Abstract

Bearing capacity of reinforced footing clearly depends on the characteristics of interface between geosynthetic and soil. A suitable solution for increasing the bearing capacity is to treat the geotextile surface by various additives. This study reported the results of plate load test on square model footing resting on reinforced sand with and without treated geotextiles to survey the effects of the treatment of geotextile on settlement and bearing capacity. The treated geotextiles were made using additives onto the surface, with a layer of sand located on the top. Geotextile sides were treated in the same way. Different additives including the lime, cement, emulsion, and the effect of the number of layers were considered. The bearing capacity ratio values (BCR), improvement ratio values (IR) and variation of load-settlement ratio obtained from the treated models were presented. The results showed that the treatment of geotextile has a great effect on the behavior of reinforced sand and thus bearing capacity. Also, the test results indicated that lime-treated geotextiles provided better improvement than other additives. The maximum improvement in the bearing capacity of square footing supported on treated geotextiles was found to be 75% compared with the pristine geotextiles.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In civil engineering, geosynthetic materials are applied to improve the behavior of the shallow footing because a cost-effective solution in poor ground conditions is the inclusion of the geosynthetic reinforcement. Reinforcements enhance the tensile force capacity of the system, thus reducing the settlement and raising bearing capacity. Several researchers have studied the use of geosynthetics to improve the behavior of footing on reinforced soil [1,2,3,4,5,6,7,8]. Reinforcement may reduce the permanent settlement of a foundation by about 20% to 30% compared to the one without reinforcement [9]. The inclusion of reinforcement significantly enhances the bearing capacity and declines the wetting-induced collapse settlement of sand pad over weak and collapsible soil [10]. Soil reinforcement can be applied to obtain the same acceptable bearing capacity at a much lower settlement with the similar density of soil, when construction is sensitive to soil settlement [11]. Reinforced soil footing (RSF) has been employed in engineering practice to improve soil’s bearing capacity and reduce footing settlement [12]. Numerical results demonstrated that the reinforcement layers improved the bearing capacity by transferring the footing load to deeper soil layers and thus reducing the stresses and strains underneath the footing [13]. From the finding of researchers [14], the results showed that settlement and bearing capacity of soil also changed with different parameters like the reinforcement length, the number of reinforcement layers, type of reinforcements, as well as the ratio of parameters of reinforcement and footings such as the width of footing (B), location of reinforcing the first layer to footing width (u/B), depth of footing to footing width (D/B), the reinforcement layer width to footing width (b/B), and type of soil.

However, each of these parameters has limitations. For example, increasing the reinforcement length does not always improve the bearing capacity. An effective geosynthetic reinforcement length is 6B [12]. The finest length of reinforcement is between 5 and 7B and the extra length is not effective [15]. For maximum bearing capacity, the optimum reinforcement length is between 2 and 8B [16]. Panigrahi and Pradhan [6] stated that the natural geotextile with size 3.5B and at the depth of 0.5B improves the bearing capacity of sandy soil. By increasing the number of reinforcement layers from an optimum number, the bearing capacity ratio (BCR) tends to reduce due to lateral slipping of sand particles on the reinforcement layers [14]. Tafreshi and Dawson [17] stated that the efficiency of reinforcement was reduced by increasing the number of the planar reinforcement layers. The optimum depth of the reinforcement also has restrictions. Abu-Farsakh et al. [12] found an influence depth of 1.25B for placing geosynthetic reinforcement regardless of the type of reinforcement and embedment depth. Based on earlier research, an appropriate approach to improve system performance and overcome these restrictions is to modify the reinforcement-soil interface properties. To achieve this goal and improve the bearing capacity of the footing, the surface of the reinforcement can be treated by additives such as resin and cement. Interface properties have a significant effect on the behavior of the structure [18]. The behavior of the interface between polymer concrete and sand was studied [19]. The performance of geotextile depends on its physical, mechanical and surface contact properties [20]. Toufigh et al. [21] conducted laboratory tests and constitutive modeling of the interface between backfill soil and a fiber-reinforced polymer material. Long et al. [22] performed a laboratory study to determine the influence of construction, characteristics of the geotextile, concrete, and load on the bond strength between concrete and geotextiles. They stated that geotextiles could be bonded to concrete by placing fresh concrete directly on a geotextile and indicated that the bond strength was significantly determined by details of the geotextile and construction. Brooks and Kenai [23] investigated the properties of a cement mortar reinforced with various types and quantities of polymer grids and steel meshes. They stated that the impact dissipated energy of polymer grids reinforced with a cement mortar was three to seven times greater than that for plain specimens. Nam et al. [24] investigated the effect of the addition of a resin impregnation process on static strength of the injection molded composites to improve the mechanical properties of natural fibers. They found that the tensile strength of natural fiber and natural fiber reinforced composites with resin impregnation method increases with polyvinyl alcohol (PVA) impregnation. Also, resin impregnation fiber could increment tensile strength, flexural strength and elongation break of composites due to the fiber capillary tubes becoming filled. Ouria and Mahmoudi [25] conducted laboratory and numerical modeling of strip footing on geotextile reinforced sand with cement-treated interface. They reported that for a bearing capacity when the geotextile was cement-treated, the geotextile length diminished by 40%.

This paper presents the results of laboratory experiments on a square footing supported by the treated geotextiles, and the results were compared with the unreinforced sand and untreated geotextiles. The type of the additive (cement, lime and emulsion) and number of reinforcements layer (N = 1, 2 and 3) were changed to understand what effects these parameters have on the reinforcement soil model. The variation of load- settlement, bearing capacity ratio values (BCR) and the Improvement Ratio (IR) obtained from the model test at large and small settlement were presented.

Materials

The materials used in this study were soil, reinforcement and additives having the following properties:

Soil

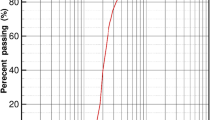

The soil used is sand (# 161) from Firoozkooh city, north of Iran. The particle size distribution was determined using the dry sieving method according to ASTM D2487 [26]. The sand properties are shown in Table 1. The soil can be classified as poorly graded (SP) according to the Unified Soil Classification System. The particle size distribution curve as shown in Fig. 1.

Reinforcement

The reinforcement used in this study is a nonwoven geotextile sheet 2.6 mm which is made polypropylene (Fig. 2). The mass per unit area was determined according to ASTM D5261 [30]. The maximum tensile strength of geotextiles were determined as per ASTM D4632 [31].The properties of geotextile are shown in Table 2. The size of the geotextile was 400 × 400 mm in all tests.

Additives

Lime

Lime is an inorganic material composed generally of calcium oxides and hydroxides. Lime is commonly used in earth structures such as highways, embankments, and roads to improve the geotechnical properties of the soils like compressibility, shear strength, etc. The types of lime used in the soil works are dolomite lime, hydrated lime, and quick lime monohydrated dolomite lime. The lime used in this study is quicklime.

Portland cement

Cement is the most commonly used construction material that has both adhesion and cohesion properties due to which it can make bonding and bind particles of solid matter into a compact durable solid mass. Portland cement is mainly used for construction purposes like soil stabilization, mortar, concrete bridges, buildings, etc. Portland cement (type II) provides moderate sulfate resistance and gives off less heat during hydration. Its typical compound composition includes C3A, C2S, C3S, C4AF, etc.

Emulsion

An emulsion is a mixture of two or more liquids that are generally immiscible but under specific transforming processes will adopt a macroscopic homogeneous aspect and a microscopic heterogeneous one. In an emulsion, one liquid is dispersed in the other. Some examples include bitumen or tar and water. Major applications of bitumen emulsion are in road construction works, such as soil stabilization and sticking asphalt layers well together. In this study, the bitumen content of emulsions is between 50 and 65%.

As indicated in the literature, lime, emulsion and cement are widely used for geotechnical applications and soil improvement [32,33,34,35,36,37,38,39,40,41,42,43,44,45,46]. These additives are used and found in most countries to improve and stabilize the soil and can be used in different conditions. Also, the implementation of the used additives is economical. In the observations of more than six months by authors, they had no destructive effect on the geotextile.

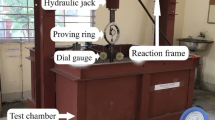

Experimental study

The laboratory model tests were conducted in a steel box, having inside dimensions of 1000 × 1000 mm in plan view and 1000 mm in depth. Three sides of the box were made of 5-mm thick steel plates. One side of the box was made of Plexiglas plates, 15 mm thickness. The box was made of steel profiles in the middle and at the bottom to avoid unsatisfactory movements of the box. In order to reduce friction, the edges and the inside walls of the box were polished. The box dimensions should be five times the model footing width to diminish scaling issues [48]. Figure 3 showed the arrangement of the test set up. Square and steel footing model was used in all tests with 25 mm thickness and 100 mm sides. The footing dimensions were selected based on the dimensions of the box and literature studies to minimize the boundary effect studies [13].The test box was filled with dried sand in 50-mm thick layers by compacting, up to 1000 mm height [49]. To reach uniform compaction, a 150 mm × 150 mm square plate with a 3.5 kg weight was dropped several times on each layer from a height of 150 mm. The number of compaction passes was pre-estimated for each layer at the beginning of the program to control the compaction energy and attain the required sand density. This technique has been used by researchers and published in different studies [4, 25]. With this method, the relative density of the sand was compacted at 70%. The standard deviation of density for tests was in the range of ± 4%. Relative densities were monitored during the tests by placing small cans of known volume placed at various desired locations in the test box. It must be said that each test was prepared by emptying the box of the previous sand and refilling it at the desired relative density. The layers of geotextile were positioned on the compacted surface in the intended position and height, and then the next layer of sand was poured. The preparation of the sand bed above the geotextile continued up to filling the box. After filling the sand to the top, the model footing was placed on the sand surface and the electrical gauges were installed on the model of footing. The footing was centered in the box and loading was performed by the hydraulic jack. The load was applied to the model footing at a rate of 1 mm/min. Loading was applied until footing settlement was achieved, equal to 25% of the footing width. Several laboratory loading tests were repeated and the results were evaluated. The same results were observed under the same conditions. In this study, reinforced model tests followed the unreinforced model tests. The layout of the reinforcement is shown in Fig. 4.

The parameters studied are given below:

B = footing width,

b = reinforcement width,

N = number of reinforcement layers,

u = distance from the base of footing to the first layer of reinforcement,

d = spacing between the layer of reinforcement.

In all the tests on reinforcement reported in this study u/B, d/B and b/B were kept equal. All the unreinforced and reinforced tests were performed using the same reinforcement dimensions, (b/B = 4) namely 400 × 400 mm, this selections were based on previous researches [48, 50,51,52]. To prepare specimens for tests, two sides of the geotextile were covered by additives. Additives were rubbed on the geotextile by hand. The amount of additive used for each side was about 250 g and 100 ml of water was added if necessary. With reference to the additive, a layer of Firoozkooh sand was placed on it. As a result of this treatment, there was a blot zone in the sand layer where the additive was permeated and bonded the sand particles to the geotextiles. In these tests, specimens were prepared by the cast-in-place method. In this method, the covered geotextile layer was placed in the box immediately. Then, the box was filled with sand. The program selected for the tests are shown in Table 3.

Results and discussion

The pressure corresponding to settlement is defined as the bearing capacity. The footing settlement (S) is expressed here in non-dimensional form in terms of the footing width (B) as the ratio (S/B in %). To estimate the measured values, a phrase for the ratio of improvement was presented. In the research literature for reinforced soils, bearing capacity ratio is widely used and is defined as BCR = qr/q0 [16, 50]. qr and q0 were determined as footing pressure on the treated reinforcement and unreinforced model at the same settlement (S), respectively.The improvement rate the of bearing capacity on the treated reinforcement is presented using Improvement Ratio (IR = qtrn /qrn) which is the ratio of the footing pressure on treated reinforcement (qtrn) to the footing pressure on pristine reinforcement (qrn) with the same number layer of reinforcement. Depending on the type of failure and the depth of the foundation, the ultimate load may occur at settlement of 4 to 25% the width of the foundation [47]. Then, the values of IR were presented for large settlement (S/B = 25%).

Unreinforced and reinforced sand

The variation of the bearing capacity versus the settlement ratio are shown in Fig. 5. At first, the settlement increased linearly with higher pressure on the footing. As indicated in the literature, the slope of the load–settlement curve of sand changes at a specific stress level which corresponds to a shear failure in the soil [16]. It should be noted that the curves of unreinforced sand and a layer of geotextile have a clear break point with decreasing slope, indicating a shear failure in the soil at S/B = 5%. Hence, no increase was observed in the range S/B = 5 ~ 20%. Two and three layers of pristine geotextiles without showing any such failure continued to rise. Then, the effect of the reinforcement was investigated. To study the effect of the number of reinforcements, laboratory tests with various numbers of geotextiles were performed. The number of geotextile layers (N) were assumed from 1 to 3. Also, the vertical spacing between the geotextile layers (d) and the vertical the depth of the first layer (u) below the footing were kept constant at d/B = 0.5 and u/B = 0.3 respectively. The above optimum values were chosen on the literature survey [53, 54]. As can be noticed from Fig. 5, for the unreinforced sand, the maximum bearing capacity was obtained at 150 kPa. Of note, the bearing capacity has been found to enhance with the increment in the number of geotextile layers and this number has a major influence. Additionally, the bearing capacity rose by increasing N = 1 to 3 layers of geotextile. The bearing capacity with a layer of geotextile was 1.47 times that of the unreinforced sand case (N = 0). The 2 and 3 layers of geotextiles raised the bearing capacity by up to 2.69 and 2.77 times a layer of geotextile respectively. Thus, three geotextile layers equal to 3 layers was chosen because the effect of reinforcement was negligible for more than two layers.

Treatment of geotextile surface by additives

The effects of the treatment of geotextile surface were investigated with same geotextile lengths (L = 4B). Other parameters of spacing between layer of reinforcement (d), footing width (B), and distance from the base of footing to the first layer of reinforcement (u) were considered constant. To find out the effects between the number of geotextiles and the bearing capacity, the tests with 1, 2 and 3 treated geotextile layers were run. Three different additives including portland cement (type II), lime and emulsion bitumen were used.

Figure 6 shows the bearing capacity (q)–settlement ratio (S/B) and BCR at various values of S/B ratio of the treated geotextiles for N = 1. Comparing the behavior of pristine geotextiles with the treated geotextiles, it is found that at S/B = 25%, lime-treated geotextiles improved the bearing capacity about 1.75 times. Furthermore, the treated geotextiles by cement and emulsion enhanced the bearing capacity to 1.55 and 1.50 times of a pristine geotextile layer, respectively (Fig. 6a). The bearing capacity and BCR value increased the most when the lime-treated geotextile was used. For lime treatment and at S/B = 25%, the maximum bearing capacity and BCR were 387 kN and 2.58, respectively. BCR linearly increases with settlement ratio until S/B = 25%. It is seen that for cement and emulsion, at S/B = 25%, BCR were 2.29 and 2.25, respectively. For all of S/B, an increment in the BCR was visible, revealing the major effect of the treated geotextiles. Figure 6b shows the BCR enhanced with larger settlement ratio (S/B) and it can be noticed that the treated geotextiles increased the BCR values.

Figure 7 displays the load-settlement ratio and BCR–settlement ratio of the different treated geotextiles types for N = 2. As shown in Fig. 7a, for emulsion, lime and cement, the bearing capacity improved for S/B values clarity, for example at S/B = 25%, up to 1.19, 1.28 and 1.29 times higher than that of two pristine geotextile layers, respectively. The lime and cement-treated geotextile provided a greater BCR than the other treated geotextiles, 3.45 and 3.48 respectively.

Variations of the measured load (q)-settlement ratio (S/B) and BCR from model tests against the values of S/B ratio were also shown in Fig. 8. It was clearly seen that the bearing capacity of foundations with lime-treated geotextile model was greater than other models (585 kPa). For both types of emulsion and cement, a similar behavior at all S/B ratios was seen in Fig. 8a. The treated geotextiles by emulsion, cement and lime elevate the bearing capacity to 1.37, 1.38 and 1.40 times that of three pristine geotextile layers, respectively. Also, for all the treated geotextiles, settlements increased at larger BCR value. Obviously, the lime-treated geotextile obtained maximum BCR = 3.9 for the largest settlement ratios (S/B = 25%) Also, maximum BCR was 3.8 and 3.83 for cement and emulsion-treated geotextile, respectively.

Comparison between the additives

The improvement ratio (IR) shows the effectiveness of geotextile treatment compared to the pristine geotextile in the same number of layers. In Fig. 9, we can see the geotextile number against improvement ratio (IR) for the treated geotextile layers at large settlement (S/B = 25%). As observed in Fig. 9, the IR curves for all treated geotextiles (cement, emulsion and lime) had a similar trend. The IR values declined with larger number of the geotextile layers from 1 to 2; then, the IR becomes constant with an increasing layer number approximately. The reason for the reduction of IR from N = 1 to 2 treated geotextile layers can be related to the type of behavior and failure of the soil. As can be noticed from Fig. 5, the curve of a pristine geotextile layer has a clear breakpoint (S/B = 5%) with decline in slope, indicating shear failure in soil. The other treated geotextile (for N = 1,2 and 3) and also two and three pristine geotextile layers without showing any such failure continue to sustain increased bearing capacity until S/B = 2.5%. Therefore in this study, the inclusion of one layer of geotextile treatment compared to a pristine geotextile layer, in addition to improving the bearing capacity, prevented the shear failure of the soil. For this reason, treating a geotextile layer has a bigger IR than two or three layers. The IR was maximum for emulsion, cement and lime in one layer (1.52, 1.55 and 1.75 increment, respectively). The minimum value of IR was obtained 1.2, belongs to two layers of treated geotextiles by emulsion which was also significant and very satisfied. Hence, one layer of treated geotextile compared to two or three layers of treated geotextiles was the most effective for all types of additives. It can be concluded that the treated geotextile evolved more strength compared to pristine geotextiles. The reaction of lime with sand produces calcium silicate hydrates and calcium aluminate hydrates [55]. Hence, these combinations are formed on the interface between sand and geotextile and lime-treated geotextiles created a strong connection between geotextiles and the sand particles. It can be said that the lime made a structure on geotextiles that bind the compacted and interlocking particles together. Due to the coagulating grains on geotextiles, the value of cohesion and the friction angle raised. As a result, the lime-treated geotextiles, increment the strength of the sand at the interface, which leads to the improvement of bearing capacity. Results indicated that cement, like lime, had a clear effect on improving the bearing capacity of the foundation. In the geotechnical, investigators have definitively obtained the point that pozzolanic reaction, carbonation and cement hydration, have significant influences on the microstructure of cementitious materials and the microstructure governs the strength expansion [56, 57]. So, cement hydration and carbonation have effective consequences on the interface between sand and geotextile and these reactions lead to the strength development. The cement binds the sand particles together to form small conglomerate masses on geotextiles, and hence higher rigidly than the pristine geotextile. When cement was added to geotextiles, both cohesion and internal friction were significantly raised. This gain in shear strength due to the addition of cement would enhance bearing capacity. The good performance of emulsion-treated geotextiles was observed. A layer of emulsion is covered on geotextiles and this layer fills the space between the aggregates. Emulsion-treated geotextiles increased the internal friction angle and adhesion compared to pristine geotextiles, due to the sticking property of emulsion and the creation of adhesion forces between the sand particles and the geotextile on sand and geotextile interface. In general, the inclusion of treated geotextile would improve the shear strength of the sand on the interface between sand and geotextile. It should be mentioned that the basic concept of soil reinforcement remains the same for all types of treated geotextiles. It is emphasized that a single performance mechanism cannot be used to describe the behavior of all treated geotextiles, actually, it is highly dependent on the type of additives. Generally, despite the suitable properties of pristine geotextile, the treated geotextile help to further develop strength and bearing capacity.

Conclusions

The paper presented the results of the experiments of square footings model supported on unreinforced sand, the pristine and treated geotextiles sand. The purpose of this paper was to study the effects treatment of the interface between sand and geotextile on settlement and bearing capacity. Three different additives including Portland cement, lime and emulsion bitumen were changed to understand the effect of these parameters on the reinforcement soil model. These results may be useful to improve the bearing capacity of footing and to design an area with similar sand.

In summary, the following conclusions were drawn from the findings in this study:

-

1.

The treated geotextiles caused more bearing capacity compared to pristine geotextiles.

-

2.

The bearing capacity can be enhanced by increasing the number of the treated geotextile layers. For all the treated geotextiles, with higher soil settlement ratio, BCR value increased.

-

3.

For a layer of treated geotextile, the bearing capacity and BCR value improved the most when the lime-treated geotextile was used. At S/B = 0.25, lime enhanced the bearing capacity to 1.75 times that of a pristine geotextile layer, with BCR at 2.58. For two layers of the treated geotextiles, the lime and cement-treated geotextile provided a greater BCR than emulsion-treated geotextiles, at 3.45 and 3.48 respectively. For three layers of the treated geotextiles, the bearing capacity of foundations with lime-treated geotextile model was greater than other models. It can be seen that the maximum BCR for lime-treated geotextile was 3.9. Hence, lime-treated geotextile appears to be a better treatment rather than others.

-

4.

For all additives and S/B = 25%, IR value was the maximum for N = 1. A layer of lime-treated geotextile had maximum IR value (1.75).

-

5.

With the implementation of a treated geotextiles, bearing capacity of foundation can be improved with local sand regarded or qualified as unsuitable. In fact treated geotextiles provide an effective solution to enhance of bearing capacity where a weak soil exists under foundation.

Major research is essential to reveal the corrosive effect of additives on geotextile in long-term and short term. The durability of treated geotextile was not investigated in this study.

Data availability

All data and models that support the findings of this study appear in the submitted article.

References

Das BM, Maji A, Shin EC (1998) Foundation on geogrid-reinforced sand-effect of transient loading. Geotext Geomembr 16(3):151–160

Aiban S, Al-Ahmadi H, Asi I, Siddique Z, Al-Amoudi OSB (2006) Effect of geotextile and cement on the performance of Sabkha subgrade. Build Environ 41(6):807–820

Sridhar R, Prathap Kumar MT (2018) Effect of number of layers on coir geotextile reinforced sand under cyclic loading. Int J Geo-Eng. https://doi.org/10.1186/s40703-018-0078-y

Azzam WR, Nasr AM (2015) Bearing capacity of shell strip footing on reinforced sand. J Adv Res 6:727–737

Hegde A, Sitharam TG (2017) Experiment and 3D-numerical studies on soft clay bed reinforced with different types of cellular confinement systems. Transp Geotech 10:73–84

Panigrahi B, Pradhan PK (2019) Improvement of bearing capacity of soil by using natural geotextile. Intl J Geo-Eng. https://doi.org/10.1186/s40703-019-0105-7

Ramjiram Thakur S, Naveen BP, Tegar JP (2021) Improvement in CBR value of soil reinforced with nonwoven geotextile sheets. Int J Geo-Eng. https://doi.org/10.1186/s40703-020-00138-9

Tavangar Y, Shooshpasha I (2020) Impacts of a nonwoven geotextile arrangement on load-bearing capacity of reinforced sand: a laboratory study. Innov Infrastruct Solut 5(1):1–9

Das BM, Shin EC (1994) Strip foundation on geogrid-reinforced clay: behavior under cyclic loading. Geotext Geomembr 13(10):657–667

Alawaji HA (2001) Settlement and bearing capacity of geogrid-reinforced sand over collapsible soil. Geotext Geomembr 19(2):75–88

El Sawwaf M, Nazir AK (2010) Behavior of repeatedly loaded rectangular footings resting on reinforced sand. Alex Eng J 49(4):349–356

Abu-Farsakh M, ChenSharma QR (2013) An experimental evaluation of the behavior of footings on geosynthetic-reinforced sand. Soils Found 53(2):335–348

Badakhshan E, Noorzad A (2017) Effect of footing shape and load eccentricity on behavior of geosynthetic reinforced sand bed. Geotext Geomembr 45(2):58–67

Badakhshan E, Noorzad A (2015) Load eccentricity effects on behavior of circular footings reinforced with geogrid sheets. J Rock Mech Geotechnic Eng 7(6):691–699

Ghosh A, Bera AK (2005) Bearing capacity of square footing on pond ash reinforced with jute. Geotext Geotext Geomembr 23(2):144–173

Cicek E, Guler E, Yetimoglu T (2015) Effect of reinforcement length for different geosynthetic reinforcements on strip footing on sand soil. Soils Found 55(4):661–677

Tafreshi SM, Dawson AR (2010) Comparison of bearing capacity of a strip footing on sand with geocell and with planar forms of geotextile reinforcement. Geotext Geomembr 28(1):72–84

Desai CS, Zaman MM, Lightner JG, Siriwardane HJ (1984) Thin-layer element for interfaces and joints. Int J Numer Anal Methods Geomech 8(1):19–43

Toufigh V, Masoud Shirkhorshidi S, Hosseinali M (2017) Experimental investigation and constitutive modeling of polymer concrete and sand interface. Int J Geomech 17(1):04016043

Dutta RK, Rao GV (2008) Potential of coir based products as soil reinforcement. Int J Earth Sci Eng 1(2):71–79

Toufigh V, Saeid F, Ouria A, Desai CS, Saadatmanesh H (2014) Laboratory study of Soil-CFRP interaction using pull-out test. Geomech Geoeng 9(3):208–214

Long JH, Paul SL, Lampo RG (1989) Bond strength between geotextiles and concrete. Geotext Geomembr 8(2):113–132

Brooks JJ, Kenai S (1989) Impact properties of polymer grid reinforced cement mortar. Int J Cem Compos Lightweight Concrete 11(3):159–165

Nam G, Wu N, Okubo K, Fujii T (2014) Effect of natural fiber reinforced polypropylene composite using resin impregnation. Agric Sci 5(13):1338

Ouria A, Mahmoudi A (2018) Laboratory and numerical modeling of strip footing on geotextile-reinforced sand with cement-treated interface. Geotext Geomembr 46(1):29–39

ASTM D2487–00, 2000. Standard Classification of Soils for Engineering Purposes (Unified Soil Classification System), ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D2487-00

ASTM D422–63., 2007. Standard Test Method for Particle-Size Analysis of Soils (Withdrawn 2016), ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D0422-63R07

ASTM D854–14., 2014. Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer, ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D0854-14

ASTM D4253–00., 2000. Standard Test Methods for Maximum Index Density and Unit Weight of Soils Using a Vibratory Table, ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D4253-00

ASTM D5261–10., 2018. Standard Test Method for Measuring Mass per Unit Area of Geotextiles, ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D5261-10R18

ASTM D4632 / D4632M-15a, 2015.Standard Test Method for Grab Breaking Load and Elongation of Geotextiles, ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D4632_D4632M-15A

Abbasi N, Mahdieh M (2018) Improvement of geotechnical properties of silty sand soils using natural pozzolan and lime. Int J Geo-Eng. https://doi.org/10.1186/s40703-018-0072-4

Amadi AA, Okeiyi A (2017) Use of quick and hydrated lime in stabilization of lateritic soil: comparative analysis of laboratory data. Int J Geo-Eng. https://doi.org/10.1186/s40703-017-0041-3

de Souza Correia N, Portelinha FHM, Mendes IS, da Silva JWB (2020) Lime treatment of a diesel-contaminated coarse-grained soil for reuse in geotechnical applications. Int J Geo-Eng. https://doi.org/10.1186/s40703-020-00115-2

Firoozi AA, Guney Olgun C, Firoozi AA, Baghini MS (2017) Fundamentals of soil stabilization. Int J Geo-Eng. https://doi.org/10.1186/s40703-017-0064-9

Gupta C, Prasad A (2018) Variables controlling strength of lime stabilized Jarosite Waste. Int J Geo-Eng. https://doi.org/10.1186/s40703-018-0074-2

Ifediniru C, Ekeocha NE (2022) Performance of cement-stabilized weak subgrade for highway embankment construction in Southeast Nigeria. Int J Geo-Eng 13(1):1–16. https://doi.org/10.1186/s40703-021-00166-z

Karim ME, Alam MJ, Hoque MS (2017) Effect of salinity of water in lime-fly ash treated sand. Int J Geo-Eng. https://doi.org/10.1186/s40703-017-0052-0

Pushpakumara BHJ, Mendis WSW (2022) Suitability of Rice Husk Ash (RHA) with lime as a soil stabilizer in geotechnical applications. Int J Geo-Eng. https://doi.org/10.1186/s40703-021-00169-w

Salamatpoor S, Salamatpoor S (2017) Evaluation of adding crushed glass to different combinations of cement-stabilized sand. Int J Geo-Eng 8(1):2–13. https://doi.org/10.1186/s40703-017-0044-0

Gupta A, Arora VK, Biswas S (2017) Contaminated dredged soil stabilization using cement and bottom ash for use as highway subgrade Fill. Int J Geo-Eng. https://doi.org/10.1186/s40703-017-0057-8

Karimi S, Aghajani HF (2023) The strength and microstructure of Cemented Sand-Gravel (CSG) mixture containing fine-grained particles. Int J Geo-Eng 14(1):1–31. https://doi.org/10.1186/s40703-023-00182-1

Nagesh S, Jagadeesh HS, Nithin KS (2021) Study on effect of laboratory roller compaction on unconfined compressive strength of lime treated soils. Int J Geo-Eng. https://doi.org/10.1186/s40703-021-00150-7

Nguyen AD, Nguyen VT, Kim YS (2023) Finite element analysis on dynamic behavior of sheet pile quay wall dredged and improved seaside subsoil using cement deep mixing. Int J Geo-Eng. https://doi.org/10.1186/s40703-023-00186-x

Nweke OM, Okogbue CO (2017) The potential of cement stabilized shale quarry dust for possible use as road foundation material. Int J Geo-Eng. https://doi.org/10.1186/s40703-017-0068-5

Safdar M, Newson T, Shah F (2021) Consolidated Drained (CID) Behavior of Fibre Reinforced Cemented Toyoura Sand in Triaxial Loading Conditions. Int J Geo-Eng. https://doi.org/10.1186/s40703-021-00165-0

Das, B. M., 2016. Principles of Foundation Engineering, 8th edition, Boston MA: Cengage Learning, pp.156–164

Lal D, Sankar N, Chandrakaran S (2017) Effect of reinforcement form on the behaviour of coir geotextile reinforced sand beds. Soils Found 57(2):227–236

Yoskimi Y, Tohano I. StatisticalSignificance of The Relative Density. Evaluation of Relative Density and its role in Geotechnical Projects Involving Cohesionless Soils: ASTM STP523-EB.7744–1, Los Angeles; 25–30 June 1972. p. 74–84

Madhavi Latha G, Somwanshi A (2009) Effect of reinforcement form on the bearing capacity of square footing on sand. Geotext Geomembr 27:409–422

Patra CR, Das BM, Atalar C (2005) Bearing capacity of embedded strip foundation on geogrid-reinforced sand. Geotext Geomembr 23(5):454–462

Kolay PK, Kumar S, Tiwari D (2013) Improvement of bearing capacity of shallow foundation on geogrid reinforced silty clay and sand. J Construct Eng 2013:1–10

Guido VA, Chang DK, Sweeney MA (1986) Comparison of geogrid and geotextile reinforced earth slabs. Can Geotech J 23(4):435–440

Omar MT, Das BM, Puri VK, Yen SC (1993) Ultimate bearing capacity of shallow foundations on sand with geogrid reinforcement. Can Geotech J 30(3):545–549

Diamond S, Kinter EB (1965) Mechanisms of soil-lime stabilization. Highway Res Rec 92(303):83–102

Ho LS, Nakarai K, Duc M, Le Kouby A, Maachi A, Sasaki T (2018) Analysis of strength development in cement-treated soils under different curing conditions through microstructural and chemical investigations. Constr Build Mater 166:634–646

Verbeck, G. (1958). Carbonation of Hydrated Portland Cement (pp. 17–36). West Conshohocken, PA, USA: ASTM International

Author information

Authors and Affiliations

Contributions

All authors conceived and designed the study. Material preparation, data collection and experiment were performed by SZ, Dr.SHL, Dr.AY and Dr.EZ. The first draft of the manuscript were performed by Dr.SHL and SZ. All authors commented on previous versions of the manuscript and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors did not receive support from any organization for the submitted work. The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zamani, S., Lajevardi, S.H., Yarivand, A. et al. Experimental study of the behavior of square footing on reinforced sand with treated geotextile. Geo-Engineering 14, 19 (2023). https://doi.org/10.1186/s40703-023-00195-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40703-023-00195-w