Abstract

Negative skin friction (NSF) effect on pile foundation design attracts the attention of geotechnical engineers and requires comprehensive research. However, the ways of consideration of NSF for the pile foundation design vary with different design codes. This study aims to compare design code requirements adhering to Construction Codes and Regulations (i.e., SNiP), Eurocode 7 (EC7), Canadian Highway Bridge Design Code (CHBDC), and AASHTO for the pile foundation design subjected to NSF and provide insights for the understanding effect of NSF on the behavior of pile foundation. The overall objective is achieved by designing three cases of a driven pile for given design conditions in Astana city. Then, a sensitivity analysis was performed to estimate the effects of the dimensions of the pile foundation and the shear strength of soils on the bearing resistance. The comparative analysis shows that pile foundation design adhering to CHBDC and AASHTO results in a more conservative strategy than SNiP and EC7 when considering Kazakhstani soil engineering conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Several Commonwealth of Independent States (CIS) countries, including Kazakhstan, are at the stage of integrating the European design codes into the local regulatory system [7]. Since 2015, the Republic of Kazakhstan's regulatory system in the construction field has been continuously changing and improving. This process involves the achievement of critical milestones: (1) the development of the construction regulations corresponding to the European design approach considering the climatic and geological conditions of the country,(2) the application of the developed design documentation to the real case conditions; (3) qualification of civil engineers; and (4) the analysis of the obtained results and correction of the performed mistakes.

The Ministry of Economics of the Republic of Kazakhstan's plan to develop new construction regulatory documents implies the accomplishment of several phases [8]. The first phase includes the development of 58 construction norms (SN RK EN) identical to Eurocode with National Annexes (NAs) considering climatic and geological conditions of Kazakhstan [23]. Eurocode represents a complex of technical standards for the design of structures and buildings for civil purposes developed by the European Committee for Standardization [32]. It includes a series of ten European technical documentation, NAs, and manuals that allow conformity to the typical design concept for the design and construction of buildings and structures from all types of construction materials, including steel, reinforced concrete, wood, masonry, and aluminum [18].

The second phase refers to the transition to the newly developed technical regulation system starting from July 2015. Since 2020 many acting normative documents in the construction field have been canceled, and all the buildings and structures have been required to be designed adhering to the European approach. The complete transition from the local regulatory system to Eurocode involved the cancellation of more than 500 SNiPs, which represent technical documentation applied from the times of the Soviet Union. It initiated the beginning of the third transition phase, which refers to the accomplishment of the reform of the technical regulation system of the construction industry by 2025. The purpose of the application of Eurocode in Kazakhstan involves (1) ensuring the safety and serviceability of the designed structures; (2) enhancement of the operational principles in the field of construction and their conformity to the international standards for the increase in competitiveness; and (3) application of the parametric approach for the use of innovative construction decisions and integration of technical novelty [35].

The development of the construction industry in the country is associated with the realization of extensive projects [25]. The authors studied the design of different types of foundations (i.e., shallow, pile, and piled raft foundations), adhering to the local and international design codes [36, 42]. The previous studies revealed that special attention is required to be paid to the design of foundations. The great interest of engineers has been attracted by pile foundation design with the development of geotechnical engineering [22]. A pile foundation representing slender structural elements for transferring structural loads to deeper soil layers is designed to achieve adequate bearing capacity through the development of positive shaft resistance and toe resistance. Positive shaft resistance is developed when pile settlement is greater than the settlement of surrounding soil. However, under the condition of adjacent soil settling exceeding the value of pile settlement, which is typical for deep compressible soil layers, there is a change in the direction of skin resistance, and negative skin friction (NSF) occurs [30].

NSF is one of the most common problems associated with the design and construction of pile foundations in consolidating soil [27]. The development of NSF is caused by the settlement of soil around the pile foundation, contributing to the increased compressive stress in a pile. Namely, NSF refers to the negative shear stress due to the downward soil movement to the pile [13]. NSF represents not only a part of the bearing resistance of the pile foundation but an external load acting on the pile foundation [31]. The main reasons for NSF include mass stowage of soil surrounding pile foundation, soil settlement due to loess, permafrost melting, and other reasons [33, 38]. Foundation failure, pile damage, or excessive soil settlement occur in the case of inadequate analysis of NSF or even ignoring the NSF effect [12]. Moreover, the NSF effect may cause greater settlement of piles compared to one not subjected to NSF, which contributes to the decrease in the overall safety of the designed structure [17].

Basically, NSF is defined as downward shear stress acting along with the pile-soil interface due to the downward movement of consolidating soil [15]. NSF causes a drag load which represents an axially compressive force acting on a pile, and downdrag, which refers to pile movement (i.e., pile settlement). Drag load depends on several factors, including pile characteristics, soil properties, degree of consolidation, and pile-soil movement. The drag load occurs due to soil consolidation caused by surcharging and dewatering or reconsolidation after pile driving and liquefaction [30]. The pile foundation design with NSF considers drag force as an unfavorable action applied to the pile foundation. Therefore, the drag load is required to be considered in pile foundation design to assess the adequateness of bearing resistance and ensure the safety of the designed structure [39].

Fellenius [16] introduced the unified design method for bearing capacity, drag load, downdrag, and settlement which considers: (1) geotechnical axial resistance; (2) pile structural strength; and (3) pile settlement. The suggested method analyzes the load transfer mechanism for defining the location of a neutral plane (NP). NP represents a location where no relative movement between pile and soil occurs [43]. The greater value of pile toe resistance causes the deeper location of NP and the greater value of drag load [14]. The location of the NP is at the equilibrium of dead load and drag force above the NP and positive shaft and tip resistances below the NP. In the unified design method, both Ultimate Limit State (ULS) and Serviceability Limit State (SLS) are satisfied simultaneously. The ULS criteria require the summation of dead and drag force acting on the foundation to be less than the structural resistance of the designed pile foundation. The SLS is considered by dead load and soil settlement (i.e., downdrag), where the settlement is required to be less than the maximum design value.

A significant number of computational methods to determine the magnitude and distribution of NSF on single piles and pile groups including empirical method [9, 37, 41], load-transfer method [6], elastic and elasto-plastic method [10, 24, 34, 40, and finite element method (FEM) [11, 19, 20, 2628, 29] have been proposed. The ways of consideration of NSF for the design of pile foundations vary with different design codes, but it is not researched sufficiently. This study aims to perform a comparative analysis of design approaches adhering to SNiP, Eurocode 7, Canadian Highway Bridge Design Code, and AASHTO for pile foundation design when subjected to NSF. The considered codes of practice represent the most well-known design codes widely used worldwide. The design codes are compared to determine the consequences and potential costs of the pile foundation design. The overall objective of the present study is achieved by performing design of a driven pile for three cases of given design conditions with sensitivity analysis.

Review of design codes

The considered codes of practice apply the global factor of safety approach to design pile foundations. The limit state design considers partial safety factors on the values of actions and resistances. The ULS analysis requires the satisfaction of the following design condition:

where \({V}_{d}\) is a design load acting on a pile foundation, kN; \({R}_{d}\) is a design bearing resistance, kN.

The Kazakhstani approach (SNiP) for designing a single pile is performed in accordance with SP RK 5.01-103-2013—Pile Foundations [4]. The design resistance of pile foundation adhering to the Kazakhstani approach represents a combination of base and shaft resistances of a pile and can be determined using the following equation:

where \({\gamma }_{c}\) is a partial factor on operational conditions; \({\gamma }_{cR}\) is a partial factor on operational conditions of soil under pile tip; \({\gamma }_{cf}\) is a partial factor on operational conditions of soil on the surface on pile shaft; \(R\) is a design resistance of soil under pile tip, kPa; \(A\) is a cross-sectional area of pile tip, m2; \(u\) is an outer perimeter of pile shaft, m; \({f}_{i}\) is a design unit shaft resistance of the \(i\)-th soil layer in contact with pile, kPa; \({h}_{i}\) is a thickness of soil layer in contact with pile shaft, m.

The design procedure for the determination of bearing resistance of pile foundation is provided in Sect. 7 of EC7 [1]. The bearing resistance of pile foundation can be identified with the help of Eq. (3):

where \({R}_{b;k}\), \({R}_{s;k}\) are characteristic values of base and shaft resistances, respectively, kN; \({\gamma }_{b}\), \({\upgamma }_{\mathrm{s}}\) are partial factors on base and shaft resistances.

The characteristic values of base and shaft resistances adhering to the European approach are determined as follows:

where \({A}_{b}\), is a base area under a pile, m2; \({A}_{s;i}\) is a pile shaft surface area in the \(i\)-th soil layer, m2; \({q}_{b;k}\) is the characteristic value of unit base resistance, kN/m2; \({q}_{s;i;k}\) is the characteristic value of unit shaft resistance in the \(i\)-th soil layer, kN/m2.

EC7 involves three design approaches (i.e., two combinations of Design Approach 1: DA1-1 and DA1-2, DA2, DA3) to provide control over soil strength and load acting on the designed structure via introducing different combinations of the partial factors. The combination of partial factors in accordance with the design approaches is applied to actions (A), ground properties (M), and resistances (R). The distribution of design approaches in European countries depends on the county’s design traditions.

Adhering to the Kazakhstani approach, the drag force (DF) can be determined using the following equation:

where \({m}_{0}\) is a coefficient of operational conditions of a pile in a settling soil; \(u\) is a perimeter of the pile’s cross-section, m; \({k}_{p,i}\) is a realization coefficient in the \(i\)-th soil layer; \({f}_{o,i}\) is a normative resistance of the \(i\)-th soil layer on the lateral surface of a pile defined in accordance with Eq. (6), kN/m2; \({l}_{i}\) is a thickness of the \(i\)-th soil layer till the location of the NP.

The normative resistance of soil on the lateral surface of a pile is defined as follows:

where \({m}_{t}\) is a coefficient of operational conditions; \(c\) is a cohesion, kN/m2; \(\upsilon\) is a Poisson’s ratio; \(\gamma\) is unit weight of soil, kN/m3; \(H\) is a depth of a soil layer, m; \(\varphi\) is an internal friction angle, °.

The design procedures for pile foundation design considering NSF effect adhering to SNiP [4], two combinations of partial factors from Design Approach 1 of Eurocode 7 [1] (i.e., DA1-1 and DA1-2), Canadian Highway Bridge Design Code (CHBDC) [3], and AASHTO [2] are provided in Table 1.

Design problem and site data

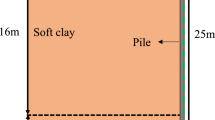

The comparative analysis of the considered codes of practice is performed based on the design problem (Fig. 1). The given problem requires the design of a single concrete square pile element with a cross-sectional area of 300 mm × 300 mm, which represents one of the most widely applied pile foundation types in Astana city in Kazakhstan. The pile foundation is driven through loam into the sandy gravel layer, which presents the common soil profile in Astana city. The typical engineering soil properties based on Alibekova and Zhussupbekov [5] are given in Table 2. The analysis is conducted for varying thicknesses of the loam layer of 5 m, 8 m, and 10 m for Case I, Case II, and Case III, respectively. The groundwater table (G.W.T.) is assumed to be at 2 m depth from the ground surface [5]. Finally, the code comparison for the pile foundation design considering the NSF effect is performed by applying a permanent dead load (DL) of 300 kN and a variable live load (LL) of 100 kN.

The NSF is assumed to be mobilized. The DF is determined for a long-term design condition. For the design simplification, the transition zone is not considered. The simplification is made to perform calculations to satisfy geotechnical ULS adhering to the design codes.

Pile analysis results

Case I

This case considers the thickness of the loam layer as 5 m with a pile length of 8 m, which contributes to the development of NSF in the settling soil layer. Figure 2 demonstrates pile force distribution at equilibrium and geotechnical ULS subjected to permanent DL of 300 kN. The NP is assumed to be located at the loam, and sandy gravel interface with fully mobilized NSF in loam and fully mobilized positive shaft resistance in sandy gravel. The DF defined by Eq. (5) is equal to 98 kN. The values of the loads acting on the pile foundation, the factored design loads, and the factored resistances are provided in Table 3.

The Kazakhstani approach (i.e., SNiP) requires the determination of factored load to be less than or equal to factored resistance to meet the ULS conditions. The factored design resistance defined by Eq. (2) results in 584 kN. SNiP suggests the DL acting on a pile to be less than the difference between 0.8 of factored bearing resistance and DF values. Thus, the factored load acting on the designed foundation equals to 498 kN. SNiP does not involve LL in the design of pile foundations considering the NSF effect. The results of the calculations meet the ULS requirements when adhering to the Kazakhstani approach.

The European approach (EC7) considers factored loads and resistances for ULS design. The long-term design condition applies 1.35 for DL and 1.35 for DF for Design Approach (DA)1-1, and 1.0 for DL and 1.25 for DF for DA1-2 so that the total factored load is 537 kN and 423 kN for DA1-1 and DA1-2, respectively. Similarly to SNiP, EC7 ignores the consideration of LL in the calculation. The factored design resistance results in 614 kN and 473 kN for DA1-1 and DA1-2, respectively. Based on the performed analysis, the design satisfies the ULS condition.

The Canadian approach (CHBDC) applies 1.2 for DL and 1.25 for DF to determine the factored design load, which results in 483 kN. The Canadian code does not include the DF value in the geotechnical ULS analysis. CHBDC applies a bearing resistance factor of 0.4 to calculate the factored resistance of 246 kN. The analysis shows that the design adhering to CHBDC does not satisfy the ULS condition for Astana. Therefore, it requires increasing pile numbers and a more conservative pile foundation design when adhering to the Canadian approach.

AASHTO applies a similar design approach as Eurocode considering drag force as a load acting on a designed pile. For long-term design conditions, AASHTO uses 1.25 for DL, 1.75 for LL, and 1.25 for DF to determine the factored load, resulting in 673 kN. Compared to EC7, AASHTO represents a more realistic pile design by considering LL and DF when modeling pile–soil interaction. To determine the factored geotechnical resistance, the code applies 0.55 for the shaft resistance below NP and 0.5 for tip resistance. As a result, the factored resistance is 141 kN that is less than the factored load. Thus, the number of piles is required to be increased to resist the same DL and LL when adhering to AASHTO, which means an increase in costs for supply and installation of pile foundation.

Case II

Case II considers the thickness of the loam layer as 8 m and a pile length of 11 m, which contributes to the development of NSF in the compressible layer. Figure 3 demonstrates pile force distribution at equilibrium and geotechnical ULS subjected to permanent DL of 300 kN. The NP is assumed to be located at the loam and sandy gravel interface with fully mobilized NSF in the loam and fully mobilized positive shaft resistance in sandy gravel. The DF defined by Eq. (5) is equal to 227 kN. The values of the loads, the factored design loads, and the factored resistances are provided in Table 4. The calculations are performed following the same design procedure as for Case I.

Compared to Case I, the value of shaft resistance has increased due to the increase in the thickness of the compressible soil layer and pile length. The analysis showed that the Kazakhstani and European approaches result in the pile foundation design that meets the geotechnical ULS requirements. Moreover, the requirements are more met than in Case I.

When adhering to CHBDC and AASHTO, the pile foundation design results in factored load exceeding factored resistance. Therefore, additional piles are required to be involved in the design to provide sufficient resistance to the designed structure.

Case III

This case considers the thickness of the loam layer as 10 m and a pile length of 13 m, which contributes to the development of NSF in the compressible soil layer. Figure 4 demonstrates pile force distribution at equilibrium and geotechnical ULS subjected to permanent DL of 300 kN. The NP is assumed to be located at the loam, and sandy gravel interface with fully mobilized NSF in the loam and fully mobilized positive shaft resistance in sandy gravel. The DF defined by Eq. (5) is equal to 341 kN. The values of the loads, the factored design loads, and the factored resistances are provided in Table 5. The calculations were performed following the same design procedure as for Case I and II.

The pile foundation design meets the ULS requirements when adhering to the Kazakhstani and European approaches. Furthermore, compared to Cases I and II, the value of shaft resistance has increased due to the increase in the thickness of the compressible soil layer and pile length. Thus, the geotechnical ULS is satisfied with a greater margin than Cases I and II.

When adhering to CHBDC and AASHTO, the pile foundation design results in factored load exceeding factored resistance. The difference between factored load and factored resistance is much higher than in Cases I and II. Therefore, additional piles are required to be involved in the design to provide sufficient resistance to the designed structure.

Discussion

The ULS condition is considered for the design of the pile foundation to ensure the safety of the designed structure by increasing the values of loads acting on the foundation and decreasing the resistances. The performed analysis of the geotechnical ULS design of pile foundation subjected to the NSF effect provides the quantitative comparison of the considered design codes (i.e., SNiP, EC7, CHBDC, and AASHTO). The phenomenon of NSF results in DF combined with DL. The considered design codes require the determination of bearing resistance by applying partial safety factors on design actions and resistances for the design of the pile foundation. As shown in the design procedure, SNiP and Eurocode include the value of DF in the calculations, whereas the variable load is ignored in the design calculations. Compared to other codes of practice, AASHTO represents a more realistic pile design by considering both LL, \({Q}_{l}\), and DF, \({Q}_{n}\), to simulate pile and soil interaction when determining the factored design load. The results demonstrate the satisfaction of the ULS condition with code requirements for Cases I through III for varying soil layer thickness. It is identified that the performed calculations for pile foundation design satisfy the ULS condition when adhering to SNiP and Eurocode. Considering the Astana soil profile, the pile foundation design results in a more conservative design that requires the application of additional piles in accordance with CHBDC and AASHTO.

The comparative analysis identified a common trend for the given design example for the Astana soil profile, which refers to the increase of geotechnical resistance with the increase of the thickness of the compressible soil layer, as shown in Figs. 2, 3, and 4. Thus, the increase in the factored resistance value is explained by increasing the thickness of the settling soil layer. The considered codes of practice factor up the value of drag force while not considering shaft resistance above NP and factoring down shaft resistance below NP. Moreover, the calculations showed that the pile foundation design adhering to CHBDC and AASHTO approaches resulted in a more expensive design compared to SNiP and EC7 due to the need to introduce additional piles. The weakness of the reviewed codes of practice would be the misunderstanding of the capacity definition. Fellenius [15] states that correctly performed settlement analysis ensuring the calculated settlement value does not exceed the maximum allowable settlement capacity analysis.

The sensitivity analysis is performed for the varying pile length, pile dimensions, and soil properties as given in Figs. 5, 6, and 7. The results show the increase of the value of factored bearing resistance with the increase of pile dimensions and undrained shear strength values. Figure 5 shows that EC7 is more sensible to the change of pile length compared to other codes of practice. Figure 6 indicates that the bearing resistance of pile foundation adhering to the Kazakhstani and European approaches changes significantly with the increase of the dimensions of a designed pile. The value of the cross-sectional area of a pile is considered in the design procedure for determining a bearing resistance given in Eqs. (2) and (3). Thus, the increase in the dimensions of a pile causes an increase in the bearing resistance. Figure 7 demonstrates that the undrained shear strength value change does not affect the bearing resistance when adhering to the Kazakhstani approach. The reason is that undrained shear strength is not involved in the design calculations when adhering to SNiP. However, the increase of the undrained shear strength parameter results in the increase of the bearing resistance of the designed pile foundation following EC7, CHBDC, and AASHTO.

Conclusion

Applying codes of practice from different regions refers to introducing different design approaches and partial factors for the same design conditions and materials. The attempt at the harmonization of the design principles for geotechnical purposes in Kazakhstan is of further consideration. The transition to Eurocode is defined by the need for integrating the Kazakhstani regulatory system with the European and international systems in the construction field. The purpose of the reform of the outdated technical base in Kazakhstan involves (1) the development of new design opportunities for local construction companies in the worldwide arena; (2) the application of new construction materials and technologies during the construction process; and (3) the increase in the quality, safety, and service life of the constructed buildings and structures.

Negative skin friction (NSF) is of great concern to civil engineers. The understanding of the mechanism of the development of NSF is significant for the design of pile foundations. NSF causes the development of drag load and downdrag. Thus, the comparative analysis of design approaches suggested by SNiP, Eurocode 7, Canadian Highway Bridge Design Code, and AASHTO is conducted to understand the design of pile foundation considering the NSF effect. The analysis is performed based on the design example of a driven pile for soil profile conditions in Astana considering the design for changing the thickness of the compressible soil layer.

The calculation results show the designed pile foundation meets the specifications of ULS analysis, adhering to SNiP and EC7 but not CHBDC and AASHTO. Therefore, the design adhering to CHBDC and AASHTO can result in a more expensive pile foundation design by installing additional piles or requiring the application of different foundation types.

The application of Ultimate Limit State (ULS) analysis by the considered codes of practice experiences criticism as some researchers suggest not including DF in geotechnical ULS calculation. It is worth mentioning that NSF is not just the problem of geotechnical resistance but Serviceability Limit State (SLS). The recommendations for further research include assessing the SLS condition to complete the comparison.

References

(1997) Eurocode 7: Geotechnical Design–Part 1: General Rules British Standards The European Union, Brussels, Belgium

(1998) AASHTO. LFRD Bridge Design Specifications American association of state highway and transportation officials, Washington, DC

(2006) Canadian Highway Bridge Design Code Canadian Standards Association, Canada

(2013) SP RK 5.01-103-2013—Pile Foundations KAZGOR, Almaty, Kazakhstan

Alibekova NT, Zhussupbekov AZ (2018) GIS technology for engineering and geological surveys LAP LAMBERT. Academic Publishing, Saarbrücken

Alonso EE, Josa A, Ledesma A (1984) Negative skin friction on piles: a simplified analysis and prediction procedure. Geotechnique 34(3):341–357. https://doi.org/10.1680/geot.1984.34.3.341

Antonova MV, Glushko DV, Belyaeva SV, Pakrastinsh L (2014) A comparative analysis of European and Russian technical documentation of building materials. Cтpoитeльcтвo yникaльныx здaний и coopyжeний 4:34–50

Bisengaliyev MD, Zaidemova ZK, Mukhambetzhanova KK (2019) Introduction of Eurocodes in the Republic of Kazakhstan Πepcпeктивы Coциaльнo-Экoнoмичecкoгo Paзвития Cтpaн и Peгиoнoв, Astrakhan, Russia, pp 131–134

Broms KF, Amesz AW, Rinck J (1969) The negative skin friction along the shaft of a foundation pile 7th international Conference on Soil Mechanics And Foundation Engineering, Mexico City

Chow YK, Chin JT, Lee SL (1990) Negative skin friction on pile groups. Int J Numer Anal Meth Geomech 14(2):75–91. https://doi.org/10.1002/nag.1610140202

Comodromos EM, Bareka SV (2005) Evaluation of negative skin friction effects in pile foundations using 3D nonlinear analysis. Comput Geotech 32(3):210–221. https://doi.org/10.1016/j.compgeo.2005.01.006

Davisson MT (1993) Negative skin friction in piles and design decisions International Conference on Case Histories in Geotechnical Engineering, St. Louis, Missouri

Fellenius BH (1972) Down-drag on piles in clay due to negative skin friction. Can Geotech J 9(4):323–337. https://doi.org/10.1139/t72-037

Fellenius BH (1984) Negative skin friction and settlement of piles Second International Seminar, Pile Foundations, Nanyang Technological Institute, Singapore, pp 1–12

Fellenius BH (2014) Piled foundation design as reflected in codes and standards DFI-EFFC International Conference on Piling and Deep Foundations, Stockholm, Sweden, pp 1013–1030

Fellenius BH (2017) Basics of foundation design

Feng Z, Hu H, Zhao R, He J, Dong Y, Feng K, Zhao Y, Chen H (2019) Experiments on reducing negative skin friction of piles. Adv Civil Eng. https://doi.org/10.1155/2019/4201842

Frank R (2007) Basic principles of Eurocode 7 on Geotechnical design 18th EYGEC, Ancona, Italy

Jeong S, Kim S, Briaud JL (1997) Analysis of downdrag on pile groups by the finite element method. Comput Geotech 21(2):143–161. https://doi.org/10.1016/S0266-352X(97)00018-9

Jeong S, Lee J, Lee CJ (2004) Slip effect at the pile–soil interface on dragload. Comput Geotech 31(2):115–126. https://doi.org/10.1016/j.compgeo.2004.01.009

Kim HJ, Mission JL, Park TW, Dinoy PR (2018) Analysis of negative skin-friction on single piles by one-dimensional consolidation model test. Int J Civil Engi 16(10):1445–1461. https://doi.org/10.1007/s40999-018-0299-7

Kurmaniyazova NZ (2019) About the introduction of Eurocode in the Republic of Kazakhstan Hayкa, Oбpaзoвaниe, Иннoвaции: Aпpoбaция Peзyльтaтoв Иccлeдoвaний, Neftekamsk, Russia, pp 134–140

Kuwabara F, Poulos HG (1989) Downdrag forces in group of piles. J Geotech Eng. https://doi.org/10.1061/(ASCE)0733-9410(1989)115:6(806)

Lambla V (2019) Construction sector in Kazakhstan 2019 market analysis and development forecasts for 2019–2024 PMR Market Insight, Krakow, Poland.

Lee CJ, Ng CW (2004) Development of downdrag on piles and pile groups in consolidating soil. J Geotech Geoenviron Eng. https://doi.org/10.1061/(ASCE)1090-0241(2004)130:9(905)

Lee CJ, Bolton MD, Al-Tabaa A (2001) Recent findings on negative skin friction in piles and pile groups in consolidating ground 5th International Conference on Deep Foundation Practice, Singapore, pp 273–280

Lee CJ, Bolton MD, Al-Tabbaa A (2002) Numerical modelling of group effects on the distribution of dragloads in pile foundations. Geotechnique 52(5):325–335. https://doi.org/10.1680/geot.2002.52.5.325

Lee CJ, Lee JH, Jeong S (2006) The influence of soil slip on negative skin friction in pile groups connected to a cap. Geotechnique 56(1):53–56. https://doi.org/10.1680/geot.2006.56.1.53

Liu J, Gao H, Liu H (2012) Finite element analyses of negative skin friction on a single pile. Acta Geotech 7(3):239–252. https://doi.org/10.1007/s11440-012-0163-x

Mashhour I, Hanna A (2016) Drag load on end-bearing piles in collapsible soil due to inundation. Can Geotech J 53(12):2030–2038. https://doi.org/10.1139/cgj-2015-0548

Orr T (2013) Implementig Eurocode 7 to achieve reliable geotechnical designs Modern Geotechnical Design Codes of Practice IOS Press, Amsterdam, The Netherlands, pp 72–86.

Poulos HG (1997) Piles subjected to negative friction: a procedure for design. Geotech Eng 28:23–44

Poulos HG, Davis EH (1975) Prediction of downdrag forces in end-bearing piles. J Geotech Eng Div 101(2):189–204. https://doi.org/10.1061/AJGEB6.0000148

Saparbayev EZ, Tulebekova AS (2019) Features of reforming normative base of the Republic of Kazakhstan. Aктyaльныe нayчныe иccлeдoвaния в coвpeмeннoм миpe 6–1:11–15

Shaldykova A, Moon S-W, Kim J, Lee D, Ku T, Zhussupbekov A (2020) Comparative analysis of Kazakhstani and European approaches for the design of shallow foundations. Appl Sci 10:2920. https://doi.org/10.3390/app10082920

Shibata T, Sekiguchi H, Yukitomo H (1982) Model test and analysis of negative friction acting on piles. Soils Found 22(2):29–39

Sun JJ, Wang LM, Huang XF (2003) A study on the position of maximum negative skin friction on piles in collapsing loess ground. J Seismolog 23(4):20–25

Tan SA, Fellenius BH (2016) Negative skin friction pile concepts with soil–structure interaction. Geotech Res 3(4):137–147. https://doi.org/10.1680/jgere.16.00006

Teh CI, Wong KS (1995) Analysis of downdrag on pile groups. Geotechnique 45(2):191–207

Terzaghi K (1967) Settlement of point bearing pile foundation; Settlement of floating pile foundation. Soil Mechanics in Engineering Practice: 540–555

Zhanabayeva A, Sagidullina N, Kim J, Satyanaga A, Lee D, Moon S-W (2021) Comparative analysis of Kazakhstani and European design specifications: raft foundation, pile foundation, and piled raft foundation. Appl Sci 11:3099. https://doi.org/10.3390/app11073099

Zhang D, Yang J, Li L, Shen Z (2015) Settlement calculation method for single pile in negative friction case considering consolidation of surrounding soils. Jpn Geotech Soc Special Publ 1(6):53–57. https://doi.org/10.3208/jgssp.CPN-27

Acknowledgements

This research was funded by the Nazarbayev University, Collaborative Research Project (CRP) Grant No. 11022021CRP1508. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the Nazarbayev University.

Author information

Authors and Affiliations

Contributions

This research is being done with the effort of five authors. AZ, and S-WM, conceptualized the study; AZ, SA, and S-WM, implemented data processing under the supervision of AS, and JK; the original draft of the manuscript was written by AZ, SA, and S-WM, with editorial contributions from AS, and JK. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

All authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhanabayeva, A., Abdialim, S., Satyanaga, A. et al. Comparative analysis of international codes of practice for pile foundation design considering negative skin friction effect. Geo-Engineering 13, 11 (2022). https://doi.org/10.1186/s40703-022-00176-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40703-022-00176-5