Abstract

Researchers have recently altered their focus and have become more interested in natural fiber-reinforced polymer composites because they are more ecologically friendly and environmentally conscious than synthetic fiber-reinforced polymer composites. Among the best sources of natural fiber, Grewia ferruginea, sometimes known locally as Lenquata, is a source of natural fiber from other plant fibers. The goal of this study was to create polyester matrix composites reinforced with short Grewia ferruginea plant fibers measuring 10, 20, and 30 mm. The fibers were extracted using the traditional water-retting method and chemically treated with 5% NaOH. The findings indicated that the average tensile strength of a single fiber from Grewia ferruginea plants is 214 MPa, with a density of 1.11 g/cm3. Furthermore, the composite, which was created with a fiber length of 10 mm, fiber weight ratio of 25 %, and polyester matrix composite of 75 %, exhibited superior performance since it is stronger than any combination that was used to create the composite in this investigation, with 18.3 MPa tensile and 35.2 MPa flexural strength.

Similar content being viewed by others

Introduction

Because of their ecological and environmental problems, natural fiber-reinforced polymer composites have recently garnered more attention than synthetic fiber-reinforced polymer composites [1]. Given their high strength-to-weight ratio, natural fibers have piqued the interest of the engineering community as reinforcing materials in polymer composites to build sustainable materials [2, 3]. Nowadays, interest in natural fibers has been growing continuously, and researchers from academia and industries are now actively engaged in exploring new natural fibers and their new applications. The main reason for this interest is linked to their specific properties that are suitable for several sophisticated fibrous applications, such as reinforcement in composites, textiles, cellulose nanomaterials, activated or conductive carbon, and biomaterials.

The unique properties that exist in natural fibers are their low density, low cost, availability, recyclability, non-toxicity, considerable strength, good thermal stability, biodegradability, low energy consumption, etc. compared to their counterpart synthetic fibers [4, 5]. According to data, the global market for biocomposites is likely to develop significantly from natural fiber composites, with a compound annual growth rate (CAGR) of 11.2% predicted for bio-based composites between 2017 and 2023 [6]. Unique qualities, including high strength and stiffness, high specific modulus, internal vibration damping, wear resistance, flexibility, and adaptability, have led to growth in the use of these PCs and FRP materials [7]. For scientists, engineers, and researchers in the field of polymer science, one of the most exciting and rapidly developing fields of study is the creation of bio-based green composites from natural resources [8].

Many Sources of natural fibers, including bananas, bamboo, jute, hemp, flax, pineapple leaves, oil palm, coconuts, sisal, and ramie, can be used to extract natural fibers. These BioSources can alter the physical, chemical, mechanical, metallurgical, and tribological behaviors of various materials [9]. Jute, flax, straw, hemp, cane sugar, kenaf, bamboo, sisal, reeds, ramie, rice husk, oats, barley, banana fiber, rye, wheat, paper mulberry, pineapple leaf fiber, papyrus, coir, pennywort, kapok, and Raphia are examples of plant fibers that are popular natural fibers [10].

The sustainability, accessibility, and adequate mechanical strength of natural fibers have long attracted attention as reinforcing agents for polymer composites [11].

Utilizing composites made of natural fibers is one of the most recent developments in the polymer industry. Natural fiber composites are more affordable, biodegradable, less harsh on processing equipment, and are made of renewable materials, which lowers the need for petroleum resources [12]. Natural fiber composites, which are eco-friendly materials, are becoming increasingly popular in the field of product manufacturing engineering[13, 14]. Owing to the most recent technological developments in the discipline, material science today plays a critical role in engineering. Research and application interest in new materials is rapidly expanding. Bicycles, sporting goods, gear, electronics, technical solutions, and biological wastewater treatment technologies are among the products made with their help[15, 16].

The objectives of this study were to highlight the importance of reducing the harmful effects of synthetic fibers and polymers on the environment, promote the use of natural materials, and concentrate research efforts on the development of biodegradable systems[17]. Fiber-reinforced polymer (FRP) composites are being used by an expanding number of industries to replace heavy and expensive conventional materials for the production of lightweight items [18]. Natural fiber-reinforced thermosetting polymers, which are immobile, and natural fiber-reinforced thermoplastic polymers, which are recyclable, are two groups of non-fiber-reinforced polymers (NFRPs) [19]. Natural resources, including minerals, plants, and animals, supply the raw components needed to reinforce natural fibers [20] [21].

In previous research work by the author [6, 7] develops Mockups and natural fiber-reinforced polymer composites made from recently discovered lignocellulosic-based biocomposites made from thermoset and thermoplastic polymers that are both biobased and non-biobased. Numerous chemical treatments, such as compatibilizers, alkali, saline, and alkali-saline, as well as the addition of cross-linking agents, including glutaraldehyde (GLA) and epichlorohydrin (EP), are examples of surface modification approaches. This study employed a retting-extraction method and chemical treatment using sodium hydroxide (NaOH) [8].

Another study conducted by the author [9] focused on pure glass, pure jute, and glass-jute hybrid laminates and examined how stacking order and hybridization affect the overall mechanical and physical characteristics of the composites. The materials were cut and placed in a lay-up (600 × 300 mm) on a one-sided mold to create the composite. Next, a layer of peel ply and flowing mesh that partially covered the materials were added. The mold was sealed using a vacuum bag and sticky tape. Finally, it was concluded that by hybridizing the jute with glass fibers, it was possible to improve the mechanical properties of the composites.

Recent research has focused on the production of lightweight natural-fiber-reinforced polymer composites. Cow dung fibers are a promising candidate as a reinforcement for resin-based polymer composites, according to a comparative study between corn stalk fiber composites and sisal fiber composites. This finding encourages the development of alternative uses of cow dung waste resources in the automotive component industry [10].

Fibers are synthetic or natural materials with a large length-to-width ratio. The strengthening of the fibers within the matrix was simple only when the fibers were removed from the plants. The retting process involves pulling fibers from plants by separating, dissolving, and breaking down pectin, gums, and other muscle components [11].

Consequently, after extraction from renewable resources, natural fibers are pretreated using various chemical agents, such as KOH, NaOH, and KMnO4. Kenaf fibers were extracted from kenaf busts using a light chemical retting procedure. In particular, a kenaf bast strand of 51 mm was submerged in 5% NaOH [12]. The treatment of organic fibers with NaOH in an alkaline state is the most commonly used technique. This procedure breaks down the lignin, oils, and waxes that coat the outer fiber cell wall, depolymerizes cellulose, and renders short-length crystallites visible [22].

In this study, a polyester matrix, curing agent, Grewia ferruginea plant fiber, and caustic soda (NaOH) were utilized to create fiber-reinforced composite materials. Polyester resin was chosen for this study owing to its excellent flexibility, chemical resistance, low water-absorbing capacity, and excellent bonding tendency. Commercially available isophthalic unsaturated polyester resin was used for this investigation. Methyl Ethyl Ketone (accelerator) and Cobalt Naphthalene (catalyst) were used to cure the resin [13].

Polyester resins generally exhibit excellent flexibility because they are cheaper than other resins and are commonly available. Among the family of thermosetting polymers, polyester resins have the best mechanical properties. Its formulation can be changed according to the requirements, and it is one of the resins that can be easily used as a matrix for polymer composites. Natural fiber composites reinforced with polyester resin are usually manufactured using the hand layup method. Owing to alkalization, there is better adhesiveness between the natural fiber matrix and the polyester reinforcement, which increases the strength of the composite. Thermoset isophthalic polyester resins have excellent mechanical properties, poor water-absorbing properties, and better bonding ability [14].

The mixing and curing ratios are also important factors. Three factors have a significant impact on the properties of short-fiber composites: fiber length, fiber orientation, and fiber weight percentage [15]. Many researchers have succeeded, according to the literature, in creating composite materials that are optimized for effective usage in specific applications by changing the fiber composition, orientation, size, or manufacturing techniques. For FRCs to be used effectively, one must understand their mechanical, electrical, thermal, and physical characteristics [16]. The manual compression hand layup method was used to develop the composite samples [17].

Long- and short-sisal fiber-reinforced composites have been studied by other researchers. Fiber composites with random and longitudinal orientations were investigated. They proved that applications requiring high strength and stiffness in a single direction may utilize continuous fibers. However, randomly oriented short fibers increase the isotropic qualities of the composite while providing lower strength [18].

In Ethiopia, the Grewia ferruginea plant is named Hochst. ex A. Rich; Tiliaceae; family, local name Ogomdi (Oromiffa), or Lenquata (Amharic.) was distributed in large amounts. It is a shrub or a small tree up to 6m high. Common in woodlands and riverbanks at altitudes between 1350 and 2700 m [19]. A photograph of the Grewia ferruginea plant fiber is shown in Figure 1.1.

In this study, the relevant physical and mechanical properties of the Grewia Ferruginea plant single fibers were characterized to determine the appropriate experimental value of the Grewia Feruginea plant that can be used for reinforcement of polyester composite products. Standing from

In this study, Grewia ferruginea plant fiber was used as a reinforcement to fabricate a polyester matrix composite.

Methods

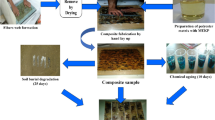

This experiment involved the following procedures: extracting Fiber from the Grewia ferruginea plant using a water retting process, treating the fiber surface with NaOH, preparing a mold for hand layup manufacturing, combining natural fiber with polyester, and testing the finished product. The overall workflow is illustrated in Fig. 1.2.

Extraction of fiber

Fibers were extracted using the retting process. Retting is the process of submerging fiber bundles in ditches, canals, or pods of freely flowing water. For the retting method, bundles of Grewia ferruginous plant sticks are joined together and transported to the water reservoir. Each bundle was placed in the water for approximately three months and covered with a stone that was purposefully made to serve as a water reservoir. The bark of each stick was peeled off in thin strips and cleaned completely with running water. The extracted fibers were then dried in a sunbath to remove any remaining moisture, and the outside pulp was repeatedly rinsed in water to reveal the inner bark [20].

Chemical Treatment of Grewia ferruginea plant fiber

The fiber collected from the Grewia ferruginea plant must be processed because it naturally has an oily appearance. The literature claims that alkali solutions work well for treating various natural fibers, and the best NaOH value was determined using the results of previous investigations [21, 23]. Using the 5% NaOH solution used in this experimental study, several researchers have frequently found the best chemical treatment for fibers based on previously cited literature. The chemical treatment was performed as follows. The weight volume percentage (w/v) mixing rule was 5wt%, or 5 g of NaOH for every 100 ml of water.

Processes parameters

The three process parameters that affect the manufactured composite are the weight fraction, fiber length, and fiber orientation presented in Table 1. Based on the literature given in this experiment, 10, 20, and 30 fiber lengths were used, and optimized fiber matrix weight ratios of 15, 25, and 35%, respectively, were selected. Scholars have often found that fiber lengths of 10, 20, and 30-mm optimum fiber lengths are optimal[24,25,26].

Density of the fiber

The density was determined Based on ASTM International - ASTM D8171-18 [28]. The liquid displacement method was used to calculate the density of the extracted natural fibers. According to Archimedes ' principles, water was used as the working substance, a liquid with the weight serving as the mass and volumetric units. The values are shown below in Table 2 with three replications, and the average value is taken as the fiber density.

Volume fractions

The definitions of the fiber volume fraction and matrix volume fraction are the ratio of the fiber volume to the composite volume and the ratio of the matrix volume fraction to the composite volume, respectively. The volume of the composite is the sum of fiber and matrix volume as shown in eq. (1).

Where Vf = Volume of the fiber, Vm = Volume of the matrix, Vc = Volume of a composite.

Void content

The void content is the difference between the experimental and theoretical densities of the produced composites [5]. The theoretical density (given in eq. (2)) was computed using the rule of mixtures to find the percentages of void content in the manufactured composites.

Where \({\rho }_{c\left(\text{theo}\right)}\) = theoretical density of the composite, \({\rho }_{f}\) = density of the fiber, \({\rho }_{m}\)= density of the matrix.

Then, we calculated the void percentage of the composite in eq. (3).

Where V% = void content in percent.

Design of Experiment (DOE) and composition of the composite

Using data from earlier studies, the ratio of the fiber and polyester combination or the composition of the composite was computed as presented in Tables 3 and Table 4 according to the mixing rule (ROM). The example prepared here included 27 flexural and 27 tensile specimens under ASTM standards; each sample was tested three times.

Subsequently, the influence of these two factors with three levels on two quality characteristics, namely the flexural and tensile strengths of the composites, were studied.

Size of the mold

A standard mold was used to prepare the specimens using the fiber volume fractions or weight fractions of polyester and fiber (FVF), which is considered a rectangular prism. So the dimension of the rectangular prism equals (6×90×170 = 91800mm3) (listed in Table 5) for tensile specimens

Preparation of specimen, methods of testing and apparatus

Every mechanical test carried out for this thesis was based on American Standard Testing Methods (ASTM). Three tests were conducted: the single-fiber tensile test (ASTM D3822) and tensile test (ASTM D638) standards. According to the ASTM standards, a hand saw and jig saw were used to cut the composite sample specimen, which was then finely polished.

Single fiber tensile test procedure

An individual Grewia ferruginea fiber is cut to an overall length of 13 cm with a known measured mass using an electronic balance (type ABS 80-4) with a capacity of 83 g and a reading of 0.1 mg to conduct the single fiber test in tension.

According to ASTM D3822, single-fiber tensile tests were carried out at room temperature on a UTM (Hounsfield) outfitted with a 500N load cell capacity of the machine. The fiber had a gauge length of 7 cm, and a cross-head speed of 10 mm/min, and 20 fiber counts were evaluated [30]. The mass and size of the fiber were measured in this study to determine the diameter (in eq. (4)) of the fiber using the indirect method of fiber diameter determination, which has been employed in many articles and research projects [31].

The single fiber tensile strength was then calculated as follows in eq. (5):

Where (σf) single fiber tensile strength, (\({F}_{f}\) ) single fiber tensile load, and (\(A) calculated\) cross-sectional area of a single fiber.

Tensile strength of the composite test procedure

Depending on the literature, using a computerized universal testing machine and the ASTM D638 method, the tensile strengths of the composites were measured at a crosshead speed of 2 mm/min [32]. Tensile tests were performed to evaluate the in-plane tensile properties of the fiber composites. The composite test was carried out in a universal tensile testing machine of the Deepack plastic Hydraulic Universal Material Tester with a 50 KN capacity at a crosshead speed of 5 mm/min at the Amhara pipe factory in Bahir Dar, Ethiopia. Tensile tests followed the ASTM D638 dumbbell-shaped (Type I) specimen required for reinforced composite testing and are presented in Table 6.

Flexural strength test (ASTM D790) procedure of the composite

The flexural strength of a material is its capacity to withstand deformation under load. The composite samples were subjected to short-beam three-point flexural strength tests to determine the flexural or bending strength values. It is a three-point bend test that, in most cases, encourages interlaminar shear failure, and is calculated using the formula below.

Where Smax = is the maximum strength of the material in MPa, \({\sigma }_{bf}\)= Flexural strength in MPa, L = Support span of the specimen mm, P = Load at a given point on the load-deflection curve in N, b = width of the specimen in mm, d = depth of the specimen in mm.

Flexural strength tests were performed using a Deepack Hydraulic Universal Material Tester with a capacity of 50 KN at a crosshead speed of 5 mm/min. Flexural strength tests were conducted according to ASTM D790, with a specimen size (illustrated in Table 7) of 120 mm × 20 mm × 6 mm and a span length of 96 mm (ASTMD790, 2010) [33].

Results and discussion

In this section, we present the results and discussion on the density and tensile properties of randomly oriented short Grewia ferruginea plant fiber-reinforced polyester matrix composite materials.

Density of Grewia ferruginea fiber

The density of the Grewia ferruginea fibers was measured based on the liquid displacement method (Archimedes principle) using water as the working liquid. The experiment was repeated thrice, and the average value was calculated.

Discussion of density result

Therefore, based on the results in Table 8, the experimental density of the 5% NaOH-treated new Grewia ferruginea plant fiber was 1.11g/cm3. When this value is compared with other natural fiber densities, it is lower than the density of coir fiber (1.15-1.46) g/cm3, hemp (1.4-1.5) g/cm3, and sisal, but greater than the date palm fiber value (0.9-1.2) g/cm3 [34]. This result implies that Grewia ferruginea fiber can be used for lightweight applications like other natural fibers by conducting more investigations on this plant fiber owing to its promising density.

Single fiber tensile test result

The results obtained from the Hounsfield (UTM) single fiber/yarn tensile testing machine are presented in Table 9.

Discussion for single fiber test

The tensile power range of the Grewia ferruginea plant single fiber strength, as determined by hand analyses, was 48 MPa to 444 MPa, and the average single fiber tensile strength for the selected and tested Grewia ferruginea plant fiber was 214 MPa. The results showed (in Table 9) that this fiber is robust and suitable for a variety of applications, including automotive and other non-load-bearing structures. Although it can be minimized using various coating techniques, the hydrophilic characteristics of the fiber may cause it to function less effectively than other petrochemicals [18].

Tensile strength result of Grewia ferruginea plant fiber reinforced composite

This study evaluated the tensile strength of a Grewia ferruginea plant fiber-reinforced composite for nine sample groups (designations), each consisting of three replicates or three specimens. Different coating techniques were used to calculate average results.

The 25% fiber (T125) weight fraction fiber-containing composites had a maximum tensile stress (18.3MPa) as (illustrated in Table 10) compared to other samples with the same fiber length but different fiber weight fractions.

The impact of the fiber content on the change in tensile strength at fiber/matrix ratios of 15/75, 25/75, and 35/65tabulated in Table 11. The Grewia ferruginea fiber ratio, which may have contributed to the ratio of 25/75 high tensile strength compared to the rest, may not have adequately reinforced the external load. At a fiber content of 25 %, the tensile strength reached its maximum at 15.6 Mpa.

Fiber/matrix ratios of 15/85, 25/75, and 35/65 showed in Table 12 the strongest correlation between the fiber content and change in tensile strength. Because some Grewia ferruginea fibers did not adequately support the external load, the 25/75 ratio had a higher tensile strength than the others. At 25% fiber content and 12.8 MPa tensile strength, the maximum tensile strength was reached.

Discussion of tensile strength result

From Figs. 1 and 2 a fiber length of 10 mm and fiber/polyester length of 25%, higher tensile properties (Young's modulus, strength, and elongation at break) were noted, indicating a relatively strong interaction between the matrix and the fiber [35]. The tensile strengths of natural fiber-reinforced polymer composites generally increase with the fiber content until they reach their optimal or highest value, beyond which they begin to decline [36].

As NFCs typically consist of hydrophilic fibers and hydrophobic matrices, fiber dispersion is a significant factor in determining the characteristics of NFCs and is a unique difficulty. Better fiber dispersion can be achieved by using an intensive process mixing method, such as a twin crew extruder, as opposed to a single-screw extruder. However, this usually comes at the expense of fiber damage, and it has been discovered that the process causes its lengths to fall drastically because of changes in temperature and screw configuration.

A reduction in tensile strength was observed at a fiber length of 30 mm, 35%fiber, and 65% polyester matrix content shown in Fig. 2. This is probably due to the difficulty of the resin to penetrate the spaces corresponding to the fiber and resin, resulting in poor wetting characteristics and therefore reducing the efficacy of stress transfer at the matrix–resin interface. One of the most important variables in discontinuous short-fiber composites that determine good mechanical performance is the critical fiber length, which is strongly influenced by the interfacial bonding between the matrix and the fiber [37].

Three-point flexural test result

This study lists the flexural sample results for each sample group with 10 mm,20 mm, and 30 mm fiber lengths and the corresponding fiber/matrix ratio illustrated in Table 13.

The Flexural property results for the F115%f, F125%f, and F135%f sample composite that is with 10mm constant length Grewia ferruginea plant fiber with 15%,25%, and 35% fiber/polyester weight fraction is presented in above Table 13. The 25% fiber (F125) weight fraction fiber-containing composites had a maximum flexural strength (35.2MPa) compared with other samples with the same fiber length but different fiber weight fractions. This indicated that the maximum weight fraction of the composite yielded better results.

The Flexural property results for the T215%f, T225%f, and T235%f sample composite that is with 20mm constant length Grewia ferruginea plant fiber with 15%,25%, and 35% fiber/polyester weight fraction is presented in above Table 14. The 25% fiber (F225) weight fraction fiber-containing composites had a maximum flexural strength (32MPa) compared to other samples with the same fiber length of 20 mm but different fiber weight fractions.

The Flexural property results for the T315%f, T325%f, and T335%f sample composite that is with 30mm constant length Grewia ferruginea plant fiber with 15%,25%, and 35% fiber/polyester weight fraction is presented in above Table 15. The 25% fiber (T325) weight fraction fiber-containing composites had a maximum flexural strength (27MPa) compared with other samples with the same fiber length but different fiber weight fractions. This indicated that the maximum weight fraction of the composite yielded better results.

Discussion of flexural strength result

As shown in Figs. 3 and 4 a fiber length of 10 mm and fiber/polyester length of 25%, higher flexural characteristics (Young's modulus, flexural strength, and elongation at break) were observed, indicating a rather strong interaction between the matrix and fiber.

Proper fiber dispersion ensures that the fibers are completely encircled by the matrix, which improves the interfacial bonding and decreases the number of voids. Better fiber dispersion can be achieved using an intensive process mixing method, such as a twin-screw extruder, as opposed to a single-screw extruder. However, this usually comes at the expense of fiber damage, and it has been discovered that process variables, such as temperature and screw configuration, cause fiber lengths to decrease drastically [38].

The loss in flexural strength was noted at 30 mm of fiber length, with polyester matrix contents of 65% and 35% of fiber. This is most likely caused by the resin having trouble penetrating the areas that correspond to the fiber and resin, which leads to poor wetting qualities and lessens the effectiveness of stress transfer at the matrix-resin interface.

The decrease in flexural strength was ascribed to the unequal mixing of the fibers and matrix in the short-fiber polyester composites as well as cluster formation. More than 35% fiber, 65% polyester matrix, and 30 mm length cannot be supported or passed through by the uneven distribution of fibers in the composite samples. When we contrast the 35.2 Mpa flexural strength results of our research with other academic efforts, it remains a promising finding for structural applications.

The excellent tensile strength of a single Ferruginea plant fiber, which ranges from 48 to 444 MPa, suggests that future research aimed at achieving notable improvements in the flexural strength of these kinds of composites should concentrate on optimizing the interfacial bond strength rather than the single fiber strength.

Conclusion

Based on various studies, alkaline treatment at a 5% NaOH concentration was applied to enhance the polyester composite made of Grewia ferruginea plant fiber adhesion qualities by lowering the plant fiber lignin content and oily surface. The fabrication process of the composite was performed using the hand lay-up method owing to its low cost and availability for short fiber-reinforced polymer composites.

Based on the above experimental results, the following conclusions can be drawn.

-

It fills the literature gap on Grewia ferruginea plant fiber characterization and usage of this fiber as a reinforcing fiber, which has not been performed before.

-

Grewia ferruginea plant Fiber extracted and reinforced with polyester matrix composite was successfully fabricated and the tensile and flexural properties of Grewia ferruginea plant Fiber reinforced polyester composite were determined with different Fiber content and Fiber length(size). Based on the results, the fiber content and fiber length affected the tensile strength and flexural strength.

-

The single-fiber test result was good when compared with existing natural fibers with a single-fiber tensile strength of 46 - 444Mpa.

-

A fiber length of 1 cm and fiber content of 25% (T125) showed better tensile and flexural strength owing to its optimum length and fiber weight ratio with a tensile strength of 18.3Mpa and flexural strength of 35.2Mpa. The Fiber cutting size improves the tensile strength, as shown in the above table, which indicates that small-size fibers provide better results in terms of tensile and flexural strength.

-

Studying the microstructure of the Grewia ferruginea plant fiber is also a good determinant factor, so it provides a better insight into its microstructural content.

-

It will give a better understanding of comparative studies that will be performed for

-

fiber extracted using different fiber extraction methods on the Grewia ferruginea plant

-

Fiber-reinforced polyester composites.

Availability of data and materials

Data are included in article/supp. materials/referenced in this article.

Abbreviations

- MTB:

-

Magnetotactic bacteria

- FRP:

-

Fiber Reinforced Polymer

- NFRP:

-

Natural Fiber Reinforced Polymers

- GLA:

-

Glutaraldehyde

- EP:

-

Epichlorohydrin

- MEKP:

-

Methyl Ethyl Ketone Peroxide

- UTM:

-

Universal Testing Machine

- FRC:

-

Fiber Reinforced Composite

- ASTM:

-

American Society for Testing and Materials

- NFC:

-

Natural Fiber Composite

- ROM:

-

Rule of Mixing

- FVF:

-

Fiber Volume Fraction

References

Saha A, Kumar S, and Kumar A. Influence of pineapple leaf particulate on mechanical, thermal and biodegradation characteristics of pineapple leaf fiber reinforced polymer composite. J Polymer Res. 2021; 28(2). https://doi.org/10.1007/s10965-021-02435-y

Functional fibers from Bambusa tulda (Northeast Indian species) and their potential for reinforcing biocomposites-ScienceDirect Materials Today Communications. Available: http://dx.doi.org/10.1016/j.mtcomm.2022.103800

A. Saha, S. Kumar, D. Zindani, S. Bhowmik, Micro-mechanical analysis of the pineapple-reinforced polymeric composite by the inclusion of pineapple leaf particulates. Proc Inst Mech Eng Part L 235(5), 1112–1127 (2021). https://doi.org/10.1177/1464420721990851

Hossain S, Jalil MA, Islam T, and Rahman MM. A low-density cellulose rich new natural fiber extracted from the bark of jack tree branches and its characterizations. Heliyon. 2022; 8(11). https://doi.org/10.1016/j.heliyon.2022.e11667

A. Saha, S. Kumar, D. Zindani, Investigation of the effect of water absorption on thermomechanical and viscoelastic properties of flax-hemp-reinforced hybrid composite. Polym Compos 42(9), 4497–4516 (2021). https://doi.org/10.1002/pc.26164

Bale J, Boimau K, and Nenobesi M. Natural composite reinforced by Lontar (Borassus flabellifer) fiber: An experimental study on open-hole tensile strength. Int J Biomater. 2017; 2017. https://doi.org/10.1155/2017/7685047

Dahy H. Natural fibre-reinforced polymer composites (NFRP) fabricated from lignocellulosic fibres for future sustainable architectural applications, case studies: Segmented-shell construction, acoustic panels, and furniture. Sensors (Switzerland). 2019; 19(3). https://doi.org/10.3390/s19030738

Mohammed AABA et al. Corn: Its Structure, Polymer, Fiber, Composite, Properties, and Applications. Polymers. 2022; 14(20). MDPI. https://doi.org/10.3390/polym14204396

Dias T da C, da Silva AAX, Tonatto MLP, and Amico SC. Experimental Investigation on the Mechanical and Physical Properties of Glass/Jute Hybrid Laminates. Polymers (Basel). 2022; 14(21). https://doi.org/10.3390/polym14214742

Wu S, Guo M, Zhao J, Wu Q, Zhuang J, and Jiang X. Characterization of the mechanical and morphological properties of cow dung fiber-reinforced polymer composites: a comparative study with corn stalk fiber composites and sisal fiber composites. Polymers (Basel). 2022; 14(22). https://doi.org/10.3390/polym14225041

Sathish S et al. A review of natural fiber composites: Extraction methods, chemical treatments and applications. Materials Today: Proceedings, Elsevier Ltd. 2021. 8017–8023. https://doi.org/10.1016/j.matpr.2020.12.1105

Wang G, Shi SQ, Wang J, Yu Y, Assistant GR, and Cheng H. Tensile properties of four types of individual cellulosic fiBERS Shuangping Cao. 2011

Karthik S and Arunachalam VP. Investigation on the tensile and flexural behavior of coconut inflorescence fiber reinforced unsaturated polyester resin composites. Mater Res Express. 2020; 7(1). https://doi.org/10.1088/2053-1591/ab6c9d

Sathishkumar GK, et al. Synthesis and mechanical properties of natural fiber reinforced epoxy/polyester/polypropylene composites: a review. J Nat Fibers. 2022; 19(10): 3718–3741. Taylor and Francis Ltd. https://doi.org/10.1080/15440478.2020.1848723

Yashas Gowda TG, Sanjay MR, Subrahmanya Bhat K, Madhu P, Senthamaraikannan P, and Yogesha B., “Polymer matrix-natural fiber composites: an overview. Cogent Eng. 2018; 5(1). Cogent OA. https://doi.org/10.1080/23311916.2018.1446667

D. K. Rajak, D. D. Pagar, P. L. Menezes, and E. Linul. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers. 2019; 11(10). MDPI AG. https://doi.org/10.3390/polym11101667

S. Kumar, A. Saha, Utilization of coconut shell biomass residue to develop sustainable biocomposites and characterize the physical, mechanical, thermal, and water absorption properties. Biomass Convers Biorefin (2022). https://doi.org/10.1007/s13399-022-03293-4

M. Haameem, M.S. Abdul Majid, M. Afendi, H.F.A. Marzuki, I. Fahmi, A.G. Gibson, Mechanical properties of Napier grass fibre/polyester composites. Compos Struct 136, 1–10 (2016). https://doi.org/10.1016/j.compstruct.2015.09.051

Y. Yiblet, E. Adamu, An ethnobotanical study of wild edible plants in Tach Gayint District, South Gondar Zone, Amhara Region, Northwestern Ethiopia. Evid-Based Complement Altern Med 2023, 1–11 (2023). https://doi.org/10.1155/2023/7837615

S. Kumar, A review on surface modification of bast fibre as reinforcement in polymer composites. Int J Mater Sci Appl 6(2), 77 (2017). https://doi.org/10.11648/j.ijmsa.20170602.12

R. Prasanna Venkatesh, K. Ramanathan, and V. Srinivasa Raman. Tensile, flexual, impact and water absorption properties of natural fibre reinforced polyester hybrid composites. Fibres Textiles Eastern Eur. 2016; 24(3): 90–94. https://doi.org/10.5604/12303666.1196617

C. Wang, S. Bai, X. Yue, B. Long, L.P. Choo-Smith, Relationship between chemical composition, crystallinity, orientation and tensile strength of kenaf fiber. Fibers Polymers 17(11), 1757–1764 (2016). https://doi.org/10.1007/s12221-016-6703-5

Hasan M, Rahman M, Chen Y and Cicek N. Optimization of typha fibre extraction and properties for bio-composite applications using desirability function analysis. Polymers (Basel). 2022; 14(9). https://doi.org/10.3390/polym14091685

Senthilkumar K, Siva I, N. Rajini, and P. Jeyaraj. Effect of fibre length and weight percentage on mechanical properties of short sisal/polyester composite. 2015

Prakash KB et al. Influence of Fiber Volume and Fiber Length on Thermal and Flexural Properties of a Hybrid Natural Polymer Composite Prepared with Banana Stem, Pineapple Leaf, and S-Glass. Adv Mater Sci Eng. 2021; 2021. https://doi.org/10.1155/2021/6329400

Jenish I et al. Fabrication and Experimental Analysis of Treated Snake Grass Fiber Reinforced with Polyester Composite. Adv Mater Sci Eng. 2021; 2021. https://doi.org/10.1155/2021/6078155

Pastukhov LV, Kanters MJW, Engels TAP, and Govaert LE. Influence of fiber orientation, temperature and relative humidity on the long-term performance of short glass fiber reinforced polyamide 6. J Appl Polym Sci. 2021; 138(19). https://doi.org/10.1002/app.50382

Standard Test Methods for Density Determination of Flax Fiber. https://doi.org/10.1520/D8171-18

M. Le Gall, P. Davies, N. Martin, C. Baley, Recommended flax fibre density values for composite property predictions. Ind Crops Prod 114, 52–58 (2018). https://doi.org/10.1016/j.indcrop.2018.01.065

M.C. Symington, W.M. Banks, O.D. West, R.A. Pethrick, Tensile testing of cellulose based natural fibers for structural composite applications. J Compos Mater 43(9), 1083–1108 (2009). https://doi.org/10.1177/0021998308097740

A. Abdela, M. Versteyhe, F. Taddese, Characterization of single enset fiber tensile properties using optimal experimental design and digital image correlation technique. Int J Mech Eng Appl 8(1), 8 (2020). https://doi.org/10.11648/j.ijmea.20200801.12

Materials P, Materials EI, Matrix P, Materials C, and Specimens P. Standard Test Method for Tensile Properties of Plastics 1. 2006; 03(2004): 1–15

ASTM INTERNATIONAL. Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. D790. Annual Book of ASTM Standards. 2002; i: 1–12. https://doi.org/10.1520/D0790-17.2

W. Ghori, N. Saba, M. Jawaid, M. Asim, A review on date palm ( phoenix dactylifera ) fibers and its polymer composites. IOP Conf Ser Mater Sci Eng 368(1), 012009 (2018). https://doi.org/10.1088/1757-899X/368/1/012009

Anand PB, Lakshmikanthan A, Chandrashekarappa MPG, Selvan CP, Pimenov DY, Giasin K. Experimental Investigation of effect of fiber length on mechanical, wear, and morphological behavior of silane-treated pineapple leaf fiber reinforced polymer composites. Fibers. 2022; 10(7). https://doi.org/10.3390/fib10070056

Md Shah AU, Sultan MT, Jawaid M, Cardona F, and Abu Talib AR. Bamboo composites review. 2016

K.R. Garadimani, G.U. Raju, K.G. Kodancha, Study on mechanical properties of corn cob particle and E-glass fiber reinforced hybrid polymer composites. Am J Mater Sci 5(3C), 86–91 (2015). https://doi.org/10.5923/c.materials.201502.18

Raja T, Anand P, Karthik M, and Sundaraj M. Evaluation of Mechanical Properties of Natural Fibre Reinforced Composites-A Review. Int J Mech Eng Technol. 2017; 8(7): 915–924. Available: https://iaeme.com/MasterAdmin/Journal_uploads/IJMET/VOLUME_8_ISSUE_7/IJMET_08_07_100.pdf

Acknowledgments

Thank you. Almighty God.

Funding

No funds are available.

Author information

Authors and Affiliations

Contributions

Yewondwosen Gzate and Aychew Asratie conceived and designed the analysis; analyzed and interpreted the data; contributed analysis tools or data; wrote the paper; revised it. Dejen Seyoum and Robinson Gnanadurai: perceived and designed the analysis; analyzed and interpreted the data; contributed analysis tools or data; wrote the paper edited. All authors have read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Seyoum, D., Asratie, A., Gnanadurai, R. et al. Experimental characterization of Grewia Ferruginea fiber reinforced polyester matrix composite materials. Functional Composite Mater 5, 7 (2024). https://doi.org/10.1186/s42252-024-00057-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s42252-024-00057-3