significant impact on rheology, because during baking and cooling of bread, multiple processes take place such as gelation, deformation, fragmentation, disintegration, solubilization and re-aggregation which are generated mainly by the behavior of starch within the matrix (Rosell 2011). Within this matrix, the starch-starch interactions are given by non-covalent bonds such as hydrogen bonds and Van der Waals forces, so its gelation is affected by the presence of other ingredients within the matrix which interfere with its water activity, since, for example, sugar, salt and proteins create a competition for the available water in the matrix, thus affecting its gelatinization (Mohamed and Rayas-Duarte 2003).

In this way, the final structure of the bread will depend on the interaction between three key components: gluten proteins (gliadins and glutenins), starch and water. During kneading, conformational changes occur in the proteins, for example, the formation and breaking of covalent bonds such as disulfide bridges and non-covalent bonds such as hydrogen bonds and hydrophobic interactions. In the baking process, denaturation of wheat proteins takes place, together with starch gelatinization, all due to the release and absorption of water (Rosell 2011). Therefore, the structural characteristics of the dough are determinant for the structural and sensory characteristics of the finished bakery product.

Addition of phenolic compounds to the wheat bread

The addition of phenolic compounds that seek to increase the antioxidant capacity of wheat bread may affect several rheological properties of the dough, such as gumminess, strength, adhesiveness, elasticity, chewiness, among others. Consequently, the sensory properties of the final product are also modified, and several studies have been conducted to understand how phenolic compounds modify the structure of dough and wheat bread (Table 1). Many of these works have analyzed the interactions between wheat proteins and phenolic compounds considering some variables such as the type or source of phenolic compound, its molecular weight, as well as particular characteristics of gluten proteins in certain varieties of wheat flour, while the interaction between phenolic compounds and starch or their effects on the protein-starch interface have not yet been studied.

There are several studies in which the addition of phenolic compounds to different foods has been evaluated to observe how they affect their antioxidant capacity before and after processing, as well as changes in their sensory and texture characteristics. Within these studies, various natural sources of phenolic compounds have been used, studying the differences in the chemical structure of the compounds, and analyzing how these differences uniquely impact the foods in which they are added. Pop et al. (2016) conducted a literature review on the enrichment of wheat bread with extracts from various sources, including green tea (Camellia sinensis), an Indian herb called “Shatavari” (Asparagus racemosus), the spice turmeric (Curcuma longa), pomegranate (Punica granatum) and onion (Allium cepa) peels. In all cases, the addition of extracts increased the antioxidant capacity of the bread (evaluated by in vitro studies), without altering the sensory properties, when maintaining the fortification levels at a maximum of 5 %. When spice extracts were used, the sensory characteristics were even better. On the other hand, the addition of flours obtained from by-products rich in phenolic compounds were able to increase antioxidant capacity and fiber content, although in these cases sensory acceptability decreased (Pop et al. 2016; Subiría-Cueto et al. 2021).

Grape seed extract has been commonly used as a nutraceutical product because it is an abundant source of catechins and proanthocyanidins with antioxidant activity. Peng et al. (2010a, b), conducted a study in which they used a grape seed extract to fortify bread and evaluated the carboxymethyllysine (CML) content in bread during cooking. CML is formed during bread baking, but its presence is undesirable because it has been linked to oxidative stress, atherosclerosis, and diabetes, so a low level of this compound is considered an important quality parameter in bread. The authors added three different concentrations of grape seed extract (300 mg, 600 mg, and 1 g), evaluating the sensory and antioxidant properties. It was observed that the antioxidant activity of the extract of grape seed extract decreased during baking, probably due to induced reactions between PAC with proteins and/or starch or due to thermal degradation of PAC. However, compared to control bread, the antioxidant activity was higher in all treatments and increased in a dose-dependent manner. CML content decreased by 30 and 50 % when 600 mg and 1 g of grape seed extract was used. It was also demonstrated that with appropriate levels of addition, a positive change in bread color could be obtained, without causing significant changes in the sensory properties of the bread. Therefore, it was concluded that the addition of grape seed extract is a viable alternative to reduce CML and the risks associated with its presence.

Liguori et al. (2020), evaluated the effect of the addition of prickly pear (Opuntia ficus-indica) mucilage in wheat bread dough, to observe if it generated any interference with the yeast and to analyze the leavening, sensory and antioxidant capacity using ABTS and FRAP assays. Two types of doughs were evaluated, the control dough which was prepared with wheat flour and water, and the treatment dough to which 150 mL of prickly pear mucilage was added replacing water. It was found that the prickly pear mucilage does not modify the dough development during the leavening process. As to the physical characteristics of the bread, the mucilage positively modified the firmness, obtaining a firmer bread compared to control. No differences were found in the volume of the bread, however, the bread added with mucilage was much lighter and firmer. Likewise, an increase in the antioxidant capacity of the bread was observed, being 1.6 times higher in ABTS assay and 2.3 times in FRAP assay with respect to the control bread, the difference found is interpreted as a synergistic effect between the antioxidant compounds present in the bread with those present in the prickly pear. The sensory properties affected were intensity of the odor, as well as in the color of the crust, however, the results obtained by the sensory panel showed that the substituted bread presented acceptable quality and attributes. These changes are possibly attributed to interactions between antioxidants compounds and mucilage carbohydrates (Liguori et al. 2020).

In another study, the addition of walnut and hazelnut flour, nuts rich in unsaturated fatty acids, proteins, carbohydrates, minerals and vitamins, as well as bioactive compounds such as carotenoids, phenolic compounds and other substances with high antioxidant potential were evaluated (Pycia and Ivanisova 2020). The authors evaluated the effect of enriching wheat bread with walnut and hazelnut flours with 1, 3, 6 and 9 g/100 g substitution on the physicochemical characteristics, texture profile and antioxidant activity of the bread. It was determined that the samples added with walnuts and hazelnuts increased almost twice the average level of minerals, and an increase in protein, fat and fiber content was also observed in the substituted samples compared to the control bread. Regarding the physicochemical characteristics, a decrease in the volume of the loaf was observed. In the case of the sample added with hazelnut a 19 % decrease compared to the control, while the bread added with walnut presented a 25 % reduction. Authors explained these reductions because the replacement of wheat flour by hazelnut and walnut flours reduces the amount of wheat proteins (gluten) which in turn affects gas retention within the matrix reducing thus the volume of the loaf. Regarding the sensory characteristics, the walnut-enriched bread showed a darkening of the loaf color due to the color of the walnut flour. The hazelnut-enriched bread presented greater hardness, due to the higher fiber content of this nut. The walnut-enriched bread presented greater cohesiveness while the hazelnut-enriched bread had greater elasticity and gumminess. Walnut-enriched bread presented a higher total phenolic content and antioxidant activity (analyzed by ABTS assay). Authors concluded that the addition of hazelnut and walnut flours has a statistically significant effect on nutritional value, textural properties, and antioxidant potential, as well as an increase in fiber and fat. This allows consider these nuts as active ingredients for both the nutritional value and the antioxidant activity of the enriched breads.

Purić et al. (2020) analyzed the addition of defatted apple seed flour, which is a by-product of the agri-food industry (mainly juice industry), for the enrichment of wheat bread. Apple seed is a rich source of oils, proteins, and dietary fiber. Therefore, different amounts of defatted apple seed flour were added as a partial substitute for wheat flour, determining its nutritional, textural, antioxidant and sensory value. It was found that samples added with 20 g/100 g defatted apple seed flour had a higher nutritional value mainly due to the high content of insoluble dietary fiber and protein, it also had a high content of total phenolic compounds, antioxidant potential and a lower energy value. However, the sample substituted with 5 % defatted apple seed flour showed better sensorial characteristics. Taking this into account, defatted apple seed flour can be a viable additive for the formulation of enriched bread, which considering that apple seed is a by-product, its use could be a viable alternative to obtain a functional food and give added value to this by-product of the agri-food industry.

There are other studies, in which instead of flours or extracts from natural sources, pure bioactive compounds were added, to analyze the impact of these compounds within the food matrix and provide a better understanding of the interactions that occur in between these compounds and the wheat dough and bread matrix (proteins and carbohydrates). An example of such studies is that of Zhang et al. 2010, who evaluated the effect of tannic acid in dough properties and bread quality. For this purpose, they added different amounts of tannic acid (0.01, 0.02 and 0.03 g/kg) during the kneading process. It was found that the stability and water absorption in the mixing was greater in the case of the dough added with 0.03 g, suggesting the interaction of these compounds with the proteins during gluten formation. At this concentration, strength and extensibility were increased, resulting in a stronger and more elastic dough. The addition of tannic acid had a directly proportional effect with loaf volume, increasing as the tannic acid concentration increased, while hardness decreased with increasing tannic acid content. The authors explained this behavior of tannic acid because it is an antioxidant that reacts with the disulfide bonds present in the gluten network and converts them into free sulfhydryl groups, which affects the rheological properties of gluten, since when tannic acid is added, the amino groups are reduced and new bonds are created between amino and carboxyl groups, suggesting that although the disulfide bonds are essential for the gluten formation, there may be other compounds that, through covalent bonds or hydrogen bridges, could help reduce the rheological impact.

Han and Bong-Kyung (2011) studied the effect of phenolic acids, such as caffeic, ferulic, syringic and gallic on dough properties. It was found that the addition of phenolic acids decreased mixing time, mixing tolerance and resistance to dough extension, affecting the quality of bread. These authors suggested that the addition of phenolic acids alter gluten proteins, because, during bread making, proteins are restructured while phenolic acids reduce high molecular weight proteins and increase the amount extractable proteins, modifying the rheological properties of the dough. Authors proposed that the mechanism of interaction between phenolic acids and wheat dough is that phenolic acids interact with the free radicals formed in gluten proteins during kneading.

Wang et al. (2014) evaluated how tannins affect the mixing properties of wheat dough, as well as the changes in the physicochemical properties and structural properties of gluten. Authors evaluated the effect of three commercial tannin concentrations (0.1 %, 0.2 and 0.3 % w/w) added to the dough. Total phenolic content, mixograph analysis, sulfhydryl content, hydrophobic surface, and Fourier-transform infrared (FTIR) spectra were determined for the study. It was observed that the addition of 0.3 % tannins improved mixing properties by promoting tolerance to overmixing, which indicated that tannins promoted the polymerization of gluten proteins, modifying their microstructure and increasing dough strength. They also found that dough added with tannins presented a reduction of disulfide bridges and an increase in the content of free sulfhydryl groups. Authors also observed that the addition of tannins increased gluten β-turn and α-helix conformation, while the β-sheet conformation decreased. Despite this, there was no decrease in the dough quality, which can be explained considering that this modification in disulfide bonds contributes to a decrease in beta-sheets within the secondary structure of proteins. While in the hydrophobic surface, no significant changes were observed between treatments. However, in the protein analysis it was observed that as the tannin concentration increased, there was an increase in larger polymers protein units, while smaller oligomeric peptides decreased, which indicates that tannins induce aggregation or polymerizing the gluten proteins that compensate the decrease in disulfide bonds, preventing the loss of the microstructure of the matrix.

Condensed tannins are polymeric phenolic compounds formed by flavan-3-ols, which can have various degrees of polymerization in their structure, so they could present very variable effects when integrated into the bread matrix. In 2016, Girard et al. conducted a study in which the effect of the molecular weight of condensed tannins on the wheat dough rheology was evaluated. For this, they used sorghum and grape seed PAC with different degree of polymerization. In the case of sorghum which contained 158 mg PAC/g extract with 93 % polymer PAC, and increase in gluten elasticity and strength was demonstrated in contrast to grape PAC, which contained 577 mg PAC/g extract with 45 % polymeric PAC. It was concluded in this study that high molecular weight PAC could be used as a natural gluten strengthener, since the higher the molecular weight of the PAC, the greater the strength of the gluten, which in practical terms could help to stabilize gluten films or help for volume enhancement of wheat-free baked goods.

The effect of phenolic compounds on the properties of dough has been explained in terms of the non-covalent phenolic-gluten interactions. The main reported interactions are hydrogen bonds and hydrophobic interactions (Tolve et al. 2021). In the case of monomeric phenolic compounds, these interactions normally reduce the strength of the dough, reducing the mixing time and improving its flexibility (Girard et al. 2018). Condensed tannins have shown greater binding interactions with proteins than hydrolysable tannins, mainly because of their structural differences. While condensed tannins show elongated and flexible structure, hydrolysable tannins present a globular and dense conformation which limits protein interactions (Girard & Awika, 2020). Consequently, condensed tannins increase gluten strength and viscosity to a greater extent compared to hydrolysable tannins.

Potential applications of the interaction between phenolic compounds and gluten

Beyond the improvement of the antioxidant capacity and health beneficial properties of bakery products, the interaction of phenolic compounds with gluten could have different applications, including the development of films for various uses such as packaging or biodegradable and edible coatings. Such films may have suitable viscoelastic and hydration properties, in addition to being transparent, flexible, colorless, and odorless. Hager et al. (2012) evaluated the influence of gallic and tannic acid on the properties of gluten films. The addition of tannic acid produced stiffer and thicker films, less resilient and flexible, with lower vapor permeability and a reddish-brown color, while gallic acid had no effect on visual appearance or thickness and the films were more elastic. This may be due to the fact that gallic acid is smaller and can generate fewer interactions with gluten than those of tannic acid which, by forming a larger number of bonds with gluten, generates an increase in film strength, which is linked to a decrease in flexibility.

Girard et al. (2018) conducted another study, in which they compared the effects of hydrolysable and condensed tannins on the strength and stability properties of gluten films and dough. For this, they used sorghum PAC, tannic acid and catechin as monomeric control. Sorghum polymeric PAC increased the strength of the films and their resistance to degradation by proteases, it also reduced their water solubility, whereas tannic acid and catechin had no significant effect on these properties of gluten films. PAC were also better than tannic acid and catechin in improving dough stability and increasing the viscosity of dough subjected to heating/cooling cycles. These differences were attributed to the polymeric and elongated structure of PAC, which presents a greater flexibility to form multiple crosslinks with gluten, interacting mostly with gliadins through hydrophobic interactions, whereas tannic acid presents a more compact structure complicating its interaction with gluten proteins.

Conclusions

The formulation of wheat breads partially substituted with food by-products, flours, or extracts rich in phenolic compounds has shown to be a successful strategy to improve the antioxidant and health properties of bread while satisfactory modifying certain sensory characteristics, including texture, color, odor and flavor, without losing product acceptability. Sensory modifications related to texture are largely due to the interactions of phenolic compounds or other antioxidants present in extracts/ flours, with gluten proteins, mainly due the ability of these antioxidants to reduce the disulfide bonds that are an essential part of the gluten matrix. However, the structure of the phenolic compounds themselves, mainly their degree of polymerization, is decisive for the final effects that their addition will have on the gluten matrix: oligomeric and polymeric compounds such as tannins, and especially condensed tannins or PAC, and to a lesser extent tannic acid (example of a hydrolysable tannin), can compensate with covalent or noncovalent crosslinks the loss of disulfide bonds, so their effects on the gluten matrix tend to be stabilizing and thus the effect on final product can be favorable. However, low molecular weight phenolic compounds, such as phenolic acids, have the effect of weakening the gluten matrix and thus the structure of the baked product. However, it is still necessary to study how phenolic compounds interact with other components of the bread matrix such as starch, or how they affect the starch-gluten-water interactions. It is also important to analyze the effect of phenolic compounds on other parts of the bread production process, including fermentation, leavening and baking, to understand more comprehensively the effects on the sensory properties of the final product.

Availability of data and materials

Not applicable.

References

Aron, P. M., & Kennedy, J. A. (2008). Flavan-3-ols: Nature, occurrence and biological activity. Molecular Nutrition and Food Research, 52(1), 79–104. https://doi.org/10.1002/mnfr.200700137

Barberan, T. F., & Andrés-Lacueva, C. (2012). Polyphenols and Health: Current state and progress. Journal of Agricultural and Food Chemistry, 60(36), 8773–8775. https://doi.org/10.1021/jf300671j

Chung, K-T., Wong, T. Y., Wei, C-I., Huang, Y. W., & Lin, Y. (1998). Tannins and human health: A review. Critical Reviews in Food Science and Nutrition, 38(6), 421–464. https://doi.org/10.1080/10408699891274273

de Camargo, A. C., Regitano-d’Arce, M. A. B., Rasera, G. B., Canniatti-Brazaca, S. G., do Prado-Silva, L., Ortiz Alvarenga, V. … Shahidi, F. (2017). Phenolic acids and flavonoids of peanut by-products: Antioxidant capacity and antimicrobial effects. Food Chemistry, 237, 538–544. https://doi.org/10.1016/j.foodchem.2017.05.046

de Camargo, A. C., Schwember, A. R., Parada, R., Garcia, S., Maróstica Júnior, M. R., Franchin, M. … Shahidi, F. (2018). Opinion on the Hurdles and Potential Health Benefits in Value-Added Use of Plant Food Processing By-Products as Sources of Phenolic Compounds. International Journal of Molecular Science, 19(11), 3498. https://doi.org/10.3390/ijms19113498

de Camargo, A. C., & Schwember, A. R. (2019). Phenolic-driven sensory changes in functional foods. Journal of Food Bioactives, 5, 6–7. https://doi.org/10.31665/JFB.2019.5173

De la Rosa, L. A., Moreno-Escamilla, J. O., Rodrigo-García, J., & Alvarez-Parrilla, E. (2019). Chapter 12. Phenolic Compounds. In Yahia, E. M. (Ed.), Postharvest Physiology and Biochemistry of Fruits and Vegetables (pp. 253–271). DOI: San Francisco. Woodhead Publishing. https://doi.org/10.1016/B978-0-12-813278-4.00012-9.

Dobraszczyk, B. J., & Morgenstern, M. P. (2003). Rheology and the breadmaking process. Journal of Cereal Science, 38(3), 229–245. https://doi.org/10.1016/S0733-5210(03)00059-6

Dziki, D., Rozylo, R., Gawlik-Dziki, U., & Swieca, M. (2014). Current trends in enhancement of antioxidant activity of wheat bread by the addition of plant materials rich in phenolic compounds. Trends in Food Science & Technology, 40(1), 48–61. https://doi.org/10.1016/j.tifs.2014.07.010

Girard, A. L., Castell-Perez, E., Bean, S. R., Adrianos, S. L., & Awika, J. M. (2016). Effect of condensed tannin profile on wheat flour dough. Journal of Agricultural and Food Chemistry, 64(39), 7348–7356. https://doi.org/10.1021/acs.jafc.6b02601

Girard, A. L., Teferra, T., & Awika, J. M. (2018). Effects of condensed vs hydrolysable tannins on gluten film strength and stability. Food Hydrocolloids, 89, 34–43. https://doi.org/10.1016/j.foodhyd.2018.10.018

Girard, A. L., & Awica, J. M. (2020). Effects of edible plant polyphenols on gluten protein functionality and potential applications of polyphenol–gluten interactions. Comprehensive Reviews in Food Science and Food Safety, 19, 2164–2199. https://doi.org/10.1111/1541-4337.12572

Goesaert, H., Brijis, K., Veraverbeke, W. S., Courtin, C. M., Gebruers, K., & Delcour, J. A. (2005). Wheat flour constituents: how they impact bread quality, and how to impact their functionality. Trends in Food Science and Technology, 16(1–3), 12–30. https://doi.org/10.1016/j.tifs.2004.02.011

Hager, A. S., Vallons, K. J. R., & Arent, E. K. (2012). Influence of acid gallic and tannic acid on the mechanical and barrier properties of wheat gluten films. Journal of Agricultural and Food Chemistry, 60, 6157–6163. https://doi.org/10.1021/jf300983

Han, H. M., & Bong-Kyung, K. (2011). Effect of phenolic acids on the rheological properties and proteins of hard wheat flour dough and bread. Journal of the Science of Food and Agriculture, 91(13), 2495–2499. https://doi.org/10.1002/jsfa.4499

Hasna, E. G. (2009). Polyphenols: food sources, properties and applications –a review. International Journal of Food Science & Technology, 44, 2512–2518

Islas, R. A., Finlay, M., Somayajulu, G., & Hou, G. (2005). Relationship of protein composition and dough rheological measurements with breadmaking performance of wheat flours (Relationship of protein composition and dough rheological measurements with breadmaking performance of wheat flours). Revista Fitotecnia, 28(3), 243–251

Kimura, H., Ogawa, S., Akihiro, T., & Yokota, K. (2011). Structural analysis of A-type or B-type highly polymeric proanthocyanidins by thiolytic degradation and the implication in their inhibitory effects on pancreatic lipase. Journal of Chromatography A, 1218(42), 7704–7712. https://doi.org/10.1016/j.chroma.2011.07.024

Liguori, G., Gentile, C., Gaglio, R., Perrone, A., Guarcello, R., Francesca, N. … Settanni, L. (2020). Effect of addition of Opuntia ficus-indica mucilage on the biological leavening, physical, nutritional, antioxidant and sensory aspects of bread. Journal of Bioscience and Bioengineering, 129(2), 184–191. https://doi.org/10.1016/j.jbiosc.2019.08.009

Manach, C., Scalbert, A., Morand, C., Remesy, C., & Jimenez, L. (2004). Polyhenols: food sources and bioavailability. American Journal of Clinical Nutrition, 79, 727–747. https://doi.org/10.1093/ajcn/79.5.727

Martínez-González, A. I., Díaz- Sanchez, A. G., de la Rosa, L. A., Vargas-Requena, C. L., Bustos-Jaimes, I., & Alvarez-Parrilla, E. (2017). Polyphenolic Compounds and Digestive Enzymes: In Vitro Non-Covalent Interactions. Molecules, 22, 669. https://doi.org/10.3390/molecules22040669

McIntosh, G. H., Royle, P. J., Leu, R. K., Regester, G. O., Johnson, M. A., Grinsted, R. L. … Smithers, G. W. (1998). Whey proteins as functional food ingredients. International Dairy Journal, 8, 425–434

Mohamed, A. A., & Rayas-Duarte, P. (2003). The effect of mixing and wheat protein/gluten on the gelatinization of wheat starch. Food Chemistry, 81, 533–545

Ou, J., Wang, M., Zheng, J., & Ou, S. (2019). Positive and negative effects of polyphenol incorporation in baked foods. Food Chemistry, 284, 90–99. https://doi.org/10.1016/j.foodchem.2019.01.096

Pamisetty, A., Ashwath, K. K., Indrani, D., & Singh, R. P. (2020). Rheological, physic-sensory and antioxidant properties of punicic acid rich wheat bread. Journal of Food Science and Technology, 57, 253–262. https://doi.org/10.1007/s13197-019-04055-3

Peng, X., Ma, J., Cheng, K. W., Jiang, Y., Chen, F., & Wang, M. (2010a). The effect of grape seed extract fortification on the antioxidant activity and quality attributes of bread. Food Chemistry, 119, 49–53. https://doi.org/10.1016/j.foodchem.2009.05.083

Peng, X., Jinyu, M., Ka-Wing, C., Yue, J., Feng, C., & Mingfu, W. (2010b). The effects of grape seed extract fortification on the antioxidant activity and quality attributes of bread. Food Chemistry, 119(1), 49–53. DOI: https://doi.org/10.1016/j.foodchem.2009.05.083

Peri, C. (2006). The universe of food quality. Food Quality and Preferences, 17(1–2), 3–8. https://doi.org/10.1016/j.foodqual.2005.03.002

Pop, A. M., Petrut, G., Muste, S., Paucean, A., Muresan, C., Salanta, L., & Man, S. (2016). Addition of plant materials rich in phenolic compounds in wheat bread in terms of functional food aspects. Hop and Medicinal Plants. 1–2

Purić, M., Rabrenović, B., Rac, V., Pezo, L., Tomasević, I., & Demin, M. (2020). Application of defeated apple seed cakes as by-product for the enrichment of wheat bread. LWT-Food Science and Technology, 130, 109391. https://doi.org/10.1016/j.lwt.2020.109391

Pycia, K., & Ivanisova, E. (2020). Physicochemical and antioxidant properties of wheat bread enriched with hazelnuts and walnuts. Foods, 9(8), 1081. https://doi.org/10.3390/foods9081081

Rodríguez Sandoval, E., Fernández Quintero, A., & Ayala Aponte, A. (2005). Reología y textura de masas: aplicaciones en trigo y maíz (Rheology and texture of doughs: applications on wheat and corn). Revista Ingeniería e Investigación, 25(1), 72–78

Rosell, C. M. (2011). The Science of Doughs and Bread Quality. Flour and Breads and Their Fortification in Health and Disease Prevention, 3–14. https://doi.org/10.1016/b978-0-12-380886-8.10001-7

Shahidi, F., Varatharajan, V., Oh, W. Y., & Peng, H. (2019). Phenolic compounds in agri-food by-products, their bioavailability and health effects. Journal of Food Bioactives, 5, 57–119. https://doi.org/10.31665/JFB.2019.5178

Shewry, P. R., & Tatham, A. S. (1997). Disulphide bonds in wheat gluten proteins. Journal of Cereal Science, 25(3), 207–227. https://doi.org/10.1006/jcrs.1996.0100

Sivam, A. S., Sun-Waterhouse, D., Perera, C. O., & Waterhouse, G. I. N. (2012). Exploring the interactions between blackcurrant polyphenols, pectin and wheat biopolymers in model breads; a FTIR and HPLC investigation. Food Chemistry, 131, 802–810. https://doi.org/10.1016/j.foodchem.2011.09.047

Subiría-Cueto, R., Coria-Oliveros, A. J., Wall-Medrano, A., Rodrigo-García, J., González-Aguilar, G., Martínez-Ruiz, N., & Álvarez-Parrilla, E. (2021). Antioxidant dietary fiber-based bakery products: a new alternative for using plant-by-products. Food Science and Technology (Campinas). https://doi.org/10.1590/fst.57520

Swieca, M., Gawlik-Dziki, U., Seczyk, L., Dziki, D., & Sikora, M. (2018). Interactions of green coffee bean phenolics with wheat bread matrix in a model of simulated in vitro digestion. Food Chemistry, 258, 301–307. https://doi.org/10.1016/j.foodchem.2018.03.081

Tatham, A. S., Miflin, B. J., & Shewry, P. R. (1985). The beta-turn conformation in wheat gluten proteins: relationship to gluten elasticity. Cereal Chemistry, 62, 405–412

Tolve, R., Simonato, B., Rainero, G., Bianchi, F., Rizzi, C., Cervini, M., & Guiberti, G. (2021). Wheat Bread Fortification by Grape Pomace Powder: Nutritional, Technological, Antioxidant, and Sensory Properties. Foods. 10, 75. https://doi.org/10.3390/foods10010075

Tsao, R. (2010). Chemistry and biochemistry of dietary polyphenols. Nutrients, 2, 1231–1246. https://doi.org/10.3390/nu2121231

Vázquez-Flores, A. A., Alvarez-Parrilla, E., López-Diaz, J. A., Wall-Medrano, A., & de la Rosa, L. A. (2012). Taninos hidrolizables y condensados: naturaleza química, ventajas y desventajas de su consumo (Hydrolysable and condensed tannins: chemistry, advantages and disadvantages of their intake). Tecnociencia Chihuahua, 6(2), 84–93

Velickovic, T. D. C., & Stanic-Vucinic, D. J. (2018). The Role of Dietary Phenolic Compounds in Protein Digestion and Processing Technologies to Improve Their Antinutritive Properties. Comprehensive Reviews in Food Science and Food Safety, 17(1), 82–103. https://doi.org/10.1111/1541-4337.12320

Versari, A., Toit, W., & Parpinello, G. P. (2013). Oenological tannins: a review. Australian Journal of Grape and Wine Research, 19, 1–10. https://doi.org/10.1111/ajgw.12002

Wang, Q., Yin, L., Fusheng, S., Xiaoyan, L., Wang, P., Jiutong, S. … Guangyuan, H. (2014). Tannins improve mixing properties through affecting physicochemical and structural properties of wheat gluten proteins. Food Research International, 69, 64–71. https://doi.org/10.1016/j.foodres.2014.12.012

White, B., Howard, L. R., & Prior, R. L. (2010). Proximate and polyphenolic characterization of cranberry pomace. Journal of Agricultural and Food Chemistry. 58, 4030–4036. https://doi.org/10.1021/jf902829g

Wieser, H. (2007). Chemistry of gluten proteins. Food Microbiology, 24(2), 115–119. https://doi.org/10.1016/j.fm.2006.07.004

Xu, J., Wang, W., & Li, Y. (2019). Dough properties, bread quality, and associated interactions with added phenolic compounds: A review. Journal of Functional Foods, 52, 629–639. https://doi.org/10.1016/j.jff.2018.11.052

Zhang, L., Cheng, L., Jiang, L., Wang, Y., Yang, G., & He, G. (2010). Effects of tannic acid on gluten protein structure, dough properties and bread quality of Chinese wheat. Journal of the Science of Food and Agriculture, 90(14), 2462–2468. https://doi.org/10.1002/jsfa.4107

Acknowledgements

Not applicable.

Funding

This review was written as part of the project “Specific and non-specific interactions between proteins and proanthocyanidins” funded by Mexico´s National Council of Science and Technology (CONACYT, SEP CB 2016–286449).

Y.A.C.-G. is a recipient of a CONACYT scholarship for graduate studies.

Author information

Authors and Affiliations

Contributions

YAC–G has written the first draft of the manuscript and substantively revised it. NRM–R, AAV–F and MG–M have made substantial contributions to the conception of the work. EA–P and LAD have made substantial contributions to the conception of the work and substantively revised the manuscript. All authors have revised and approved the submitted version of the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interest

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Czajkowska–González, Y.A., Alvarez–Parrilla, E., del Rocío Martínez–Ruiz, N. et al. Addition of phenolic compounds to bread: antioxidant benefits and impact on food structure and sensory characteristics. Food Prod Process and Nutr 3, 25 (2021). https://doi.org/10.1186/s43014-021-00068-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s43014-021-00068-8