Abstract

Background

Pressure to abolish farrowing crates is increasing, and producers are faced with decisions about which alternative system to adopt. For sow welfare, well designed free farrowing systems without close confinement are considered optimal but producers have concerns about increased piglet mortality, particularly crushing by the sow. Reporting accurate performance figures from commercial farms newly operating such systems could inform the transition process. This study investigated performance on three commercial farms operating four different zero-confinement systems, three of which were newly installed. A total of 3212 litters from 2920 sows were followed from farrowing to weaning over a three-year period with key performance indicators (KPIs) recorded. Mixed Models (LMMs, GLMMs) determined the influence of different factors (e.g. farrowing system, sow parity, management aspects) and litter characteristics on performance, including levels and causes of piglet mortality.

Results

Piglet mortality was significantly influenced by farm/system. Live-born mortality ranged from 10.3 to 20.6% with stillbirths ranging from 2.5 to 5.9%. A larger litter size and higher parity resulted in higher levels of mortality regardless of system. In all systems, crushing was the main cause of piglet mortality (59%), but 31% of sows did not crush any piglets, whilst 26% crushed only one piglet and the remaining sows (43%) crushed two or more piglets. System significantly influenced crushing as a percentage of all deaths, with the system with the smallest spatial footprint (m2) compared to the other systems, recording the highest levels of crushing. Time from the start of the study influenced mortality, with significant reductions in crushing mortality (by ~ 4%) over the course of the three-year study. There was a highly significant effect of length of time (days) between moving sows into the farrowing accommodation and sows farrowing on piglet mortality (P < 0.001). The less time between sows moving in and farrowing, the higher the levels of piglet mortality, with ~ 3% increase in total mortality every five days. System effects were highly significant after adjusting for parity, litter size, and days pre-farrowing.

Conclusion

These results from commercial farms demonstrate that even sows that have not been specifically selected for free farrowing are able, in many cases, to perform well in these zero-confinement systems, but that a period of adaptation is to be expected for overall farm performance. There are performance differences between the farms/systems which can be attributed to individual farm/system characteristics (e.g. pen design and management, staff expertise, pig genotypes, etc.). Higher parity sows and those producing very large litters provide a greater challenge to piglet mortality in these free farrowing systems (just as they do in crate systems). Management significantly influences performance, and ensuring sows have plenty of time to acclimatise between moving in to farrowing accommodation and giving birth is a critical aspect of improving piglet survival.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Background

Pressure to abolish farrowing crates is increasing, particularly in Europe, where political debate about the continued use of close-confinement systems has intensified following successful campaigns by animal advocacy groups to ‘End the Cage Age’ [1]. The result of this European Citizens’ Initiative (ECI) was a commitment by the European Commission (first tabled in 2021) to phase out and eventually prohibit the use of close-confinement systems for all farmed species. There was also a realisation by many in the industry that transitioning to higher welfare alternatives with less confinement is inevitable and ‘free farrowing is a matter of how not when’ [2]. However, barriers to uptake of such systems do exist, including costs, the potential for increased labour demand and continued concerns about increases in piglet mortality, particularly from crushing by the sow. Some farmers have expressed greater confidence in managing piglet mortality in alternative farrowing systems [2] and good performance results are reported in some countries already operating free farrowing, notably Norway and Switzerland (e.g. [3,4,5,6]). Many of those transitioning to alternative systems in countries where there are currently no restrictions on the use of confinement for farrowing and lactation have favoured adopting temporary crating systems as an ‘insurance policy’ to lessen this concern over potential increases to piglet mortality [7]. Whilst good temporary crating systems offer better sow welfare than conventional crates [7], they do not confer the same welfare benefits as true free farrowing systems (i.e. zero-confinement) due to the restriction of highly motivated prepartum nest-site seeking and nest-building behaviours, which are characterised by increased activity, rooting, pawing, searching for suitable nest-building materials, turning around and arranging those materials [8,9,10]. Feedback from building and completing a nest pre-partum can affect neuroendocrine regulation of maternal behaviour during and post-partum [11], with evidence of improvements in sow hormonal balance and colostrum quality [12], as well as positive maternal behaviours including increased responsiveness to piglet distress calls, increased maternal bonding and a positive effect on nursing behaviour [9, 13,14,15]. Reduced piglet birth intervals, reduced stillbirths and reduced postnatal mortality have also been reported (reviewed by [16]). Farmers installing temporary crating systems also risk incurring the same public reaction as poultry farmers who installed ‘enriched cages’ to replace battery cages for laying hens; the consumer’s view was that ‘a cage is still a cage’ [17, 18]. The installation of enriched cages for laying hens proved costly as such systems are precluded from many markets and are also targeted under the ECI [1].

Despite the concerns of producers regarding potential increases in piglet mortality when the sow is loose for farrowing, the consumer’s negative view on confinement, particularly for expectant mothers, is global and enduring [19,20,21]. An EU-wide survey on the attitudes of European citizens to animal welfare in 2023 [21] reported that 89% of respondents believe that ‘ensuring animals are not kept in individual cages is important’.

There has been a great deal of research into designing zero-confinement farrowing systems that optimise animal welfare [8, 22] and data have been published demonstrating that some systems can offer equivalent levels of piglet mortality to conventional farrowing crates [23, 24]. However, it is likely that farmers will be more receptive to data that are commercially relevant to them, coming from free farrowing systems having been adopted or trialled (i.e. partial adoption [25]) on commercial farms. However, data on performance from commercial farms, specifically operating zero-confinement systems, are sparce. Generally, these types of data are only available from countries that have been operating free farrowing systems for a sustained period of time (e.g. Sweden 1987; Norway 2000; Switzerland 2007 (after a 10-year transition period)) and, whilst these countries offer valuable insights about their experience, the performance data may not be as valuable to someone considering transitioning now.

This project aimed to address this knowledge gap by collecting key performance indicators from sows farrowing in different zero-confinement systems operated on commercial UK farms. Our objective was to report commercially relevant performance data, determining any influential biological and environmental factors affecting performance in these zero-confinement systems, particularly piglet mortality.

Methods

Animal housing and management

The study was conducted over a three-year period (2013–2016) on three participating commercial farms in the United Kingdom, operating four different free farrowing (FF) systems as well as conventional farrowing crates. The project was focused on the FF systems and did not involve comparative work in crates. Data were collected on 3212 litters from 2920 (primi- and multi- parous) sows. Table 1 describes the farms, farrowing systems, sow genetics and breeding herd management. Pictures of systems are provided in Supplementary Materials (Figure S1).

Sows were assigned to farrowing accommodation within each farm based on the farm’s routine schedule (i.e. not experimentally controlled). Animals were generally moved into the farrowing accommodation approximately four days before their expected farrowing date (average 4.17 days ± SD 2.42).

Substrate provision and heating

Upon entry to farrowing accommodation on Farm 1, in system A (Fig. 1A) wood shavings and 5 kg long-stemmed straw (i.e. enough to cover the solid floor area) was provided in the nesting area and shavings and straw provided in the creep area. The building containing the farrowing pens was initially kept at 22 ± 1 °C and was gradually reduced automatically to 18 ± 1 °C. A 75w heat lamp was suspended over the covered creep area 1 m above the creep floor. Pre-partum, pens were cleaned out daily with soiled straw and shavings being removed and replenished as necessary. Pens were cleaned out weekly post-partum to remove any soiled bedding and a dry powder applied to the solid area to keep it dry and avoid slipping.

Free farrowing systems operated on three commercial farms. Farm 1 operated system (A) (a Danish Free Farrower design), Farm 2 operated system (B) (PigSAFE design) and Farm 3 operated both systems (C) (a ‘360®’ temporary crate in its open position for the trial) and (D) (a ‘Solari’ system with an indoor kennel and outdoor run). All drawings to scale and created by Pig 333 from author description. Pig length represents the 95th percentile of a modern hyperprolific sow as determined by Nielsen et al. 2018 [26]

On Farm 2, in system B (Fig. 1B) 10 kg long-stemmed straw was provided to cover the nesting area when sows were moved in. The building containing the farrowing pens was initially kept at 22 °C and was gradually reduced automatically to 18 °C. A 75w heat lamp was suspended over the covered creep area 1 m above the creep floor and the creep area also contained a heat pad starting at 35 °C and reducing to 30 °C by weaning. Pre-partum, pens were cleaned out daily with soiled straw being removed and replenished as necessary. Post-partum, soiled straw was removed daily until no straw was present in the pen.

On Farm 3, in system C (Fig. 1C) stockpeople gave approximately two handfuls of shredded paper when farrowing was imminent and the buildings containing the farrowing pens were kept at 22 °C, with the additional heat mat along one side of each pen starting at 36 °C and reducing to 30 °C by weaning. Room temperature was gradually reduced automatically to 18 °C by day ten post-partum and to 16 °C by weaning. In system D (Fig. 1D) the nest area contained 5 kg of long-stemmed straw (i.e. enough to cover the solid floor) from the day of sow entry into the farrowing system, whilst the entire creep floor was covered in wood shavings. Pens on system D were routinely cleaned out weekly with straw and wood shavings replenished. Pre-partum, additional straw or wood shavings were added to nests when required and soiled straw was removed and replenished post-partum. As the pens had no ambient temperature controls, a 400 w electric heater was located at one end of each covered creep, these being individually switched off three to five days post-partum.

Sow and piglet husbandry

Feeding

On Farm 1, gestating sows were fed a wet ration of approximately 2.5-3 kg per day (14.47% CP, 13.11 DE MJ/Kg) through electronic sow feed stations (SCHAUER Agrotronic GmbH, Austria) allowing individual feeding. Water was available ad libitum. Upon entry into the farrowing accommodation, sows were fed on an automated liquid feed system once a day into troughs over the slatted area of the pen. Sows were fed a transition ration (18.32% CP, 14.07 DE MJ/Kg) pre-farrowing and for one week post-farrowing and then changed onto a lactation ration (19.77% CP, 14.39 DE MJ/Kg) on an automatic feed curve to gradually increase feed throughout lactation. Once all sows had farrowed within the building, feeding frequency was increased to twice daily and then increased to four times daily by the end of lactation. Water was available ad libitum for sows (bite drinker) and piglets (bowl and nipple drinker) (Fig. 1A). Creep feed (Primary Diets, AB Agri Ltd, Peterborough, UK) was introduced in the creep area from 10 days of age and increased according to appetite until weaning.

On Farm 2, gestating sows were fed a pelleted gestation diet (gilts: 12.52% CP, 12.08 DE MJ/kg; sows: 11.95 CP%, 12.33 DE MJ/kg) through electronic sow feed stations allowing individual feeding (Nedap Livestock Management, The Netherlands) with levels based on a feed curve set by body condition, time of year and stage of gestation. Gilts were fed as a group using dump feeders in their accommodation (Table 1). Water was available ad libitum. Upon entry into the farrowing house, sows had pelleted lactation feed (17% CP 13.36 DE MJ/kg) dispensed through a Gestal feed dispenser (Jyga Technologies, Canada) set to a curve, which could be increased during lactation and adapted for individuals depending on size of litter, parity and appetite. Feed increased from 1.5 kg pre-farrowing to up to 8-12 kg during lactation. Creep feed for piglets (Primary Diets, AB Agri Ltd, Peterborough, UK) was introduced in the creep area from 10 days of age and increased according to appetite until weaning. Water was available ad libitum for all sows (bite drinker) and piglets (nipple drinker) (Fig. 1B).

On Farm 3, gestating sows were fed via dump-feeders once daily with approximately 3 kg of pelleted feed per sow per day (gilts = 12.42% CP, 12.52 DE MJ/Kg; sows = 11.85% CP, 12.47 DE MJ/Kg). Water was available ad libitum. Upon entry into the farrowing accommodation, sows were hand-fed once daily in the morning, onto the floor of the nest area in system D or troughs in system C, until all sows in a building had farrowed, after which sows were fed twice a day. Feed was a lactation diet (15.98% CP, 13.69 DE MJ/kg) and was gradually increased from 2 to 10 kg per sow per day throughout lactation. A handful of creep feed (Primary Diets, AB Agri Ltd, Peterborough, UK; followed by Flat Deck, A-One Feed Supplements Ltd, Thirsk, UK) was provided once daily on the floor in all systems from approx. 10 days of age until weaning. Water was available ad libitum for sows (button drinker – System C) and piglets (nipple drinker – System C– Fig. 1C) and from a water bowl shared by sows and piglets for System D (Fig. 1D).

Piglet procedures

At the time of the study, in accordance with veterinary advice for each farm and in accordance with regulations (The Welfare of Farmed Animals (England) Regulations, 2007) permitting certain procedures once ‘measures to improve environmental conditions or management systems have first been carried out’, piglets were tail docked on Farms 2 and 3 and teeth were clipped or ground. None of these procedures were implemented on Farm 1. Piglets were given 1 ml of Uniferon (Farm 1) (Pharmacosmos A/S, Holbaek, Denmark; each ml contains 200 mg iron(III) as iron(III) hydroxide) or Gleptosil (Farms 2 and 3) (Ceva Animal Health Ltd, Amersham, UK; each ml contains 200 mg iron as gleptoferron complex (498 mg/ml)). On Farms 2 and 3 piglets were also given 0.5 ml of Betamox (Norbrook Laboratories Ltd, Newry, Northern Ireland; each ml contains 150 mg (15% w/v) Amoxicillin (as Amoxicillin Trihydrate 17.21%w/v)) within 24 h of birth.

Data collection

Data were collected on sows from the time that they were moved into the farrowing accommodation until weaning. Days were assigned a number based on the farrowing date (i.e. farrowing date = day 0 (D0), day before farrowing = day − 1 (D-1) etc.). On move-in day, sows were weighed (on farms where weighing equipment was available) and body condition scored (1–5 scale of increasing body condition, visually assessed using the AHDB scoring systemFootnote 1). Sows were scored for signs of lameness according to D’Eath’s protocol [27]. On D0, whether or not a sow was induced to farrow, savaged any piglets, was given oxytocin (Oxytocin-S, 10 iu/ml, single dosage 0.2-1.0 ml) in the case of dystocia or post-birth milking difficulties, and/or an internal examination because of farrowing problems was recorded. The number of functional teats were counted. The key performance indicators (KPIs) of total litter size, number born dead, alive and mummified were recorded along with litter birth weight (on farms where weighing equipment was available). Any other deaths or injuries were noted, and the cause of death was ascertained by gross examination of piglets using the descriptions in Table 2. Fostering information was recorded throughout lactation in order to calculate total mortality and live-born mortality at weaning adjusting the number of piglets at risk for numbers fostered on/off. At weaning (average weaning age 25.7 ± SD 4.13 days) sows were weighed (where possible), scored for signs of lameness and body condition scored. The number of piglets weaned per sow, and litter weaned weight (where possible) were recorded.

Data processing and statistical analyses

Data were processed to calculate per litter percentage total mortality (TM%), percentage live-born mortality (LBM%) and percentage still-born mortality (SB%) for the period from birth to weaning (see data dictionary in Supplementary Materials Table S1 which lists numeric data collected and equations for all derived numeric variables). Fostering adjustments were taken into account. Mortality results were also split between any deaths that occurred pre-processing (PRE) (i.e. within the first 24 h before stockpeople undertook any interventions and piglet husbandry procedures) and post-processing to weaning (POST). This was done to distinguish effects that could more easily be attributed to the sow without the influence of human intervention, including fostering adjustments. The percentages of each type of live-born death (Crushed (CSH), Low viability (LV), Starved (STV), and Other) were calculated similarly for the period from birth to weaning, and split to distinguish PRE and POST processing deaths (see Supplementary Materials Table S1). Analyses focused on each type of live-born death as the percentage of litter size (adjusting for fostering as appropriate, referred to in data dictionary as Crushed% etc.), but some results are also given on the percentage of the death types within all deaths (referred to in data dictionary as CSH% etc.). Other key numerical variables analysed included the Cumulative batch number (i.e. rank of the batch by farrowing date within system based on this dataset) to measure within system effects of time (a proxy for learning), the number of days pre-farrow that sows were moved into farrowing pens and lameness and body condition scores at farrowing and weaning. Weight measurements for sows and litters were recorded at farrowing and weaning, but, apart from litter birth weight, these were missing for about 1/3rd of litters (Supplementary Materials Table S1). Categorical variables in the data (Supplementary Material – Data dictionary Table S2) included identifiers for sows and for sow by parity (the data rows for all the recorded performance data), as well as identifiers for batch, pen, and system (A, B, C, D). Other variables treated as categorical in the statistical analyses were parity, with parity 5 or more grouped together (P5+), whether the sow had a pharmacologically induced farrowing (IND), whether oxytocin (OXY) was given and whether there was savaging of one or more piglets (SAV). There were substantial missing data for these three variables, and for lameness and body condition scores (see Supplementary Materials – Data dictionary Tables S1 and S2).

Initial data checking, cleaning and exploration was carried out on the full dataset, as described in Supplementary Material - Statistical analysis - additional details. Generalised linear mixed models (GLMM) with logit link and binomially distributed residual variation were used to analyse mortality and mortality types, with response measure being the mortality count per litter (e.g. Crushed_tot: Total number of crushed piglets) and binomial total the appropriate litter size measurement (e.g. BA + F_ADJ (Total liveborn piglets after fostering adjustments to weaning– i.e. foster in and foster out– Supplementary Materials Table S1)). GLMMs with log link and Poisson distributed residual variation were used to analyse count data (e.g. BA: Total number of born alive piglets, WEANED: Number of weaned piglets). Linear mixed models (LMM) were used to analyse numerical data (e.g. weights, days pre-farrowing, parity) as well as some mortality data (appropriately transformed) when counts were low and GLMMs would not converge. Random effects included in the models were Batch, Pen, and Sow, though as less than 10% of sows had multiple litters in the dataset Sow had to be dropped from some models, particularly in GLMMs where counts were low, or other models based on fewer litters due to missing data. Candidate fixed effects fitted as categorical variables were System, Parity, SAV, OXY, IND (see Supplementary Materials– Data dictionary Table S2). Candidate fixed effects included as covariates (with linear effects on analyses scales) were numerical variables Cumulative batch number, Days_pre_farrow, weights, Lameness and body CS at Farrowing and Weaning, TEATS, and appropriate litter size measurements (see Supplementary Materials– Data dictionary Tables S1 and S2). Alternative time effects to Cumulative batch number were investigated (such as year and time in year of farrowing) but time in year effects were not consistent between systems and so, for simplicity, Cumulative batch number is reported to examine the effect of length of time that the systems had been monitored for the project. Note that the fixed effect, System, investigated here may reflect the four different types of systems, or could reflect other aspects of these particular four systems, as there is no replication in this study within each type of system. Furthermore, substantially fewer data were collected on systems B and C, and therefore, there is substantially more statistical power for comparisons between systems A and D.

GLMMs and LMMs were first investigated, and estimates produced, with single fixed effects on their own and then, for the most important response measures, models were investigated with several fixed effects included. In order to aid interpretation, estimates from the models are mean ± SE shown on back transformed scales (for example percentages, or counts,…) with explanatory covariates also back transformed. P values are based on approximate F tests when available but otherwise are based on Wald tests. See Supplementary material - Statistical analysis – additional details for more information on modelling. Data were initially collated and cleaned using Excel. Further data cleaning and processing including calculation of derived variables, exploratory and statistical analysis was conducted using code in Genstat (23rd edition, VSN International Ltd).

Results

Over the course of the project 2920 sows produced 46,789 piglets (including 4.75% born dead) in 3212 litters across the three participating farms, with about 10% of sows recorded for two or more litters. Most of these litters were from systems A (n = 1646, 51.2%), and D (n = 1356, 42.2%), with 121 litters (3.77%) from system B (2.77%) and 89 from C. Performance data from birth to weaning were collected on the majority of sows and piglets.

Sow characteristics

The average parity of sows was 3.03 (SD 1.52) and ranged from 1 to 7 (medians and actual counts per parity, per system are presented in Supplementary Materials Table S3). Whilst Farm 2 had lower average parity than Farms 1 and 3, this was marginally insignificant (Farm 1, system A = 3.12 ± SE 0.12; Farm 2, system B = 2.48 ± SE 0.21; Farm 3, system C = 2.96 ± SE 0.24 and system D 2.93 ± SE0.11, F3,115=2.31, P = 0.080, from LMM). Average sow body CS upon entry to the farrowing house and exit at weaning was 3.08 (SD 0.31) and 2.89 (SD 0.25) respectively. Whilst statistically there were highly significant differences between farms, numerical differences were small (respectively, estimated mean range 3.03–3.34, 2.72–2.97, F3,90=13.78, F3,88=16.44, both P < 0.001, from LMM). Mean body weight increased with parity (respectively, estimated mean range from parities 1 to 5+, 215.0-309.5 Kg at farrowing, 178.2-259.3 Kg at weaning, F4,1101=661.36, F4,875=414.74, both P < 0.001, from LMM). However, sow body weight loss (%) between farrowing and weaning was fairly similar between parities (range 16.2-18.2%, F4,835=3.3, P = 0.010, from LMM). Average lameness score was low upon entry to the farrowing house, 0.11 (SD 0.40), and at weaning, 0.17 (SD 0.50). Whilst statistically there were highly significant differences between farms, differences were numerically small (respectively, estimated mean range 0.06–0.17, 0.02–0.37, F3,111=6.57, F3,99=17.44, both P < 0.001, from LMM). Sows had an average of 14.2 ± SD 1.1 functional teats.

Performance

Influence of system, sow condition, parity and litter size

Overall, the average percentage total mortality (TM%), live-born (LBM%) and stillborn (SB%) mortality per litter was 19.3% (SD 15.5), 15.7% (SD 14.6) and 4.3% (SD 7.5) respectively, but there were differences in KPIs between farms/systems (P < 0.001, Table 3). Mean percentage mortality was highest in A and lowest in D and this was mainly evident in the PRE-processing period (P < 0.001– Table 3). Whilst mean total numbers of piglets born (TB), and totals born alive (BA) were highest in A, and lowest in B, mean numbers weaned was lowest in A and highest in D and C. Mean percentage weaned of total born was lowest in A and highest in D (F3,141=58.16, P < 0.001, A: 79.1% B: 87.3% C: 85.1% D: 89.9% from GLMM).

Sow parity significantly affected performance with performance generally decreasing from parity 2 onwards (see detailed Results in Supplementary Materials, Table S4, Figure S2). There were some highly significant effects of sow body CS at weaning on TM% and LBM% mortality respectively, (Wald/ndf)1=12.56, (Wald/ndf)1=18.64 both P < 0.001, from GLMMs), with sows of higher weaning CS returning higher mortality rates. There was no significant effect on KPIs of sow lameness before farrowing (P = 0.381–0.853, from GLMMs) or at weaning (P = 0.108–0.670, from GLMMs).

Piglet mortality percentages increased markedly with litter size measures (P < 0.001, see detailed Results in Supplementary Materials Table S5, Figure S3).

Testing effects of system on TM%, LBM% and SB% after adjusting for parity and pertinent litter size measures resulted in decreased F-test statistics by about 10–20% (results not shown) compared to the GLMMs with system alone (Table 3). However, the adjusted tests for the system effects remain highly significant (P < 0.001) suggesting that there are system effects on piglet mortality that cannot be accounted for by differences in sow parity and/or litter size.

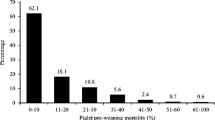

The majority of piglet deaths on all farms were registered as crushing by the sow (58.7%±SD 37.2% of all deaths - Fig. 2). Crushing deaths as a percentage of BA adjusted for fostering (see Supplementary Material Table S1) was highest in system A (14.6% estimate from GLMM) and lowest in D (7.4% from GLMM), but as a percentage of all deaths, system C was substantially higher than all other systems, with 76.3% (from GLMM) of deaths due to crushing (Fig. 2; Table 4, Supplementary Materials Table S5, all P < 0.001). System also significantly influenced the percentage of all other types of mortality (all P < 0.001, Fig. 2; Table 4) and to a lesser extent as a percentage of all deaths (Supplementary Materials – Table S5). The percentage of piglets crushed of BA adjusted for fostering increased with parity from about 9.2% in parities 1 and 2 to 12.3% for parity 5 or more (means estimated from GLMM, P < 0.001, Table 4). Increases in percentage piglets crushed of BA adjusted for fostering was large (means estimated from GLMM, P < 0.001) from about 1.3% for five piglets to 14.5% for 17 piglets. Testing effects of system on percentage piglets crushed of BA adjusted for fostering after adjusting for parity and the pertinent litter size measure resulted in a decreased F-test statistic by 23% (results not shown) compared to the GLMMs with system alone (Table 4). However, the adjusted tests for the system effect remains highly significant (P < 0.001) suggesting that there are system effects on crushing that cannot be accounted for by differences in sow parity and/or litter size.

When looking at the number of crushed piglets per litter, this ranged from 0 to 13, however the majority of sows (57%, n = 1751) crushed 0 or just one piglet (Fig. 3a), with the highest numbers crushed per litter (13) coming from two litters from Farm 1 (system A). There were significant differences between systems in the number of crushed piglets per litter (P < 0.001, F3,142=34.68 from GLMM; Fig. 3b) with the most piglets crushed in A and the least in D (means estimated from GLMM: A 2.1, B 1.3, C 1.8 and D 1.0).

(a) Percentage of sow litters across all farms (n = 3074) that crushed no piglets (0, green circle) or crushed between 1–13 piglets (blue circles). The area of the circles represents the number of sows. (b) Percentage of sow litters in each farrowing system (A, B, C, D) that crushed no piglets (0) or crushed between 1–13 piglets

Influence of length of time system operational on farm

There was a marginally statistically significant effect of Cumulative batch number within system on PRE-processing LBM% (F1,73=5.29, P = 0.024), but not POST-processing LBM% (F1,74=0.01, P = 0.940). There was a marginally statistically significant effect of the Cumulative batch number within system on the percentage of piglets crushed in total and PRE-processing, but not POST-processing (Crushed %, F1,77=6.0, P = 0.017, PRE-Crushed %, F1,74=7.48, P = 0.008, POST-Crushed %, F1,71=0.30, P = 0.585, from GLMMs with Cumulative batch number only) with less crushing over time by about 4% (from GLMM) over the four systems. There was a marginally statistically significant interaction between System and Cumulative batch number for the percentage of piglets crushed in the PRE-processing period (F3,165=2.90, P = 0.037; Fig. 4), which suggested that crushing was steady and low for System D (at just under 4%), and initially high but decreasing for System A (from about 9–5%) and B, but increasing for System C. However, the SEs for systems B and C are very large (Fig. 4) and so evidence for the observed trends for those two systems is weak.

Influence of farrowing management

There was a highly significant effect on piglet mortality of length of time (days) between moving sows into farrowing accommodation and sows giving birth (TM%: (Wald/ndf)1=30.01; LBM%: (Wald/ndf)1=30.49; SB%: F1,1130=15.03; Crushed %: F1,2809=27.68; PRE-Crushed %: F1,2209= 24.71; POST-Crushed %: F1,2781=7.21, all P < 0.001, from GLMMs – Fig. 5). The less time between move in and farrowing, the higher the levels of mortality, by about 3% total mortality every five days.

There were some system differences in days pre-farrowing (F3,92=21.99; P < 0.001, from LMM). System A and C averaged the shortest length of time between moving in and farrowing at 3.04 ± SD 1.65 and 3.69 ± SD 2.67 days respectively and system B and D averaged the longest time at 5.26 ± SD 2.03 and 5.53 ± SD 2.52 respectively. Testing effects of system on TM%, LBM%, SB%, Crushed % (Total, PRE and POST) after adjusting for parity, pertinent litter size measures, and days pre-farrowing resulted in decreased F-test statistics by about 25–50% (results not shown) compared to the GLMMs with system alone (Tables 3 and 4). However, the adjusted tests for the system effects remain highly significant (P < 0.001) suggesting that there are system effects on piglet mortality that cannot be accounted for by differences in sow parity, litter size and/or days pre-farrowing. Effects of pertinent litter size measures and parity are fairly similar in the GLMMs with all four fixed effects and the GLMMs with these two measures alone. Effects of days pre-farrowing are highly significant when tested after parity and litter size (P = < 0.001–0.003), but more marginal when tested last after system (SB% P = 0.536, TM% P = 0.027, LBM% P = 0.018, Crushed % P = 0.041, POST-Crushed % P = 0.258), apart from for PRE-Crushed % (P < 0.001), for which the effect of days pre-farrowing is similar in GLMMs with all four terms and with days pre-farrowing alone. This suggests that whilst differences in days pre-farrowing are to some extent a between system effect, there is also evidence that days pre-farrowing affects mortality within systems, particularly on percentage of crushed piglets pre-processing.

There were statistically significant interactions between system and days pre-farrowing on mortality (TM%: (Wald/ndf)3=6.61, P < 0.001; LBM%: (Wald/ndf)3=3.91, P = 0.008; SB%: (Wald/ndf)3=3.02, P = 0.029; Crushed %, (Wald/ndf)1=4.04, P = 0.007 from GLMMs). Mortality decreased markedly with days pre-farrowing for system A, but remained fairly steady for system D (SEs for B and C are very large). Note that this interaction was not significant for PRE-Crushed % ((Wald/ndf)1=0.90, P = 0.441, from GLMM) suggesting that percentage of crushed piglets pre-processing decreased with days pre-farrowing similarly in all four systems.

Savaging, induction and use of oxytocin was only measured for about 60% of the litters and rarely measured for farms C and D. Percentage of litters for which savaging was observed was 1.2%, whilst use of oxytocin was 8.9% and induction 37.6% of litters both mainly in Farm A. Savaging, as expected, affected mortality (TM%: F1,1418=5.67, P = 0.017; LBM%: F1,1322=9.02 P = 0.003), predominantly in the PRE-processing period (PRE-TM%: F1,1498=5.59, P = 0.018; PRE-LBM%: F1,1192=11.97, P = 0.001, all from GLMMs).

Discussion

Our results demonstrate that most domestic sows can perform well in these free farrowing systems and that results can improve with time, although there are system effects suggesting that certain systems are more challenging for successful free farrowing. It is also important to note that the system effects observed here may reflect the four different designs of farrowing system, or could reflect other management aspects of these particular four systems, as there is no replication in this study of systems across farms. Furthermore, substantially fewer data were collected on systems B and C, and therefore, statistically significant system differences observed were most frequently as a result of differences between systems A and D.

The study recorded sows on commercial units with three newly installed systems and one established system. Total mortality of all piglets in the study was 19.3%, which included 4.3% stillbirths. Comparative commercial data from indoor free farrowing herds are sparse but can be found from countries that have banned farrowing crate use. In Norway, figures from a 2018 study on 14 commercial farms reported total mortality at 23.4%, including 6.3% stillbirths, with average total born litter size calculated from their figures as 15.14 piglets [28]. In a Swiss study, Weber et al. [4] reported live-born mortality between 11.5 and 13.5% from 255 farms where average born alive litter size was 12.8 piglets. A Swedish study in 2019 [29] followed 318 litters and reported 20.9% live-born mortality from an average born alive litter size of 14.3 piglets. Live-born mortality for the four systems in our study ranged from 10.3 to 20.6% from born alive litter sizes ranging from 13.0 to 14.4 piglets. Thus, our results are in line with the range of figures reported by these studies.

Improvement over time was evident (averaged over the four systems), supporting the notion that a transition period is to be expected when adopting a new free farrowing system, as documented in other studies, particularly in commercial trials [3, 30]. There was, however, an interesting interactive effect of system and cumulative batch (i.e. time) on the amount of crushing mortality observed in the first 24 h post-partum, with crushing being steady and low for the established system (D), decreasing markedly for one of the newly installed free farrowing systems (A), decreasing somewhat for B, but increasing for system C. However, it should be noted that the standard errors for systems B and C were very large and so evidence for the observed trends for those two systems is relatively weak, possibly due to data being collected on substantially fewer litters.

Farrowing system was shown to influence the levels of different types of mortality. Whilst crushing mortality was the predominant cause of death on all farms in this study (agreeing with reports from other studies [31,32,33]), the levels of crushing differed. Despite Farm 1, system A recording the highest mortality levels in the study, they did not record the highest value for crushing as a percentage of total mortality. This was registered on Farm 3, predominantly by system C. This was the newly installed temporary crate system (the ‘360’), operated in its open position for the trial. It was the smallest system (occupying the same footprint as a conventional farrowing crate) and such limited space influences how easily sows can avoid making contact with their litter when changing posture. This is something noted by other authors using temporary crating systems in their open position for farrowing [34]. In addition, the creep area in system C was not clearly defined or enclosed (which it was for the other three systems). Given the choice sows would delineate space into areas for resting/farrowing/nursing, eating and elimination [8, 22, 35] and providing covered creeps has been shown in some studies to reduce crushing mortality [36]. This lack of defined functional space for both sows and piglets could have increased the risk of piglets becoming trapped during sow posture changes, which is something noted by other authors who associated small nest spaces and narrow widths with higher piglet mortality in their studies [7, 34, 37]. The dimensions of the nest space are likely to influence the quality of mother-young interactions, particularly how well sows are able to turn and group or cluster their piglets during the pre-lying period, which is a behaviour associated with carefulness [38, 39]. As well as the lack of avoidance space, it is possible the sows in system C were more restless during farrowing, as a result of the lack of appropriate substrate (sows in C only received some shredded paper) as well as limited space to perform satisfactory nest-building behaviour. Thwarted nest-building behaviour can increase stress (recorded as elevated plasma cortisol and ACTH concentrations in crated as opposed to free farrowing sows [40, 41]) and reduce circulating levels of hormones, such as oxytocin, known to modulate maternal nurturing behaviour [9, 42]. Behavioural observations of sows in these systems would offer more insight to support these discussions and any comparisons should be treated with caution as there were many differences between farms and systems that could affect performance, including specific system designs and farrowing room factors, genetics, stockperson skill level and experience of both staff and sows. This latter point is highly influential on how well alternative systems perform [3, 43, 44] and is particularly critical as more farms transition from farrowing crates to less confined farrowing systems and are operating multiple systems on farm that both staff and sows alternate between. There are risks with this strategy as noted by King et al. [43, 44] in other work conducted within this project. They demonstrated the effect of previous farrowing system on current performance, noting that sows farrowing in the same system for repeated parities showed lower piglet mortality than those swapping between systems, and emphasised the importance of consistency in order to achieve sustained good performance. When returned to the same farrowing system as that experienced during the previous farrowing, sows show adapted farrowing behaviours including reduced restlessness [45]. Stockpeople are also likely to adapt and optimise their husbandry practices to enhance performance. In the current study, one practice (of those measured) was highlighted as detrimental to piglet survival; late entrance into the farrowing accommodation. This agrees with previous research [46, 47] and it is likely that late entrance into farrowing accommodation is disruptive to maternal behaviours that can enhance piglet survival, namely nest-building. The level of disturbance farrowing sows might experience is also likely to impact maternal behaviour. The natural behaviour of an expectant sow is to seek a nest-site that is isolated from the main herd and potential predators. Such a site minimises risk of disturbance, thus minimising sow posture changes risking piglet crushing during and after farrowing, allowing a sustained period of contact between mother and young, facilitating successful suckling and the formation of essential bonds before reintegration with the main herd [8, 10]. Such an ideal nest-site is difficult to replicate under indoor commercial conditions, even in well designed free farrowing accommodation, as disturbance from neighbouring sows and stockperson activity are almost inevitable. The level of disturbance is influenced by pen design and the number of pens per farrowing room; too many pens per room can be disruptive and hyper-responsive sows maybe particularly sensitive to their neighbours [18]. Disturbance during parturition is known to negatively influence oxytocin levels [48], could influence the length of the important non-responsive phase after the birth of the last piglet [11] which facilitates safe udder access for piglets and may influence subsequent restlessness of the sow and risk of piglet crushing. In this study, there was high potential for disturbance particularly on Farm 1, system A where there were 72 pens per room and on Farm 3 in system C where the 360s were in close proximity to each other, had low pen sides and there were 20 per room. Farm 2, system B only had 4 pens per room and Farm 3, system D had the potential for the least disturbance with sows essentially singly housed in high-sided kennels with runs. This highlights the importance of design details, not only for the individual pen but also for the overall farrowing room [18].

Regardless of farrowing system, all key performance indicators were heavily influenced by litter size and age of the sow. Large litters are well-known to be a major risk factor for early piglet mortality [49,50,51,52]. Increasing litter size is often accompanied by a reduction in average birth weight, including a higher proportion of piglets showing intrauterine growth retardation (IUGR) [53] and increased numbers of stillborn piglets. Lower birth weight is associated with greater mortality and IUGR piglets in particular can require targeted interventions by staff if they are to survive [54]. Regardless of the robustness of the piglet, when sows consistently produce more piglets than functional teat space, interventions by stockpeople are paramount to ensure early colostrum intake and maximise piglet survival [54]. This is challenging in conventional systems but could be more so when the sow is loose and stockpeople have little experience with free farrowing management. This was the case with Farms 1 and 2. However, Farm 2 only trialled 8 pens (system B), whereas Farm 1 was operating 72 pens (system A) in one barn, had the highest numbers born alive (14.44, range 1–24) and returned the highest live-born piglet mortality (20.6%). Average teat number on this farm was 14.1 ± SD 0.9.

The parity effect we observed in this study (older sows having higher mortality) may partly be explained by the increase in litter size observed with increasing parity. Farm 1 had higher average parity compared to the other farms and had a higher level of stillbirths. Older sows tend to give birth to more piglets and more stillborn piglets [32, 49, 55, 56]. Older sows may also have fewer functional teats, which are less accessible, especially to low viability piglets, and may have a reduced milk yield [57]. Compared to young sows, older sows have a larger mass and body weight, often accompanied with reduced mobility, which are all heightened risk factors for damaging crushing of piglets or a failure to respond to the calls of a trapped piglet [58]. Sow weight could only be accurately recorded on a subset of animals, but body condition score was recorded on the majority and the observation that sows of higher weaned body condition score returned higher piglet mortality rates may support the notion of heavier sows being less mobile, with greater potential to damage their piglets. Alternatively, this result may reflect that higher mortality means fewer piglets nursed and so less body tissue mobilisation occurred for those sows. It is likely a combination of sow, piglet and environmental factors influencing these results that are difficult to disentangle. Observing the behaviour of sows of different body condition scores to determine their mobility around their piglets would more fully inform this discussion, as would observations of piglet behaviour.

Conclusion

These results from commercial farms demonstrate that even sows that have not been specifically selected for free farrowing are able, in many cases, to perform well in zero-confinement systems, but that a period of adaptation is to be expected for overall farm performance. In addition these results suggest it would be more challenging to operate a system designed for temporary crating, with limited space, as a zero-confinement system since the risks of crushing are particularly high. Therefore, systems that afford more space, and are designed with the mindset that the sow will be loose throughout, could be less challenging to operate in the long-term. However, some caution is required when drawing conclusions about system designs, as there was no replication of the types of systems across the different farms.

Optimising management protocols can improve piglet survival. In particular, giving sows enough time in their farrowing accommodation prior to their due date has been highlighted as a key management procedure to reduce piglet mortality.

Crushing remains the main cause of piglet death, but many sows do not crush any piglets. Providing more information on the behaviour and physiology of these successful free farrowing sows and their offspring should allow for the optimisation of breeding programmes to select for maternal traits for sows which will perform well in free farrowing systems. However, system design and management of large litter sizes should also be improved, given the high influence these factors have on performance. Genetic selection for prolificacy has been driven by economic considerations, but poses particular challenges in zero-confinement systems.

Data availability

The datasets used for producing the results presented in this study are available from the corresponding author upon reasonable request.

References

European Union. European Citizens Initiative on End the Cage Age. 2020 [cited 2023 Nov 7]. Available from: https://ec.europa.eu/commission/presscorner/detail/en/QANDA_21_3298.

Dipple S, Baxter EM. Freedom in Farrowing and Lactation webina. Free. Farrowing Lact. (FFL21). 2021. Available from: https://www.openagrar.de/receive/%0Aopenagrar_mods_00073594?lang=en.

Andersen IL, Ocepek M. Farrowing Pens for Individually Loose-Housed Sows: Results on the Development of the SowComfort Farrowing Pen. Agriculture. 2022;12:868. https://doi.org/10.3390/agriculture12060868.

Weber R, Burla J-B, Jossen M, Wechsler B. Excellent Performance with Larger Litters in Free-Farrowing Pens - Agrarforschung Schweiz. Swiss Agric. Res. 2020 Apr. Available from: https://www.agrarforschungschweiz.ch/en/2020/04/excellent-performance-with-larger-litters-in-free-farrowing-pens/.

INGRIS. Årsstatistikk 2022. 2022. https://norsvin.no/nyheter/ingris-2022-fantastisk-framgang-og-store-forskjeller/.

Weber R, Burla J-B, Jossen M. Piglet Losses in Free-Farrowing Pens: Influence of Litter Size. Agrar Schweiz. 2020 [cited 2021 Aug 23];11:53–8. https://doi.org/10.34776/afs11-53e.

Goumon S, Illmann G, Moustsen VA, Baxter EM, Edwards SA. Review of Temporary Crating of Farrowing and Lactating Sows. Front Vet Sci. 2022;9:1810. https://doi.org/10.3389/fvets.2022.811810.

Baxter EM, Lawrence AB, Edwards SA. Alternative farrowing systems: design criteria for farrowing systems based on the biological needs of sows and piglets. Animal. 2011;5. https://doi.org/10.1017/s1751731110002272.

Yun J, Valros A. Benefits of prepartum nest-building behaviour on parturition and lactation in sows-a review. Asian-Australasian J. Anim. Sci. Asian-Australasian Association of Animal Production Societies; 2015. p. 1519–24. https://doi.org/10.5713/ajas.15.0174.

Jensen P. Observations on the maternal behaviour of free-ranging domestic pigs. Appl Anim Behav Sci. 1986;16:131–42. https://doi.org/10.1016/0168-1591(86)90105-X.

Algers B, Uvnäs-Moberg K. Maternal behavior in pigs. Horm Behav. 2007;52:78–85. https://doi.org/10.1016/j.yhbeh.2007.03.022.

Maria N, Jinhyeon Y, Shah H, Stefan B, Anna V, Nicoline S et al. Sow nest-building behavior in communal farrowing relates to productivity and litter size. Appl Anim Behav Sci. 2023;269:106117. Available from: https://doi.org/10.1016/j.applanim.2023.106117.

Rosvold EM, Newberry RC, Andersen IL. Early mother-young interactions in domestic sows – nest-building material increases maternal investment. Appl Anim Behav Sci. 2019;219:104837. https://doi.org/10.1016/j.applanim.2019.104837.

Herskin MS, Jensen KH, Thodberg K. Influence of environmental stimuli on nursing and suckling behaviour in domestic sows and piglets. Anim Sci. 1999;68:27–34. https://doi.org/10.1017/S1357729800050049.

Herskin MS, Jensen KH, Thodberg K. Influence of environmental stimuli on maternal behaviour related to bonding, reactivity and crushing of piglets in domestic sows. Appl Anim Behav Sci. 1998;58:241–54. https://doi.org/10.1016/S0168-1591(97)00144-5.

Monteiro MS, Muro BBD, Carnevale RF, Poor AP, Araújo KM, Viana CHC et al. The beneficial effects of providing prepartum sows with nesting materials on farrowing traits, piglet performance and maternal behavior: A systematic review and meta-analysis. Appl Anim Behav Sci. 2023;259:105795. https://doi.org/10.1016/j.applanim.2022.105795.

Weary DM, Ventura BA, Von Keyserlingk MAG. Societal views and animal welfare science: understanding why the modified cage may fail and other stories. Animal. 2016;10:309–17. https://doi.org/10.1017/S1751731115001160.

Baxter EM, Moustsen VA, Goumon S, Illmann G, Edwards SA. Transitioning from crates to free farrowing: A roadmap to navigate key decisions. Front Vet Sci. 2022;9. https://doi.org/10.3389/fvets.2022.998192.

Vandresen B, Hötzel MJ. Pets as family and pigs in crates: public attitudes towards farrowing crates. Appl Anim Behav Sci. 2021;236:105254. https://doi.org/10.1016/j.applanim.2021.105254.

Vandresen B, Hötzel MJ. Mothers Should Have Freedom of Movement—Citizens’ Attitudes Regarding Farrowing Housing Systems for Sows and Their Piglets. Animals. 2021;11:3439. Available from: https://www.mdpi.com/2076-2615/11/12/3439.

European Commission Directorate-General for Health and Food Safety. Attitudes of Europeans towards animal welfare – Summary. Publ Off Eur Union. 2023;533. Available from: https://data.europa.eu/doi/10.2875/93051.

Pedersen LJ, Malmkvist J, Andersen HML. Housing of sows during farrowing: a review on pen design, welfare and productivity. Livest hous mod Manag to ensure Optim Heal Welf Farm Anim. Wageningen Academic; 2013. pp. 93–111. https://doi.org/10.3920/978-90-8686-771-4.

Baxter EM, Lawrence AB, Edwards SA. Alternative farrowing accommodation: Welfare and economic aspects of existing farrowing and lactation systems for pigs. Animal. 2012;6. https://doi.org/10.1017/s1751731111001224.

EFSA AHAW, Nielsen SS, Alvarez J, Bicout DJ, Calistri P, Nielsen SS, Alvarez J, Bicout DJ, Calistri P, Canali E et al. Welfare of pigs on farm. EFSA J. 2022;20. https://doi.org/10.2903/j.efsa.2022.7421.

Pannell DJ, Claassen R. The Roles of Adoption and Behavior Change in Agricultural Policy. Appl Econ Perspect Policy. 2020;42:31–41. https://doi.org/10.1002/aepp.13009.

Nielsen SE, Kristensen AR, Moustsen VA. Litter size of Danish crossbred sows increased without changes in sow body dimensions over a thirteen year period. Livest Sci. 2018;209:73–6. https://doi.org/10.1016/j.livsci.2018.01.015.

D’Eath R B. Repeated locomotion scoring of a sow herd to measure lameness: consistency over time, the effect of sow characteristics and inter-observer reliability. Anim Welf. 2012;21:219–31. https://doi.org/10.7120/09627286.21.2.219.

Kielland C, Wisløff H, Valheim M, Fauske AK, Reksen O, Framstad T. Preweaning mortality in piglets in loose-housed herds: etiology and prevalence. Animal. 2018;12:1950–7. https://doi.org/10.1017/S1751731117003536.

Olsson A-C, Botermans J, Englund J-E. Acta Agriculturae Scandinavica, Section A-Animal Science Piglet mortality-A parallel comparison between loose-housed and temporarily confined farrowing sows in the same herd Piglet mortality-A parallel comparison between loose-housed and temporarily confined farrowing sows in the same herd. 2019. https://doi.org/10.1080/09064702.2018.1561934.

Baxter EM, Edwards S. Optimising sow and piglet welfare during farrowing and lactation. Underst Behav Improv Welf pigs. 2021. p. 121–76. https://doi.org/10.19103/AS.2020.0081.04.

Weber R, Keil NM, Horat R. Piglet mortality on farms using farrowing systems with or without crates. Anim WelfareAnimal Welf. 2007;16:277–9. https://doi.org/10.1017/s0962728600031511.

Rangstrup-Christensen L, Krogh MA, Pedersen LJ, Sorensen JT. Sow level risk factors for early piglet mortality and crushing in organic outdoor production. Animal. 2018;12. https://doi.org/10.1017/S1751731117002178.

KilBride AL, Mendl M, Statham P, Held S, Harris M, Marchant-Forde JN, et al. Risks associated with preweaning mortality in 855 litters on 39 commercial outdoor pig farms in England. Prev Vet Med. 2014;117:189–99. https://doi.org/10.1016/j.prevetmed.2014.08.004.

Yun J, Han T, Björkman S, Nystén M, Hasan S, Valros A, et al. Factors affecting piglet mortality during the first 24 h after the onset of parturition in large litters: effects of farrowing housing on behaviour of postpartum sows. Animal. 2019;13:1045–53. https://doi.org/10.1017/S1751731118002549.

Nannoni E, Aarnink AJA, Vermeer HM, Reimert I, Fels M, Bracke MBM. Soiling of pig pens: a review of eliminative behaviour. Animals. MDPI AG; 2020. pp. 1–21. https://doi.org/10.3390/ani10112025.

Ramirez BC, Hayes MD, Condotta ICFS, Leonard SM. Impact of housing environment and management on pre-/post-weaning piglet productivity. J Anim Sci. 2022;100. https://doi.org/10.1093/jas/skac142.

Cronin GM, Dunsmore B, Leeson E. The effects of farrowing nest size and width on sow and piglet behaviour and piglet survival. Appl Anim Behav Sci. 1998;60:331–45. https://doi.org/10.1016/S0168-1591%2898%2900159-2.

Weber R, Keil NM, Fehr M, Horat R. Factors affecting piglet mortality in loose farrowing systems on commercial farms. Livest Sci. 2009;124:216–22. https://doi.org/10.1016/j.livsci.2009.02.002.

Burri M, Wechsler B, Gygax L, Weber R. Influence of straw length, sow behaviour and room temperature on the incidence of dangerous situations for piglets in a loose farrowing system. Appl Anim Behav Sci. 2009;117:181–9. https://doi.org/10.1016/j.applanim.2008.12.005.

Lawrence AB, McLean KA, Jarvis S, Gilbert CL, Petherick JC. Stress and parturition in the pig. Reprod Domest Anim. 1997;32:231–6. https://doi.org/10.1111/j.1439-0531.1997.tb01287.x.

Jarvis S, Calvert SK, Stevenson J, van Leeuwen N, Lawrence AB. Pituitary-adrenal activation in pre-parturient pigs (sus scrofa) is associated with behavioural restriction due to lack of space rather than nesting substrate. Anim Welf. 2002;11:371–84. https://doi.org/10.1017/S0962728600025100.

Yun J, Swan KM, Farmer C, Oliviero C, Peltoniemi O, Valros A. Prepartum nest-building has an impact on postpartum nursing performance and maternal behaviour in early lactating sows. Appl Anim Behav Sci. 2014;160:31–7. https://doi.org/10.1016/j.applanim.2014.08.011.

King RL, Baxter EM, Matheson SM, Edwards SA. Consistency is key: interactions of current and previous farrowing system on litter size and piglet mortality. Animal. 2019;13. https://doi.org/10.1017/S1751731118000927.

King RL, Baxter EM, Matheson SM, Edwards SA. Sow free farrowing behaviour: Experiential, seasonal and individual variation. Appl Anim Behav Sci. 2018;208. https://doi.org/10.1016/j.applanim.2018.08.006.

Jarvis S, Van der Vegt BJ, Lawrence AB, McLean KA, Deans LA, Chirnside J et al. The effect of parity and environmental restriction on behavioural and physiological responses of pre-parturient pigs. Appl Anim Behav Sci. 2001;71:203–16. https://doi.org/10.1016/S0168-1591(00)00183-0.

Pedersen LJ, Jensen T. Effects of late introduction of sows to two farrowing environments on the progress of farrowing and maternal behavior. J Anim Sci. 2008 [cited 2021 Aug 30];86:2730–7. Available from: https://academic.oup.com/jas/article/86/10/2730/4789152.

King RL, Baxter EM, Matheson SM, Edwards SA. Temporary crate opening procedure affects immediate post-opening piglet mortality and sow behaviour. Animal. 2019;13. https://doi.org/10.1017/S1751731118000915.

Lawrence AB, Petherick JC, McLean K, Gilbert CL, Chapman C, Russell JA. Naloxone prevents interruption of parturition and increases plasma oxytocin following environmental disturbance in parturient sows. Physiol Behav. 1992;52:917–23. https://doi.org/10.1016/0031-9384(92)90371-8.

Wientjes JGM, Soede NM, van der Peet-Schwering CMC, van den Brand H, Kemp B. Piglet uniformity and mortality in large organic litters: Effects of parity and pre-mating diet composition. Livest Sci. 2012;144:218–29. https://doi.org/10.1016/j.livsci.2011.11.018.

Rangstrup-Christensen L, Schild SLA, Pedersen LJ, Sørensen JT. Causes of preweaning mortality in organic outdoor sow herds. Res Vet Sci. 2018;118:171–80. https://doi.org/10.1016/j.rvsc.2018.02.010.

Hales J, Moustsen VA, Devreese AM, Nielsen MBF, Hansen CF. Comparable farrowing progress in confined and loose housed hyper-prolific sows. Livest Sci. 2015;171:64–72. https://doi.org/10.1016/j.livsci.2014.11.009.

Peltoniemi O, Han T, Yun J. Coping with large litters: management effects on welfare and nursing capacity of the sow. J Anim Sci Technol. 2021;63:199–210. https://doi.org/10.5187/jast.2021.e46.

Matheson SM, Walling GA, Edwards SA. Genetic selection against intrauterine growth retardation in piglets: A problem at the piglet level with a solution at the sow level. Genet Sel Evol. 2018 [cited 2022 Apr 3];50:1–11. https://doi.org/10.1186/s12711-018-0417-7.

Baxter EM, Schmitt O, Pedersen LJ. Managing the litter from hyperprolific sows. The suckling and weaned piglet. Wageningen Academic Publishers; 2020 [cited 2020 Dec 22]. p. 71–106. https://doi.org/10.3920/978-90-8686-894-0_3.

Hales J, Moustsen VA, Nielsen MBF, Hansen CF. Higher preweaning mortality in free farrowing pens compared with farrowing crates in three commercial pig farms. Animal. 2014;8:113–20. https://doi.org/10.1017/s1751731113001869.

Rangstrup-Christensen L, Krogh MA, Pedersen LJ, Sørensen JT. Sow-level risk factors for stillbirth of piglets in organic sow herds. animal. 2017 [cited 2022 Apr 4];11:1078–83. Available from: https://doi.org/10.1017/s1751731116002408.

Balzani A, Cordell HJ, Edwards SA. Relationship of sow udder morphology with piglet suckling behavior and teat access. Theriogenology. 2016;86:1913–20. https://doi.org/10.1016/j.theriogenology.2016.06.007.

Ostović M, Pavičić Z, Tofant A, Kabalin AE, Menčik S, Potočnjak D, et al. Sow parity, body length, postural changes and piglet crushing. Vet Arh. 2012;82:319–226. https://hrcak.srce.hr/file/125107.

Acknowledgements

The authors would like to thank the staff and owners of the commercial farms involved, for their commitment to the project, and for permitting the use of their farms’ data and facilitating the research. The authors are grateful for discussions with the other steering group members – PIC/Genus plc, JSR Genetics and JS Sainsbury's plc – during the project and for their continued support in fulfilling the project goals.

Funding

The FREESOW project, from which the data for this manuscript are derived, was funded by JS Sainsbury’s plc. Further analysis and publication has been supported by the Animal Welfare Foundation (AWF). AWF is a fundraising and grant giving charity (charity number 1192203) directed by veterinary and animal welfare professionals, which uses scientific knowledge to improve the welfare of animals through research, education and debate. More information can be found at www.animalwelfarefoundation.org.uk. EMB and SB receive grant-in-aid from the Scottish Government’s Rural and Environment Science and Analytical Services Division (RESAS SRUC-A2-5).

Author information

Authors and Affiliations

Contributions

SAE and EMB: FREESOW project idea, project funding from JS Sainsburys plc, project management, intellectual input, practical animal work, writing/editing, statistical analysis interpretation; EMB: secured Animal Welfare Foundation project funding. NB and RK: data collection, practical animal work, animal and technical help; SB: statistical analysis and interpretation. All authors read, commented and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

The project received ethical approval from Newcastle University’s Animal Welfare and Ethics Review Body, Approval 379.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Baxter, E.M., Bowers, N., King, R. et al. Factors contributing to high performance of sows in free farrowing systems. Porc Health Manag 10, 16 (2024). https://doi.org/10.1186/s40813-024-00366-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40813-024-00366-w