Abstract

Expansive soils are problematic due to their swell—shrinkage behavior and low compressive strength. They are modified generally with additives such as lime, fly ash, and various other inorganic and organic materials. Chemical stabilization treatments can improve expansive soil properties for its reuse in geotechnical applications. The present study investigates the properties of two types of subgrade soil treated with Lime and compacted by three different methods in the laboratory. The study is mainly focused to bring out the effect of different methods of compaction on the unconfined compressive strength of Lime treated soils and untreated soils. Laboratory investigation included pH, Atterberg limits, cation exchange capacity (CEC), compaction, unconfined compression strength (UCS), California Bearing Ratio (CBR), Scanning Electron Micrographs (SEM) and EDAX before and after lime treatment. Tests were performed on lime treated soils (2, 4, 6 and 8% of lime). The soil samples for unconfined compressive strength test were prepared by static, dynamic and roller compaction methods in the laboratory. Roller compaction was performed using indigenously fabricated Roller compactor cum Rutting Analyzer (RCRA). The results indicate that dry unit weight and UCS of roller compacted lime treated soil is lower than that of dynamic compacted soil. However, dry unit weight and UCS of lime treated roller compacted soil are closer to that of statically compacted soil. Cation exchange capacity of both soils before and after treatment with lime were examined, CEC reduced with increase in lime content.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In India, Construction of highways, airports and other infrastructure facility is continuously undertaken as developmental works. The subgrade on which roads are constructed must be of good quality with desirable properties. However, the existing soil condition may not be suitable for construction at some locations where weak soils such as expansive soil exists.

In India about 51.8 million hectares of the land area are covered with weak soils. Weak soils are a worldwide problem that poses several challenges for Civil Engineers. In Karnataka state, northern parts are covered with expansive soil. Various methods are adapted to improve the Engineering characteristics of weak soils. The problematic soils are either removed and replaced by good and better quality material or treated using additive. Lime treatment has become an accepted method for increasing the strength and durability of soils. Lime is the conventional additive to improve strength of expansive soil. Addition of lime improves workability and reduces swell shrink characteristics of expansive soil.

The soil in the field is compacted by static or dynamic compaction using rollers. In the laboratory, the unconfined compressive strength of soil samples is determined after preparing the samples either by static or dynamic compaction. To simulate field condition, a novel equipment Roller Compactor cum Rutting Analyzer (RCRA) was developed and fabricated. RCRA is a laboratory equipment providing rolling condition similar to field condition. The unique features of this compactor is that pressure can be varied from 0.6 to 3 N/mm2. The rolling speed can be varied. The roller provides a kneading effect during compaction of specimens.

Literature review

The soil subgrade is compacted in field using different rollers depending on the type of soil. The different methods of compaction generally adopted are static, dynamic, kneading and vibratory compaction.

Earlier studies on roller compactor

Vivek et al. [1] investigated the rutting characteristics of WBM layer after compacting it in RCRA. The layer was compacted using roller and later rutting wheel was inserted and rut depth was measured.

Kiran et al. [2] indigenously built an equipment known as roller compactor cum rutting analyzer (RCRA) capable of performing both compaction and rutting on a layer. It simulates field conditions of both compaction and rutting in laboratory. A set of vertical and horizontal transducers measure movements and a programmable logical circuit with control screen for monitoring, recording and operating is included.

Studies on method of compaction

Edwin et al. [3] investigated the effect of dynamic and static methods of compaction on soil strength in the laboratory. Soil samples of different densities were prepared by adding peat into three agricultural soils at 0%, 4%, 8% and 12%, air-dry mass basis. The soils were dynamically compacted using 5, 15 and 25 blows of the proctor hammer at moisture contents which varied from 5 to 55%, and bulk density and penetration resistance were measured. The soil was then loosened and repacked to the same bulk densities using static compaction imposed via a hydraulic press and penetration resistance was again measured. Peak strengths of soils achieved from the two compaction methods were compared and the two sets of values were highly correlated (P = 0.001). Results indicate that as long as the same soils are compacted statically or dynamically at the similar moisture contents to same bulk densities, similar strength values are expected. The effect of method of soil compaction on soil strength is not important.

Abdi Ali Al-Khafaji et al. [4] studied the effect of different compaction energy on sub base course of roads. The soil for sub base under class B was compacted by standard proctor and modified compaction methods using a modified mould for compaction. The void ratio and porosity of both methods were compared. It was found that at same water content the void ratio and porosity of modified proctor compaction was less than that of standard proctor compaction test.

Vinay et al. [5] investigated the vibratory roller compaction on four soils. Relative compaction, dry density, degree of compaction was determined. Laboratory and field investigations were compared. It was concluded that degree of compaction of various types of soil increases as the number of passes of vibratory roller increases. Different soil type achieves different degree of compaction at same number of passes of roller.

Studies on lime and soil

Sujit Kumar et al. [6] evaluated the effect of lime stabilization on two extreme soils i.e., montmorillonite rich expansive soil and a silica rich non-expansive soil. An optimum lime content beyond which the strength improvement decreased was determined and found that this phenomenon is predominantly observed with silica rich soils that forms silica gel. The excessive lime treatment forms large amount of silica gel which is highly porous resulting in the reduction of strength gain due to loss in strength from gel pores. In addition to that these gel materials hold a large amount of water, leading to increased plasticity and swelling. Therefore, excessive lime treatment is avoided for silica rich soils.

de Souza Correia et al. [7] studied the effect of diesel contamination on coarse grained soil and assess the viability of a lime treatment. Presence of oil and lime in soil influences the Engineering properties and mineralogical properties of soil. It was reported that crystallization of calcite was present in both natural and oil contaminated soils treated with lime increasing particle flocculation resulting in enhancing strength properties of oil contaminated soil and also this oil contaminated soil shows increase in Engineering properties after lime treatment and certain curing period.

Abbasi et al. [8], investigated the influence of different amounts of lime and natural pozzolan on geotechnical properties of a silty sand. Evaluation of compaction characteristics, compressive strength and bearing capacity of the treated soil had been done and compaction test results showed that addition of both lime and pozzolona alone and with together cause increase in optimum moisture content and decrease in maximum dry density. Statistical analysis using SPSS software showed that adding both lime and natural pozzolana shows significant increase in compressive strength instead of adding them alone. Hence, soil treated with 3% lime and 15% pozzolan provides 16 times higher compressive strength than untreated sample and CBR values of treated soil is found 12 times more than untreated sample.

Bhuvaneshwari et al. [9], evaluated expansive soil behavior with lime. Expansive soil near Chennai was treated with lime in varying percentages 2, 4, 6, and 8%. In addition to Initial consumption of Lime value, the concept of Lime Modification Optimum was highlighted. Microstructure studies were conducted.

Ghobadi et al. [10], studied the effect of lime percentage and pH value on shear strength of soils. It was found that high pH of 9 exhibits higher shear strength compared to lower pH values.

Experimental study

Materials used

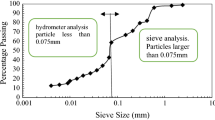

Expansive soil

Black cotton soil was procured from Gulbarga district from Karnataka. The soil was excavated from a depth of 1.0 m and pulverised to 4.75 mm down, oven dried and stored in air tight container as per IRC:51-1992 [19]. The properties of soil are shown in Table 1 and is classified as A-7-6 as per AASHTO with 62% clay having high activity of 1.41. The soil is denoted as soil-SE henceforth in this paper.

Red soil

Red soil was locally procured from BMSCE campus. The soil was excavated from a depth of 0.8 m. Collected soil was pulverised to 4.75 mm down, oven dried and stored in air tight containers. The soil was classified as A-7-5 as per AASHTO and exhibited 27% clay having activity of 0.78. The soil symbolised as soil-SR henceforth in this paper.

Lime

Hydrated lime was procured from local market. The specific gravity was found to be 2.33.

Methodology

The experiments were carried out in two phases. First phase involved compacting two different soils SE and SR by static, dynamic and Roller compaction methods in the laboratory at their optimum moisture content and maximum dry density obtained from Modified proctor compaction test. Soil specimens were extracted, trimmed to required specified dimension to determine Unconfined compressive strength as per IS 2720-PARTX-(1991) [14]. In the second phase, soil SE and soil SR were treated with different percentage of lime. The Initial consumption lime (ICL) value was found as per Eades and Grim method. Further, both soils were treated with three different lime contents (< ICL, at ICL and > ICL) and compacted by static, dynamic and roller compaction. Soil samples were extracted after resting period of 3 h. Samples were cured for 7 days and 28 days before testing for unconfined compressive strength.

Static compaction was performed in an UTM using 1000 cc mould by applying downward pressure till the desired density was achieved. Roller compaction was performed using RCRA equipment which was fabricated. Dynamic compaction was performed using auto compactor.

Roller compactor and rutting analyzer

RCRA is an indigenously built compactor that produces field compaction kneading effect in laboratory by rolling effect. The compactor is capable of applying pressures from 0.6 to 3 N/mm2. The rolling speed of the compactor can be varied and is capable of recording densification data during compaction of specimen. RCRA has provision to mount either compacting wheel for compaction or to mount rutting wheel to the same frame. Firstly, to compact soil, compacting wheel is mounted. The dimensions of the mould is 45 cm × 28 cm × 15 cm. After knowing the volume of the mould, maximum dry density the quantity of soil required was calculated. Water content equal to optimum moisture content of the soil was added and mixed well. The height of soil after compaction 12 cm was marked. The soil was poured into the RCRA mould and spread uniformly. Wooden plate was placed on the top for ensuring level surface and Roller was passed until the thickness of the soil was 12 cm. The compacted soil was left for few hours to set properly. Later, three samples for unconfined compressive strength test were extracted using sample extractor. The density and water content of the samples were measured. Later it was subjected to unconfined compressive strength test. The density after compaction was measured after demoulding. Table 2 shows the comparison between dynamic compaction, static compaction and RCRA, Fig. 1 shows the RCRA apparatus.

Results and discussions

Initial lime consumption

The minimum lime content required for soil is determined based on Eades and Grim test [11, 13]. The percentage of lime at which the soil–lime mix gives a pH of 12.4 is considered as initial consumption of Lime (ICL) required for a soil. To determine the optimum lime requirement of soil 20gm of the soil sample passing 425 micron mesh is taken in a bottle. A given percentage of lime is added by weight and mixed thoroughly. To this added 100 cc of distilled water and mixed thoroughly. The slurry so formed is kept at room temperature and after an hour, it is shaken again to ensure a uniform mixing of ingredients and its pH is determined by pH meter. The minimum percentage of lime which gives a pH of 12.4 when mixed with soil in the form of slurry, is the optimum percentage of lime for stabilization. After the test, the initial lime content was found to be 3% for the soil- SR and 4% for soil-SE as shown in Fig. 2.

Specific gravity

The specific gravity test was conducted for lime treated expansive soil and Red soil as per IS: 2720 (Part III/Sec 1)—1980 [20]. The effect of addition of lime is to reduce specific gravity of soils. The results are shown in Fig. 3 below.

Plasticity characteristics

The Atterberg’s limit test were carried out for different lime content at different curing period to establish the plasticity characteristics of the lime stabilized soil. Addition of lime to soil decreases the plasticity characteristics of the soil. Tables 3 and 4 gives the values of the liquid limit, plastic limit and plasticity index of lime treated soil SE and SR respectively. The results are tabulated for 7 days cured samples.

The effect of addition of lime is to decrease the plasticity index of the soil. However, Bhuvaneshwari [9] reports that effect of lime on liquid limit extends to both extremes. It can cause increase or decrease in liquid limit depending on individual soil being tested. For calcium saturated clays increase in liquid limit upon addition of lime occurs. Thus increase in liquid limit and decrease of plastic limit together causes increase in plasticity index.

For 2% and 4% lime treated SE soil liquid limit reduces. However, 6% lime addition increases the liquid limit. Ingles [15] explain that reduction in liquid limit is due to development of attractive forces. The reason for increase in liquid limit is due to change of fabric from dispersed to flocculated structure which imbibes more water. Also, formation of cementitious products takes place.

Cation exchange capacity

The exchangeable calcium, sodium, potassium and magnesium ion contents of SE and SR soils were determined. Soil fraction passing 425 micron sieve were subjected to three successive treatments with neutral 1 normal ammonium acetate solution to displace their cations. The amount of each displaced ion was determined by atomic absorption spectrophotometry. The CEC is found by summing up the concentrations of displaced cations and expressed as meq/100 mg.

It is observed from Table 5 that CEC values decreased with increase in lime content for both SE & SR soil samples. This shows that due to strong chemical reaction, exchangeable cations decrease and results in formation of coarser particles due to flocculation and aggregation. This leads to formation of large void ratio and is validated from scanning electron micrographs shown in Figs. 11b and 12b. The Figs. 11b and 12b also indicates reduction in radii of pore spaces.

Compaction characteristics

In order to find out the compaction characteristics, Modified proctor compaction tests were carried out on Untreated and treated soil SE and soil SR lime mixes as per IS 2720(part 8) [20]. The details of optimum water content and maximum dry unit weight for different soil lime mixes are shown in Table 6 and Figs. 4 and 5.

The addition of lime increases the optimum moisture content and decreases the maximum dry unit weight making it workable at higher range of water content. Lime addition makes the soil fabric flocculated with formation of crystalline cementitious products. This is the reason for increase in strength. Fang [18] describes that such improved properties of soil due to addition of lime is due to three basic chemical reactions—(i) cation exchange and flocculation-agglomeration (ii) Pozzolonic reaction resulting in cementitious products (iii) Carbonation.

CBR tests

California bearing ratio(CBR) tests were conducted as per IS 2720-Part 16 [20] for lime treated soil samples cured for 7 days and soaked for 4 days. The samples were compacted at 95% of the modified maximum dry unit weight at optimum moisture content.

The result of CBR Test on lime treated soil samples cured for 7 days and soaked for 4 days is shown in the Fig. 6 below.

From Table 7 it is seen that maximum CBR was achieved at 6% lime content for both the soils. Upon increasing the lime content to 8%, a decrease in CBR was observed for both soils. Figures 11 and 12 shows the SEM test results which indicates the reduction in void spaces due to addition of lime, which is due to aggregation soil particles. This aggregation of soil particles due to addition of lime is responsible for the increase in CBR strength of both the soils [16].

Further, UCS tests were carried out at 4%, 6% and 8% lime content for both soils.

Unconfined compressive strength (UCS)

The time and method of compaction dependent behavior of soil lime mixes in terms of strength were studied by conducting UCC tests. Soil treated with different percentages of lime (4%, 6% and 8%) were compacted by static, dynamic and roller compaction in the laboratory at their maximum dry density (MDD) and optimum moisture content (OMC). From the compacted soil, samples for UCS testing were extracted, trimmed to required dimensions, wrapped properly and cured in desiccators at room temperature for 7 days and 28 days. The bottom of desiccators was filled with water to minimize evaporation of water from samples. The UCC tests were conducted on samples at strain rate of 1.25 mm/min as a strain controlled test and tested till failure.

Soil SE

Figures 7 and 8 shows the unconfined compressive strength of 7 days cured soil SE samples at varying percentages of lime and compacted by different methods. It is observed from Fig. 7 that at all added percentages of lime, UCS is higher for dynamic compacted samples. Static and roller compacted samples exhibit almost similar UCS. However, as the percentage of lime increases an increase in UCS was observed. Samples treated with 6% and 8% lime exhibited closer UCS.

The effect of method of compaction as clearly indicated in Fig. 8 brings out that unconfined compressive strength of dynamically compacted soil samples is higher compared to other two methods. It is observed that static and roller compacted soil SE samples exhibit closer UCS. However, Roller compacted samples have slightly higher UCS compared to statically compacted soil samples. This trend is similar at different lime content used in this study.

Soil-SR

A similar trend was observed for soil-SR as shown in Figs. 9 and 10.

Dry unit weight

The soils were compacted at their respective maximum dry unit weight for all the three methods of compaction. The same was ascertained by measuring the density of UCS samples extracted after compaction. The results are shown in Tables 8 and 9.

The Untreated soil SE classified as highly compressible was not subjected to roller compaction due to its soft and compressible nature. Soil SE treated with 4%, 6%, 8% was subjected to roller compaction.

The dry unit weight of dynamically compacted UCS samples exhibited higher value compared to static and roller compacted samples for both soils. For example, consider Soil SE treated with 6% lime, the measured dry unit weight by dynamic compaction was 16.33 kN/m3 and by roller compaction was 15.83 kN/m3. However, for statically compacted specimens the dry unit weight was 15.6 kN/m3. It is observed that the density of roller compacted specimens in laboratory is lower than dynamically compacted specimens but higher than statically compacted soil [17]. The same trend was indicated by soil SR also for different lime contents.

Scanning Electronic Microscope (SEM) and EDAX

The microstructure of untreated and soil treated soil with 6% of lime cured for 28 days was studied using SEM. Figures 11a and 12a shows the micro fabric of untreated soils at 200× which is characterized by clay particles with wide void spaces. Figures 11b and 12b exhibits the microstructure of 6% lime treated soils and shows dense clay matrix with closer spacing of particles and formation of clusters and aggregations. This is reason for higher UCC strength of lime treated soils. When compared to Figs. 11a with b and 12a, b void space in soil has reduced by addition of lime, reduction in void space is attributed due to the aggregation of soil. Hence reduction in void spaces and strong chemical interaction such as cation exchange and pozzolonic activity between soil and lime has caused increase in strength properties of soil.

Since CEC values reduce with increase in % lime added to soil SE and soil SR, leading to reduced void space and closer packing, UCC strength of lime treated soil increases.

EDAX

EDAX test has been carried out on untreated soil SE and soil SR and soils treated with 6% lime and results obtained are tabulated in Tables 10 and 11. Table shows the change in different elements of soil treated by lime.

Table 10 and 11 shows the chemical composition of untreated and treated soil SE and soil SR. It has been observed that percentage of calcium has increased from 2.06 to 4.38 for soil SE and from 0.67 to 4.87 for soil SR. Hence due to increase in calcium content pozzolanic reactions takes place in the soil resulting in increase in strength of the soil.

Conclusion

Based on the experimental investigation on two soils-SE and soil-SR, the following conclusions can be drawn:

-

1.

Untreated soil-SE is classified as A-7-6 and soil -SR belongs to A-7-5 group.

-

2.

Irrespective of soil type, Roller compacted soil samples exhibit slightly higher UCS than statically compacted samples. But roller and static compacted UCS are much closer when compared to UCS of soil compacted by dynamic method. Hence static compaction is closer to field rolling conditions and it can be used as standard method for compaction of soil in laboratories instead of dynamic compaction.

-

3.

Lime content: The ICL value for soil -SR was 3% and for soil -SE was found to be 4%. Addition of lime to both A-7-6 and A-7-5 soil increases the UCS.

-

4.

CBR: Untreated Soil- SE with a very low CBR of 0.73% with addition of 6% lime, exhibited a higher CBR of 49% when cured for 7 days. Untreated soil -SR with a low value of CBR of 3.2%, upon 6% lime addition CBR increased to 73% with 7 days curing.

-

5.

UCS: For lime treated soil with any given curing period, dynamically compacted soil samples exhibited higher dry unit weight and UCS followed by Roller compacted samples. Among the three methods of compaction, statically compacted soil samples exhibit minimum dry unit weight and UCS. Hence it can be inferred that roller compaction of soil has lower density compared to dynamically compacted soil. However, roller compaction and static compaction are much closer in terms of dry density and UCS.

-

6.

Microstructure: SEM’s were conducted to reason out the improvement in properties of treated soils. It was observed reduction in void space due to aggregation of lime treated soil particles. Hence the strength of lime treated soil increased. The increase was higher for dynamically compacted soil due to higher maximum dry unit weight.

-

7.

Cation Exchange Capacity (CEC): CEC reduces with increase in lime content justifying the changes in mineralogy of soil. Hence strength increases with increase in lime content.

References

Vivek VG (2018) Strength and rutting characteristics of WBM with partial replacement of aggregate by steel slag. IOSR J Mech Civil Eng (IOSR-JMCE) 15(1):1. https://doi.org/10.9790/1684-1501010715

Kiran Kumar BV, Jagadeesh HS, Sathyamurthy R. Roller compactor cum rut analyzer an alternative compactor for bituminous mix design. The Masterbuilder; 2012

Ekwue EI, Birchb R, Chewittc J (2015) Effect of dynamic and static methods of compaction on soil strength. West Indian J Eng 37(2):74–78 (ISSN 0511-5728)

Ali Al-Khafaji SA (2016) Effect of the different energy of compaction on subbase course of roads. Saudi J Eng Technol 1:86–91

Vinay A, Hemanth Y. Study and comparison of soil compaction between laboratory and field to simulate field compaction for rural roads. Int Res J Eng Technol IRJET. e-ISSN: 2395-0056. 02(04)|July-2015 www.irjet.net p-ISSN: 2395-0072.

Sujit Kumar D, Manowar H (2012) Lime stabilization of soils: reappraisal, ASCE. J Mater Civ Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000431

de Souza CN, Portelinha FHM, Mendes IS, da Silva JWB (2020) Lime treatment of a diesel-contaminated coarse-grained soil for reuse in geotechnical applications. Int J Geo-Eng. https://doi.org/10.1186/s40703-020-00115-2

Abbasi N, Mahdieh M (2018) Improvement of geotechnical properties of silty sand soils using natural pozzolan and lime. Int J Geo-Eng. https://doi.org/10.1186/s40703-018-0072-4

Bhuvaneshwari S, Robinson RG, Gandhi SR (2013) Behaviour of lime treated cured expansive soil composites. Indian Geotech J. https://doi.org/10.1007/s40098-013-0081-3 (ISSN 0971-9555)

Ghobadi MH, Abdilor Y, Babazadeh R (2013) Stabilization of clay soils using lime and effect of pH variations on shear strength parameters. Bull Eng Geol Environ 73(2):611–619. https://doi.org/10.1007/s10064-013-0563-7

IRC: 51-1992. Guidelines for the use of soil-lime mixes in road construction.

IRC: 37-2012. Guidelines for the design of flexible pavement.

Eades JL, Grim RE (1966) A quick test to determine lime requirements of lime stabilization. Highway Res Rec 139:61–72

IS: 2720. Methods of test for soils.

Ingles OG, Metcalf JB (1972) Soil stabilization. Butterworth, Sydney

Kuttah D (2019) Strong correlation between the laboratory dynamic CBR and the compaction characteristics of sandy soil. Int J Geo-Eng. https://doi.org/10.1186/s40703-019-0102-x

Khalid U, Ur Rehman Z (2018) Evaluation of compaction parameters of fine grained soils using standard and modified efforts. Int J Geo-Eng. https://doi.org/10.1186/s40703-018-0083-1

Fang HY (1991) Foundation engineering handbook, 2nd edn. Van Nostrand Reinhold Publishing Company, New York

IRC: 49-1992. Recommended practice for pulverization of black cotton soil for lime stabilization.

Khanna SK, Justo CEG, Veeraragavan A. Highway engineering

Punmia BC, Jain Ak. Soil Mechanics and Foundations.

Acknowledgements

The authors acknowledge TEQIP-II of BMS college of Engineering for providing financial assistance to carry out the present study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nagesh, S., Jagadeesh, H.S. & Nithin, K.S. Study on effect of laboratory roller compaction on unconfined compressive strength of lime treated soils. Geo-Engineering 12, 22 (2021). https://doi.org/10.1186/s40703-021-00150-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40703-021-00150-7