Abstract

Nowadays, diverse leather usage conditions and increasing demands from consumers challenge the leather industry. Traditional leather manufacturing is facing long-term challenges, including low-value threshold, confined application fields, and environmental issues. Leather inherits all the biomimetic properties of natural skin such as flexibility, sanitation, cold resistance, biocompatibility, biodegradability, and other cross-domain functions, achieving unremitting attention in multi-functional bio-based materials. Series of researches have been devoted to creating and developing leather-based flexible multi-functional bio-materials, including antibacterial leather, conductive leather, flame-retardant leather, self-cleaning leather, aromatic leather, and electromagnetic shielding leather. In this review, we provide a comprehensive overview of the commonly used leather-based functional materials. Furthermore, the possible challenges for the development of functional leathers are proposed, and expected development directions of leather-based functional materials are discussed. This review may promote and inspire the emerging preparation and applications of leather for flexible functional bio-based materials.

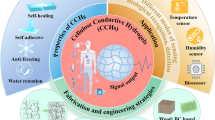

Graphical Abstract

Similar content being viewed by others

1 Introduction

As a flexible, hygienic, and durable biomass material, leather is obtained from the by-products of animals through a series of processes, in which various chemicals are employed [1,2,3]. Leather manufacturing for making use of rawhide waste is one of the earliest processing contents of human beings, which mainly involves four processes, including pre-tanning, tanning, post-tanning, and finishing (as manifested in Fig. 1) [4]. Preparing raw hides and skins for appropriate interaction with tanning agents is the primary purpose of pre-tanning processes, while the central role of post-tanning is to improve the mechanical and sensory properties of tanned leathers [2, 5]. Besides, the tanning process, which is the crucial step for leather-making, leads to actual conversion from raw hides/skins to leather through stabilizing collagen against the damage of heat, enzymatic and so on [6,7,8,9,10,11]. Finally, as one of the essential processes in the leather-making industry, finishing can increase the variety of leather appearance and increase the application properties of leather, such as mechanical property, antibacterial property, and hydrophobic property [12, 13].

Advanced technological options for leather processing [4]. Copyright 2015, Journal of Cleaner Production

Up to now, artificial synthetics still cannot match the structure marvel of skin and leather, and the products based on leather always remain unique and showcase excellent comfort and hygiene, making leather remain the consumers’ first consideration. Due to the implementation of stricter environmental protection policies from pole to pole, the development of the leather industry has been subject to restrictions ascribed to the generation of tannery wastewater, sludge, and other solid waste. Therefore, the leather industry is rapidly transforming and upgrading. Interestingly, nowadays, leather-making has become cleaner, greener, and more friendly, and the many fundamental nature of leather, including fullness, air permeability, cold resistance, and flexural strength, have been a progressive improvement. Furthermore, many interdisciplinary technologies have been adopted in up-to-date leather-making processes, and many emerging materials have been introduced as tanning, retanning, fatliquoring, and finishing agents to fabricate multi-functional leather.

The rapid development of sundry functional leathers has been witnessed during the past decade, e.g., antibacterial leather, conductive leather, flame-retardant leather, self-cleaning leather, aromatic leather, waterproof leather, electromagnetic shielding leather, X-ray shielding leather and so on (as displayed in Fig. 2). The development of functional leather will meet the living and production needs of consumers, improve the application value of natural leather biomass, and promote the long-term development of the traditional leather industry. Herein, we attempt to comprehensively review the types and recent researches of leather-based flexible functional materials. Moreover, the research outlook in this aspect is also proposed. This review will serve to inspire researchers and engineers towards novel leather chemicals and manufacturing technologies to boost the industrial fabrication of functional leather.

2 Fabrication and utilization of functional leather

2.1 Antibacterial leather

As protein is the main component of leather, hence leather is prone to breed microorganisms, including bacteria, fungi, and mold, during the storage process, which may affect the structure and properties of leather and even damage the health of users. The antibacterial treatment of leather can inhibit the growth of bacteria, thereby reducing the health problems of users. In recent years, researchers mainly have applied antibacterial agents into the tanning and finishing processes of leather to prepare antibacterial leather. According to the different sources and components, antibacterial agents can be subdivided into natural, organic, and inorganic antibacterial agents, and the silver-related antibacterial agents are most widely used in the preparation of antibacterial leather.

In 2018, gallic acid modified silver nanoparticles (GA@Ag NPs) were first fabricated in situ syntheses [14]. The antibacterial leather was prepared after GA@Ag NPs were successfully filled into the leather matrix as a retanning agent. Interestingly, the resultant leather possessed a high payload of silver nanoparticles against laundry, displaying strong and long-term antibacterial ability. Simultaneously, a composite coating was facilely fabricated onto the leather surface via the layer-by-layer assembly of positively charged chitosan and negatively charged gallic acid modified silver nanoparticles (GA@Ag NPs), with subsequent immobilization on leather by chemical cross-linking [15]. After being treated by CS/GA@Ag NPs, the leather showcased efficiently antibacterial activities against Escherichia coli (E. coli) and Staphylococcus aureus (S. aureus) through a “kill-release” strategy. After that, I. Carvalho et al. used the hydrothermal method to prepare titanium dioxide (TiO2) and Ag-TiO2 nanoparticles with anatase phase, and the two kinds of nanoparticles were applied on the leather substrates with different surface finishing [16]. In contrast with the leather samples covered by TiO2 nanoparticles, all the samples covered by Ag-TiO2 nanoparticles displayed antimicrobial activity, indicating Ag was the leading antimicrobial agent.

According to the research of E. Rohaeti et al., after modified by coating Ag NPs synthesized with an extract from green betel leaf, the suede leather can effectively kill E. coli, outperforming the leather without modification by 1.8 times and the silver nanoparticles in incubation for 36 h by 1.3 times [17]. Meanwhile, biogenic Ag NPs, synthesized using aqueous plant extract of Portulaca oleracea L. at 75 ℃ in 20 min, were applied to leather preservation [18]. There was no growth of leather isolates and deterioration of treated leather even after six months, while untreated leather began to deteriorate by the isolates, showing the efficiency of biogenic Ag NPs in preserving leather. Recently, the antibacterial leather was obtained through in-situ deposition of Ag NPs onto the leather surface by employing trisodium citrate. The prepared leather demonstrated excellent antimicrobial properties, including 100% bacterial reduction efficiency against both S. aureus and E. coli, and more than 93% fungal reduction efficiency against Candida albicans [19]. Besides, as reported by Barana et al., the aqueous extracts of the Nardostachys jatamansi root was used to synthesize stable Ag NPs by bio-reduction of Ag+ to Ag0, and the experimental results showed that the obtained Ag NPs co-polymer nanocomposite had a great potential in developing the fungal-free leather materials and products [20]. Furthermore, as illustrated in Fig. 3, poly(dimethyl diallyl ammonium chloride-methacrylic acid)/silver deposited ZnO composite was prepared by in-situ method and used in leather re-tanning process [21]. Due to the synergistic antimicrobial action of Ag/ZnO and N+ in the composite, the re-tanned leather demonstrated good antibacterial and anti-mildew properties [21].

Assembly process of P(DMDAAC-MAA)/Ag/ZnO composite [21]. Copyright 2021, Advanced Powder Technology

2.2 Conductive leather

Now, conductive leather and conductive leather-based sensors have attracted considerable attention in capturing postures and monitoring human activities. In 2014, a conducting leather was fabricated using in-situ polymerization of pyrrole [22]. The resultantly leather, with a maximum conductivity of 7.4 S/cm, can be used for making conductive gloves for operating touch-screen devices [22]. And then, self-colored and conducting leathers were prepared by using in-situ polymerization of aniline, in which ammonium persulfate and hydrochloric acid were playing the roles of oxidant and dopant, respectively [23]. The treated leathers are bluish-green, indicating the toxic and expensive dyes used during the coloration process can be avoided entirely. According to the research of Xie et al., a strain sensor based on the leather substrate was prepared by filtering the aqueous dispersion of conductive nanomaterials [24]. The as-prepared sensor possesses special microstructure, which not only inherits the air permeability, mechanical property, and biocompatibility of leather, but also shows excellent sensing performances [24]. As demonstrated in Fig. 4, a newly designed electronic skin (e-skin) was reported by Zou et al., the e-skin based on leather integrated leather with various functional materials, such as carbon nanotubes (CNTs), silver nanowires (Ag NWs), to endow the leather with sensing performance [25].

Schematic of the design principle of leather-based e-skin; light blue material denotes pure leather, and dark blue material is leather-based e-skin [25]. Copyright 2019, Advance Science

In 2020, a leather-based e-whisker was created by introducing conductive ink into leather [26]. Due to the porosity of leather, a 3D conductive pathway in leather was formed after the ink permeated into it. The prepared leather-based e-whisker has high sensitivity and can be used to detect a height difference of 50 μm, so it`s pretty capable for wind mapping, surface texture detecting, spatial distribution mapping, etc. [26]. Meanwhile, in the open air, a highly efficient and scalable laser direct writing (LDW) technique was employed to mask-freely prepare highly sensitive strain sensors on leather [27]. The sensors were constructed by the carbon flake, which was synthesized by LDW carbonization of collagen fibers, and this device can provide maximum sensitivities about 2010 and 51 for tension and compression strain detection, respectively [27]. In addition, a dry electrode, which is a breathable, biocompatible, and soft device that adheres to the skin comfortably, with leather as substrate and polypyrrole (PPy) as conductive material was prepared by Zhang and co-workers for ECG monitoring [28]. Based on the natural surface and hierarchical structure of leather, the conformal contact and extended wear can be realized by this electrode, and the quality of the collected electrophysiological signals can also be ensured [28]. Recently, due to the good mechanical strength, flexibility, permeability, long-term durability and visual acceptance, the top grain leather and split leather of pig were utilized as the substrate to fabricated a novel electrode to detect electrocardiogram signals [29]. The natural leather was pre-treated with Ar plasma and a thin silver paste coating was brush-painted on the surface to gain electrical conductivity [29]. Meanwhile, the leather was integrated with the mixture of conductive polymer, poly(3,4-ethylenedioxythiophene)/poly(styrenesulfonate) (PEDOT:PSS), and layered double hydroxides (LDHs) by using simple and effective vacuum filtration method [30]. The fabricated sensor based on leather possessed superior sensitivity (GF = 2326.84), tunable strain range (0–70%), fast tensile response time (160 ms), and good stability in 1000 stretching-relaxing/compression-relaxing cycles [30].

2.3 Flame-retardant leather

Leather and leather products are extremely flammable ascribe to various flammable additives used in the manufacturing process. Interestingly, the introduction of flame retardants in the leather-making process can effectively inhibit the occurrence of combustion. Leather flame retardants can be subdivided into organic, inorganic, and organic/inorganic hybrid flame retardants according to their composition. In 2005, to investigate the effect of phosphorus-based flame-retardant compounds containing nitrogen atoms on the treatment of leather samples and to improve their flame retardancy, the flame-retardant finishing was carried out according to the pad-dry-cure method with finishing formulations consisting of pyrovatex, etherified methylolated melamine, and the catalyst (NH4)2SO4 at different concentrations [31]. The results indicated that pyrovatex CP can be successfully used as a flame retardant for leather. Then, by combining the advantages of intumescent flame retardant and montmorillonite, Jiang et al. made toward developing a novel polymer/layered silicate nanocomposite used for leather flame retardant by the intercalation compounding method, the results attested the prepared nanocomposite has a good synergistic effect for improving the flame-retardant performance of leather [32]. As an organophosphorus compound, tributyl phosphate (TBP) shows a fire-retardant effect in different materials and applications. In 2018, two typical vegetable tannings, mimosa and tara, were used for tanning lime splitting cattle leather, and then, TBP was applied to the vegetable-tanned leather, which was non-finished [33]. After the application of 21% TBP, the limiting oxygen index (LOI) of mimosa tanned leather was 39.7%, while the LOI of tara tanned leather was 34.9%, proving that TBP can endow vegetable tanned leather with a good flame retardant effect. In addition, after the phosphoramidate-based diol was covalently embedded into polyurethane chain, the waterborne polyurethane/graphene nanocomposite (PN/G-WPU) was synthesized by emulsification with graphene oxide (GO) aqueous solution and in-situ reduced with hydrazine hydrate [34]. The results indicated the excellent dispersion and strong interfacial interaction of graphene with polyurethane matrix, which favors the PN/G-WPU penetrating into leather fibers. Therefore, the flame retardancy and smoke suppression performance of the leather can be effectively improved by the PN/G-WPU retanning agent.

After that, an in-situ method was employed to fabricate the nanocomposites (MZBMSO/s-LDH), which were based on modified zanthoxylum bungeanum maxim seed oil (MZBMSO) fatliquoring agent and stearate-layered double hydroxide (s-LDH) [35]. The leather treated by MZBMSO/s-LDH, compared with treated by MZBMSO, had an excellent softness and a notable improvement on flame retardancy, and the LOI increased from 23.6 to 28.0%, and the smoke density index decreased from 25 to 6 [35]. According to the research of Pan et al., the PVA(PEG)-SiO2-GO nanocomposites were fabricated by loading the near-spherical SiO2 nanoparticles with polyvinyl alcohol (PVA-SiO2) or polyethylene glycol (PEG-SiO2) onto GO nanosheets [36]. After the leather samples were treated by PVA-SiO2-GO and PEG-SiO2-GO during the tanning process, the LOI of leather was increased to 31.2% and 30.1% respectively. The reason may be that GO accelerated the forming of compact char layer, and isolated heat and burnable gases from the unburned leather, and released non-flammable gases to dilute O2 [36]. Recently, as depicted in Fig. 5, a bio-based caprolactam modified casein was played the role of a template to fabricate MgAl layered double hydroxide nanomaterial (Temp@MgAl-LDH) by using coprecipitation method, then modified casein emulsion and Temp@MgAl-LDH were blended and applied as a flame retardant in leather finishes [37]. The results showed that the increase of Temp@MgAl-LDH content can effectively improve the flame retardancy of leather, the LOI of leather can reach 28.5%, and smoke density decreased obviously when the content of Temp@MgAl-LDH was 5%. Moreover, after the hetero-structured filler layered double hydroxide-reduced graphene oxide was prepared by an in-situ co-precipitation method, the waterborne casein-based nanocomposite latex was prepared by solution blending, which can effectively enhance the fire-resistant and smoke suppression properties of the leather [38].

Preparation route of flame retardant finished leather [37]. Copyright 2021, Applied Surface Science

2.4 Self-cleaning leather

Traditional leather is easily contaminated by pollutants due to its inherent hydrophilicity, which limits its application. Therefore, self-cleaning technology is widely used to create self-cleaning leathers to enhance the quality of the leather and increase its market value. According to different working principles, self-cleaning leather can be divided into photocatalytic (super-hydrophilic) self-cleaning and super-hydrophobic self-cleaning leather.

2.4.1 Photocatalytic (super-hydrophilic) self-cleaning leather

The principle of photocatalytic (super-hydrophilic) self-cleaning is the contact angle of the water droplets on the surface of the substrate is close to 0°, so the water droplets on the surface of the substrate can quickly disperse to wet the substrate completely. The water on the substrate surface can effectively avoid the direct contact of pollutants with the substrate, and the original dirty on the surface of the substrate will be degraded and separated under catalytic action. After Wang et al. [39] first reported the research on the super-hydrophilic surface of TiO2 in 1997, TiO2 has attracted widespread attention. Due to the advantages of nontoxicity, harmlessness, and good chemical stability, TiO2 and modified TiO2 have been widely used in the preparation of functional leather. According to the research of Aurora et al., to improve the photocatalytic activity of TiO2 nanoparticles (TiO2 NPs) in the visible light region, the TiO2 NPs doped with N and Fe were fabricated and then applied to the leather-making [40]. Under the irradiation of visible light, the leather treated with Fe–N co-doped TiO2 NPs demonstrated the fastest degradation efficiency towards methylene blue stains. Furthermore, after TiO2 NPs and N–TiO2 NPs were modified by Ag NPs via the electrochemical method, these nanoparticles displayed excellent photoinduced catalytic properties in the visible domain [41]. Interestingly, as presented in Fig. 6, the enhanced photocatalytic properties in the visible light domain were confirmed on the leather surface through self-cleaning stains of ball pen ink, Orange II, and methylene blue dyes that were recorded for treated leather surfaces with Ag–N–TiO2 NPs [41].

Self-cleaning effect of Ag–N–TiO2 NPs, Ag–TiO2 NPs, and TiO2 NPs on the leather surface exposed to UV and visible light [41]. Copyright 2016, Open Chemistry

Furthermore, the hydrothermal method was used to prepare SiO2 doped TiO2 NPs, which can be used for leather coating as the alternative to halogen-based flame retardants and dry-cleaning solvents [42]. After the leather surface was treated by the composites of film-forming polymers and 10% SiO2 doped TiO2 NPs, the leather exhibited photocatalytic properties against methylene blue dye under UV and visible light, which ascribed to reactive species generation with effect on surface hydrophilicity increase [42]. To increase the properties and performances of the solvent-free polyurethane film (SFPU) in the artificial material industry, the hollow nano-TiO2 spheres (HNTSs) with large surface area, high permeability performance, and high photocatalytic performance were introduced into the SFPU film, which has effectively enhanced the mechanical property, water vapor permeability, and photocatalytic performance of the SFPU and synthetic leather [43]. Recently, compared to the state-of-the-art, Maria et al. proposed a facile method for polymer composite preparation and leather surface covering to develop multifunctional leather [44]. The photocatalytic properties of bovine leather surface treated with 0.5% multi-walled carbon nanotubes (MWCNTs) were shown against an olive oil stain after visible light exposure, which was attributed to reactive oxygen species generation and supported by contact angle measurements in dynamic conditions, with the generation of hydrophilic properties. In addition, according to the research of Xu and her co-authors, zein-based amorphous TiO2 composite microcapsules were innovatively prepared based on zein, tetra butyl ortho titanate, and PEO106PPO70PEO106 via interface template synthesis method, and the composite film containing the as-prepared nanocomposite has the potential to endow leather with self-cleaning property [45].

2.4.2 Super-hydrophobic self-cleaning leather

The principle of super-hydrophobic self-cleaning is that the contact and sliding angle of the water droplets on the surface of substrate were more significant than 150° and less than 10° respectively, so the droplets will not spread on the surface of the substrate but roll off easily, and the dirt on the substrate surface will be taken away, which is also called the self-cleaning effect of the lotus leaf [46]. In 2015, the super-hydrophobic leather coating was fabricated by layer-by-layer spraying [47]. More specifically, the coating was obtained by spraying polyacrylate emulsion and followed by spraying ethanol dispersion of hydrophobic SiO2 NPs, and the hydrophobicity of the coating could be tuned by the layers of hydrophobic SiO2 NPs [47]. Then, Munusamy et al. reported a successful demonstration of the “click” polymerization approach to prepare a novel copolymer of single-walled carbon nanotubes (SWCNTs) with aromatic moieties, and the super-hydrophobic behavior of leather can be found when coated with a copolymer of SWCNTs [48]. However, the micro-nano structure of the super-hydrophobic surface is fragile and is easily damaged under mechanical wear, so the wear-resistant super-hydrophobic technology has received widespread attention. In 2018, super-hydrophobic artificial material was fabricated for the first time [49]. Superhydrophobicity and self-cleaning were obtained after applying the nanoparticle-binder coating, and the contact angle and sliding angle were about 160° and 3°, respectively. Moreover, superoleophobicity was achieved when the contact angle and sliding angle were about 155° and 4°, separately [49].

Most hydrophobic materials cannot be applied directly to specific surfaces like leather because of incompatibility. Therefore, Vijaya et al. endowed the surface of the leather with hydrophobicity in various degrees as well as super-hydrophobicity by utilizing the conjugates of methacrylic polymers and various carbon nanomaterials (CNT) [50]. As reported in Fig. 7, the superhydrophobicity of the leather surface was supplied by CNT-poly(methyl methacrylate) conjugate plausibly because of the synergy of surface roughness and inherent low surface energy of the polymer. After that, the amphiphilic hollow SiO2 Janus particles were fabricated by sequential grafting hydrophilic and hydrophobic monomers onto both sides of the hollow SiO2 particles [51]. The prepared SiO2 Janus particles had the potential to promote the application of super-hydrophobic coating on leather, and the treated leather had a water contact angle of 162.2° and can still maintain super-hydrophobicity even after 140 cycles of abrasion. Recently, Carlos and co-authors developed hydrophobic coatings on leather by plasma polymerization with a low-pressure plasma system using an organosilicon compound as chemical precursor [52]. The results attested that the surface modification can impart a water repellent effect to leather but not alter the visual appearance and haptic properties. Simultaneously, a fluorine/silane free super-hydrophobic material was created by exploring the imine chemistry for synthesizing a ligand through a two-step process in a non-toxic solvent, followed by reacting the synthesized ligand with the metal ion in an aqueous medium [53]. The water contact angle of the leather increased to 155° after being treated by this super-hydrophobic material, indicating the super-hydrophobic property of the leather.

Fabrication schematic of durable super-hydrophobic coating on leather [51]. Copyright 2020, Nanoscale

2.5 Aromatic leather

Leather will produce a peculiar smell in the application process due to the special smell of the skin itself and the use of chemical materials in leather-making. Interestingly, leather perfuming technology can well mask or eliminate the odor of the leather. Therefore, the preparation and application of aromatic leather have gradually attracted people’s attention. Traditional leather perfuming techniques are usual directly introduce the fragrances or perfumes into the leather. However, most essences or perfume have shortcomings such as easy volatilization, poor thermal stability, and bad compatibility, so the treated leather cannot be used for a long time. Currently, microencapsulation has been one of the effective ways to prepare aromatic leather. In 2014, after miniemulsion polymerization was used to fabricate polyacrylate nanocapsules loaded with lilial (PNLs), PNLs were applied directly to leather [54]. The results showed that some PNLs were appearing on the surface of the leather finished by the PNLs when it was flexed 5000 times. However, after the strong mechanical actions, PNLs tended to aggregate into large particles due to the high elastic state. And then, encapsulation was used to arrest the volatility of flavors and fragrances to produce aromatic leather. According to the research of Velmurugan et al., the emulsion polymerization technique was used to manufacture fragrant nanospheres with chitosan and acrylic acid as the wall materials [55]. After these nanospheres were optimized during the application in leather processing, the lemongrass oil in the nanospheres can be well retained in the leather matrix even after washing with water and solvent.

After that, the scent oils were encapsulated by using chitosan as the wall material via emulsion polymerization technique, and the encapsulation efficiency, oil load, and content of the products have been investigated and optimized [56]. After applying the encapsulated scent oils into leather, the perception, strength, washability, and diffusion coefficient of the leather have been systematically studied. The “smart scented” leather has been made through incorporating of pleasant smells, which increases in value of leather. In 2018, the interfacial condensation approach was adopted to develop chitosan-coated SiO2 nanocapsules with a double-shelled structure using Pluronic F127 as the template [57]. The inner layer and outer layer of the nanocapsules were SiO2 and chitosan respectively, which have the function of continuously releasing vanillin. After the nanocapsules were applied to the leather finishing, the vanillin in the leather was controlled releasing, and other properties of the finished leather were also improved, including mechanical property, hygienic property, and antibacterial property. Recently, as represented in Fig. 8, Xu et al. first reported a route of crafting zein-sodium alginate microcapsules loaded with artemisia argyi essence and casein modified by caprolactam, which can be used as leather finishes [58]. The essence in the leather treated by the coating comprising zein-sodium alginate based microcapsules was controlled releasing and could release for 6 weeks.

Schematic illustration of the synthesis of the coating with zein-sodium alginate based microcapsules [58]. Copyright 2021, Journal of Industrial and Engineering

2.6 Waterproof leather

Leather is easy to absorb water ascribed to its high surface energy which in virtue of the many hydrophilic groups including hydroxyl, amino, and carboxyl groups on the side chains of leather, and the use of hydrophilic chemicals in leather-making, such as surface-active agents. With the development of the leather market and the demand of the international market, waterproof leather is more and more favored by the market. In the initial research, grease was employed to coat the leather surface and fill the pores of leather fibers to prepare waterproof leather. However, the air permeability of the leather is significantly reduced, and the peculiar smell of the leather will also affect its application. Now, waterproof leather is mainly fabricated by using waterproofing agents which are hydrophilic to treat the leather surface or fill the leather. In 2016, the properties of composites based on acrylic polymers and polyvinilethynildihidroxichlorsilan were investigated, the results showed that the polymer composites with polyvinilethynildihidroxichlorsilan increased the waterproof property of shoe upper leather by 1–2 times compared to those with polyethylhydrosiloxane [59].

Moreover, the waterproofness of leather also can be enhanced by adjusting the processes of leather-making involving the operations from pre-tanning to finishing. As reported in Barana et al., three sets of experiments in which the tanning and finishing techniques were different were conducted to analyze the changes of waterproofness [60]. In addition, to further enhance and assess the waterproofness of leather, the finishes in each experiment were changed by adopting various waterproof fatliquors [60]. The results proved that water vapor permeability would decrease as the waterproofness improvement of the leather. Recently, a new type of leather fabric was fabricated by using the woven process. This leather fabric was different from traditional leather-thermoplastic polyurethane bionic leather fabric, which had fantastic gloss, abrasion resistance, and water resistance, and had a bionic texture that traditional leather lacks [61]. In addition, according to the research of Su et al., the fluorinated polyurethanes containing short branched fluorocarbon chains were prepared by a novel strategy, and then it was applied in leather-making [62]. Since the coating surface has abundant fluorine-containing chain segments, the treated leather showed outstanding performances, such as high wear resistance, good hydrophobicity, low water absorption, and potential photodegradability [62].

2.7 Electromagnetic shielding leather

With the prosperity of highly integrated electronic telecommunication technology and personal electronic devices, electromagnetic radiation pollution has become severe and challenging issue in our daily life and work [63, 64]. Leather owns the unique spatial structure and dielectric property; hence, it may be a potential raw material as an absorption matrix to produce electromagnetic waves (EW) shielding composites with wonderful performances. For example, the unique hierarchically suprafibrillar structure in leather is possible to increase the transfer time and enlarge the transmission routes of the EW transmission in the leather via multiple diffuse reflections within the hierarchical structure of leather. Therefore, the research and development of electromagnetic shielding leather have received extensive attention. Currently, electromagnetic shielding leather, which can achieve shielding effect through reflection or absorption, is often prepared by the coating method, the dip coating method, the chemical plating method, etc. Metal-based materials can reflect EW effectively due to their high conductivity, so they have been used as EW shielding materials for a long time. In 2016, a lightweight, high-performance and wearable nanocomposite shielding material was prepared by using Cu@Ag nanoflakes to coat the surface of the leather matrix (LM) that was used as a microwave-absorptive substrate [65]. In this way, an extremely low content of Cu@Ag nanoflakes is enough for LM-Cu@Ag to achieve superior high shielding ability (~ 100 dB), showing lightweight high-performance shielding ability in a board frequency range. As provided in Fig. 9, metal nanoparticles (MNPs) were coated onto a leather matrix (LM) to craft a lightweight and high-performance EW shielding composite that has both absorption and reflection abilities to EW [66]. When the coated MNPs was 4.58 wt%, the EW shielding effectiveness and specific shielding effectiveness of the as-prepared metal/LM membrane were about 76.0 dB and 200.0 dB cm3 g− 1 separately in the frequency range of 0.01–3.0 GHz, indicating that more than 99.9% of EW was shielded [66].

Recently, Polydopamine modification and pH-triggered hydrogen bonding have been combined to create a tough interface to prepare waterborne polyacrylate/graphene@polydopamine composites with flexibility and mechanical robustness [67]. The composite with filler loading of 20 wt% exhibited an EMI shielding effectiveness of 58 dB at 0.6 mm thickness and thermal conductivity of 1.68 W/m K, respectively [67]. Overall, the leather coated with this composite showed outstanding EMI shielding, flexibility, and heat dissipation performance. Then, the facile vacuum-assisted filtration process was used to fabricate multifunctional wearable silver nanowire decorated leather (AgNW/leather) nanocomposites with hierarchical structures for integrated visual Joule heating, electromagnetic interference (EMI) shielding and piezoresistive sensing [68]. The resultant AgNW/leather nanocomposites exhibit extremely low sheet resistance of 0.8 Ω/sq, superior visual Joule heating temperatures up to 108 °C at low supplied voltage of 2.0 V, excellent EMI shielding effectiveness (EMI SE) of ~ 55 dB, and outstanding piezoresistive sensing ability in human motion detection [68].

a Hierarchically fibrous structure of LM. b–f Field emission scanning electron microscope images of different levels of microstructures of LM [66]. Copyright 2018, ACS Applied Materials and Interfaces

2.8 X-ray protection leather

As a kind of electromagnetic wave, X-ray has been broadly used in our daily life [69, 70]. However, long-term exposure to X-ray will directly or indirectly cause harmful effects on human health [71]. Therefore, the composite protection materials based on leather with high shielding efficiency, lightweight, flexibility, and wearability will significantly promote the present investigation on X-ray protection materials [72]. The natural leather (NL) can effectively absorb the energy of X-ray after taking the “dipping-solvent removal” strategy and changing the retanning process. Herein, according to the research of Li et al., a co-doped Bi/Ce-NL composite with excellent X-ray attenuation in the energy range of 20–120 keV was successfully fabricated [72]. Due to the uniform distribution of Bi2O3 and CeO2 nanoparticles in the hierarchical structure of NL, the X-ray attenuation was significantly promoted by improving the weak absorption region of Bi with Ce via synergistic effects of the two elements.

Meanwhile, a high-shielding, low secondary radiation, lightweight, flexible, and wearable X-ray protection material was prepared by coimpregnating La2O3 and Bi2O3 nanoparticles in natural leather (NL) with an additional Bi2O3 coating at the bottom surface of the leather [73]. The prepared Bi28.2@Bi3.48La3.48-NL (28.2 and 3.48 mmol cm− 3 are the loading contents of elements) showed excellent X-ray shielding ability (65–100%) in a wide energy range of 20–120 keV with reduced scattered secondary radiation (30%) [73].

As exhibited in Fig. 10, an advanced X-ray shielding material based on the leather that containing bismuth and iodine (BiINP-LM) was crafted by Wang et al., the favorable interactions between bismuth iodide and leather realized the stable and well-dispersed loading of high-Z element components [74]. The resulting leather displayed an excellent X-ray attenuation efficiency of more than 90% in the photon energy range below 50 keV, and the X-ray attenuation efficiency was 65% when the photon energy was 83 keV, which averagely exceeded about 3% than that of the 0.25 mm lead plate and about 5% than that of the 0.65 mm commercial lead apron [74]. Recently, Wang and her co-authors further developed a structural material with high mass attenuation coefficients in a wide energy range (10–100 keV) [75]. The backscatter radiation was drastically reduced due to the integration of high-Z elements in hierarchical collagen nanofibers, resulting in only 28% of secondary radiation compared with a standard lead plate [75]. In addition, the water vapor permeability of the engineered leather is nearly 340 times higher than commonly used synthetic and natural polymers.

A Graphic illustration of the facile two-step “impregnation-desolation” strategy for the preparation of the BiINP-LM sample; SEM images of B LM and C BiINP-LM [74]. Copyright 2020, ACS Applied Materials and Interfaces

2.9 Other functional leather

In addition to the above functional leathers, other functional leathers have also been widely used, for example, thermal camouflage leather, sensory leather, and so on. The past years have witnessed a rapid development of thermal camouflage materials, which have many potential applications in personal thermal management, infrared stealth, and functional wearable device, etc. [76, 77]. Accordingly, the thermal camouflage armor with multiple functions was developed by making direct editing on the natural thermal insulation structure of cowhide [78]. As manifested in Fig. 11, the tasks of trapping stagnant air, blocking infrared absorptive groups, and reflecting infrared radiation from heat objects were achieved by the SiO2 NPs, which were in situ grown on the hierarchically fibrous scaffold of leather [78]. In addition, the direct thermal transmission from heat objects to the thermal camouflage armor was suppressed by the thermal insulation layer of SiO2 NPs on the back surface of leather [78].

The schematic illustration showing the preparation from a leather to b leather/SiO2 and c SiO2-leather/SiO2; d thermal image and corresponding optical image of leather/SiO2 placed on the grassland at night; thermal images of people’s hand covered by the e leather/SiO2, f leather and g leather-SiO2 [78]. Copyright 2019, Chemical Engineering Science

Recently, two kinds of leather-based multi-stimuli responsive chromic devices named UV/thermo/electrochromic device and UV sensor were developed based on the unique micro-nano structure, high strength, durability, and softness of leather [79]. As demonstrated in Fig. 12, when faced with applied UV radiation, heat, and voltage, this leather-based device indicated instantaneous and reversible chromic responses with different color-changing styles [79]. Furthermore, the leather-based device owned high design flexibility and broad applicability because the pattern was formed with the assistance of 3D printed molds and the dyes/pigments have a broad selection.

Overall responsive behavior of the leather-based UV/thermo/electrochromic device [79]. Copyright 2021, Advanced Functional Materials

3 Conclusions and outlook

With the increase in demand and the expansion of the market, more and more leather-based functional materials are gradually developed. The progress of multi-functional leather will increase the ontological value of natural leather biomass, broaden the application areas of natural leather, and boost the sustainable development of the conventional leather industry. Furthermore, the researches of functional leather will further promote the creation of novel functional leather chemicals and the invention of related new manufacturing technologies and processes.

Meanwhile, the issues listed in the following still need to be further considered and solved: (1) Although functional leathers emerge in an endless stream, most functional leathers still have circumscribed functions, and the preparation and application of functional leathers with on-demand multiple functions is still a tremendous challenge; (2) Most researches mainly focus on the traditional application of leather, and there is huge application potential and opportunities for leather in new research fields, such as flexible electronics, human-computer interaction, and health care; (3) Many functional leathers have been created in the laboratories of institutes and universities or the R&D department of companies, however, most of them almost cannot be reproduced or mass-produced.

Therefore, in the future, we should make good use of the advantages of leather substrate, such as excellent mechanical properties and good air permeability, and increase the researches on leather-based materials with multiple integrated functions, and enhance the competitiveness of traditional leather products comprehensively. In addition, we are supposed to carry out creative researches on the special structure of leather, and vigorously promote the application of leather as the functional devices in more interdisciplinary fields, such as electromagnetic shielding devices, flexible sensing devices, and medical diagnostic devices.

Availability of data and materials

Not applicable.

Change history

06 May 2023

A Correction to this paper has been published: https://doi.org/10.1186/s42825-023-00121-x

References

China CR, Maguta MM, Nyandoro SS, Hilonga A, Kanth SV, Njau KN. Alternative tanning technologies and their suitability in curbing environmental pollution from the leather industry: a comprehensive review. Chemosphere. 2020;254:126804.

Moreira M, Hansen E, Giacomolli G, Morisso F, Aquim P. Evaluation of chemical products in leather post-tanning process and their influence in presence of neutral salts in raw tannery effluent. J Am Leather Chem Assoc. 2019;114(4):108–17.

Navarro D, Wu J, Lin W, Fullana-i-Palmer P, Puig R. Life cycle assessment and leather production. J Leather Sci Eng. 2020;2:1–13.

Dixit S, Yadav A, Dwivedi PD, Das M. Toxic hazards of leather industry and technologies to combat threat: a review. J Clean Prod. 2015;87:39–49.

Abd El-Monem F, Hussain AI, Nashy E-SH, Abd El-Wahhab H, Naser AE-RM. Nano-emulsion based on acrylic acid ester co-polymer derivatives as an efficient pre-tanning agent for buffalo hide. Arab J Chem. 2017;10:3861–9.

Hao D, Wang X, Liu X, Su R, Duan Z, Dang X. Chrome-free tanning agent based on epoxy-modified dialdehyde starch towards sustainable leather making. Green Chem. 2021;23:9693–703.

Sun Q, Zeng Y, Wang Y, Yu Y, Shi B. Preparation and assistant-dyeing of formalde between sulfonation degree and retanning performance of aromatic syntans. J Leather Sci Eng. 2021;3:1–10.

Liu Q, Wu M, Tian Z. Preparation and assistant-dyeing of formaldehyde-free amphoteric acrylic retanning agent. J Leather Sci Eng. 2021;3:1–13.

China CR, Nyandoro SS, Munissi JJ, Maguta MM, Meyer M, Schroepfer M. Tanning capacity of Tasmania burttii extracts: the potential eco-friendly tanning agents for the leather industry. J Leather Sci Eng. 2021;3:1–9.

Wang X, Sun S, Zhu X, Guo P, Liu X, Liu C, et al. Application of amphoteric polymers in the process of leather post-tanning. J Leather Sci Eng. 2021;3:1–9.

Huang W, Song Y, Yu Y, Wang Y, Shi B. Interaction between retanning agents and wet white tanned by a novel bimetal complex tanning agent. J Leather Sci Eng. 2020;2:1–9.

Wang C, Wu J, Li L, Mu C, Lin W. A facile preparation of a novel nonleaching antimicrobial waterborne polyurethane leather coating functionalized by quaternary phosphonium salt. J Leather Sci Eng. 2020;2:2.

Fan Q, Ma J, Xu Q. Insights into functional polymer-based organic-inorganic nanocomposites as leather finishes. J Leather Sci Eng. 2019;1:1–10.

Liu G, Haiqi G, Li K, Xiang J, Lan T, Zhang Z. Fabrication of silver nanoparticle sponge leather with durable antibacterial property. J Colloid Interface Sci. 2018;514:338–48.

Xiang J, Ma L, Su H, Xiong J, Li K, Xia Q, et al. Layer-by-layer assembly of antibacterial composite coating for leather with cross-link enhanced durability against laundry and abrasion. Appl Surf Sci. 2018;458:978–87.

Carvalho I, Ferdov S, Mansilla C, Marques S, Cerqueira M, Pastrana L, et al. Development of antimicrobial leather modified with Ag–TiO2 nanoparticles for footwear industry. Sci Technol Mater. 2018;30:60–8.

Rohaeti E, Kasmudjiastuti E, Murti R, Dodi I. Enhancement of antibacterial activity of suede leather through coating silver nanoparticles synthesized using piper betle. Rasayan J Chem. 2020;13:628–35.

Kate S, Sahasrabudhe M, Pethe A. Biogenic silver nanoparticle synthesis, characterization and its antibacterial activity against leather deteriorates. Jordan J Biol Sci. 2020;13:493–8.

Elsayed H, Hasanin M, Rehan M. Enhancement of multifunctional properties of leather surface decorated with silver nanoparticles (Ag NPs). J Mol Struct. 2021;1234:130130.

Priya S, Murali A, Preeth DR, Dharanibalaji K, Jeyajothi G. Green synthesis of silver nanoparticle-embedded poly (methyl methacrylate-co-methacrylic acid) copolymer for fungal-free leathers. Poly Bull. 2021:1–20.

Su Y, Li P, Gao D, Lyu B, Ma J, Zhang J, et al. High-efficiency antibacterial and anti-mildew properties under self-assembly: an environmentally friendly nanocomposite. Adv Powder Technol. 2021;32(7):2433–40.

Wegene JD, Thanikaivelan P. Conducting leathers for smart product applications. Ind Eng Chem Res. 2014;53:18209–15.

Jima Demisie W, Palanisamy T, Kaliappa K, Kavati P, Bangaru C. Concurrent genesis of color and electrical conductivity in leathers through in-situ polymerization of aniline for smart product applications. Polym Adv Technol. 2015;26:521–7.

Xie R, Hou S, Chen Y, Zhang K, Zou B, Liu Y, et al. Leather-based strain sensor with hierarchical structure for motion monitoring. Adv Mater Technol. 2019;4:1900442.

Zou B, Chen Y, Liu Y, Xie R, Du Q, Zhang T, et al. Repurposed leather with sensing capabilities for multifunctional electronic skin. Adv Sci. 2019;6:1801283.

Xie R, Zhu J, Wu H, Zhang K, Zou B, Zhang X, et al. 3D-conductive pathway written on leather for highly sensitive and durable electronic whisker. J Mater Chem C. 2020;8:9748–54.

Wang Z, Chen B, Sun S, Pan L, Gao Y. Maskless formation of conductive carbon layer on leather for highly sensitive flexible strain sensors. Adv Electron Mater. 2020;6(9):2000549.

Zhang K, Kang N, Zhang B, Xie R, Zhu J, Zou B, et al. Skin conformal and antibacterial PPy-leather electrode for ECG monitoring. Adv Electron Mater. 2020;6:2000259.

Song Y, Huang Y, Zou Y, Gou L. Performance of a flexible electrode based on natural leather. J Mater Sci Mater Electron. 2021;32:4891–902.

Zong Y, Tan S, Ma J. Flame-retardant PEDOT:PSS/LDHs/leather flexible strain sensor for human motion detection. Macromol Rapid Commun. 2022;43:2100873.

Mohamed OA, Abdel-Mohdy F. Preparation of flame-retardant leather pretreated with pyrovatex CP. J Appl Polym Sci. 2006;99:2039–43.

Jiang Y, Li J, Li B, Liu H, Li Z, Li L. Study on a novel multifunctional nanocomposite as flame retardant of leather. Polym Degrad Stab. 2015;115:110–6.

Acikel SM, Celik C, Gurbuz D, Cinarli A. Flame retardant effect of Tri Butyl Phosphate (TBP) in vegetable tanned leathers. Text Appar. 2018;28:135–40.

Zhang P, Xu P, Fan H, Zhang Z, Chen Y. Phosphorus–nitrogen flame retardant waterborne polyurethane/graphene nanocomposite for leather retanning. J Am Leather Chem Assoc. 2018;113(5):142–50.

Lyu B, Wang Y, Gao D, Ma J, Li Y. Intercalation of modified zanthoxylum bungeanum maxin seed oil/stearate in layered double hydroxide: toward flame retardant nanocomposites. J Environ Manag. 2019;238:235–42.

Pan H, Wang S, Wang X, Gong C, Ding T. Synergistic effects of hydrophilic nano-SiO2/graphene oxide@copolymer nanocomposites in tanning leather. Adv Powder Technol. 2020;31:3910–20.

An W, Ma J, Xu Q. Bio-template synthesis of MgAl layered double hydroxide with enhanced flame retardant property for leather finishes. Appl Surf Sci. 2021;551:149409.

An W, Ma J, Xu Q, Zhang H, Wei L, Yuan L. Construction of hetero-structured fillers to significantly enhance the fire safety of bio-based nanocomposite coating. Appl Surf Sci. 2022;575:151767.

Wang R, Hashimoto K, Fujishima A, Chikuni M, Kojima E, Kitamura A, et al. Light-induced amphiphilic surfaces. Nature. 1997;388(6641):431–2.

Petica A, Gaidau C, Ignat M, Sendrea C, Anicai L. Doped TiO2 nanophotocatalysts for leather surface finishing with self-cleaning properties. J Coat Technol Res. 2015;12:1153–63.

Gaidau C, Petica A, Ignat M, Iordache O, Ditu LM, Ionescu M. Enhanced photocatalysts based on Ag–TiO2 and Ag–N–TiO2 nanoparticles for multifunctional leather surface coating. Open Chem. 2016;14:383–92.

Gaidau C, Petica A, Ignat M, Popescu LM, Piticescu RM, Tudor IA, et al. Preparation of silica doped titania nanoparticles with thermal stability and photocatalytic properties and their application for leather surface functionalization. Arab J Chem. 2017;10(7):985–1000.

Guo X, Lyu B, Gao D, Cheng K, Kou M. Water vapor permeability and self-leaning properties of solvent-free polyurethane improved by hollow nano-TO2 spheres. J Appl Polym Sci. 2020;183(1):49638.

Maria S, Carmen G, Cosmin-Andrei A, Ioana S, Silvana V, Andreea M, et al. Multifunctional leather surface design by using carbon nanotube-based composites. Materials. 2021;14(11):3003.

Xu Q, Bai Z, Ma J, Huang M, Qiu R, Wu J. Interface template synthesis of zein-based amorphous TiO2 composite microcapsules with enhanced photo-catalysis. Colloids Surf A. 2021;630:127534.

Zheng J, Qu G, Yang B, Wang H, Zhou L, Zhou Z. Facile preparation of robust superhydrophobic ceramic surfaces with mechanical stability, durability, and self-cleaning function. Appl Surf Sci. 2022;576:151875.

Ma J, Zhang X, Bao Y, Liu J. A facile spraying method for fabricating superhydrophobic leather coating. Colloids Surf A. 2015;472:21–5.

Krishnamurthy M, Murugan P, Murali A, Jaisankar SN, Mandal AB, Samanta D. "Click” polymer of carbon nanotubes for superhydrophobic glass and leather. Green Mater. 2017;5(2):46–52.

Gurera D, Bhushan B. Fabrication of bioinspired superliquiphobic synthetic leather with self-cleaning and low adhesion. Colloids Surf A. 2018;545:130–7.

Ayyappan VG, Prakash D, Jaisankar SN, Sadhukhan N, Sayem Alam Md., Samanta D. Nanoconjugates of methacrylic polymers: Synthesis, characterization, and immobilization to leather. J Appl Polym Sci. 2020;137(18):48627.

Bao Y, Zhang Y, Ma J. Reactive amphiphilic hollow SiO2 Janus nanoparticles for durable superhydrophobic coating. Nanoscale. 2020;12(31):16443–50.

Ruzafa SC, Carbonell BMP, Ricote LS, Pérez AH, Pérez LMÁ, Bañón GE, et al. Hydrophobic leather coating for footwear applications by a low-pressure plasma polymerisation process. Polymers. 2021;13(20):3549.

Ramesh RR, Jonnalagadda RR. Fabrication of zirconium based coordination polymers for fluorine/silane free superhydrophobic coatings. Chem Eng J. 2021;431:134262.

Jing H, Weijun D, Liqin L, Zuobing X. Synthesis and application of polyacrylate nanocapsules loaded with lilial. J Appl Polym Sci. 2014;131(8):40182.

Velmurugan P, Nishter NF, Baskar G, Dhathathreyan A, Rao JR. Development of smart leathers: incorporating scent through infusion of encapsulated lemongrass oil. RSC Adv. 2015;5(74):59903–11.

Velmurugan P, Ganeshan V, Nishter NF, Jonnalagadda RR. Encapsulation of orange and lavender essential oils in chitosan nanospherical particles and its application in leather for aroma enrichment. Surf Intern. 2017;9:124–32.

Fan Q, Ma J, Xu Q, Wang J, Ma Y. Facile synthesis of chitosan-coated silica nanocapsules via interfacial condensation approach for sustained release of vanillin. Ind Eng Chem Res. 2018;57(18):6171–9.

Xu Q, Bai Z, Ma J, Yang Y, Huang M. Zein-sodium alginate based microcapsules for essence controlled releasing coating as leather finishes. J Ind Eng Chem. 2021;100:204–11.

Abdujalil D, Tolqin K. Hydrophobization of shoe upper leather on the basis of new polymer composites and kinetics of absorption of moisture by leather. Eur J Anal Appl Chem. 2016;2:26–9.

Shahriar A, Murad AW, Ahmed S. Enhancement of waterproofing properties of finished upper leather produced from bangladeshi cow hides. Eur J Eng Technol Res. 2019;4(7):63–71.

Wang Y, Li X, Chen Y. Research on innovation and application of thermoplastic polyurethane elastomer bionic leather fabric from the perspective of sustainable design. IOP Conf Ser Earth Environ Sci. 2021;706(1):012032.

Su S, Wang J, Li C, Yuan J, Pan Z, Pan M. Short-branched fluorinated polyurethane coating exhibiting good comprehensive performance and potential UV degradation in leather waterproofing modification. Coatings. 2021;11(4):395.

Ma Z, Kang S, Ma J, Shao L, Zhang Y, Liu C, et al. Ultraflexible and mechanically strong double-layered aramid nanofiber-Ti3C2Tx MXene/silver nanowire nanocomposite papers for high-performance electromagnetic interference shielding. ACS Nano. 2020;14(7):8368–82.

Chen Y, Zhang H, Yang YB, Wang M, Cao AY, Yu ZZ. High-performance epoxy nanocomposites reinforced with three-dimensional carbon nanotube sponge for electromagnetic interference shielding. Adv Funct Mater. 2016;26(3):447–55.

Liu C, Huang X, Zhou J, Chen Z, Liao X, Wang X, et al. Lightweight and high-performance electromagnetic radiation shielding composites based on a surface coating of Cu@Ag nanoflakes on a leather matrix. J Mater Chem C. 2016;4:914–20.

Liu C, Wang X, Huang X, Liao X, Shi B. Absorption and reflection contributions to the high performance of electromagnetic waves shielding materials fabricated by compositing leather matrix with metal nanoparticles. ACS Appl Mater Interfaces. 2018;10(16):14036–44.

Wei L, Ma J, Zhang W, Bai S, Ren Y, Zhang L, et al. pH triggered hydrogen bonding for preparing mechanically strong, electromagnetic interference shielding and thermally conductive waterborne polymer/graphene@polydopamine composites. Carbon. 2021;181:212–24.

Ma Z, Xiang X, Shao L, Zhang Y, Gu J. Multifunctional wearable silver nanowire decorated leather nanocomposites for joule heating, electromagnetic interference shielding and piezoresistive sensing. Angew Chem Int Ed. 2022;61:e202200705.

Qin ZZ, Ahmed S, Sarker MS, Paul K, Adel ASS, Naheyan T, et al. Tuberculosis detection from chest x-rays for triaging in a high tuberculosis-burden setting: an evaluation of five artificial intelligence algorithms. Lancet Dig Health. 2021;3(9):e543-54.

Hussian TAA. Evaluation the safety and security procedures used in X-ray clinics in Al-Harthiya-Baghdad. J Phys Conf Ser. 2021;2114:012009.

Alcaraz M, Olivares A, Achel DG, García-Gamuz JA, Castillo J, Alcaraz-Saura M. Genoprotective effect of some flavonoids against genotoxic damage induced by X-rays in vivo: relationship between structure and activity. Antioxidants. 2022;11(1):94.

Li Q, Wang Y, Xiao X, Zhong R, Liao J, Guo J, et al. Research on X-ray shielding performance of wearable Bi/Ce-natural leather composite materials. J Hazard Mater. 2020;398:122943.

Li Q, Zhong R, Xiao X, Liao J, Liao X, Shi B. Lightweight and flexible Bi@Bi-La natural leather composites with superb X-ray radiation shielding performance and low secondary radiation. ACS Appl Mater Interfaces. 2020;12:54117–26.

Wang Y, Ding P, Xu H, Li Q, Guo J, Liao X, et al. Advanced X-ray shielding materials enabled by the coordination of well-dispersed high atomic number elements in natural leather. ACS Appl Mater Interfaces. 2020;12(17):19916–26.

Wang Y, Zhong R, Li Q, Liao J, Liu N, Joshi NS, et al. Lightweight and wearable X-ray shielding material with biological structure for low secondary radiation and metabolic saving performance. Adv Mater Technol. 2021;6(3):2100050.

Hong S, Shin S, Chen R. An adaptive and wearable thermal camouflage device. Adv Funct Mater. 2020;30(11):1909788.

Salihoglu O, Uzlu HB, Yakar O, Aas S, Balci O, Kakenov N, et al. Graphene-based adaptive thermal camouflage. Nano Lett. 2018;18(7):4541–8.

Wang X, Tang Y, Wang Y, Ke L, Ye X, Huang X, et al. Leather enabled multifunctional thermal camouflage armor. Chem Eng Sci. 2019;196:64–71.

Jia L, Zeng S, Ding H, Smith AT, LaChance AM, Farooqui MM, et al. Leather-based multi-stimuli responsive chromisms. Adv Funct Mater. 2021;31(35):2104427.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (2207081675), Fellowship of China Postdoctoral Science Foundation (2021M692000), Key R&D Program of Shaanxi Province (2022GY-272), Young Talent Support Program Project of Shaanxi University Science and Technology Association (20200424), and Department of education’s Production-Study-Research combined innovation Funding—“Blue fire plan (Huizhou)” of 2018 (CXZJHZ201801).

Funding

This work was financially supported by the National Natural Science Foundation of China (220708167 5), Science and Technology Project of Xianyang City (Grant 2018k02-28), Fellowship of China Postdoctoral Science Foundation (2021M692000), Key R&D Program of Shaanxi Province (2022GY-272), Young Talent Support Program Project of Shaanxi University Science and Technology Association (20200424), and Department of education’s Production-Study-Research combined innovation Funding - “Blue fire plan (Huizhou)” of 2018 (CXZJHZ201801).

Author information

Authors and Affiliations

Contributions

ZB: Summarizing related literatures and writing this paper; XW and XL: Designing the outline of this article and revising the draft; MZ, OY, LX, SZ, SD, TL and YS: Retouching pictures, downloading and analyzing part of literatures; MH: Assist in revising the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bai, Z., Wang, X., Zheng, M. et al. Leather for flexible multifunctional bio-based materials: a review. J Leather Sci Eng 4, 16 (2022). https://doi.org/10.1186/s42825-022-00091-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1186/s42825-022-00091-6