Abstract

Aim

This systematic review aimed to evaluate the use of three-dimensional (3D) printed bone models for training, simulating and/or planning interventions in oral and cranio-maxillofacial surgery.

Materials and methods

A systematic search was conducted using PubMed® and SCOPUS® databases, up to March 10, 2019, by following the Preferred Reporting Items for Systematic reviews and Meta-Analysis (PRISMA) protocol. Study selection, quality assessment (modified Critical Appraisal Skills Program tool) and data extraction were performed by two independent reviewers. All original full papers written in English/French/Italian and dealing with the fabrication of 3D printed models of head bone structures, designed from 3D radiological data were included.

Multiple parameters and data were investigated, such as author’s purpose, data acquisition systems, printing technologies and materials, accuracy, haptic feedback, variations in treatment time, differences in clinical outcomes, costs, production time and cost-effectiveness.

Results

Among the 1157 retrieved abstracts, only 69 met the inclusion criteria. 3D printed bone models were mainly used as training or simulation models for tumor removal, or bone reconstruction. Material jetting printers showed best performance but the highest cost. Stereolithographic, laser sintering and binder jetting printers allowed to create accurate models with adequate haptic feedback. The cheap fused deposition modeling printers exhibited satisfactory results for creating training models.

Conclusion

Patient-specific 3D printed models are known to be useful surgical and educational tools. Faced with the large diversity of software, printing technologies and materials, the clinical team should invest in a 3D printer specifically adapted to the final application.

Similar content being viewed by others

Introduction

Technological development strongly drives the evolution of oral and cranio-maxillofacial surgery [1]. Among all the additive manufacturing (AM) processes, “three-dimensional printing” (3DP), often used synonymously with additive manufacturing, is playing an ever-growing role. This technology involves the fabrication of objects through the deposition of material using a print head, nozzle, or other printing technology [2]. It allows creating objects layer-by-layer through computer-aided design/computer-aided manufacturing (CAD/CAM). It was originally developed in the 1980s to accelerate the production of small and custom-designed objects, but it revolutionized the prototyping concepts and embraced many applications in manufacturing industries. Later on, AM’s applications started to be integrated in several medical techniques and procedures, giving some important inputs to various domains, such as dentistry, maxillofacial surgery, orthopedics and neurosurgery. Frequent clinical applications of 3D printing in everyday practice include the fabrication of surgical templates employed to improve the accuracy of the surgery and reduce the duration and morbidity of surgical interventions. It is now applied in routine in oral and craniofacial surgery [3, 4]. More recently, the progress made in the 3D-printing of implantable biomaterials were applied to the fabrication of custom implants, based on patients’ radiological data: even if a large amount of these commercial custom implants are milled, 3D-printing technologies can be employed for large bone defects reconstruction like cranioplasty [5] or Temporo-mandibular joint replacement [6].

Three-dimensional printing techniques involve creation of accurate physical 3D models from the patient’s radiological data. The first step consists in obtaining the Digital Imaging and COmmunications in Medicine (DICOM) files from patient’s imaging exams, such as computed tomography (CT) or magnetic resonance imaging (MRI) scans. Then software is used to transform them into a digital 3D object file, such as standard tessellation language (STL), among other formats. For surgical model fabrication, this new file can be printed with different techniques, such as vat photopolymerization (VP), material extrusion (ME) or binder jetting (BJ). 3D printing encompasses different techniques, each of them having its own benefits and drawbacks (Fig. 1). Several printing materials can be used, each with specific mechanical and accuracy properties. Sometimes, a post-curing step is required to obtain the finished product [7]. The obtained surgical models can fulfill three different purposes: training, planning and simulating. An example of three different models is shown in Fig. 2.

Examples of anatomical models fabricated by Additive manufacturing. A: A mandible model fabricated using SLA to serve as a template for bone allograft preparation during surgery. B: A model fabricated using SLA to visualize the extent of a bone defect (cleft) for planning the bone reconstructive surgery. C: A model representing a section of a mandible. It was used for training students in dental implant surgery

A training model is produced to enhance the quality of the teaching, by allowing students and clinicians to perform high-quality surgical training. Adequate haptic feedback and moderate cost are the most important characteristic of training models. Instead of training on cadaver or animal models, students can enhance their skills on accurate 3DP models that reproduce the haptic feedback of the patient’s bone [8]. Although cadaveric specimens have high anatomical and physical validity, they are often challenging to obtain, lack patient-specific pathologic features, and are associated with costs that may be prohibitive to repetitive training [9]. Several authors described temporal bone surgeries [10, 11], implant treatment or maxillary sinus floor augmentation [12] training in realistic in vitro conditions using these 3D-printed models. Thus, one of the most important characteristics of a training model is the low cost.

Secondly, a 3DP model could be made for planning complex surgeries and to fully understand the patient’s conditions. The manipulation of the patient anatomical structures helps to get a better understanding of his specific condition and to plan the required surgical interventions [13]. These models are often used in orthognathic and reconstructive surgeries, giving the possibility of a better comprehension and more predictable results [14,15,16,17]. Measurements and surgical pre-operative evaluations can be performed on these models. Thus, the most important characteristic of a planning model is accuracy.

Finally, a simulating model is produced to perform a surgery before it is done in clinics. This type of models must be accurate with a patient-like haptic feedback. Users can act on these models like they are working on patients. Simulating models are used by clinicians before preforming important surgical interventions, such as tumor excisions [18] and pediatric mastoidectomy [19]. The right mechanical properties, such as the elastic modulus, the stiffness or the drilling force, are fundamental parameters that allow the operator to experience haptic feedback similar to that encountered during actual surgery. Thus, one of the most important characteristic of a simulating model is related to its mechanical properties.

A surgeon wanting to invest in a printer can be overwhelmed in his choice by the numerous options available, between printing materials and technologies. Moreover, the cost-benefit ratio must be taken into consideration, as cheap technologies can be sufficient for some applications. Our hypothesis was that each application of the surgical model could be correlated with a specific 3D printing technology. This systematic review investigated the state of the art of printing materials and techniques proposed to create models for training, simulating and planning interventions in oral and craniofacial surgery. The research focused on the regions of head and neck, scanning articles that belong to different fields: dentistry and oral surgery, maxillofacial surgery, ear-nose-throat surgery and cranial surgery. These results also provided practical suggestions for choosing the optimal 3D printing technique and material for each application objective.

Methods

Study protocol

The protocol of this systematic review was registered in ‘PROSPERO: International prospective register of systematic reviews’ (CRD42019117468) and followed the PRISMA guidelines.

The main question, that was not PICO compliant, was: ‘What are the existing printed bone models currently used for training, planning and simulating interventions in oral and cranio-maxillofacial surgery?’ The impossibility of using a PICO question and performing a meta-analysis are two missing points of PRISMA checklist.

Search strategy

Medline (PubMed) database and Scopus database were searched up to March 10, 2019 with the following equation:

(additive manufacturing OR rapid prototyping OR bone model OR bone models OR anatomical models OR anatomical model OR phantom OR phantoms OR simulation model OR simulation models OR 3D−printed models OR 3D printed models OR 3D−printed model OR 3D printed model) AND (planning OR hands−on OR train OR training OR simulation) AND (surgery OR surgical OR dentistry OR dental OR teaching OR pre−operative) AND (maxillofacial OR oral OR skull base OR jaw bones OR jaw OR sinus OR mandible OR temporal bone OR teeth OR maxilla OR human bone OR implant) NOT biology NOT cartilage NOT mathematical

This process only selected articles that had search terms in the title or in the abstract without any restriction on language.

The search was also launched with the following MeSH (PubMed) terms: (“Surgical Procedures, Operative” OR “Teaching”) AND “Printing, Three-Dimensional” AND “Models, Anatomic” AND “Head”.

Other interesting original research articles were added through manual search.

Science mapping

A science mapping analysis of subject domains was performed by using keyword co-occurrence networking on VOSviewer (free software, version 1.6.15, Centre for Science and Technology Studies, Leiden University, The Netherlands, 2017). A network analysis of the Pubmed MeSH keywords was generated from the matrix of retrieved papers (threshold value at 90). The MeSH terms-document matrix allowed to measure document similarities between clusters of topics.

Study selection

All original full papers written in English/French/Italian and dealing with the fabrication of 3D printed models of head bone structures obtained from 3D imaging data were considered as potentially eligible. Case report, case series, pilot studies and comparative studies were included in this research.

Literature reviews, conference abstracts, articles employing animal tissues or cadaver models or models not aimed to the head region were excluded.

Study analysis

All the retrieved references, after launching the search algorithm, were managed using Endnote® Abstracts of studies retrieved using the search strategy and those from additional sources were screened independently by three authors (M.M, A.N. and S.C) to identify studies that potentially met the inclusion criteria. Papers fulfilling the inclusion criteria, and those presenting insufficient data in the title and the abstract to make a decision, were selected for full analysis. After reading the full texts, the proper articles were included in an evidence table. Any disagreement over the eligibility of studies was resolved through discussion and consensus among the authors.

Quality assessment

The quality of the included studies was assessed using a modified version of the Critical Appraisal Skills Programme (CASP) tool [20]. For each of the 10 questions of this tool, there were three possible answers: ‘Yes’, ‘Can’t tell’ or ‘No’. Every ‘Yes’ scored 1 point, while ‘No’ or ‘Can’t tell’ scored 0 points. Total scores were converted to percentages and studies were allocated to one of three categories; ‘Good quality’ for a score of 67–100%, ‘Average quality’ for 34–66% and ‘Poor quality’ for 0–33%.

Data extraction

The data were extracted and critically appraised by two independent authors (M.M and G.M.M.).

Using a standardized data extraction form, the authors extracted the following data: year of publication, data acquisition system, type of printing technique involved, material, accuracy, production time, haptic feedback, treatment time, clinical outcomes, cost and purpose of the publication: training, planning, simulation (multiple possibilities for each paper).

Data analysis

A narrative synthesis of the data was conducted due to the heterogeneity of study designs and methods. For the same reason it was not possible to perform a meta-analysis.

In order to address the general question of defining the state of the art of 3D printing to address the surgical planning, simulation and training needs, the authors identified as crucial these characteristics: accuracy, haptic feedback and cost.

Results

Search general results

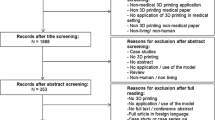

After database screening and removal of duplicates using Endnote® [21], 1157 articles were identified. After abstract screening, 119 studies were selected. After full text reading, 64 articles were selected, plus 5 other articles found among the related ones found by additional manual search (Fig. 3). The main reason for excluding articles was a content not addressing AM models issues. Many excluded articles dealt with analogic models, virtual models or perfusion-based models, or related to the orthopedic and veterinary fields. Six articles were not written in English/French/Italian.

Eight articles were excluded after reviewers’ discussion: three authors involved commercial models [22,23,24], one article dealt with papercraft models [25], one article dealt with a silicon model molded on a 3D printed mold [26] and 3 articles dealt with other surgical fields (orthopedics [27, 28] and veterinary sciences [29]).

The spatial representation of the relationships between the Mesh keywords was displayed through a science map (Fig. 4). The networks noticeably highlighted the interest for modelling human patients from imaging data through a computer assisted procedure. Bone surgery, prosthetic rehabilitation and radiotherapy were among the most represented families of clinical applications. “Mandible” was the most co-occurring bone keywords. “Material testing”, “treatment outcome” and “clinical competence” were often studied. These graphic references did not show any Mesh keywords regarding the 3D printing technologies themselves (under the threshold).

Quality assessment (Table 1)

With the modified Critical Appraisals Skills Programme (CASP) tool [20] the reviewers have identified as “high-quality studies” only 8 original researches. The authors classified as “average quality studies” and “poor quality studies” 46 and 15 articles respectively. The lack of quantitative or rigorous tests and appropriate study designs were found in most of the selected studies.

General information (Table 2)

Only 5 articles (6%) were published before 2008. Ten articles (18%) were published between 2009 and 2014. Forty-two articles (78%) were published between 2015 and March 10, 2019.

Among all articles, 3 were pilot studies, 12 were case reports, 4 were case series, 29 were validation studies and only 6 were comparative studies. The authors classified as “validation studies” all original researches that had described and eventually evaluated a process to fabricate a printed bone model. The reviewers classified as “comparative studies” all the researches that compared models printed by different techniques or models printed by different printers using the same technique. Lastly, a paper comparing a bone model to a cadaver’s bone was also considered as a comparative study [59].

Purposes of the articles

The models mentioned in the selected articles were used for different purposes (Table 2). In 31 articles the models were used to plan a surgery, in 19 they were used to simulate the surgery, and in 32 they were used for training of students or clinicians. This total (82) exceeded the total number of papers, as some models were used for multiple purposes.

Surgical field

The reports on 3DP models concerned multiple surgical domains (Table 2). Oral and maxillofacial surgery had the largest share with 43% of articles describing the use of AM models, followed by ENT surgery (29%), dentistry (14%), and cranial surgery (14%).

Therapy (Table 2)

In dentistry, bone models were more frequently used for simulating dental implant placement [30, 41, 81]. In oral and maxillofacial surgery, the models were more frequently used for planning a bone reconstruction [15,16,17, 36, 40, 47, 50, 53, 72] or a tumor removal [18, 49, 56]. The models prepared for ENT surgery were mostly used for training surgical temporal access [10, 31, 52, 63,64,65,66,67,68, 85, 87] and mastoidectomy [39, 51, 59,60,61]. Finally, in the field of cranial surgery, the models were most frequently used for the training of the pre-sigmoid approach [73] or craniotomy [54].

Image acquisition and processing

Image acquisition and processing are the first steps to create a 3DP model (Table 3). The most frequently used radiological exam was the CT, followed by cone beam computed tomography (CBCT) and MRI. Software was used to process the radiological data. The most frequently used were Mimics® (Materialise, Leuven, Belgium), followed by OsiriX® (Pixmeo, Geneva, Switzerland) and 3D Slicer® (Surgical Planning Laboratory, Isomics Incorporated, Cambridge, USA). Most of the authors did not specify entirely their digital work-flow to create the STL printable file, making it difficult to reproduce the procedure properly.

Printing systems and materials

Material extrusion (ME) printing was the preferred technique to create models, followed by material jetting (MJ), respectively 32% and 22% of the articles (Table 3). Binder jetting and vat photopolymerization (VP) technique were both involved in 10% of papers. Powder bed fusion printers were used in 16% of articles while 9% did not mentioned the type of 3D printer involved. Among all the references selected, the most frequently used material was acrylonitrile butadiene styrene (ABS), currently only used with material extrusion printers.

Quantitative evaluation

Accuracy and mechanical characteristics are strongly dependent on the 3D printer’s characteristics, on the involved printer material and the size of the model. Only three authors analyzed the mechanical properties of their models through quantitative tests [43, 67, 83]. Due to the differences in the printing materials and measuring methods, it was not possible to compare their results (Table 4). For the same reason, it is impossible to compare the model accuracy, despite the fact that several authors measured the geometric discrepancy (Table 5) [9, 43, 51, 61, 79].

Qualitative evaluation

Most of the authors analyzed the accuracy and haptic feedback of their models using self-made questionnaires and they usually concluded that 3DP models were accurate. Two authors declared respectively less than 100 and 125 μm of geometrical discrepancy between the real bone and the model [33, 81]. Some other authors stated that discrepancies could reach 680 μm, depending on the size of the model [47]. The haptic feedback was declared adequate in 75% of articles that investigated it through qualitative tests. A model made of calcium sulfate hemihydrate was considered “too hard” [43] and another 3DP model was “too soft” [65]. Few authors showed that it was difficult to print small bones [10, 52, 63] and it was reported that some materials melted during drilling [37, 43]. Few authors reported benefiting of a reduction in treatment time up to 20% in the operating room thanks to the models [18, 50, 75]. A third (35%) of the articles affirmed that the clinical outcomes could potentially be improved by using these techniques, thanks to the better planning and the enhanced comprehension of the patient pathological status. Considering costs and production time, ME printed models were the cheapest [38, 39, 42, 60] and the fastest printers [65, 67]. Cost-effectiveness depended on each clinical case and was more striking when several models needed [82]. Only 7% of the authors suggested that their method was not cost-effective [43, 61, 63, 78].

Discussion

Our original impression was validated by the results, suggesting that, before investing in a printer, the major application of the models needs to be considered. Oral and maxillofacial models for bone surgery applications are mostly used for planning and simulating surgical interventions. Printed products exhibit a wide range of different properties, varying with the machine and the printing material. The main results showed that surgical treatment times can be reduced up to 20%, and that the failure rate tends to decrease [40, 50, 71]. Many authors suggested that clinical outcomes can be improved, but their findings were not supported by any control group [12, 18, 19, 33,34,35,36, 41, 42, 50, 56, 58, 76, 78, 86]. Only Banaszewski et al. involved a control group to compare the use of the 3D printed model for planning the surgical reconstruction of the mandible to the traditional technique. They found that the functional and aesthetic results were greater in the group where a 3DP models were applied [41]. A planning model needs to be accurate, but cheap also, as one patient cannot cover extensively all expenses. A training model requires essentially to reproduce relevant haptic feedback and to be an inexpensive investment. These two qualities are also expected to simulate a surgical intervention, but also with a high level of accuracy.

Accuracy

The MJ printers are currently the most accurate printers, with printed models exhibiting a geometrical discrepancy of 90 μm when compared to the patient’s bone [76]. The second most accurate printing technique, according to the analyzed articles, is powder bed fusion (PBF). Wanibuchi et al. showed an accuracy ranging from 100 μm to 300 μm on a temporal bone model measured with a digital caliper [51]. This result was confirmed by another study where a geometrical discrepancy of 150 μm was observed between the model and the bone [43]. BJ and ME were reported to be less accurate methods. A geometrical discrepancy of 400 μm was observed when using a BJ printer to print a skull base [43]. Most of the researches involving ME printers did not measure quantitatively the models’ accuracy, except in one case where they reported a discrepancy reaching 680μm [47]. Our study did not retrieve any paper measuring the accuracy of VP printers, but was previously reported as being high [8].

The lack of quantitative evaluation of the printing accuracy was one of the major limitations of the studies included in this review. The accuracy is related to the printer, the radiological image segmentation process, the size of the printed object and the printing material. For example, a ME printer cannot reach the same precision as an VP or MJ printer due for first to the dimension of the nozzle, but its accuracy could be sufficient to reach the operator’s purposes. Depending on the radiological images processing technique a 3D-printed model will always exhibit some discrepancies, the operator has to keep it in mind processing the radiological data.

Haptic feedback

A good haptic feedback is the most important characteristic of training models and it is strongly dependent on the mechanical characteristics of the printing material. The two fundamental parameters for a model that aims to reproduce the bone haptic feedback are adequate elastic modulus and tensile strength. No quantitative test is currently available to describe the surgeon’s haptic feedback during a surgical intervention. Most of the authors created their own questionnaires and asked students and surgeons with different experience about their sensations. Thus, the results were difficult to compare as evaluation protocols were different and also because of the conclusions subjective. However, most of the them were satisfied with their printed models.

The principal materials for ME printers were polylactic acid (PLA), ABS, polycarbonate (PC), polyethylene terephthalate glycol-modified (PETG) and nylon. In the articles included in this review, there was no consensus regarding the best material to reproduce the bone characteristics. One of the PLA’s advantages was its biological properties, as it is known to be biodegradable and non-toxic. Moreover, its haptic feedback was similar to bone at low temperature while drilling [37]. Haffner et al., compared five different materials, and stated that PETG was the most realistic material, followed by PC, PLA and ABS. Nylon properties were considered as not realistic enough [39]. PC was blamed to melt too easily during drilling while ABS could easily reproduce the bone haptic feedback during a cortical mastoidectomy [43]. Favier et al. compared the mechanical characteristics of their models. With Young’s Modulus respectively of 2000–3000 N/mm2 and 1700 N/mm2, the MJ and PBF printed models were considered as realistic. Regarding PBF printing, Mori et al. reported that their model was realistic but the feeling of drilling the cancellous part of the bone model lacked the ‘crispy touch’ of real bone [82]. This subjective declaration underlines the need for objective criteria to evaluate the haptic feedback of the models. Among all the materials used in the BJ printing technique, cyanoacrylate powder with hydroquinone resembled the most to sheep cortical bone, which was often used as a surgical training model [85].

Unfortunately, no author did quantitative or comparative tests using models printed by VP. However most authors suggested that this technique was efficient for creating adequate models, enhancing the quality of the training [12, 35] and suitable for planning complex surgeries [15] or dental implant treatments [30].

The segmentation technique is also an important parameter that it has to be considered for obtaining realistic 3D printed models. Segmenting the trabecular bone structures results in a more realistic haptic feedback when compared to fully solid prints.

Cost

Cost remains an important parameter that cannot be ignored. There are multiple additional costs in terms of software, printers, printing materials, operators and training hours to produce an in-house 3DP model.

In order to print a model, the first step is to process the DICOM file into an STL file. Among all the commercial software available, the commercial software package Mimics®, was the most widely used software, despite a relatively high cost when compared to others. Many free or open source software are available, like ITK-Snap®, Slicer® or InVesalius® [31, 35, 39, 40, 60, 79]. OsiriX® possesses a free version (demo) that allows to export STL renderings [12, 46, 47, 52, 63].

ME printers were the cheapest printers, with reported prices ranging between 2500$ and 3000$ [47, 82]. However, as previously mentioned, these showed limitations in terms of accuracy. PLA and ABS were the cheapest reported materials [32, 37, 39, 47, 52, 82]. PC cost was reported to range from 105$ to 155$ for the production of a mandible [43, 57]. The cost for a temporal bone model using BJ was around 400$ [67]. MJ models costs ranged from 270$ to 1000$. One team affirmed that these models were too expensive [66], but two others suggested that they were satisfied by their investment in these models [15, 56]. LS printers are not cheap, but no authors talked mentioned any price. Printing a skull base using polyamide with an LS printer was reported to cost 250–280$ [85]. Two teams used VP printers and they declared being satisfied by the results [12, 35]. A forgotten cost is related to the post-curing machine for object printed trough VP technologies.

The production time can also be considered as a decisive cost. ME printers were the fastest, producing a pediatric temporal bone model in 4.5 h and a mandible with a maxilla in 6 h [37, 39]. The production time of an MJ model was less than a day [9, 56]. The time needed to design the STL file is also important to consider. Only one author discussed about the total production time of a LS printer, and reported a need for 4 to 5 days [43]. The learning curve of a few months to master and to properly use the software for STL processing is obvious. In every case, the conversion from the DICOM to an adequate STL file could take several hours. One author reported that “the 3DP technique is really cost-effective, only if the operator plans to produce several models to amortize the cost of the 3D printer” [82].

It’s important to know these costs because the cost-benefit ratio has to be considered before investing in this technique that can get several advantages but it presents some drawbacks in comparison to traditional techniques [63, 78].

Suggestions

As pre-surgical tools, 3D models can make the surgical outcomes more predictable and safer, reducing the surgeon’s stress and the intervention time [40, 50]. Furthermore, they can strongly improve the quality of clinical education, allowing students to simulate various surgical interventions and to discuss easily about their clinical cases with their mentors [34, 35, 42].

Evaluating the best image processing workflow remains difficult as no author described neither the entire workflow not the human cost involved. The most used training models are made with ME printers. This technology is the cheapest and allows producing suitable training models, despite their limited accuracy. The most appropriate ME printing materials are ABS, PLA and PETG [43]. Temporal bone models printed with PETG were reported to ensure adequate haptic feedback whileperfor drilling, and they were very helpful during training sessions [39].

To obtain an adequate simulation model, BJ and VP printers seem more indicated. They showed adequate performances in reproducing training models of the maxilla and their accuracy is really satisfying for creating planning models [12, 18]. It is also possible to create models for simulating surgeries, thanks to their good haptic feedback [12, 14, 18]. Also MJ printers allow to produce models that provide good haptic feedback and that can be used to simulate complex surgeries before entering the operating room [14]. Generally, they cost more than the VP ones, as well as the BJ ones [35, 61]. PBF printers allow to produce accurate bone models in polyamide and glass fiber, but without satisfying haptic feedback [82].

Printing time and cost are very variable, depending directly on the type of 3D printer, the printing material, the accuracy and the mechanical characteristics required. Figure 5 demonstrates the main differences among the analyzed 3D printing technologies, depending on the applications.

Conclusions

The present literature review showed that nowadays, AM models are useful tools in the surgical field.

Several parameters must be considered before choosing a 3D printing model workflow, such as the processing software, the type of 3D printer, the expected mechanical characteristics, accuracy and haptic feedback of the printing material, the production time and the human and material costs.

Due to the large amount of different parameters that has to be considered by the operator, the financial investment in a 3D printer should be made with the precise idea of the final application.

Limitations

This analysis was at first limited by the diversity of workflows and applications, involving different materials, printers and testing methods. Despite difficulties for comparing results from a study to another, some common protocols were found for the 3 main purposes of 3D-printed bone models (planning, simulation and training).

The lack of common reliable qualitative tests to evaluate the models was an evident limitation, thus future studies should focus on standardized methods to evaluate 3D-printed models of bone macro- and micro-structures.

Availability of data and materials

All data generated or analyzed during this study are included in this published article [and its supplementary information files].

Change history

02 December 2020

An amendment to this paper has been published and can be accessed via the original article.

Abbreviations

- 3D:

-

Three-dimensional

- 3DP:

-

Three-dimensional printed; Three-dimensional printing

- ABS:

-

Acrylonitrile butadiene styrene

- AM:

-

Additive manufacturing

- BJ:

-

Binder jetting

- CAD/CAM:

-

Computer-aided design/computer-aided manufacturing

- CBCT:

-

Cone beam computed tomography

- CT:

-

Computed tomography

- DICOM:

-

Digital imaging and communications in medicine

- ENT:

-

Ear, nose and throat

- ME:

-

Material extrusion

- MJ:

-

Material jetting

- MRI:

-

Magnetic resonance imaging

- PBF:

-

Powder bed fusion

- PC:

-

Polycarbonate

- PETG:

-

Polyethylene terephthalate glycol-modified

- PLA:

-

Polylactic acid

- STL:

-

Standard triangulation language

- VP:

-

Vat photopolymerization

References

Naveau A, Bou C, Sharma A. Evolution of Topics in Maxillofacial Prosthetics Publications. Int J Prosthodont. 2018;31(6):565–8. https://doi.org/10.11607/ijp.5894.

ASTM International. Standard Terminology for Additive Manufacturing Technologies 1,2. 2013:2–4. doi:https://doi.org/10.1520/F2792-12A.2.

D’Haese J, Ackhurst J, Wismejier D, et al. Current state of the art of computer-guided implant surgery. Periodontology 2000. 2017;73(25):121–33. https://doi.org/10.1111/prd.12175.

Lin HH, Lonic D, Lo LJ, et al. 3D printing in orthognathic surgery − a literature review. J Formos Med Assoc. 2018;117(7):547–58. https://doi.org/10.1016/j.jfma.2018.01.008.

Gonzalez-perez-somarriba B, Centeno G, Vallellano C et al.. Evaluation of total alloplastic temporo-mandibular joint replacement with two different types of prostheses : A three-year prospective study. 2016;21(6). doi:https://doi.org/10.4317/medoral.21189.

Charles Champeaux, Sebastien Froelich and Caudron Y. Titanium Three-Dimensional Printed Cranioplasty for Fronto-Nasal Bone Defect 2019;30(6):1802–1805. doi:https://doi.org/10.1097/SCS.0000000000005493.

Park JY, Gao G, Jang J, Cho D. 3D printed structures for delivery of biomolecules and cells: tissue repair and regeneration. J Mater Chem B. 2016. https://doi.org/10.1039/C6TB01662F.

Crafts TD, Ellsperman SE, Wannemuehler TJ, Bellicchi TD, Shipchandler TZ, Mantravadi AV. Three-Dimensional Printing and Its Applications in Otorhinolaryngology. Head Neck Surg. 2017;156(6):999–1010. https://doi.org/10.1177/0194599816678372.

Hsieh TY, Cervenka B, Dedhia R, Strong EB, Steele T. Assessment of a patient-specific, 3-dimensionally printed endoscopic sinus and skull base surgical model. JAMA Otolaryngol - Head Neck Surg. 2018;144(7):574–9. https://doi.org/10.1001/jamaoto.2018.0473.

Probst R, Stump R, Mokosch M, Röösli C. Evaluation of an infant temporal-Bone model as training tool. Otol Neurotol. 2018;39(6):e448–52. https://doi.org/10.1097/MAO.0000000000001839.

Takahashi K, Morita Y, Ohshima S, Izumi S, Kubota Y, Yamamoto Y, Takahashi S, Horii A. Creating an optimal 3D printed model for temporal Bone dissection training. Ann Otol Rhinol Laryngol. 2017;126(7):530–6. https://doi.org/10.1177/0003489417705395.

Somji SH, Valladares A, Ho Kim S, Cheng Paul Yu Y, Froum SJ. The use of 3D models to improve sinus augmentation outcomes - a case report. Singap Dent J. 2017;38:63–70. https://doi.org/10.1016/j.sdj.2017.10.002.

Marconi S, Pugliese L, Botti M, et al. Value of 3D printing for the comprehension of surgical anatomy. Surg Endosc. 2017. https://doi.org/10.1007/s00464-017-5457-5.

Xiao Y, Sun X, Wang L, Zhang Y, Chen K, Wu G. The application of 3D printing Technology for Simultaneous Orthognathic Surgery and Mandibular Contour Osteoplasty in the treatment of craniofacial deformities. Aesthet Plast Surg. 2017;41(6):1413–24. https://doi.org/10.1007/s00266-017-0914-z.

Arce K, Waris S, Alexander AE, Ettinger KS. Novel patient-specific 3D printed fixation tray for mandibular reconstruction with fibular free flaps. J Oral Maxillofac Surg. 2018. https://doi.org/10.1016/j.joms.2018.04.028.This.

Chou PY, Hallac RR, Shih E, et al. 3D-printed models of cleft lip and palate for surgical training and patient education. Cleft Palate-Craniofacial J. 2018;55(3):323–7. https://doi.org/10.1177/1055665617738998.

Lim C, Campbell D, Cook N, Erasmus J. A case series of rapid prototyping and intraoperative imaging in orbital reconstruction. Craniomaxillofacial Trauma Reconstr. 2015;08(02):105–10. https://doi.org/10.1055/s-0034-1395384.

Yusa K, Yamanochi H, Takagi A, Iino M. Three-dimensional printing model as a tool to assist in surgery for large mandibular tumour: a case report. J Oral Maxillofac Res. 2017;8(2):1–7. https://doi.org/10.5037/jomr.2017.8204.

Gargiulo P, Arnadottir I, Gislason M, Edmunds K, Olafsson I. New directions in 3D medical modeling: 3D-printing anatomy and functions in neurosurgical planning. J Healthc Eng. 2017;2017. https://doi.org/10.1155/2017/1439643/.

Critical Appraisal Skills Programme (2018). CASP Qualitative Checklist. [online] Available at: https://casp-uk.net/wp-content/uploads/2018/01/CASP-Qualitative-Checklist-2018.pdf. Accessed: 20/11/2018. 1994;(2018).

EndNote X9, Clarivate Analytics, Web of Science. Philadelphia; Clarivate. 2013(64).

He LH, Purton D, Swain M. A novel polymer infiltrated ceramic for dental simulation. J Mater Sci Mater Med. 2011;22(7):1639–43. https://doi.org/10.1007/s10856-011-4350-3.

He LH, Foster Page L, Purton D. An evaluation of dental operative simulation materials. Dent Mater J. 2012;31(4):645–9. https://doi.org/10.4012/dmj.2011-264.

Güth JF, Ponn A, Mast G, Gernet W, Edelhoff D. Description and evaluation of a new approach on pre-clinical implant dentistry education based on an innovative simulation model. Eur J Dent Educ. 2010;14(4):221–6. https://doi.org/10.1111/j.1600-0579.2009.00614.x.

Hiraumi H, Sato H, Ito J. Papercraft temporal bone in the first step of anatomy education. Auris Nasus Larynx. 2017;44(3):277–81. https://doi.org/10.1016/j.anl.2016.07.017.

Chang DR, Lin RP, Bowe S, et al. Fabrication and validation of a low-cost, medium-fidelity silicone injection molded endoscopic sinus surgery simulation model. Laryngoscope. 2017;127(4):781–6. https://doi.org/10.1002/lary.26370.

Wang MY, Wang JQ, Shi Y, et al. Printed three-dimensional anatomic templates for virtual preoperative planning before reconstruction of old pelvic injuries. Chin Med J. 2015;128(4):477–82. https://doi.org/10.4103/0366-6999.151088.

Brouwers L, Teutelink A, van Tilborg FAJB, de Jongh MAC, Lansink KWW, Bemelman M. Validation study of 3D-printed anatomical models using 2 PLA printers for preoperative planning in trauma surgery, a human cadaver study. Eur J Trauma Emerg Surg. 2018;0(0):1–8. https://doi.org/10.1007/s00068-018-0970-3.

Athanasiou KA, Verstraete FJM, Winer JN, Cissell DD, Arzi B, Lucero S. The application of 3-dimensional printing for preoperative planning in oral and maxillofacial surgery in dogs and cats. Vet Surg. 2017;46(7):942–51. https://doi.org/10.1111/vsu.12683.

Lanis A, Alvarez del Canto O, Barriga P, Polido WD, Morton D. Computer-guided implant surgery and full-arch immediate loading with prefabricated-metal framework-provisional prosthesis created from a 3D printed model. J Esthet Restor Dent. 2019;31(3):199–208. https://doi.org/10.1111/jerd.12458.

Freiser ME, Ghodadra A, Hirsch BE, AA MC. Evaluation of 3D Printed Temporal Bone Models in Preparation for Middle Cranial Fossa Surgery. Otol Neurotol. 2019;40(2):246–53. https://doi.org/10.1097/MAO.0000000000002073.

Zhuo C, Lei L, Yulin Z, et al. Creation and validation of three-dimensional printed models for basic nasal endoscopic training. Int Forum Allergy Rhinol. 2019;00(0):1–7. doi:https://doi.org/10.1002/alr.22306.

Bhadra D, Shah NC, Arora A, Meetkumar SD. Deducing a surgical dilemma using a novel three Dimensionaldimensional printing technique Dhaval. J Conserv Dent. 2018;21:582–5. https://doi.org/10.4103/JCD.JCD.

Lin B, Zhu Y, Liu Y, et al. Using three-dimensional printing to create individualized cranial nerve models for Skull Base tumor surgery. World Neurosurg. 2018;120:e142–52. https://doi.org/10.1016/j.wneu.2018.07.236.

Reymus M, Fotiadou C, Hickel R, Diegritz C. 3D-printed model for hands-on training in dental traumatology. Int Endod J. 2018;51(11):1313–9. https://doi.org/10.1111/iej.12947.

Sugahara K, Takano M, Koyama Y, et al. Novel condylar repositioning method for 3D-printed models. Maxillofac Plast Reconstr Surg 2018;40(1):0–4. doi:https://doi.org/10.1186/s40902-018-0143-7.

Werz SM, Zeichner SJ, Berg BI, Zeilhofer HF, Thieringer F. 3D printed surgical simulation models as educational tool by maxillofacial surgeons. Eur J Dent Educ. 2018;22(3):e500–5. https://doi.org/10.1111/eje.12332.

Lin WJ, Lin W, Lin JC, et al. A novel three-dimensional-printed paranasal sinus–skull base anatomical model. Eur Arch Oto-Rhino-Laryngol. 2018;275(8):2045–9. https://doi.org/10.1007/s00405-018-5051-z.

Haffner M, Quinn A, Hsieh TY, Strong EB, Steele T. Optimization of 3D print material for the recreation of patient-specific temporal Bone models. Ann Otol Rhinol Laryngol. 2018;127(5):338–43. https://doi.org/10.1177/0003489418764987.

Jacek B, Radosław W, Wiesław K, et al. 3D printed models in mandibular reconstruction with bony free flaps. J Mater Sci Mater Med. 2018;29(2):10–5. https://doi.org/10.1007/s10856-018-6029-5.

Alodadi A. Utilizing three-dimensional printing in treating challenged dental implant cases. World J Dent. 2018;9(3):235–41. https://doi.org/10.5005/jp-journals-10015-1540.

Reddy GV, Vasamsetty P, Kumar Malyala S, Alwala A. Training young maxillofacial surgeons or trainees using additive manufacturing. Mater Today Proc. 2018;5(2):4046–9. https://doi.org/10.1016/j.matpr.2017.11.665.

Favier V, Zemiti N, Mora OC, Subsol G, Captier G, Lebrun R, Crampette L, Mondaine M, Gilles B. Geometric and mechanical evaluation of 3D-printing materials for skull base anatomical education and endoscopic surgery simulation - A first step to create reliable customized simulators. PLoS One. 2017;12(12):e0189486. https://doi.org/10.1371/journal.pone.0189486.

Alrasheed AS, Nguyen LHP, Mongeau L, Funnell WRJ, Tewfik MA. Development and validation of a 3D-printed model of the ostiomeatal complex and frontal sinus for endoscopic sinus surgery training. Int Forum Allergy Rhinol. 2017;7(8):837–41. https://doi.org/10.1002/alr.21960.

Wang L, Ye X, Hao Q, et al. Comparison of two three-dimensional printed models of complex intracranial aneurysms for surgical simulation. World Neurosurg. 2017;103:671–9. https://doi.org/10.1016/j.wneu.2017.04.098.

Javan R, Davidson D, Javan A. Nerves of steel: a low-cost method for 3D printing the cranial nerves. J Digit Imaging. 2017;30(5):576–83. https://doi.org/10.1007/s10278-017-9951-z.

Legocki AT, Duffy-Peter A, Scott AR. Benefits and limitations of entry-level 3-dimensional printing of maxillofacial skeletal models. JAMA Otolaryngol - Head Neck Surg. 2017;143(4):389–94. https://doi.org/10.1001/jamaoto.2016.3673.

Ghizoni E, Ph D, Paulo J, et al. 3D-printed Craniosynostosis model: a new simulation surgical tool. World Neurosurg. 2017. https://doi.org/10.1016/j.wneu.2017.10.025.

Wiedermann JP, Joshi AS, Jamshidi A, Conchenour C, Preciado D. Utilization of a submental island flap and 3D printed model for skull base reconstruction: infantile giant cranio-cervicofacial teratoma. Int J Pediatr Otorhinolaryngol. 2017;92:143–5. https://doi.org/10.1016/j.ijporl.2016.11.014.

Jacobo OM, Giachero VE, Hartwig DK, Mantrana GA. Three-dimensional printing modeling: application in maxillofacial and hand fractures and resident training. Eur J Plast Surg. 2018;41(2):137–46. https://doi.org/10.1007/s00238-017-1373-0.

Wanibuchi M, Noshiro S, Sugino T, et al. Training for Skull Base surgery with a colored temporal Bone model created by three-dimensional printing technology. World Neurosurg. 2016;91:66–72. https://doi.org/10.1016/j.wneu.2016.03.084.

Bone TM, Mowry SE. Content validity of temporal Bone models printed via inexpensive methods and materials. Otol Neurotol. 2016;37(8):1183–8. https://doi.org/10.1097/MAO.0000000000001131.

Florentino VGB, De Mendonça DS, Bezerra AV, et al. Reconstruction of frontal bone with custom-made prosthesis using rapid prototyping. J Craniofac Surg. 2016;27(4):e354–6. https://doi.org/10.1097/SCS.0000000000002627.

Kondo K, Harada N, Masuda H, et al. A neurosurgical simulation of skull base tumors using a 3D printed rapid prototyping model containing mesh structures. Acta Neurochir. 2016;158(6):1213–9. https://doi.org/10.1007/s00701-016-2781-9.

Lim SH, Kim YH, Kim MK, Nam W, Kang SH. Validation of a fibula graft cutting guide for mandibular reconstruction: experiment with rapid prototyping mandible model. Comput Assist Surg. 2016;21(1):9–17. https://doi.org/10.3109/24699322.2016.1167245.

Pacione D, Tanweer O, Berman P, Harter DH. The utility of a multimaterial 3D printed model for surgical planning of complex deformity of the skull base and craniovertebral junction. J Neurosurg. 2016;125(November):1194–7. https://doi.org/10.3171/2015.12.jns151936.

Chan HHL, Siewerdsen JH, Vescan A, Daly MJ, Prisman E, Irish JC. 3D rapid prototyping for otolaryngology-head and neck surgery: applications in image-guidance, surgical simulation and patient-specific modeling. PLoS One. 2015;10(9):1–18. https://doi.org/10.1371/journal.pone.0136370.

Dickinson KJ, Matsumoto J, Cassivi SD, et al. Individualizing Management of Complex Esophageal Pathology Using Three-Dimensional Printed Models. Ann Thorac Surg. 2015;100(2):692–7. https://doi.org/10.1016/j.athoracsur.2015.03.115.

Hochman JB, Rhodes C, Wong D, Kraut J, Pisa J, Unger B. Comparison of cadaveric and isomorphic three-dimensional printed models in temporal bone education. Laryngoscope. 2015;125(10):2353–7. https://doi.org/10.1002/lary.24919.

Cohen J, Reyes SA. Creation of a 3D printed temporal bone model from clinical CT data. Am J Otolaryngol - Head Neck Med Surg. 2015;36(5):619–24. https://doi.org/10.1016/j.amjoto.2015.02.012.

Rose AS, Webster CE, Harrysson OLA, Formeister EJ, Rawal RB, Iseli CE. Pre-operative simulation of pediatric mastoid surgery with 3D-printed temporal bone models. Int J Pediatr Otorhinolaryngol. 2015;79(5):740–4. https://doi.org/10.1016/j.ijporl.2015.03.004.

Ernoult C, Bouletreau P, Meyer C, Aubry S, Breton P, Bachelet JT. Reconstruction assistée par l’impression 3D en chirurgie maxillofaciale. Rev Stomatol Chir Maxillofac Chir Orale. 2015;116(2):95–102. https://doi.org/10.1016/j.revsto.2015.01.010.

Mowry SE, Jammal H, Myer C, Solares CA, Weinberger P. A novel temporal bone simulation model using 3D printing techniques. Otol Neurotol. 2015;36(9):1562–5. https://doi.org/10.1097/MAO.0000000000000848.

Hochman JB, Rhodes C, Kraut J, Pisa J, Unger B. End user comparison of anatomically matched 3-dimensional printed and virtual haptic temporal Bone simulation: a pilot study. Otolaryngol - Head Neck Surg (United States). 2015;153(2):263–8. https://doi.org/10.1177/0194599815586756.

Longfield EA, Brickman TM, Jeyakumar A. 3D printed pediatric temporal Bone. Otol Neurotol. 2015;36(5):793–5. https://doi.org/10.1097/mao.0000000000000750.

Rose AS, Kimbell JS, Webster CE, Harrysson OLA, Formeister EJ, Buchman CA. Multi-material 3D models for temporal bone surgical simulation. Ann Otol Rhinol Laryngol. 2015;124(7):528–36. https://doi.org/10.1177/0003489415570937.

Hochman JB, Kraut J, Kazmerik K, Unger BJ. Generation of a 3D printed temporal bone model with internal fidelity and validation of the mechanical construct. Otolaryngol - Head Neck Surg (United States). 2014;150(3):448–54. https://doi.org/10.1177/0194599813518008.

Chenebaux M, Lescanne E, Robier A, Kim S, Bakhos D. Evaluation of a temporal bone prototype by experts in otology. J Laryngol Otol. 2014;128(7):586–90. https://doi.org/10.1017/S0022215114001297.

Narayanan V, Narayanan P, Rajagopalan R, et al. Endoscopic skull base training using 3D printed models with pre-existing pathology. Eur Arch Oto-Rhino-Laryngology. 2015;272(3):753–7. https://doi.org/10.1007/s00405-014-3300-3.

Cui J, Chen L, Guan X, Ye L, Wang H, Liu L. Surgical planning, three-dimensional model surgery and preshaped implants in treatment of bilateral craniomaxillofacial post-traumatic deformities. J Oral Maxillofac Surg. 2014;72(6):1138.e1–1138.e14. https://doi.org/10.1016/j.joms.2014.02.023.

Gil RS, Roig AM, Obispo CA, Morla A, Pagès CM, Perez JL. Surgical planning and microvascular reconstruction of the mandible with a fibular flap using computer-aided design, rapid prototype modelling, and precontoured titanium reconstruction plates: a prospective study. Br J Oral Maxillofac Surg. 2015;53(1):49–53. https://doi.org/10.1016/j.bjoms.2014.09.015.

Jardini AL, Larosa MA, Filho RM, et al. Cranial reconstruction: 3D biomodel and custom-built implant created using additive manufacturing. J Cranio-Maxillofacial Surg. 2014;42(8):1877–84. https://doi.org/10.1016/j.jcms.2014.07.006.

Jabbour P, Chalouhi N. Simulation-based neurosurgical training for the presigmoid approach with a physical model. Neurosurgery. 2013;73(SUPPL. 4):2011–4. https://doi.org/10.1227/NEU.0000000000000090.

Li J, Li P, Lu H, et al. Digital design and individually fabricated titanium implants for the reconstruction of traumatic zygomatico-orbital defects. J Craniofac Surg. 2013;24(2):363–8. https://doi.org/10.1097/SCS.0b013e3182701243.

Ciocca L, Mazzoni S, Fantini M, Persiani F, Marchetti C, Scotti R. CAD/CAM guided secondary mandibular reconstruction of a discontinuity defect after ablative cancer surgery. J Cranio-Maxillofacial Surg. 2012;40(8):e511–5. https://doi.org/10.1016/j.jcms.2012.03.015.

Mori K, Yamamoto T, Nakao Y, Esaki T. Surgical simulation of cerebral revascularization via skull base approaches in the posterior circulation using three-dimensional skull model with artificial brain and blood vessels. Neurol Med Chir (Tokyo). 2011;51(2):93–6 http://www.ncbi.nlm.nih.gov/pubmed/21358148.

Morrison DA, Guy DT, Day RE, Lee GYF. Simultaneous repair of two large cranial defects using rapid prototyping and custom computer-designed titanium plates: a case report. Proc Inst Mech Eng Part H J Eng Med. 2011;225(11):1108–12. https://doi.org/10.1177/0954411911422766.

Nikzad S, Azari A, Ghassemzadeh A. Modified flapless dental implant surgery for planning treatment in a maxilla including sinus lift augmentation through use of virtual surgical planning and a 3-dimensional model. J Oral Maxillofac Surg. 2010;68(9):2291–8. https://doi.org/10.1016/j.joms.2010.02.002.

Katatny IE, Masood SH, Morsi YS. Evaluation and Validation of the Shape Accuracy of FDM Fabricated Medical Models. Adv Mater Res. 2009;83–86:275–80. https://doi.org/10.4028/www.scientific.net/amr.83-86.275.

Lambrecht JTH, Berndt D, Christensen AM, Zehnder M. Haptic model fabrication for undergraduate and postgraduate teaching. Int J Oral Maxillofac Surg. 2010;39(12):1226–9. https://doi.org/10.1016/j.ijom.2010.07.014.

Sohmura T, Kusumoto N, Otani T, Yamada S, Wakabayashi K, Yatani H. CAD/CAM fabrication and clinical application of surgical template and bone model in oral implant surgery. Clin Oral Implants Res. 2009;20(1):87–93. https://doi.org/10.1111/j.1600-0501.2008.01588.x.

Mori K. Dissectable modified three-dimensional temporal bone and whole skull base models for training in skull base approaches. Skull Base. 2009;19(5):333–43. https://doi.org/10.1055/s-0029-1224862.

Radley GJ, Sama A, Watson J, Harris RA. Characterization, quantification, and replication of human sinus bone for surgery simulation phantoms. Proc Inst Mech Eng Part H J Eng Med. 2009;223(7):875–87. https://doi.org/10.1243/09544119JEIM577.

Cohen A, Laviv A, Berman P, Nashef R, Abu-Tair J. Mandibular reconstruction using stereolithographic 3-dimensional printing modeling technology. Oral Surg Oral Med Oral Pathol Oral Radiol Endodontol. 2009;108(5):661–6. https://doi.org/10.1016/j.tripleo.2009.05.023.

Suzuki M, Hagiwara A, Ogawa Y, Ono H. Rapid-prototyped temporal bone and inner-ear models replicated by adjusting computed tomography thresholds. J Laryngol Otol. 2007;121(11):1025–8. https://doi.org/10.1017/S0022215107006706.

Mavili ME, Canter HI, Saglam-Aydinatay B, et al. Use of three-dimensional medical modeling methods for the precise planning of orthognathic surgery. J Craniofacial Surg. 18(4):740–7. https://doi.org/10.4103/JCD.JCD_133_18.

Suzuki M, Ogawa Y, Kawano A, Hagiwara A, Yamaguchi H, Ono H. Rapid prototyping of temporal bone for surgical training and medical education. Acta Otolaryngol. 2004;124(4):400–2. https://doi.org/10.1080/00016480410016478.

Müller A, Krishnan KG, Uhl E, Mast G. The application of rapid prototyping techniques in cranial reconstruction and preoperative planning in neurosurgery. J Craniofac Surg. 2003;14(6):98. https://doi.org/10.1097/00001665-200311000-00014.

Löppönen H, Holma T, Sorri M, et al. Computed tomography data based rapid prototyping model of the temporal bone before cochlear implant surgery. Acta Oto-Laryngologica, Suppl. 1997;6489(529):47–9. https://doi.org/10.3109/00016489709124077.

Acknowledgements

None.

Funding

This work was funded by “Agence Nationale de la Recherche” (ANR-16-CE18-0009-01).

Author information

Authors and Affiliations

Contributions

All the authors contributed equally to this manuscript. They worked together to design this study, to analyze the data and to write the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original publication contained an incorrect version of figure 4, this has been updated.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Meglioli, M., Naveau, A., Macaluso, G.M. et al. 3D printed bone models in oral and cranio-maxillofacial surgery: a systematic review. 3D Print Med 6, 30 (2020). https://doi.org/10.1186/s41205-020-00082-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s41205-020-00082-5