Abstract

Biomass of algae is a very potent adsorbent for absorbing aqueous waste containing heavy metals and organic dyes. This study purposes to confirm the ability of adsorbents from green algae Nannochloropsis sp. modified with silica (ASN) and followed by coating magnetite particles (ASN-MPs) to absorb simultaneously the mixture of Methylene Blue (ME) and Cu(II) cations in aqueous solution. Simultaneous sorption of ME and Cu(II) cations to ASN and ASN-MPs was carried out by the batch method with the interaction pH condition 7, contact time 90 min, and initial concentrations of ME and Cu(II) cations (0.1–1.0 mM). Based on adsorption data, Cu(II) cations have a greater adsorption rate and capacity (qm) compared to ME at the same contact time and initial concentration. The adsorption capacity (qm) values of the bi-component ME and Cu(II) cation mixture in ASN and ASN-MPs were 1.39 × 10− 1 and 5.32 × 10− 1 mmol g− 1, respectively, with the binary Langmuir adsorption isotherm constant for Cu(II) cations greater than ME. Modified adsorbent from algae Nannochloropsis sp. with silica matrix and magnetite particle coating is an adsorbent that has a high effectiveness in the collective sorption of ME and Cu(II) cations. Therefore, these adsorbents can be used for the adsorption of cation mixtures of heavy metals and organic dyes that are cationic in solution.

Similar content being viewed by others

Introduction

Organic dyes and heavy metals are sources of pollutants that are often found in the environment, especially in waters. Heavy metals and dyes are produced from by-products or various industrial wastes such as textiles and petrochemicals. Heavy metals such as Cu exposed to the environment can come from electroplating plants, mining, industrial, and municipal wastes [1] while organic dyes such as Methylene Blue (ME) are applied considerably as agents of dyes in varied industry such as the pharmaceutical, leather, paper and textile industries [2]. Because of this, the presence of these toxic chemicals needs to be reduced from the environment so that they do not have a negative impact on human health and the surrounding environment.

At present, several methods have been developed to reduce pollution from aqueous waste in the form of physicochemical technology including ion exchange, coagulation, flocculation, chemical oxidation, electrochemical techniques, membrane separation, adsorption, and photocatalysis which have been applied for the purpose of removing dyes and metal ions from wastewater [3,4,5,6]. From some of these technologies, the adsorption method is more often used for the treatment of aqueous waste containing heavy metals or hazardous dyes. This is done with the consideration that the process of adsorption method is easy, the cost applied is not expensive, and it is safe for the environment [7]. Sorption processes typically use adsorbents derived from the synthesis or modified natural material.

Currently, various adsorbents have been developed from natural materials for waste treatment before being discharged into the environment, such as algal biomass. Biomass from algae is originally a very potent adsorbent to absorb pollutants of inorganic materials like heavy metals [8,9,10] and organic materials originated from toxic dye agents [11, 12]. Algal biomass has a great potential to bind dyes, especially organic dyes in the form of cations as well as metal ions. Several studies have shown that live algae and its biomass may absorb organic cations and metal ions [13, 14]. Adsorption of metal ions and dyes on algal biomass occurs through reaction mechanisms involving the contribution of active groups of proteins, polysaccharides, and functional groups like hydroxyl, amino, sulfate ions, carboxyl, etc. [15].

However, the ability of algae to bind these chemical compounds is very limited by several constraints such as small size, low density and easily damaged due to degradation by other microorganisms [16]. In addition, algae cannot be used directly in the adsorption column, because it is very soft and is not granular [6]. To increase the capacity and rate of algal adsorption on adsorbents as well as physical and chemical stability, various attempts were made including modifying algal biomass using various supporting matrix in the form of inorganic and organic materials [2, 15]. Materials produced from inorganic-organic hybrids, such as algal-silica hybrids, are promising substances for poisonous dye and heavy metal ion adsorbents [17, 18].

The physical and chemical quality of adsorbents derived from algae was able to be performed by employing the sol-gel process in making adsorbents with silica support matrices, because these processes produce homogeneous adsorbents [19]. In addition, a rising in the sorption rate of the adsorbate was able to be carried out using magnetite particle coating techniques [20]. The adsorbent coating technique by particles of magnetite is safe for environment, since it does not produce side products that conceive contamination like suspended solids, besides that it also accelerates the process of isolating the adsorbate from the solution caused by the magnetic properties of the adsorbent [21]. By using the adsorbent coating technique using magnetite particles, we obtain an adsorbent with a high adsorption rate and capacity to the adsorbate, so that the adsorption process becomes more efficient.

In a waste treatment system, multicomponent mixtures are often found, namely the presence of various types of chemical compounds both inorganic and organic compounds, therefore it is necessary to develop an adsorbent that is not only effective at absorbing heavy metals, but also effective against other compounds such as dyes contained in the mixture from ME. Therefore, the purpose of this work is to learn the competition for sorption of a mixture of ME and Cu(II) cations in solution on modified Nannochloropsis sp. (algae-silica-magnetite). The adsorbents used in this study have complex chemical and biological compositions, so it is very interesting to study from a theoretical and experimental point of view in their application as a material for absorbing dyes and metal ions in solution. Biomass from Nannochloropsis sp. algae has been modified with silica followed by coating with magnetite (Fe3O4) particles utilized as an effective and cheaper adsorbent to separate ME and Cu(II) cations simultaneously from the solution. The adsorption competition between ME and Cu(II) cations in biomass modified with silica followed by coating magnetite particles (ASN-MP) adsorbents was studied with a series of batch experiments including: variations in contact time, initial concentration, sequential desorption, and re-use of adsorbent tests. Simultaneous adsorption kinetics and isotherm parameters as well as their mechanism are evaluated to predict the sorption properties of ME and Cu(II) cations by ASN-MPs.

Materials and methods

Materials

The used materials in this work include Nannochloropsis sp. algae originating from Balai Besar Budidaya Laut Lampung (the Lampung Sea Cultivation Bureau), Republic of Indonesia. The used chemicals were obtained from European Pharmacopoeia consisting of: tetraethyl orthosilicate (TEOS), FeSO4·4H2O, FeCl3·6H2O, HCl, NaOH, ethanol, ME, CuSO4·5H2O, and Na2EDTA. Magnetite particles were synthesized according to the procedure by Buhani et al. [6]. Stocks of ME dye and CuSO4·5H2O solutions were each prepared with a concentration of 1000 mM which was used as standard solution and adsorbate. All the experiments in this study used double distilled water.

Preparation of adsorbent and materials: Nannochloropsis sp., ASN, and ASN-MPs

Nannochloropsis sp. algae were neutralized (up to neutral pH) by rinsing with water, then dried for 3 d with air dry. The algae biomass was then placed at 40 °C for 2–3 h then crushed using a 100 mesh (0.149 mm) grinder. The Nannochloropsis sp. algae biomass was used to make ASN-MPs adsorbents in the following way: a total of 5.0 mL of TEOS and 2.5 mL of deionized water was mixed into a plastic bottle, then added 0.1 g magnetite. The mixture was stirred for 30 min using a magnetic stirrer. When stirring, the pH of the solution was made to be pH of 2 with the addition of 1 M HCl by dropwise. In another bottle, Nannochloropsis sp. biomass (0.4 g) and ethanol (5 mL) were mixed by a magnetic stirrer for 30 min. Then, the two solutions were mixed while stirring until the mixture turns into a gel. The formed gel was filtered with filter paper and allowed for 24 h. The gel was afterward rinsed using deionized water and ethanol with a ratio of 60/40 to pH ≈ 7. Furthermore, the gel was placed in the oven at 40 °C for 2–3 h and crushed using a grinder until smooth with a size of 100 mesh.

Characterization of ASN and ASN-MPs adsorbent

The ASN adsorbents and ASN-MPs were investigated by Fourier-transform infrared spectroscopy (FTIR) to recognize specific functional groups (Shimadzu Prestige-21 IR, Japan). The adsorbent crystallinity level was analyzed by X-Ray Diffraction (XRD, Shimadzu 6000, Japan). The distribution of particle size from material was also investigated by the particle size analyzer (Fritsch Analysette 22). Surface morphological analysis and element constituents were performed using Scanning Electron Microscopy with Energy Dispersive X-Ray (SEM-EDX) (Zeiss MA10, Germany).

Adsorption experiments

The experiments to study the adsorption competition ME and Cu(II) cations were carried out under the following adsorption conditions: a dose of 0.1 g adsorbent was used in a batch system controlled by a shaker (Stuart reciprocating shaker SSL2), the sorption process was held at 27 °C, interaction pH was 7, and an adsorbate volume was 50 mL with the concentration of each adsorbate is of 0.1–1.0 mM. The adsorption kinetics of ME and Cu(II) cations in the mixture were studied with varying contact times between 15 and 120 min. The adsorption rate was determined based on the pseudo first order kinetics, pseudo second order kinetics and the intra-particle diffusion pattern (IPD) to be discussed later. For the simultaneous adsorption experiment, each solution of ME and Cu(II) cation at the similar concentration (between 0.1–1.0 mM) was mixed with the optimum contact time. The simultaneous adsorption isotherm pattern of ME and Cu(II) cation was determined using the Langmuir adsorption isotherm equation, Freundlich, and the Langmuir isotherm equation for a binary mixture. The adsorption experiment was carried out in 3 times of parallel repetitions. UV-Vis spectrophotometer (Agilent Cary 100, U.S.A) was performed to analyze the concentrations of ME at a maximum wavelength of 664 nm. The concentrations of Cu(II) cations were tested with atomic absorption spectrophotometer (AAS) (Perkins Elmer 3110, U.S.A).

The following equations (Eqs. (1), (2), and (3)) were used to determine an amount of adsorbed ME or Cu(II) cations per unit mass of adsorbent and the percentage of adsorbed ME or Cu(II) cations.

Concentrations (mM) of ME or Cu(II) cation solution at initial state, equilibrium, and certain time of t were expressed as Co, Ce, and Ct, respectively. The mass of adsorbent (g), the volume of the solution (L), the amount of ME or Cu(II) cations adsorbed per unit mass (mmol g− 1), and the percentage of the ME or Cu(II) cation adsorption are expressed by m, V, q, and R, respectively.

Sequential desorption

To find out the type of interaction between ASN-MPs adsorbents with ME or Cu(II) cations, a sequential desorption experiment was conducted as follows: 0.1 g of ASN-MPs adsorbents were added to each ME or Cu(II) cation at conditions (pH = 7, T = 27 °C, t = 90 min, volume = 50 mL, and adsorbate concentration 0.1 mM). Adsorbates adsorbed on the AS-MPs adsorbent were sequentially released using several eluents such as aquades, HCl (0.1 M), and Na2EDTA (0.1 M).

Reusability of adsorbent

The ability to reuse adsorbents was studied by performing the adsorption process singly at the optimum condition (adsorbent dosage = 0.1 g, pH = 7, T = 27 °C, t = 90 min, volume = 50 mL, and adsorbate concentration 0.1 mM). The adsorbate adsorbed was eluted by an eluent of 0.1 M HCl (50 mL). Then, the distilled water was used to rinse the adsorbent to reach neutral pH. The adsorption-desorption process was repeated several times, up to % adsorption from ME or Cu(II) cations < 80%.

Results and discussion

Characterization of ASN and ASN-MPs adsorbent

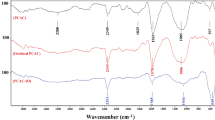

To find out the success of the modification process of Nannochloropsis sp. algae using silica matrix and magnetite particle coating, identification of the adsorbent functional groups was carried out using FTIR. In ASN adsorbents (Fig. 1b) and ASN-MPs (Fig. 1c), there is a relatively similar IR absorption with the appearance of absorption bands at wave numbers around 794.8–784.3 cm− 1 originating from Si-O-Si and 482.9–432.9 cm− 1 of the Si-O stretching vibrations (siloxan groups) derived from silica as a matrix. The contribution of Nannochloropsis sp. algae to ASN and ASN-MPs is indicated by the appearance of absorption bands in the region of wavenumber 2931.8 cm− 1 originating from C-H stretching vibration absorption from (−CH2) aliphatic as shown in Fig. 1a. In addition, absorption bands were seen in wavenumbers 3448.7–3442.7 cm− 1 originating from hydroxyl groups (−OH) and 1658.8–1651.1 cm− 1 (carbonyl groups). This shows that there has been a hybridization between Nannochloropsis sp. and silica matrix. The presence of magnetite particles in ASN and ASN-MPs could not be observed through FTIR spectrum. In addition, the absence of absorption in the area of wavenumber 964.4 cm− 1 indicating the stretching vibration of silanol (Si-OH) on the ASN-MPs adsorbent (Fig. 1c) as shown in the ASN spectrum (Fig. 1b) indicates that there has been an interaction between the silanol groups and the magnetite particles. The presence of magnetite particles in ASN-MPs is strengthened from the results of the EDX spectrum [8].

Figure 2 displays the morphology of ASN (Fig. 2a) showing an agglomeration originating from the amorphous silica matrix and Nannochloropsis sp.; this is supported by elemental constituent data from the analysis of EDX on ASN (Fig. 2c) consisting of Si, O, C, and N. The ASN-MPs adsorbent (Fig. 2b) shows a more contrasting morphology and the presence of granules with smaller size and in the form of agglomerate. This is supported by elemental constituent data obtained in EDX spectra (Fig. 2d) showing the existence of Fe elements of magnetite particles, in addition to other elements (Si, O, C, and N) as found in ASN.

The presence of magnetite particles in the modified Nannochloropsis sp. algae can be observed by comparing the XRD pattern between ASN and ASN-MPs (Fig. 3). The presence of magnetite particles (Fe3O4) in ASN-MPs can be seen from the results of the analysis with XRD (Fig. 3b). The XRD diffraction pattern in ASN-MPs has the most intense appearance at 2θ = 35.6° which corresponds to the diffraction pattern of Fe3O4 particles [6] while it does not appear in ASN (Fig. 3a). The XRD diffraction pattern in ASN-MPs has a broad 2θ and lower intensity compared to Fe3O4, due to the presence of amorphous silica matrix [22] and Nannochloropsis sp. which cause a decrease in the level of material crystallization.

Addition of magnetite particles to ASN (Fig. 4b) results in a decrease in mean and median of particle size in ASN-MPs (Fig. 4c). The mean and median of particles sizes in ASN are 1.5 and 1.6 μm and in ASN-MPs are 1.4 and 1.5 μm, respectively. This shows the decrease in particle size after coating with Fe3O4 particles. In Fig. 4, it can be observed that there is a decrease in volume (%) for large particle size diameters from 12.9% in ASN to 11.7% in AS-MPs and an increase in volume (%) in small particle size from 3.5% in ASN to 4.7% in AS-MPs. These data are in line with the results of observations on the surface morphology of adsorbents with SEM, as previously discussed, that the presence of Fe3O4 particles in ASN-MPs produces material with a relatively smaller particle size [6].

The adsorbent surface charge plays a significant part in determining the optimal interaction between adsorbent and adsorbate, therefore the surface charge of the adsorbent needs to be known in studying the sorption process. The surface charge is determined by the zero point of charge (pHPZC) which is specified as the point when the zeta potential value has value of zero. The positive surface charge is indicated by pH < pHPZC, whereas the negative surface is shown by pH > pHPZC [23]. In current study, the pHPZC of ASN and ASN-MPs is around 7.3 and 7.4, respectively (Fig. 5). Based on the pHPZc values of the two adsorbents, the interaction pH in the collective adsorption process from ME and Cu(II) cation solution was conditioned at pH 7.0. When the pH of the solution is below pHPZC, the adsorbent will be positively charged while the ME solution and Cu(II) cations under these conditions will also be positively charged, so there will be a repulsion between the positive charge of the adsorbent and the adsorbate [24]. At pH 7, the interaction between adsorbent and adsorbate can occur optimally due to at the pH, the adsorbent surface charge tends to be neutral and will be negative while the ME and Cu(II) cations solution are positively charged. At pH > 7 adsorption will tend to decrease, because adsorbates such as a solution of ME and Cu (II) cations will undergo hydrolysis which results in a negatively charged species. The same thing is true to the adsorbent surface charge which tends to be negative because of pH > pHpzc [20]. Thus, in this condition, there will be a repulsion between the negative charge of the adsorbent and adsorbate.

Adsorption kinetics of ME and cu(II) cations

The impact of contact time on sorption between solution of ME and Cu(II) cations can be seen in Fig. 6 showing that the amount of ME and Cu(II) cations adsorbed on ASN-MPs tends to be greater than ASN. In addition, Fig. 6 shows that Cu(II) cations are more adsorbed than ME dyes in both ASN or ASN-MPs.

To better understand the adsorption performance of ME dyes and Cu(II) cations adsorbed in ASN and ASN-MPs, the adsorption kinetics model was used. Pseudo-first-order (Eq. (4)) and pseudo-second-order (Eq. (5)) kinetics [10] could be applied to analyze the adsorption characteristics of ME dyes and Cu(II) cations shown in Table 1.

where qt and qe (mmol g− 1) are total adsorbate (ME or Cu(II) cation) adsorption capacity at certain time of t (min) and equilibrium, serially. While k1 (min− 1) and k2 (g mmol− 1 min− 1) express the first and second order rate constants, respectively.

Table 1 describes the values from R2 (linear correlation coefficient) of the pseudo-first and -second-order kinetics models. Both ME and Cu(II) cations on ASN and ASN-MPs are more likely to take the pseudo-second-order kinetics pattern. From the value of the pseudo second order rate constant (k2) contained in Table 1, it can be observed that the k2 values of the ME and Cu(II) cation adsorbed on ASN-MPs are 9.0 × 10− 3 and 9.8 × 10− 3 g mmol min− 1, respectively. These values are greater than the ASN with k2 values for ME and Cu(II) of 3.8 × 10− 3 and 7.0 × 10− 3 g mmol min− 1, respectively. This shows that, the presence of Fe3O4 particles increases the adsorption rate of ME or Cu(II) cation on ASN-MPs. Therefore, the Fe3O4 particle coating causes the adsorbent to be magnetic, so it tends to increase the adsorption rate.

Adsorption mechanism

The significant section in the investigation of adsorption kinetics is the adsorption mechanism, because it will give an overview of reaction happened between adsorbate and adsorbent. In the process of the adsorption, the amount of adsorbed adsorbate is always expected to be more adsorbed and easily released again (desorption). The mechanism of adsorption between ME and Cu(II) cations is controlled by the surface characteristics of the adsorbent used [25, 26]. The mechanism of adsorption to ME and Cu(II) cations on ASN-MPs was analyzed using the proposal of Weber and Morris (Eq. (6)) about the intra-particle diffusion pattern (IPD) [27, 28]. The IPD pattern can be utilized to study the diffusion process of targets absorbed by adsorbents that can be used in simulating kinetics data [29].

where the rate constant of intra-particle diffusion is stated by kid (mmol g− 1 min− 0.5), and a constant describing resistance for mass transfer in the border layer is represented by C (mmol g− 1). Through the slope and intercept of lines resulted from plots of qt versus t0.5 will be produced kid and C (Fig. 7) as displayed in Table 2.

Figure 7 describes two linear parts occurred for all plots. This model indicates that involvement of the adsorption models is more than one model. The external mass transfer occurs at the first linear section in the adsorption period of 0–60 min. The diffusion of intraparticle is indicated at the second linear section in the adsorption period of 60–120 min. The origin (C ≠ 0) does not traverse by the second linear part, this shows that the rate and external mass transfer is not controlled only by the intraparticle diffusion but also it occurs simultaneously [27]. Based on observations in Fig. 7, there are two steps that represent the migration of ME and Cu(II) cations through the solution into the adsorbent external surface and further directed diffusion through the adsorbate target into the adsorbent active site respectively through the pore cavity and the adsorbent active group, according to diffusion theory at adsorption process. The mechanism of adsorption may be illustrated in two dissimilar means namely electrostatic adsorption and diffusion. This is because of the porosity and existence of negative charge in the functional groups of adsorbents [24]. This is supported by determining the mechanism of adsorption of ME and Cu(II) cations through sequential desorption using several eluents such as distilled water, HCl solution, and Na2EDTA to release ME and Cu(II) cations which have been adsorbed on ASN-MPs through entrapment interactions, electrostatic interaction, and complex formation (Fig. 8).

In Fig. 8 can be seen the results of sequential desorption of ME dye and Cu(II) cations contained in ASN-MPs by using an eluent, HCl (0.1 M), and continued with Na2EDTA (0.1 M). Figure 8 indicates that the percentage of ME dye and Cu(II) cations eluted using 0.1 M HCl is greater than elution using water and 0.1 M Na2EDTA solution. This indicates that both ME and Cu(II) ions adsorbed on ASN-MPs tend to be dominated by electrostatic interactions. ME is an organic cation and Cu(II) cation is positively charged so that it can interact with ASN-MPs which has a negatively charged surface. ASN-MPs tend to be negatively charged because they have functional groups consisting of hydroxyl, carbonyl, and amines from Nannochloropsis sp., whereas siloxan and silanol groups are from silica matrix.

Adsorption isotherm

The simultaneous competition for adsorption of ME and Cu(II) cations with varying initial concentrations of ASN and ASN-MPs can be seen in Fig. 9. The results illustrate that the amount of adsorbate adsorbed goes up with rising initial concentration of adsorbate used. In fact, at the use of high initial concentrations, the amount of adsorbate adsorbed reaches a maximum. In other words, increasing the concentration increases the amount of adsorbate adsorbed. The sorption capacity raises caused by an enhancement in the initial concentration of ME dyes and Cu(II) cations as a booster to increase the adsorption capacity because in this condition there are more adsorbates which occupy the active sites on the adsorbent surface [30].

Figure 9 states that the qe value for Cu(II) cations is greater than that of ME in both ASN and ASN-MPs at the same initial concentration. In addition, it can also be seen that the qe value of ASN-MPs adsorbents is relatively higher for ME and Cu(II) cations than ASN adsorbent. The data in Fig. 9 were analyzed using the Langmuir (Eq. (7)) and Freundlich (Eq. (8)) adsorption isotherm model with the assumption that the adsorption between ME and Cu(II) cation did not influence each other in competing to occupy adsorbent active sites [31, 32].

where KL (L mg− 1) and KF ((mg g− 1) (L mg− 1)1/n) are the Langmuir constant and Freundlich constant, respectively. The analysis results of the adsorption data using Langmuir and Freundlich adsorption isotherm models can be seen in Fig. 10 and Table 3.

Furthermore, the simultaneous adsorption of ME dyes and Cu(II) cation in a bi-component system was analyzed using the Langmuir isotherm equation for a binary mixture (Eq. (9)) [33, 34]. The multi-component Langmuir model was the most frequently used to fit the binary biosorption data. The mathematical expression that represents the model of the Langmuir isotherm for a binary mixture can be written as follows:

where qm is Langmuir constant related to the capacity of adsorption, b1 (ME) and b2 (Cu(II) cation) are the binary Langmuir isotherm constants. These values are determined using a multiple linear regression equation as displayed in Fig. 11 and Table 4.

Figure 10 and Table 3 show that the R2 indicates that the adsorption isotherm pattern of ME is more likely to attend the Freundlich adsorption isotherm. Adsorption of ME dyes on ASN and ASN-MPs goes on multiform faces of multilayer adsorbents via physical interactions [33,34,35]. Adsorption of Cu(II) cations trends to take the Langmuir adsorption isotherm showing that the interaction of Cu(II) cations to adsorbents is a chemical interaction.

The Langmuir isotherm assumes that each site of active adsorption and adsorbate binding ability is equivalent and does not depend on the adjacent site being occupied or not. This assumption shows that adsorption occurs in the surface layer of the adsorbent monolayer, after distributing the adsorption energy evenly to the entire surface [36, 37].

From the data presented in Table 4, it can be observed that the qm values for the bi-component mixture of ME dyes and Cu(II) cation in ASN and ASN-MPs are 1.39 × 10− 1 and 5.32 × 10− 1 mmol g− 1, respectively with the binary Langmuir constant isotherm b2 > b1. This shows that both the qm value and the adsorption isotherm constant from the analysis results with the binary Langmuir model (bi-component system) are in line with the results obtained from the Langmuir adsorption isotherm model (mono-component). From the results of data analysis using the Langmuir adsorption isotherm model in the form of mono-component and bi-component at the simultaneous adsorption of ME and Cu(II) cations in ASN-MPs, it may be assumed that the adsorption capacity of Cu(II) cations is greater than ME on ASN-MPs (Tables 3 and 4).

This shows that the active groups in adsorbents derived from algal biomass (hydroxyl, carbonyl, and amines groups) and silica matrix (siloxan and silanol groups) as well as the magnetic properties of adsorbents can increase the quantity of available active sites on the adsorbent [6, 7]. The Cu(II) cations are more easily adsorbed by ASN-MPs because Cu(II) cations have a smaller size (hydrated cation size (1.96 Å)) [38] compared to ME with a greater molecule size.

From the data shown in Table 4, it can be seen that in the bi-component adsorption, ASN-MPs have b1 and b2 values greater than ASN. This shows that ME and Cu(II) cation are more adsorbed on ASN-MPs compared to ASN. These data are in line with data on mono-component adsorption (Table 3) which shows that the qm value of ME and Cu(II) cation on ASN-MPs is greater than that on ASN. The increased adsorption on ASN-MPs occurred because modification of algal biomass with silica followed by coating with magnetite particles had increased the number of adsorption active sites and made ASN-MPs to be magnetic. The presence of magnetite particles causes the adsorbent to be magnetic thereby increasing its attraction to the adsorbate [8].

Adsorption of ME and Cu(II) cation by the ASN-MPs adsorbent results qm values of 2.92 × 10− 1 mmol g− 1 (93 mg g− 1) and 8.77 × 10− 1 mmol g− 1 (56 mg g- 1) (Table 3), respectively. If the adsorption capacity (qm) of the ASN-MPs is compared with other adsorbents such as multi-wall carbon nanotubes as ME adsorbents with qm value of 48 mg g− 1 [23] and HNO3-modified CNTs which adsorb Cu(II) cation with qm value of 29 mg g− 1 [39], then it can be seen that ASN-MPs have a qm value that is greater than these adsorbents. Thus, it can be stated that ASN-MPs can be an effective material for absorbing metal ions or coloring agents in solution both in mono- and bi-component.

Reuse of adsorbents

The study of the ability to reuse adsorbents is one of the important parameters that needs to be determined to investigate the effectiveness of repeated use of adsorbents applied in the process of adsorption.

In this work, reuse of ASN-MPs adsorbents was carried out through an adsorption-desorption process of 5 repetitions of ME and Cu(II) cations (Fig. 12). The sorption results of ME and Cu(II) cations were released using distilled water and continued with solution of HCl (0.1 M). The HCl was effective as eluent to release ME and Cu(II) cations from ASN-MPs which were adsorbed through the electrostatic interaction mechanism. This interaction occurs through proton substitution of ME as organic cations [40] and Cu(II) cations as hydrated cations in solution. The adsorption-desorption process was carried out repeatedly 3 times and apparently it did not reduce the percentage of ME and Cu(II) cations adsorbed significantly (Fig. 12). The percentage of ME and Cu(II) cations adsorbed began to decrease at the 4th adsorption repetition, this was caused by the reduction of the adsorbent active sites due to the desorption process and adsorbent washing.

Conclusions

Adsorbent production from Nannochloropsis sp. algae biomass modified by silica matrix and magnetite particle coating has been successfully carried out. The application of ASN-MPs adsorbents on the simultaneous adsorption of solution pair of ME and Cu(II) cations with the batch method shows that Cu(II) cations are more adsorbed than ME in simultaneous adsorption which is dominated by electrostatic interaction mechanism. ASN-MPs adsorbent is effective in absorbing ME and Cu(II) cations in solution and it can be used up to 3 times the adsorption repetition without a significant reduction in adsorption capacity. Thus, this adsorbent can be applied for the absorption of cation mixtures of organic dyes and heavy metals that are cationic in solutions derived from industrial waste.

Availability of data and materials

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Al-Saydeh SA, El-Naas MH, Zaidi SJ. Copper removal from industrial wastewater: a comprehensive review. J Ind Eng Chem. 2017;56:35–44.

Guler UA, Ersan M, Tuncel E, Dugenci F. Mono and simultaneous removal of crystal violet and safranin dyes from aqueous solutions by HDTMA-modified Spirulina sp. Process Saf Environ. 2016;99:194–206.

Jamwal HS, Kumari S, Chauhan GS, Reddy NS, Ahn JH. Silica-polymer hybrid materials as methylene blue adsorbents. J Environ Chem Eng. 2017;5:103–13.

Holkar CR, Jadhav AJ, Pinjari DV, Mahamuni NM, Pandit AB. A critical review on textile wastewater treatments: possible approaches. J Environ Manage. 2016;182:351–66.

Kanakaraju D, Ravichandar S, Lim YC. Combined effects of adsorption and photocatalysis by hybrid TiO2/ZnO-calcium alginate beads for the removal of copper. J Environ Sci China 2017;55:214–23.

Buhani, Hariyanti F, Suharso, Rinawati, Sumadi. Magnetized algae-silica hybrid from Porphyridium sp. biomass with Fe3O4 particle and its application as adsorbent for the removal of methylene blue from aqueous solution. Desalin Water Treat. 2019;142:331–40.

Buhani, Musrifatun, Pratama DS, Suharso, Rinawati. Modification of Chaetoceros sp. biomass with silica-magnetite coating and adsorption studies towards Cu(II) ions in single and binary system. Asian J Chem. 2017;29:2734–8.

Buhani, Rinawati, Suharso, Yuliasari DP, Yuwono SD. Removal of Ni(II), Cu(II), and Zn(II) ions from aqueous solution using Tetraselmis sp. biomass modified with silica-coated magnetite nanoparticles. Desalin Water Treat. 2017;80:203–13.

Vijayaraghavan K, Sathishkumar M, Balasubramanian R. Interaction of rare earth elements with a brown marine alga in multi-component solutions. Desalination. 2011;265:54–9.

Montazer-Rahmati MM, Rabbani P, Abdolali A, Keshtkar AR. Kinetics and equilibrium studies on biosorption of cadmium, lead, and nickel ions from aqueous solutions by intact and chemically modified brown algae. J Hazard Mater. 2011;185:401–7.

Angelova R, Baldikova E, Pospiskova K, Maderova Z, Safarikova M, Safarik I. Magnetically modified Sargassum horneri biomass as an adsorbent for organic dye removal. J Clean Prod. 2016;137:189–94.

Daneshvar E, Vazirzadeh A, Niazi A, Kousha M, Naushad M, Bhatnagar A. Desorption of methylene blue dye from brown macroalga: effects of operating parameters, isotherm study and kinetic modeling. J Clean Prod. 2017;152:443–53.

Buhani, Suharso, Satria H. Hybridization of Nannochloropsis sp. biomass-silica through sol-gel process to adsorb Cd(II) ion in aqueous solutions. Eur J Sci Res. 2011;51:467–76.

Flores-Chaparro CE, Ruiz LFC, de la Torre MCA, Huerta-Diaz MA, Rangel-Mendez JR. Biosorption removal of benzene and toluene by three dried macroalgae at different ionic strength and temperatures: algae biochemical composition and kinetics. J Environ Manage. 2017;193:126–35.

Sayadi MH, Salmani N, Heidari A, Rezaei MR. Bio-synthesis of palladium nanoparticle using Spirulina platensis alga extract and its application as adsorbent. Surf Interfaces. 2018;10:136–43.

Harris PO, Ramelow GJ. Binding of metal ions by particulate biomass derived from Chorella vulgaris and Scenedesmus quadricauda. Environ Sci Technol. 1990;24:220–28.

Kayan A, Arican MO, Boz Y, Ay U, Bozbas SK. Novel tyrosine-containing inorganic-organic hybrid adsorbent in removal of heavy metal ions. J Env Chem Eng. 2014;2:935–42.

Lee KE, Morad N, Teng TT, Poh BT. Preparation, characterization and application of Mg(OH)2-PAM inorganic-organic composite polymer in removing reactive dye. Iranica J Energy Environ. 2012;3:37–42.

Buhani, Suharso, Aditiya I, Al Kausar R, Sumadi, Rinawati. Production of a Spirulina sp. algae hybrid with a silica matrix as an effective adsorbent to absorb crystal violet and methylene blue in a solution. Sustain Environ Res. 2019;29:27.

Lin YF, Chen HW, Lin KL, Chen B, Chiou C. Application of magnetic particles modified with amino groups to adsorb copper ions in aqueous solution. J Environ Sci-China. 2011;23:44–50.

Araghi SH, Entezari MH. Amino-functionalized silica magnetite nanoparticles for the simultaneous removal of pollutants from aqueous solution. Appl Surf Sci. 2015;333:68–77.

Mohmood I, Lopes CB, Lopes I, Tavares DS, Soares AMVM, Duarte AC, et al. Remediation of mercury contaminated saltwater with functionalized silica coated magnetite nanoparticles. Sci Total Environ. 2016;557–8:712–21.

Ai LH, Zhang CY, Liao F, Wang Y, Li M, Meng LY, et al. Removal of methylene blue from aqueous solution with magnetite loaded multi-wall carbon nanotube: kinetic, isotherm and mechanism analysis. J Hazard Mater. 2011;198:282–90.

Ebadollahzadeh H, Zabihi M. Competitive adsorption of methylene blue and Pb(II) ions on the nano-magnetic activated carbon and alumina. Mater Chem Phys. 2020;248:122893.

Achak M, Hafidi A, Ouazzani N, Sayadi S, Mandi L. Low cost biosorbent "banana peel" for the removal of phenolic compounds from olive mill wastewater: kinetic and equilibrium studies. J Hazard Mater. 2009;166:117–25.

Buhani, Puspitarini M, Suharso R, Rilyanti M, Sumadi. Adsorption of phenol and methylene blue in solution by oil palm shell activated carbon prepared by chemical activation. Orient J Chem. 2018;34:2043–50.

Liang YD, He YJ, Wang TT, Lei LH. Adsorptive removal of gentian violet from aqueous solution using Co Fe2O4/activated carbon magnetic composite. J Water Process Eng. 2019;27:77–88.

AbdEl-Salam AH, Ewais HA, Basaleh AS. Silver nanoparticles immobilised on the activated carbon as efficient adsorbent for removal of crystal violet dye from aqueous solutions. A kinetic study. J Mol Liq. 2017;248:833–41.

Dogan M, Abak H, Alkan M. Adsorption of methylene blue onto hazelnut shell: kinetics, mechanism and activation parameters. J Hazard Mater. 2009;164:172–81.

Zabihi M, Asl AH, Ahmadpour A. Studies on adsorption of mercury from aqueous solution on activated carbons prepared from walnut shell. J Hazard Mater. 2010;174:251–6.

Ho YS, Porter JF, Mckay G. Equilibrium isotherm studies for the sorption of divalent metal ions onto peat: copper, nickel and lead single component systems. Water Air Soil Poll. 2002;141:1–33.

Foroutan R, Esmaeili H, Abbasi M, Rezakazemi M, Mesbah M. Adsorption behavior of Cu(II) and Co(II) using chemically modified marine algae. Environ Technol. 2018;39:2792–800.

Fagundes-Klen MR, Ferri P, Martins TD, Tavares CRG, Silva EA. Equilibrium study of the binary mixture of cadmium-zinc ions biosorption by the Sargassum filipendula species using adsorption isotherms models and neural network. Biochem Eng J. 2007;34:136–46.

Kleinubing SJ, da Silva EA, da Silva MGC, Guibal E. Equilibrium of Cu(II) and Ni(II) biosorption by marine alga Sargassum filipendula in a dynamic system: competitiveness and selectivity. Bioresour Technol. 2011;102:4610–7.

Shao YM, Zhou LC, Bao C, Ma JJ, Liu MZ, Wang F. Magnetic responsive metal-organic frameworks nanosphere with core-shell structure for highly efficient removal of methylene blue. Chem Eng J. 2016;283:1127–36.

Xin X, Wei Q, Yang J, Yan L, Feng R, Chen G, et al. Highly efficient removal of heavy metal ions by amine-functionalized mesoporous Fe3O4 nanoparticles. Chem Eng J. 2012;184:132–40.

Larraza I, Lopez-Gonzalez M, Corrales T, Marcelo G. Hybrid materials: magnetite-Polyethylenimine-Montmorillonite, as magnetic adsorbents for Cr(VI) water treatment. J Colloid Interf Sci. 2012;385:24–33.

Martell AE, Hancock RD. Metal complexes in aqueous solution. New York: Plenum Press; 1996.

Li YH, Ding J, Luan ZZK, Di ZC, Zhu YF, Xu CL, et al. Competitive adsorption of Pb2+, Cu2+, and Cd2+ ions from aqueous solutions by multiwalled carbon nanotubes. Carbon. 2003;41:2787–92.

Varghese SP, Babu AT, Babu B, Antony R. γ-MnOOH nanorods: efficient adsorbent for removal of methylene blue from aqueous solutions. J Water Process Eng. 2017;19:1–7.

Acknowledgements

Ministry of Research and Technology/National Innovation and Research Agency (Kemenristek/BRIN) of the Republic of Indonesia has funded this project with contract number: 179/SP2H/AMD/LT/DPRM/2020. Technical Service Unit of the Integrated Laboratory and the Technology Innovation Center–University of Lampung (UPT Laboratorium Terpadu dan Sentra Inovasi Teknologi–Universitas Lampung) also has provided the instruments to be used in this project.

Funding

This work was funded by Ministry of Research and Technology/National Innovation and Research Agency (Kemenristek/BRIN) of the Republic of Indonesia with contract number: 179/SP2H/AMD/LT/DPRM/2020.

Author information

Authors and Affiliations

Contributions

The manuscript was mainly based on a draft written by Buhani and Suharso, and written through contributions of all authors. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Buhani, Wijayanti, T.A., Suharso et al. Application of modified green algae Nannochloropsis sp. as adsorbent in the simultaneous adsorption of Methylene Blue and Cu(II) cations in solution. Sustain Environ Res 31, 17 (2021). https://doi.org/10.1186/s42834-021-00090-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s42834-021-00090-y