Abstract

Background

Facial deformities often demand reconstructive surgery and the placement of three-dimensional (3D) printed craniomaxillofacial prostheses. Prostheses manufacturing requires patients’ computed tomography (CT) images. Poor quality images result in incorrectly sized prostheses, necessitating repeat imaging and refitting. The Centre for Rapid Prototyping and Manufacturing (CRPM) produces most facial prostheses in South Africa but does not have a prescribed optimised CT protocol. Therefore, this study was undertaken.

Methods

A collection of CRPM STLs used in the design and manufacturing of craniomaxillofacial prostheses is available. The image quality of stereolithography (STL) files of CRPM CT scans was evaluated to determine what constitutes good image quality. This collection was scrutinised for inclusion in the image quality evaluation. After scrutiny, 35 STLs of individuals ≥15 years of age were selected and included metadata attached to the DICOM file. Furthermore, only STLs created without manipulation by the same designer were included in the collection. Before the qualitative evaluation of the STLs, eight different critical anatomical reference points (CARPs) were identified with the assistance of an expert team. A visual acuity rating scale of three categories was devised for each CARP, where 1 was allocated to poor visual acuity, 2 to partial, and 3 to good visual acuity. Similarly, rating scales were devised for the presence of concentric rings and the overall impression score awarded by the two designers involved in the design and manufacturing of the prostheses. This stereolithography measurement rubric (SMR) was then applied to the 35 STLs by a team of three experts, including the two designers, during a structured evaluation session. The scores were used to calculate summary and inferential statistics.

Results

Scores grouped around the central rating of partial visual acuity. The three evaluators’ mean total CARP scores ranged from 13.1 to 14.4 (maximum possible score 24), while the mean total CARP + ring scores ranged from 15.8 to 17.1 (maximum possible score 27). No significant differences were detected between the evaluators’ scores.

Conclusion

This SMR appears to be the first of its kind. This image quality assessment of STLs provides the groundwork for finer CT image quality evaluation to formulate a CT imaging protocol for the CRPM to design and manufacture accurate internal cranial prostheses.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Background

Facial deformities and disfigurements may have a profound psychosocial impact on an individual. The visibility of disfigurement and being perceived as ‘abnormal’ by society can present various challenges. People with disfigurements often experience rejection by society, who treats them as outcasts, resulting in their suffering from anxiety, severe depression and poor self-esteem [1, 2]. The cause of facial disfigurements can be either congenital or acquired. Most facial disfigurements are acquired, while malformed or the absence of facial features is examples of congenital disfigurements. Acquired disfigurements are mainly the result of systemic pathologies, for example, cancer, but could result from traumatic events, including motor vehicle accidents and assaults [3]. In South Africa, statistics show that facial trauma injuries mainly result from the high prevalence of road traffic accidents, assaults and shack fires. Shack fires and primus stoves are the leading causes of burn injuries in South Africa, which can also cause facial disfigurements [4].

Patients with facial disfigurements often seek medical interventions to improve their physical appearance. While some restorative interventions can be performed for improved functional purposes, such as chewing, most interventions are for aesthetic reasons [5]. Improvement of such deformities may require cranial reconstructive surgery and placement of implants or prostheses. Maxillofacial prostheses are considered by many the primary choice of treatment for functional rehabilitation, aesthetic reconstruction and rebuilding a patient’s confidence, and can either be external, internal or both [6]. The process of manufacturing a maxillofacial prosthesis involves the creation of a three dimensional (3D) solid object from a 3D digital file through the process of additive manufacturing (AM) [7]. A good and appropriate prosthesis results in patients demonstrating improved mental health, social engagement and the ability to lead productive lives [8]. Manufacturing craniomaxillofacial prostheses require computed tomography (CT) images of the facial area, from which a prosthesis is designed for 3D printing.

The quality of preoperative CT images is crucial, as it is used to plan and print an implant unique to an individual. The accuracy of the 3D printed model of a patient’s anatomy has a major influence when selecting appropriate treatment options by clinicians. When suboptimal CT images are used for the reconstructive model design and manufacturing, it could result in incorrect sizing of the printed device, which could have detrimental effects during surgery and may require repeated imaging and refitting, which could cause patient distress [9]. Historically, the end goal for CT imaging was for the diagnosis of disease and not necessarily the design and manufacturing of a 3D printed implant. Manmadhachary [10] stated that the accuracy of a 3D medical model generated from CT images has not been investigated sufficiently yet.

The Centre for Rapid Prototyping and Manufacturing (CRPM) at the Central University of Technology, Free State (CUT) in Bloemfontein, South Africa, is responsible for most craniomaxillofacial prostheses design and manufacturing in South Africa. Currently, the CRPM does not have a prescribed optimised CT imaging protocol specifically for the design and manufacturing of internal cranial prostheses. The need for standardisation and optimisation in protocols remains, as CT scanners differ in their capabilities and various clinical indications require unique protocols [11]. The adoption of standard imaging protocols, especially in specialised modalities such as CT and magnetic resonance imaging (MRI), may reduce the chance of error or discrepancy in some areas of radiology practice [12]. To develop an optimised CT protocol, understanding what constitutes a good quality CT scan is thus required. Therefore, this study was undertaken to devise a measurement rubric that can be used to evaluate the image quality of STLs generated from CT scan Digital Imaging and Communications in Medicine (DICOM) files. This study formed part of a larger study with the end goal to produce an optimised CT protocol with CT parameter threshold values to design and manufacture craniomaxillofacial prostheses at CRPM. Towards this end goal, an STL collection was subjected to different image quality evaluations, of which the first was to apply a rubric to evaluate STL image quality.

Methods

Selection of STLs for image quality measurement

At the CRPM, access to a collection of STLs used to design and manufacture craniomaxillofacial prostheses was available. This collection comprised 48 STLs that were derived from original CT DICOM files, to which access could not be obtained. The collection of STLs was scrutinised for their appropriateness for the study by applying the following exclusion criteria:

-

(i)

non-CT data images, such as MRI and cone-beam CTs;

-

(ii)

duplicate STLs; and

-

(iii)

STLs without CT scan metadata.

Once all the non-CT data images and duplicates were removed, the resultant STL data collection was scrutinised for age appropriateness and the presence of CT scan metadata. To ensure the most uniform collection of STLs for the study, only STLs of patients 15 years or older were included in the STL data collection (n = 35). STLs of patients younger than 15 were deemed inappropriate, as the CT parameter selection may differ greatly from that of the CT parameter selection for adult patients [13].

To further ensure uniformity, only STLs created without manipulation by the same designer were included in the STL collection. The designer opened the original CT DICOM files in Materialise Mimics® Medical version 24.0 and Materialise 3-matic® (Materialise NV; Leuven. Belgium) and segmented the data by applying the default threshold settings (a minimum of 226 Hounsfield unit [HU] value and a maximum of 3071 HU) with region growing. Artificial intelligence (AI) automated segmentation was not applied in the process. The ‘optimal’ STL quality setting was selected during the “calculate meshing” step. The computer hardware used to create the STLs met the minimum requirements stipulated by Mimics. When creating the STLs, no artifacts were removed by the designer. Because of the uniform treatment of the CT DICOM files during the creation of the STLs, this collection of STLs was deemed appropriate to test a measurement rubric that could be used to evaluate the image quality of STLs.

Measurement of STL image quality

For the measurement of STL image quality, three steps were followed. In the first step, appropriate image quality variables were identified and thereafter referred to as evaluation items. In the second step, an STL measurement rubric (SMR) was formulated to measure the respective evaluation items of STL image quality. In the last step, the SMR was applied to measure the image quality of the selected STLs. An expert evaluation task team was constituted and included the two designers responsible for prostheses design at CRPM, a specialist who had extensive experience working with similar data sets. After a lengthy discussion, the expert evaluation task team agreed that five evaluation items should be used for STL image evaluation (Table 1). Two additional image quality evaluation items were added to the list to provide a more robust measurement of the respective STLs; one relating to the presence or absence of concentric rings on an STL, and the other relating to the overall impression of the two designers who used the STLs in prosthesis design.

Several CARPs were identified for the evaluation of the image quality of the STLs. In the event that some of the CARPs could be missing from a CT scan, the expert evaluation task team suggested that more than five CARPs should be identified to ensure that a sufficient number of measurements could be generated for each of the CT scans. Thus, the team suggested eight different CARPs of various anatomical regions of the cranium, including cranial foramina, cranial sutures and particular structures such as the mandible and the teeth (Table 2).

The SMR was created to measure the respective evaluation items in consultation with the evaluation team. The team members agreed that a 3-point rating scale that focused on the visual acuity of the respective CARPs would be appropriate for measuring the image quality of the STLs. The 3-point rating comprised a rating of “1” that indicated poor visual acuity; “2” that indicated partial visual acuity; and “3” that indicated good visual acuity of a particular CARP. Table 3 provides the SMR containing the rating scales and descriptions for the ten evaluation items used in the measurement of the image quality of the STLs. For the measurement of the STL image quality, three evaluators were identified and included the two designers and a specialist member of the expert evaluation task team. At a meeting, the evaluators were tasked to score each STL individually by applying the guidelines of the SMR. The scores were thereafter captured on Excel spreadsheets designed for the study.

Statistical analysis

Several statistical analyses were performed on the measurements of the different evaluation items used to measure the image quality of the respective STLs. Summary statistics were calculated for all evaluation items. Inferential statistics were also performed on the measurements to ascertain to what extent the measurements of the three evaluators were consistent with one another. Hence the following hypotheses were derived:

-

H1: If the differences in measurements by the three evaluators for the individual CARPs were 5% or less, then the differences were not because of random fluctuations. This hypothesis was tested through the application of the Kruskal-Wallis one-way analysis of variance (ANOVA).

-

H2: If the differences in measurements by the three evaluators for the Total CARP score were 5% or less, then the differences were not because of random fluctuations. This hypothesis was tested through the application of the Kruskal-Wallis one-way ANOVA.

-

H3: If the differences in measurements by the three evaluators for the Total CARP + ring score were 5% or less, then the differences were not because of random fluctuations. This hypothesis was tested through the application of the Kruskal-Wallis one-way ANOVA.

-

H4: If the differences in measurements by the two designer evaluators for the Overall impression score were 5% or less, then the differences were not because of random fluctuations. This hypothesis was tested through the application of the Mann-Whitney U test.

To ascertain if an association existed between the Overall impression score of the design evaluators and the two evaluation items, Total CARP score and Total CARP + ring score, Spearman’s rank correlation coefficients were calculated. Thus, the following hypotheses were derived:

-

H5: If the Total CARP score is associated with the Overall impression score, then a high Total CARP score will result in a high Overall impression score.

-

H6: If the Total CARP + ring score is associated with the Overall impression score, then a high Total CARP + ring score will result in a high Overall impression score.

Classification of STL image quality

For the classification of the image quality of the STLs, a systematic classification process was required so that the STLs could be classified into a number of image quality categories. It was therefore decided that three broad image quality categories would be appropriate for the evaluation of the STLs. For the STL image quality classification, the measurements of the evaluation items, Total CARP score and Total CARP + ring score, were deemed appropriate. Both these evaluation items encompass a more or less holistic evaluation of an STL’s image quality. The Total CARP score is a composite value of all the CARP measurements, while Total CARP + ring score is a composite value of all the CARP measurements and whether rings were present on an STL. Thus, a systematic step-by-step process was devised to guide the classification of the STL image quality. The systematic step-by-step process was as follows:

-

1.

Firstly, the rating scores of the three evaluators for the evaluation items Total CARP score and Total CARP + ring score were listed for each STL;

-

2.

The Total CARP score values were then used to classify the STLs into three broad image quality categories, low (L), medium (M) and high (H), where a rating value of 1–8 implied low STL image quality, 9–16 medium STL image quality and 17–24 high STL image quality;

-

3.

The Total CARP + ring score values were also used to classify the STLs into three broad image quality categories, L, M and H, where a rating value of 1–9 implied low STL image quality, 10–18 medium STL image quality and 19–27 high STL image quality; and

-

4.

To obtain the final image quality classification category for an STL, the classification categories were compared for each STL and the final image quality classification category awarded to an STL by choosing the highest image quality category. For example, a classification of H would be awarded to an STL when at least one of either the Total CARP score or Total CARP + ring score was categorised as H.

Ethical considerations

The study was approved by the Health Sciences Research Ethics Committee (HSREC; reference number UFS-HSD2020/1719/2601) of the University of the Free State and the Free State Province Department of Health, South Africa. Furthermore, because of the retrospective nature of the study, patient informed consent was not required. All CT scan data from CRPM used during the research study were anonymised and no personal information of any of the patients was disclosed.

Results and discussion

STL image quality analysis

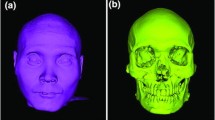

Through the application of the SMR, the expert evaluation team graded the different CARPs on the STLs in terms of visual acuity. By applying the 3-point rating scale of the SMR, the team was able to grade each of the CARPs in terms of visual acuity into categories indicating poor, partial and good visual acuity. To better understand the visual representation of these ratings, representative examples were selected and are illustrated in Table 4.

The mode and median of the scores of the eight individual CARPs of the three evaluators were grouped around the central rating of partial visual acuity. Similarly, the CARP scores were also closely grouped around the central rating of partial visual acuity. When considering the Total CARP scores of the three evaluators, the mean values ranged from 54.6% (13.1) to 60.0% (14.4) of the maximum possible score of 24. In contrast, the mean total CARP + ring scores ranged from approximately 58.5% (15.8) to 63.3% (17.1) of the maximum possible score of 27. Interestingly, ring artifacts were visible in only a few of the STLs. Furthermore, the overall impression scores of the two designers were similar. Table 5 summarises the evaluators’ measurement scores for the evaluation items of the STLs and their summary statistics.

Evaluators’ STL image quality scoring

Four hypotheses were tested to compare the STL image quality scoring results of the different evaluators. The eight CARP Kruskal-Wallis tests performed on the three evaluators’ STL image quality scores revealed no significant differences between the three evaluators at α = 0.05 (Table 6). Similarly, for the Total CARP score and Total CARP + ring score, the differences between the scores of the three evaluators were also non-significant. When the Overall impression scores of the two designers were compared, the Mann-Whitney U test also revealed no significant differences at α = 0.05.

Association between overall impression and total scores

Two further hypotheses were tested to determine whether the Overall impression score was associated with the Total CARP score and Total CARP + ring score of the two designer evaluators. Spearman’s rank correlation calculations (rs) revealed that for both the evaluators, significantly strong associations were found between their Overall impression score and Total CARP score, as well as the Total CARP + ring score (Table 7).

Classification of the STL image quality

In an attempt to categorise the different STLs according to their image quality, the classification guide was followed. According to the mean Total CARP score, 20% of the 35 STLs fell into the high image quality category (Table 8). However, when the STLs were categorised according to the more lenient classification of Total CARP + ring score, 31.4% of the STLs fell into the high image quality category. After merging the mean Total CARP score and the Total CARP + ring score STL image quality classifications, 34.3% (12 STLs) were ultimately classified into the high image quality category.

Conclusion

In this study, a user-friendly SMR was developed and successfully applied to categorise 35 cranial STLs into three broad image quality categories. An extensive review of the literature confirmed that this SMR for STL image quality analysis appears to be a first of its kind. The SMR comprised several evaluation items, of which most were accompanied by a 3-point rating scale to grade the visual acuity of the STLs. After the application of the SMR, 12 of the 35 STLs were deemed to be high image quality STLs, which could be used to develop an optimal CT imaging protocol for CRPM. The metadata attached to the STLs will be used to ascertain which CT scan parameters are appropriate for such an optimised CT imaging protocol for the design and manufacturing of internal cranial prostheses. An optimised CT imaging protocol will reduce the number of resizing of prostheses, repeat CT imaging and also limit patient distress.

A user-friendly SMR was developed and used to successfully grade the image quality of STLs generated from CT scan DICOM files. The ability to grade the image quality of STLs makes it possible to plan for more accurate CT scan parameters to design and manufacture internal cranial prostheses.

Availability of data and materials

All data generated and analysed during this study are included in this published article.

Abbreviations

- 3D:

-

Three-dimensional

- ANOVA:

-

Analysis of variance

- CARP:

-

Critical anatomical reference point

- CRPM:

-

Centre for Rapid Prototyping and Manufacturing

- CT:

-

Computed tomography

- DICOM:

-

Digital Imaging and Communications in Medicine

- HSREC:

-

Health Sciences Research Ethics Committee

- MRI:

-

Magnetic resonance imaging

- SMR:

-

STL measurement rubric

- STL:

-

Stereolithography

References

Arunachalam D, Thirumoorthy A, Devi S, Thennarasu. Quality of life in cancer patients with disfigurement due to cancer and its treatments. Indian. J Palliat Care. 2011;17(3):184–90. https://doi.org/10.4103/0973-1075.92334.

Sykes BE, Curtis TA, Cantor R. Psychosocial aspects of maxillofacial rehabilitation. II. A long-range evaluation. J Prosthet Dent. 1972;28(5):540–5. https://doi.org/10.1016/0022-3913(72)90065-0.

Yadav SK, Shrestha S. A study on posttraumatic experience of road traffic accident afflicted maxillofacial trauma patient at a tertiary hospital. J Nat Sci Biol Med. 2017;8(1):40–5. https://doi.org/10.4103/0976-9668.198358.

Maritz D, Wallis L, Van der Merwe E, Nel D. The aetiology of adult burns in the Western Cape, South Africa. Burns. 2012;38(1):120–7. https://doi.org/10.1016/j.burns.2010.12.007.

Pillay L, Mabongo M, Buch B. Prevalence and aetiological factors of maxillofacial trauma in a rural district hospital in the Eastern Cape. S Afr Dent J. 2019;73(5):348–53 http://www.scielo.org.za/pdf/sadj/v73n5/06.pdf (Accessed 10 Mar 2022).

Angrish A. The role of 3D printing in the design and manufacture of prosthetic devices. Med Device Online. Guest column, 27 May 2014. https://www.meddeviceonline.com/doc/the-role-of-d-printing-in-the-design-and-manufacture-of-prosthetic-devices-0001 (Accessed 10 Mar 2022).

Haleem A, Javaid M. Role of CT and MRI in the design and development of orthopaedic model using additive manufacturing. J Clin Orthop Trauma. 2018;9(3):213–7. https://doi.org/10.1016/j.jcot.2018.07.002.

Khasnabis C. Standards for Prosthetics and Orthotics Service Provision 2015–2017 Work Plan. Version 4 September 2015. http://www.who.int/phi/implementation/assistive_technology/workplan_p-o_standards.pdf (Accessed 10 Mar 2022).

George E, Liacouras P, Rybicki FJ, Mitsouras D. Measuring and establishing the accuracy and reproducibility of 3D printed medical models. Radiographics. 2017;37(5):1424–50. https://doi.org/10.1148/rg.2017160165.

Manmadhachary A. CT imaging parameters for precision models using additive manufacturing. Multiscale Multidisc Model Exp Design. 2019;2(3):209–20. https://doi.org/10.1007/s41939-019-00046-1.

Trattner S, Pearson GDN, Chin C, Cody DD, Gupta R, Hess CP, et al. Standardization and optimization of CT protocols to achieve low dose. J Am Coll Radiol. 2014;11(3):271–8. https://doi.org/10.1016/j.jacr.2013.10.016.

Brady A, Laoide RÓ, McCarthy P, McDermott R. Discrepancy and error in radiology: concepts, causes and consequences. Ulster Med J. 2012;81(1):3–9 https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3609674/ (Accessed 10 Mar 2022).

Nievelstein RAJ, Van Dam IM, Van der Molen AJ. Multidetector CT in children: current concepts and dose reduction strategies. Pediatr Radiol. 2010;40(8):1324–44. https://doi.org/10.1007/s00247-010-1714-7.

Gray H. Gray's Anatomy of the Human Body. 20th ed. Philadelphia: Lea & Febiger; 1918.

Saavedra-Abril JA, Balhen-Martin K, Zaragoza-Velasco K, Kimura-Yahama ET, Saavedra S, Stoopen ME. Dental multisection CT for the placement of oral implants: technique and applications. Radiographics. 2010;30(7):1975–91. https://doi.org/10.1148/rg.307105026.

Acknowledgements

The authors would like to thank Dr. Kobus van der Walt, Mr. Johan Els and Mr. André Heydenrych from CRPM, CUT, for their time and contributions during the STL image quality measurement; the Radiological Society of North America (RSNA) for providing written permission for the use of the image in Table 2 (as indicated per footnote); and Dr. Daleen Struwig, medical writer/editor, for assistance with the technical and editorial preparation of the manuscript.

Permission to use third-party material

The Radiological Society of North America (RSNA) provided written permission for the use of the image in Table 2 (as indicated per footnote) from Saavedra-Abril JA, Balhen-Martin K, Zaragoza-Velasco K, Kimura-Yahama ET, Saavedra S, Stoopen ME. Dental multisection CT for the placement of oral implants: technique and applications. Radiographics. 2010;30(7):1975–1991, page 1978. Copyright holder: RSNA.

Unpublished conference presentation

This article has been included in the conference proceedings (pp. 527–542) of the 37th International Manufacturing Conference (IMC37), 7 & 8 September 2021, hosted by the Athlone Institute of Technology, a constituent institute of the Technological University of the Shannon, Athlone, Ireland. Available at: https://www.manufacturingcouncil.ie/imc-conference-archive.

Disclaimer

The grant holder acknowledges that opinions, findings and conclusions or recommendations expressed in any publication generated by the NRF-supported research are that of the author(s) alone and that the NRF accepts no liability whatsoever in this regard.

Funding

This work is based on the research supported fully/partially by the National Research Foundation (NRF) of South Africa (Grant Number: 129510), UFS/CUT Multi-, Inter- and Trans- (MIT) Disciplinary collaborative research grant and DHET University Capacity Development Grant (UCDG), who funded this research. The Technological Higher Education Network South Africa (THENSA), in partnership with the Department of Higher Education and Training (DHET) and Tshwane University of Technology (TUT), provided partial financial and academic support during this study.

Author information

Authors and Affiliations

Contributions

Both authors contributed equally to the research in terms of conceptualisation, methodology, validation, formal analysis, investigation, writing – original draft and writing – review and editing. The author(s) read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

The study was approved by the Health Sciences Research Ethics Committee (HSREC; reference number UFS-HSD2020/1719/2601) of the University of the Free State and the Free State Province Department of Health, South Africa. Furthermore, because of the retrospective nature of the study, patient informed consent was not required. All CT scan data from CRPM used during the research study were anonymised and no personal information of any of the patients was disclosed.

Consent for publication

Not applicable.

Competing interests

The authors do not have any competing interests to declare.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Muller, H., Fossey, A. Stereolithography (STL) measurement rubric for the evaluation of craniomaxillofacial STLs. 3D Print Med 8, 25 (2022). https://doi.org/10.1186/s41205-022-00151-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s41205-022-00151-x