Abstract

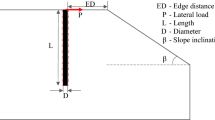

Pile foundations are adopted if a soil of low bearing capacity extends to a considerable depth or if the structure is heavy or the settlement due to the structure is large. It transfers the load to a strong, stable stratum of soil. The behaviour of soil in slope and piles embedded in it is an elaborated soil-structure interaction problem. This paper presents the results of experimental investigations on a single pile subjected to lateral load by varying relative density of soil in the horizontal and sloping ground with three different slopes of 1V: 2H, 1V: 2.5H and 1V: 3H. The lateral load carrying capacity of the pile is considerably decreased when the lateral load is applied in the direction of the slope. It is found that the lateral load carrying capacity of the pile is increased for higher relative density of sand and the lateral capacity of the pile is greater in flatter slope than in steeper slope. The effect of different slopes on normalized lateral load versus displacement for the lateral load applied in the direction along and against slope is quantified. A set of empirical equations are formulated to determine the deflection, fixity depth and moment for the pile in sloping ground.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

When there is a very weak layer of soil, then such soil cannot support or transfer a load of superstructure into stronger soil strata. To bypass this weak layer, pile foundations are adopted to transfer the load. Pile foundation transfers load to a strong soil layer. Most of the pile-supported structures are subjected to lateral loads. To study the behaviour of laterally loaded piles, the following methods are employed. (i) Beam on Winkler foundation approach (ii) Boundary Element method (iii) Elastic continuum approach (iv) Finite element method. Theory of elasticity (Poulos [1], Pise [2], Randolph [3], Budhu and Davies [4]) or theory of subgrade reaction (Matlock and Ripperger [5]) is considered for these above-mentioned approaches. In laterally loaded piles, load–deflection behaviour is nonlinear; hence it requires nonlinear analysis. Most of the coastline has sloping surfaces towards the sea. Slope instability is quite common in these areas due to the low shear strength of the soil. The instability of ground surface can occur due to dredging, siltation, erosion due to wave, self-weight, surcharge load and earthquake. Hence, to study the behaviour of soil-structure interaction in a sloping ground, it is essential to understand the failure mechanism.

Matlock et al. [6] presented a general solution for laterally loaded pile resting on elastic medium, and expressions for bending moment, shear force, soil reaction and deflection were introduced. From these parameters, soil modulus was presented as per Winkler’s hypothesis. Reese et al. [7] presented a method to predict p-y curves using properties of sand and pile dimensions based on experimental studies. Matlock [8] and Reese et al. [9] modified the subgrade reaction method by introducing “p-y” curves to consider the soil nonlinearity. The elastic solutions were modified using yield factors to account for soil nonlinearity by Budhu et al. [4] and Poulos et al. [10]. From Matlock experimenta results [8], it is concluded that there was a significant deterioration in soil resistance if the pile deflection is exceeding 20% of pile diameter. Gandhi et al. [11] performed experimental work on driven piles subjected to lateral load. They concluded that if the number of piles is increased in the given spacing, the efficiency of the pile group will be decreased. Narasimha Rao et al. [12] did experimental studies on pile groups located in marine clay and found that the lateral load capacity of the pile system is primarily depended on the rigidity of the pile-soil system. Muthukkumaran et al. [13] found out that the lateral capacity of the pile is optimized at 16% and 8% of the pile diameter in dense sand and loose to medium sands respectively. Deenadayal et al. [14] studied the response of a single pile in the sloping ground, and they developed non-dimensional p-y curves for various slopes such as 1V: 1H, 1V: 2H, 1V: 3H and 1V: 5H. They included the effect of the L/D ratio in their study.

Almas Begum et al. [15] did an experimental investigation to obtain an equation for the depth of fixity of pile and develop a graphical non-dimensional relationship between lateral load and bending moment of the pile. Parameters, such as the effect of the ground surface, embedment length of the pile and relative density of cohesionless soil, are considered in the study. Muthukkumaran [16] conducted an experimental study on a pile in sloping ground subjected to forward and reverse loading and presented the difference in response of pile in sloping and horizontal ground. Due to the passive wedge resistance, the lateral capacity of the pile in reverse loading was more than the pile in forward loading. Madhusudan Reddy et al. [17] did experiments on pile subjected to combine lateral and uplift loading. They concluded that the ultimate lateral load carrying capacity of the pile is increased significantly under combined loading. Jegatheeswaran et al. [18] performed a numerical analysis to study the behaviour of a pile in a sloping ground under the combined action of lateral and axial load. Pile in the horizontal ground and sloping ground (1V: 1.5H, 1V: 2H and 1V: 2.5H) had been considered using the Plaxis 2D analysis.

Yin et al. [19] evaluated the lateral behaviour of piles in the slope. Their study revealed that the depth of fixity of pile was 1.6 D from the ground surface for the pile located in the horizontal ground, whereas the depth of fixity increased to 3.6 D and 5.6 D for the pile in the sloping ground with the slope angle of 30 ° and 60 ° respectively. Chong Jiang et al. [20] concluded that the loading direction of the pile could be neglected if the pile is placed more than 7 D from the slope of the crest. Said et al. [21] did a numerical study to find out p-multiplier; that is used to develop p-y curves. They also noted that the sloping effect would vanish if the pile is placed 8 D from the crest of the slope.

Though the behaviour of pile in horizontal ground under lateral loading is well known, its behaviour on sloping ground is not studied in detail. This paper has introduced empirical relationships between load and deflection, fixity depth and embedment length, bending moment and load for the sloping ground 1 V: 2H, 1 V: 2.5H and 1 V: 3H.

Properties of materials used in the experiment

The properties of soil were found through laboratory experiments as per the concerned code of Indian Standards. IS 2720 (Part III and Part IV) [22, 23] are used to determine the specific gravity of the sand and to perform sieve analysis respectively. Based on the particle size distribution curve, the soil used in the experimental study was poorly graded sand (Fig. 1). The summary of engineering properties and index properties determined for the sand were presented in Table 1.

To arrive to the uniform density of sand in the test tank, pipe and cone arrangement is used as shown in Fig. 2. This pipe and cone arrangement is known as sand raining device. It contained a hopper connected with a long pipe of 24.8 mm internal diameter, 245 mm length and a reversed cone at the bottom. Sand weighing 8 kg could fill in this hopper. The sand is passed through this pipe and is dispersed by 60 ° due to a reversed cone at the bottom. Sand density could be varied by changing the height of fall of sand particles. This arrangement was fine-tuned by more trials to find out the height of fall for required relative density (Fig. 3).

An aluminium pipe of outer diameter 25 mm with 1.5 mm thickness was used as a pile. Pile was instrumented by pasting 120 ohms resistance of strain gauges having gauge factor 2 and gauge length 3 mm. Strain gauges are pasted along the pile length at a spacing of 100 mm, and the locations of strain gauges are shown in Fig. 4.

To find out the flexural stiffness of the pile and calibration constant of the strain gauge, a simple bending test was conducted and two point loads are applied on the 540 mm length of the beam (Fig. 5). The load was applied at 1/3rd span from both supports to produce constant moment in the middle 1/3rd span. The deflection at the centre of the beam was measured with the help of a dial gauge. Pile was instrumented by pasting strain gauges at four locations in order to sense the strain occurred at each position. Strain gauges were connected with data acquisition system to know the strain values in the beam. The obtained readings from the strain gauges were recorded automatically in computer by using the Spider 8—Catman professional software. The bending moment was calculated and plotted against the value of the measured strain. The response of strain was found to be linear with the bending moment. The calibration constant was found from the slope in Fig. 6, and it was 40.2Nmm per microstrain. Flexural stiffness was calculated by using the given Eq. (1), and its value was 534.13×106 Nmm2. The material properties of sand and pile are presented by Kavitha et al. [24].

where P-Applied load, \(a\)-Distance between load point and support, \(l\)-Length between two supports, \(\delta\)-Deflection.

Experimental setup

In order to fix the tank dimension, the influence zone for the pile is calculated based on the Rankine’s earth pressure theory. The stiffness factor of the pile is found out based on the instruction given in IS 2911/Part 1 [25]. The zone of influence of the pile is calculated using the depth of fixity ‘Zf” as suggested by Davisson et al. Phi (ɸ) value of sand is taken as 28°, ηh for medium sand is 7.5 MN/m3.

Depth of fixity (for horizontal ground):

Hence, the tank size of 0.985 m × 0.53 m × 0.77 m was selected to carry out the experimental work. The tank was made of steel on three sides and a transparent material on one side. The type of loading was static, and no other lateral load at the ground surface was applied. Pile has placed 530 mm away from the left side of the tank. Pile is placed first, and sand is filled with the help of the sand raining device. Horizontal displacement was measured with the use of mechanical dial gauges. It was fixed at the top of the pile just above the ground surface to measure displacement due to lateral load. Strain gauges were deployed along the pile length to sense the strain occurred at each depth after application of load, which was applied at every 15 min interval. The load applied in the lateral direction (Fig. 7) was increased up to the deflection of the pile of 5 mm, and the load corresponding to 5 mm deflection was taken as the ultimate lateral load carrying capacity of the pile. For all lateral load tests, the pile head is maintained as a free headed condition (Fig. 8).

Comparison of experimental result with the analytical solution

Pulley arrangement is used to apply the static lateral load for pile in the horizontal ground. The top displacement of the pile and the bending moment values along the length of the pile were recorded for each load with the help of a dial gauge and from the strain gauges. The test was repeated for three different relative densities of 25, 35 and 45%. The behaviour of pile in the horizontal ground through the results obtained from experiments was compared with the analytical solution of Matlock and Reese. The displacement and bending moment of pile were shown in Fig. 9a, b. This comparison is presented by Kavitha et al. [26]. The comparison of displacement of the pile with Matlock & Reese is good, whereas the maximum bending moment was under-predicted by 20.2% in the analytical solution. The lateral load capacity of the pile in the horizontal ground is obtained in the experiment as 181.9N, 154.3N and 120.5N for sand having a relative density of 45 %, 35% and 25%, respectively. The normalised lateral capacity is obtained using P(max)H, which corresponds to the lateral load capacity of the pile embedded in the sand with 45% relative density. The behaviour of pile in the horizontal ground based is presented in Fig. 10. The effect of relative density is observed only after the normalised displacement of 0.5. The normalised lateral load capacity is 1, 0.848 and 0.663 for relative density of 45, 35and 25% respectively. The lateral load capacity of the pile was increased with the increment of the relative density of sand as shown in Fig. 10.

Pile performance in sloping ground

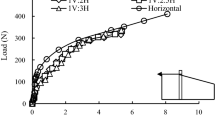

Three different slopes (1V: 3H, 1V: 2.5H and 1V: 2H) and two types of loading, such as pull along the slope and pull against the slope, are considered for this study. The pull along and against the slope can be called forward loading and reverse loading, respectively.

The comparison of normalised lateral load vs displacement curve is indicated a reduction in the lateral load carrying capacity of the pile in 1V: 3H sloping ground by 71% for the pull against the slope and 79% for pull along the slope compared to the lateral load capacity of the pile in the horizontal ground (Fig. 11). This reduction is due to the increase in depth of fixity (i.e. depth at which maximum bending moment occurred) when the surface of the ground is changed from flatter to steeper slope, as shown in Fig. 12.

Results and discussion

Lateral load behaviour

The maximum load carrying capacity of the pile in the horizontal ground, P(max)H, is used for normalising the lateral load in the sloping ground, and the corresponding déflection (20% of pile diameter) is used to normalise the deflection and the corresponding bending moment, M(max)H to normalise the bending moment. The normalised lateral load vs displacement for forward and reverse loading is shown in Figs. 13 and 14, respectively. The comparison between these two types of loading is tabulated in Table 2. Value of P/P(max)H is high for the slope of 1V: 3H ground under forward and reverse loading. The volume of soil occupied in the test tank is more for the flatter slope than the steeper slope, and hence the load carrying capacity of the pile is more in the flatter slope. The passive zone is more in reverse loading than the forward loading for the same slope. Due to the incremental of the passive zone, the lateral load capacity of the pile subjected to pull against slope is more than the pile subjected to pull along the slope. The pile’s embedment length in a flatter slope is high, whereas it is less in a steeper slope. Due to the increase of the embedment length, pile lateral load capacity is increased.

Regression analysis is performed to find out the relationship between y/ymax and P/P(max)H.

In forward loading,

In reverse loading.

where S-Slope, For 1V: 3H, S = 0.33.1V: 2.5H, S = 0.4, 1V: 2H, S = 0.5, P(max)H-Ultimate load in horizontal ground corresponding to ymax deflection, Lf–Fixity depth below the slope, Le–Embedment length

The scatter plot between the measured and formulated values of y/ymax for forward and reverse loading is given in Figs. 15 and 16. The R2 is equal to 0.9821 and 0.9936 for both forward and reverse loading; hence the fit holds well in agreement.

The scatter plot between the measured and formulated values of Lf for forward and reverse loading is given in Figs. 17 and 18. The R2 is equal to 0.9802 and 0.9993 for both forward and reverse loading; hence the fit holds well in agreement.

Bending moment behaviour

Bending moment variation along the depth of the pile subjected to different lateral loads applied in both forward and reverse direction are given in Figs. 19, 20 and 21 for the three different slopes. The depth of fixity of pile under reverse loading is less than forward loading. Hence the pile subjected to reverse loading has greater load carrying capacity. For the same load, the value of M/M(max)H is decreased as the slope is varied from 1V: 2H to 1V: 3H indicating that the flatter slope has less bending moment. The normalised bending moment vs normalised lateral load for all the three slopes in forward and reverse loading is shown in Fig. 22. Maximum bending moment value is more for pile in steeper slope than pile in flatter slope irrespective to the direction of loading. In each slope, bending moment values along the pile subjected to forward loading is more than the pile in reverse loading.

The relationship between Mmax/M(max)H and P/P(max)H is given by performing regression analysis in Eqs. (10) and (11) for forward and reverse loading respectively.

The scatter plot between the measured and formulated values of Mmax/M(max)H for forward and reverse loading is given in Figs. 23 and 24. The R2 is equal to 0.9808 and 0.9557 for both forward and reverse loading; hence the fit is in good agreement.

Conclusion

Based on the experimental studies on the pile in horizontal and sloping ground subjected to forward and reverse lateral loading, the following conclusions are drawn:

-

The increase in relative density from 25 to 45% increases the horizontal ground lateral capacity by 50%.

-

The loading direction and the change in the ground surface are greatly influenced by the lateral load capacity of the pile.

-

The lateral capacity of pile decreases by 91%, 84% and 79% for 1:2, 1:2.5 and 1:3 slopes than in horizontal ground when subjected to forward loading.

-

The lateral capacity of pile decreases by 79%, 72% and 71% for 1:2, 1:2.5 and 1:3 slopes than in horizontal ground when subjected to reverse loading.

-

The lateral load capacity of the pile in forward loading is 34.5% to 57.4% less than reverse loading depending on the flatter(1V: 3H) to steeper (1V: 2H)slope.

-

Due to the reduction in the passive zone just ahead of the pile in the sloping ground, its lateral load capacity is less than the lateral load capacity of the pile in horizontal ground. However, the fixity depth of pile is in the range of 10 to 15 D for sloping ground compared to 4 to 6 D in the horizontal ground. Consequently, the maximum bending moment in the sloping ground is 2 to 5 times the maximum bending moment in the horizontal ground.

-

Depth of fixity of pile is increased in case of forward loading than reverse loading due to the reduction of soil mass at the top.

-

Maximum bending moment is increased in steeper slope than flatter slope due to the reduction of soil resistance.

-

The passive resistance of soil in front of the pile is increased in reverse loading than forward loading.

-

The equation to find out the depth of fixity, lateral deflection and the maximum bending moment of the pile under forward loading and reverse loading are given. These equations are applicable for the slope of 1V: 2H, 1V: 2.5H, 1V:3H.

Abbreviations

- P:

-

Lateral pull (N)

- Y:

-

Pile displacement (mm)

- Ep :

-

Young’s modulus of pile (N/mm2)

- D:

-

Diameter of Pile in (mm)

- ϒ :

-

Unit weight of soil (N/mm3)

- ɸ:

-

Angle of friction in sand (o)

- L:

-

Length of pile (mm)

- LL:

-

Lateral load (N)

- Ld :

-

Embedment length of pile (mm)

- Ip :

-

Moment of inertia of pile (mm4)

- Pu :

-

Ultimate lateral bearing capacity of the pile (N)

- Mu :

-

Ending moment of the pile in the horizontal ground under the load Pu (Nmm)

- Mmax :

-

Maximum bending moment (Nmm)

- ηh :

-

Modulus of subgrade reaction (MN/m3)

- Zf :

-

Depth of fixity (mm)

- SG:

-

Strain gauge

References

Poulos HG (1971) Behaviour of laterally loaded piles I-single piles. J Soil Mech Found Div 97(5):711–732

Pise PJ (1984) Lateral response of free-head pile. J Geotech Eng 110(12):1805–1809

Randolph MF (1981) The response of flexible piles to lateral loading. Geotechnique 31:247–259

Budhu M, Davies TG (1987) Nonlinear analysis of lateral loaded piles in cohesionless soils. Can Geotech J 24:289–296

Matlock. H., and Ripperger, E.A. (1956). Procedures and instrumentation for test on a laterally loaded pile. Proc Int Conf. on Soil Mechanics and Foundation Engineering, Bureau of Engineering Research, University Of Texas, Special Publication 29, 1–39

Matlock H, Reese LC (1960) Generalized solutions for laterally loaded piles. J Soil Mech Found Eng Div 86:63–91

Reese LC, Cox WR, Koop FP (1974) Analysis of laterally loaded piles in sand. Proc Offshore Technol Conf 2018:472–483

Matlock, H. (1970) Correlations for design of laterally loaded piles. Proc. 2nd Annual offshore tech. Conference, Houstan, Texas, 577–593

Reese LC, Welch RC (1975) Lateral loading of deep foundations in stiff clay. J Geotech Geoenviron Eng 101:633

Poulos HG, Davis EH (1980) Pile foundation analysis and design. John Wiley and Sons, New York

Gandhi SR, Selvam S (1997) Group effect on driven piles under lateral load. J Geotech Geoenviron Eng 123(8):702–709

Narasimha Rao S, Ramakrishna VGST, Babu Rao M (1998) Influence of rigidity on laterally loaded pile groups in Marine Caly. J Geotech Geoenviron Eng 124(6):542–549

Muthukkumaran K (2014) Effect of slope and loading direction on laterally loaded piles in cohesionless soil. Int J Geomech. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000293

Deendayal R, Muthukkumaran K, Sitharam TG (2018) Analysis of laterally loaded group of piles located on sloping ground. Int J Geotech Eng. https://doi.org/10.1080/19386362.2018.1448521

Almas Begum N, Muthukkumaran K (2009) Experimental investigation on single model pile in sloping ground under lateral load. Int J Geotech Eng. https://doi.org/10.3328/IJGE.2009.03.01.133-146

Muthukkumaran K (2014) Effect of slope and loading direction on laterally loaded piles in cohesionless soil. Int J Geomech 14(1):1–7. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000293

Madhusudan Reddy K, Ayothiraman R (2015) Experimental studies on behaviour of single pile under combined uplift and lateral loading. J Geotech Geoenvironmental Eng. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001314

Jegatheeswaran B, Muthukkumaran K (2016) Behavior of pile due to combined loading with lateral soil movement. Geo Engineering. https://doi.org/10.1186/s40703-016-0021-z

Yin P, He W, Yang ZJ (2018) A simplified nonlinear method for a laterally loaded pile in sloping ground. Adv Civ Eng. https://doi.org/10.1155/2018/5438618

Jiang C, He J-L, Liu L, Sun B-W (2018) Effect of loading direction and slope on laterally loaded pile in sloping ground. Adv Civ Eng. https://doi.org/10.1155/2018/7569578

Said SE, Fayed AL, El Mossallamy Y (2020) P-Y curves of laterally loaded piles near earth slopes. Int J Eng Adv Technol 9:4

IS 2720 – Part III/Sec 2(1980) Test for soils – Part III: determination of specific gravity – section 2: fine, medium and coarse grained soils. Bureau of Indian Standards, New Delhi, India.

IS 2720-Part 4 (1985) Methods of test for soils – part 4: grain size analysis. Bureau of Indian Standards, New Delhi, India

Perumalsamy K, Ranganathan S (2020) Experimental study on pipe sheet pile wall berthing structure. Indian Geotech J. https://doi.org/10.1007/s40098-020-00479-3

IS 2911 Part I/Sec 2 (1979), Code of Practice for Design and Construction of Pile Foundations: Part I: Concrete Piles, Section 2: Bored Cast-in-Situ Piles, Bureau of Indian Standards, New Delhi, India

Kavitha.P, Sundaravadivelu.R (2017) Soil structure interaction analysis of a berthing structure under lateral loading-by numerical approach, 36th International Conference on Ocean, Offshore & Artic Engineering OMAE 2017, ASME proceedings, Volume 9, DOI:10.1115, ISBN: 978-0-7918-5777-9

Author information

Authors and Affiliations

Contributions

This research is being done with the effort of two authors. First author had carried out the study and wrote the manuscript under the guidance of second author. Second author supervised the study. Both authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Perumalsamy, K., Ranganathan, S. Single pile in cohesionless soil in sloping ground under lateral loading. Geo-Engineering 13, 8 (2022). https://doi.org/10.1186/s40703-022-00173-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40703-022-00173-8