Abstract

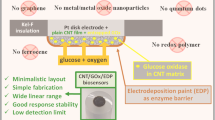

This paper describes a simple electrochemical sensing platform based on single-walled carbon nanotube (SWCNT) electrodes for glucose detection. The device fabrication using O2-plasma treatment allows precision and uniformity for the construction of three SWCNT electrodes on the flexible plastic substrate. Glucose assay can be simply accomplished by introducing a glucose sample into the fabricated biosensor. The marked electrocatalytic and biocompatible properties of biosensors based on SWCNT electrodes with the incorporation of ferrocenecarboxylic acid and polyethylene glycol enable effective amperometric measurement of glucose at a low oxidation potential (0.3 V) with low interferences from coexisting species. The device shows efficient electroanalytical performances with high sensitivity (5.5 μA·mM−1·cm−2), good reproducibility (CV less than 3%), and long-term stability (over a month). A linear range of response was found from 0 to 10 mM of glucose with a fast response time of 10 s. This attractive electroanalytical device based on GOx/FCA/PEG/SWCNT electrodes offers a promising system to facilitate a new approach for diverse biosensors and electrochemical devices.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Introduction

Glucose is one of the essential nutrients and has been widely used in the food and drug industry. It plays an important role in human life as a major energy source and metabolic intermediate. However, the abnormal level of glucose in blood is considered to be responsible for endocrine and metabolic disorders such as diabetes mellitus, which may cause serious diseases (e.g., kidney failure, blindness, and heart disease) (Sun and James 2015). According to the World Health Organization, more than 400 million people suffer from diabetes, indicating that it has already become a worldwide public health threat (WHO, 2022). For this reason, simple, sensitive, and easy-to-use glucose sensors are highly required for the millions of diabetics supposed to check their own glucose levels daily. Until now, various detection methods have been attempted for the development of reliable and sensitive glucose biosensor, such as electrochemistry (Hu et al. 2014), spectrometric colorimetry (Xu et al. 2019; Park et al. 2022), chemiluminescence (Hao et al. 2013; Chaichi and Ehsani 2016), Raman scattering (Hu et al. 2017), and fluorometry (Liu et al. 2016). Among these methods, electrochemical sensing techniques provide significant advantages over other techniques owing to high sensitivity, simplicity, rapid response, miniaturization, and portability. Moreover, it is readily amenable to commercialization because of low manufacturing cost with the help of recent microfabrication advances.

Since the discovery of carbon nanotubes (CNTs) (Iijima 1991), they have attracted significant research attention in many fields due to their excellent electrical, mechanical, thermal, and optical properties (Liu et al. 2011; Chen and Dai 2013; Hu et al. 2004). CNTs with such outstanding properties have been adopted in various applications such as field emission displays, chemical sensors, thin film transistors, and transparent electrodes for optoelectronic devices (Lee et al. 2017; Park et al. 2014; Wang et al. 2014; Hwang et al. 2015; Schroeder et al. 2019). In particular, the electrical conductivity and large surface have made them suitable for biosensors. CNT surfaces with abundant carboxylic acid sites created by the purification process may provide special opportunities for the adsorption and encapsulation of biomolecules. The remarkable electrical properties of CNTs have established them as the ideal electrode for electrochemical biosensors. Based on these advantages, CNTs have extensively been used in a wide range of electrochemical biosensing studies, such as therapeutic drug sensors (Vashist et al. 2011; Chipeture et al. 2019), amperometric enzyme sensors (Erden et al. 2015; Fang et al. 2016), and immuno/DNA sensors (Li and Lee 2017). The high electrocatalytic activity of CNTs promotes effective electron transfer in electrochemical reactions, making them greatly attractive for dehydrogenase/oxidase-based amperometric biosensors to determine clinically important analytes (e.g., glucose, cholesterol, lactate, pyruvate, and ethanol), which generate the electrochemically detectable products (e.g., NADH and H2O2) with the assistance of their corresponding enzymes (Jacobs et al. 2010; Shi et al. 2011; Savk et al. 2019; Kul et al. 2013; Gao et al. 2010). Recently, several electrochemical biosensors using CNT composites or modified CNTs have already been reported (Barsan et al. 2015; Yang et al. 2010; Zhang et al. 2010; Shrestha et al. 2016). However, they present some limitations for fabricating and miniaturizing sensors, such as the need for complicated manufacturing processes, extra supporting electrodes, and external stirring/injecting equipment.

In this paper, we developed a simple and facile electrochemical sensing device based on single-walled carbon nanotube (SWCNT) for glucose detection. The three SWCNT electrode system was simply fabricated on a polyethylene terephthalate (PET) film by O2-plasma treatment. The amperometric glucose sensor was constructed with the incorporation of ferrocenecarboxylic acid (FCA), polyethylene glycol (PEG), and glucose oxidase (GOx) to achieve enhanced electron transfer and high biocompatibility. Well-fabricated SWCNT electrodes on plastic films were characterized by scanning electron microscopy (SEM) and Raman spectroscopy. The impressive abilities of biosensors were investigated by cyclic voltammetric and chronoamperometric techniques. This simple glucose biosensor showed a fast response, high sensitivity, good reproducibility, and long-term stability.

Experimental section

Reagents

GOx from Aspergillus niger (EC 1.1.3.4), FCA, PEG (Mn 10,000), glucose, ascorbic acid (AA), and uric acid (UA) were purchased from Sigma-Aldrich (St. Louis, MO, USA) and used without further purification. A SWCNT aqueous solution (0.2 mg/mL) was obtained from Topnanosys (Cheonan, South Korea). Positive photoresist polymer (AZ4620) and developer (AZ400K) were purchased from AZ Electronic Materials (Somerville, NJ, USA). Phosphate-buffered saline (0.1 M PBS, pH 7.2) was obtained from Biosesang (Seongnam, South Korea). All aqueous solutions were prepared with double distilled water (ddH2O).

Preparation of conductive SWCNT film

The homogeneous SWCNT films were fabricated by a vacuum filtration method (Wu et al. 2004). Briefly, the SWCNT aqueous solution was sonicated for 30 min and then centrifuged at 14,000 rpm for 10 min. A 200 μL of the suspended solution was diluted with 100 mL of ddH2O and filtered through an anodic aluminum oxide (AAO) membrane with 0.2 μm pore size. The AAO membrane under the SWCNT thin layer was removed in a 3 M NaOH solution, and the remaining SWCNT thin layer was then transferred to a PET polymer film after adjusting the solution to neutral pH using ddH2O. Then, the heat treatment at 60 °C for 30 min was carried out to increase the adhesion between the SWCNT layer and PET film substrate.

Fabrication of three SWCNT electrodes on PET film using O 2 -plasma treatment

Conductive SWCNT films were patterned using a standard photolithography method and subsequent O2-plasma treatment (Fig. 1a). A positive photoresist polymer (AZ4620) was spin-coated onto the produced SWCNT films at 1,500 rpm for 1 min, followed by exposure to UV light (~ 365 nm) through a designed mask and development with the AZ400K solution sequentially. O2-plasma treatments were performed at a 100 mTorr chamber pressure, 500 W power, and a substrate reflective frequency of 13.56 MHz for 5 min. After O2-plasma etching, the remaining photoresist polymer on the SWCNT films was removed with an ethanol solution and rinsed with ddH2O. The morphological and chemical changes of SWNCT film were characterized by SEM (Hitachi S-4800, Hitachi Ltd., Japan) and Raman spectroscopy (Renishaw 2000, operating with a 633 nm He–Ne laser, Renishaw Inc., UK). The resulting array of three SWCNT electrodes (a working electrode, a counter electrode, and a reference electrode) corresponds to Fig. 1b. Each electrode unit has a square end (3.5 mm × 4.0 mm) for the electrical contact.

Schematic diagram of a the fabrication of SWCNT electrodes by O2-plasma treatment and b the construction of glucose biosensors based on a three SWCNT electrode system. The gap between the PET substrate and hydrophilic cover film produced by Teflon tape allows the capillary addition of a sample with a volume less than 10 μL. Dimensions represent millimeters

Construction of glucose biosensor based on GOx/FCA/PEG/SWCNT electrodes

To construct the glucose biosensor, ~ 100-μm-thick Teflon tape was placed on the fabricated PET substrate with three SWCNT electrodes as shown in Fig. 1b. For glucose assays, the casting mixture was prepared by dissolving 0.15 g of GOx and 3.5 mg of FCA in 15 mL of 0.1 g/mL PEG at the molar ratio of 1:16. Then, 2 μL of the mixture was drop-casted on the detecting zone of a SWCNT electrode used as working electrode. After that, it was allowed to dry at 25℃ and 70% humidity for 2 h to form a homogeneous coating, then a hydrophilic cover film was overlaid onto the PET substrate. A sample volume of less than 10 μL was required to fill up the biosensor by capillary flow.

Electrochemical characterization and analytical performances using glucose biosensor.

Cyclic voltammetric and chronoamperometric measurements were performed on the glucose biosensor with a CHI660C electrochemical analyzer (CH Instruments Inc., USA). In a three-electrode setup for electrochemical assays, each SWCNT electrode functioned as the working electrode, the counter electrode, and the reference electrode. All electrochemical experiments were performed in PBS solution at room temperature.

Results and discussion

Fabrication and characterization of three SWCNT electrodes system

O2 plasma etching in a capacitively coupled plasma (CCP) system was chosen for SWCNT electrode patterning on PET substrate. Other plasma methods such as an inductively coupled plasma (ICP) and a reactive ion etching (RIE) plasma are widely used for CNT etching on a silicon wafer or metal substrates, but they are unsuitable to be applied for polymer substrates. The reactive ion bombardment accelerated by radio frequency bias and the high temperature resulting from plasma generation in ICP and RIE systems can cause polymer substrates to damage and deform easily (Paul et al. 2012; Powell et al. 2003; Behnam et al. 2007). In contrast with ICP and RIE etching, CCP-based plasma treatment has the advantages on: (1) uniformity of plasma density; (2) low operating temperature; (3) relatively low ion energies, which allow the homogeneity of etched patterns on a large-scaled area and the favorable processes for plastic substrate with good reproducibility and reliability with high feature resolution Additional file 1: (Fig. S2). The plasma fabrication process for SWCNT films included photolithography and subsequent O2-plasma treatment. During the plasma treatment, SWCNTs underneath the patterned photoresist polymer were protected from etching and damage by O2-plasma while the exposed SWCNTs were destroyed. The area patterned by O2-plasma treatment was more transparent than the area protected with the photoresist polymer as shown in Fig. 2. The clear electrode patterns demonstrated the effectiveness of SWCNT fabrication using this method. For a more detailed characterization, the morphological changes of the SWCNTs were investigated by SEM. In the left SEM image, networks of carbon nanotubes showed no damage and a clear connection. However, the morphologies of the SWCNTs exposed to O2-plasma treatment changed substantially. This morphology change can be described as the destruction of whole SWCNTs due to the chemical etching of O2-plasma. The destruction started gradually from SWCNT defects and resulted in the conversion of SWCNT to volatile CO2, CO, and H2O (Han et al. 2010; Mathur et al. 2012; Su et al. 2013). The average resistivity and transparency of the fabricated SWCNT devices were ~ 400 Ω/sq and 80%, respectively. The thickness of the SWCNT electrode was controlled to be ~ 100 nm, which allowed the suitable resistivity and transparency for use as a flexible electrode. SWCNT devices showed high flexibility with negligible changes in resistivity at hard bending.

Figure 3 shows Raman spectra of partial areas in a patterned SWCNT film corresponding to Fig. 2. We noted the change in peaks at 1598 cm−1 (G-line) and 1335 cm−1 (D-line) in SWCNTs corresponding to graphite/ordered carbons and amorphous/disorder carbons, respectively (Park et al. 2015; Dennany et al. 2010). When comparing the PR-covered area (a) and exposed area (b), the representative CNTs peaks at 1598 cm−1 and 1335 cm−1 greatly decreased after O2-plasma treatment and decreased by almost 99% compared with the PR-covered area. Moreover, the intensity ratio (ID/ IG) increased from 0.128 (a) to 0.725 (b), which indicates an increase in disordered phases. This reveals that ordered carbons of CNTs changed to amorphous carbons by O2-plasma etching, resulting in the conversion of disordered carbons to volatile CO2. These results were consistent with those observed in SEM images.

Morphologies of GOx/FCA/PEG-modified SWCNT electrode

Additional file 1: Figure S1 shows the dependence of surface morphologies of GOx/FCA/PEG-modified SWCNT electrodes on incubation conditions. Morphological changes due to changes in relative humidity were observed by optical microscopy. The surface morphology of GOx/FCA/PEG incubated at a humidity of 20% was inhomogeneous and uneven, while the surface homogeneity became better with an increase in incubation humidity. This indicates that a slow drying process is favorable for the modification of GOx/FCA/PEG on SWCNT electrodes. Consequently, uniform and well-distributed GOx/FCA/PEG was achieved at a humidity of 70%. This uniform surface modification on SWCNT electrodes can provide a homogeneous reaction matrix with entrapped GOx and FCA, resulting in an increase in the electrochemically effective surface area. Thus, the modification of GOx/FCA/PEG on the SWCNT electrode was carried out under humid conditions (70%) for further experiments.

Electrochemical characterization of GOx/FCA/PEG/SWCNT-based biosensor

Figure 4 shows the typical cyclic voltammetric curves obtained at the three SWCNT electrodes with incorporated GOx and FCA. An FCA mediator was chosen as an artificial electron transferring agent due to some attractive features: (a) the reaction of GOx with FCA is largely independent of oxygen concentration in the sample, and (b) the interference of unwanted species such as uric acid (UA) and ascorbic acid (AA) can be avoided due to its low oxidation potentials. In the presence of FCA, the electrochemical reaction of glucose can be described as follows:

where M(ox) and M(re) represent the oxidized (FCA+) and reduced (FCA) forms of FCA mediator (Wang 2008). In the absence of glucose, well-defined oxidation and reduction peaks for FCA were observed at 0.25 and − 0.15 V. After the addition of 10 mM glucose, the oxidation peak current increased sharply, whereas the reduction peak current disappeared. These electrochemical behaviors indicate that the FCA+ is converted to FCA through a glucose enzymatic reaction and then re-oxidized to FCA+ during the anodic sweep, which is dependent on the glucose concentration. Moreover, the disappearance of the reduction peak is attributed to the irreversible oxidation of FCA in which electro-oxidized FCA+ is converted to FCA through enzymatic reduction by GOx while staying in a reduced state (as presented in reaction 2). It reveals that the FCA in our device can act as an efficient electron transfer shuttle between the FAD center of GOx and the SWCNT electrode.

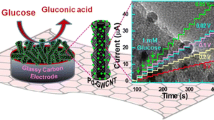

Glucose assay using GOx/FCA/PEG/SWCNT-based biosensor

Figure 5a shows the current responses of a biosensor after the addition of a glucose solution. Chronoamperometric experiments were carried out at an oxidation potential of 0.3 V. As the concentration of glucose varies, the biosensor exhibited excellent electrocatalytic oxidation activity for glucose. Each chronoamperometric current quickly reached a stable state, indicating the fast response of the biosensor, which was attributed to the considerable electrical properties of SWCNT-based electrodes. Figure 5b shows the calibration curve to amperometric responses depending on glucose concentration. The glucose biosensor exhibited a good linear range from 0 to 10 mM with a response time of 10 s. This biosensor offered a good sensitivity of 5.5 μA·mM−1·cm−2 and detection limit (LOD) of 28 μM with regression equation: I (μA) = 2.058 + 0.495 [glucose] (mM) (R2 = 0.989), indicating the high analytical performance and reliability of our device (Additional file 1: Table S1). The reproducibility of this device was investigated by testing glucose levels (in triplicate) on independently prepared biosensors; the coefficient of variation (CV) was less than 3%, demonstrating good reproducibility. The apparent Michaelis–Menten constant (\({K}_{\mathrm{m}}^{\mathrm{app}}\)) gives an indication of the enzyme/analyte kinetics for this device, and it can be determined by the Lineweaver–Burk plot (inset of Fig. 5b) (Ang et al. 2015; Wang et al. 2010).

where ISS is the steady-state current after the addition of the substrate, C is the substrate concentration, and Imax is the maximum current measured under a saturated substrate condition. The \({K}_{\mathrm{m}}^{\mathrm{app}}\) was determined by an analysis of the slope and intercept for the plot of the reciprocals of the steady-state current versus glucose concentration. The \({K}_{\mathrm{m}}^{\mathrm{app}}\) given in our study was calculated to be 2.16 mM. The small value of \({K}_{\mathrm{m}}^{\mathrm{app}}\) implies that the GOx/FCA/PEG/SWCNT electrode possesses a high affinity to glucose, resulting in the sensitive detection of glucose.

Stability and selectivity of biosensor

Figure 6 shows the long-term stability and selectivity of a glucose biosensor. To define the stability of this biosensor, the amperometric responses were investigated in the presence of a 4 mM glucose concentration, which is similar to a normal blood glucose level. The sensor displays a highly stable response during the extended experiment with storage at 4℃. The sensor retained 95% of its initial current response for glucose after one month, indicating good stability of the sensor. For interference tests, the amperometric current responses to 0.1 mM of AA and UA, which are present in physiological samples, were examined together with 4 mM glucose (the physiological concentration range is from 0.03 to 0.15 mM for AA and from 0.1 to 0.4 mM for UA, respectively). In Fig. 6b, the interference effects of AA and UA on glucose detection were found to be 9.9% and 7.3%, respectively. These results demonstrate the selective and stable analytical performance of this glucose biosensor, which may be attributed to electric/electrocatalytic and biocompatible properties of SWCNTs in cooperation with FCA and PEG, making it more applicable for practical use.

Conclusion

In summary, we have successfully constructed an amperometric glucose biosensor based on three SWCNT electrodes. The developed electrochemical sensing device offered attractive analytical behavior for glucose detection. The low-potential analysis attributed to the modification of GOx/FCA/PEG/SWCNT allowed the selective detection of glucose against other interfering species. This glucose biosensor showed a good linear range from 0 to 10 mM with a rapid response time of 10 s, high sensitivity of 5.5 μA·mM−1·cm−2, and good stability over a month. These remarkable results may be attributed to the biocompatibility of the GOx/FCA/PEG/SWCNT electrode and the fast electron transfer between SWCNT and the redox center of GOx with the assistance of FCA. We believe that this facile SWCNT-based biosensor holds great promise for glucose analysis in point-of-care testing, and moreover it is amenable to various electrochemical biosensing applications with the advantages of simplicity, rapid response, sensitivity, and stability.

Availability of data and materials

All details of experimental data are presented in this article and additional file.

Abbreviations

- SWCNT:

-

Single-walled carbon nanotube

- FCA:

-

Ferrocenecarboxylic acid

- PEG:

-

Polyethylene glycol

- GOx:

-

Glucose oxidase

- PET:

-

Polyethylene terephthalate

- UA:

-

Uric acid

- AA:

-

Ascorbic acid

References

Ang LF, Por LY, Yam MF. Development of an amperometric-based glucose biosensor to measure the glucose content of fruit. PLoS ONE. 2015;10: e0111859.

Barsan MM, Ghica ME, Brett CMA. Electrochemical sensors and biosensors based on redox polymer/carbon nanotube modified electrodes: a review. Anal Chim Acta. 2015;881:1–23.

Behnam A, Choi Y, Noriega L, Wu Z, Kravchenko I, Rinzler AG, Ural AJ. Nanolithographic patterning of transparent, conductive single-walled carbon nanotube films by inductively coupled plasma reactive ion etching. Vac Sci Technol B. 2007;25:348–54.

Chaichi MJ, Ehsani MA. Novel glucose sensor based on immobilization of glucose oxidase on the chitosan-coated Fe3O4 nanoparticles and the luminol-H2O2-gold nanoparticle chemiluminescence detection system. Sens Actuators B Chem. 2016;223:713–22.

Chen T, Dai L. Carbon nanomaterials for high-performance supercapacitors. Mater Today. 2013;16:272–80.

Chipeture AT, Apath D, Moyo M, Shumba M. Multiwalled carbon nanotubes decorated with bismuth (III) oxide for electrochemical detection of an antipyretic and analgesic drug paracetamol in biological samples. J Analyt Sci Technol. 2019;10(1):1–3.

Dennany L, Sherrell P, Chen J, Innis PC, Wallacea GG, Minett AIEPR. characterisation of platinum nanoparticle functionalised carbon nanotube hybrid materials. Phys Chem Chem Phys. 2010;12:4135–41.

Erden PE, Kaçar C, Öztürk F, Kılıç E. Amperometric uric acid biosensor based on poly(vinylferrocene)-gelatin-carboxylated multiwalled carbon nanotube modified glassy carbon electrode. Talanta. 2015;134:488–95.

Fang Y, Umasankar Y, Ramasamy RP. A novel bi-enzyme electrochemical biosensor for selective and sensitive determination of methyl salicylate. Biosens Bioelectron. 2016;81:39–45.

Gao Q, Sun M, Peng P, Qi H, Zhang C. Electro-oxidative polymerization of phenothiazine dyes into a multilayer-containing carbon nanotube on a glassy carbon electrode for the sensitive and low-potential detection of NADH. Microchim Acta. 2010;168:299–307.

Han KN, Li C, Bui MN, Seong GH. Patterning of single-walled carbon nanotube films on flexible, transparent plastic substrates. Langmuir. 2010;26:598–602.

Hao M, Liu N, Ma Z. A new luminol chemiluminescence sensor for glucose based on pH-dependent graphene oxide. Analyst. 2013;138:4393–7.

Hu L, Hecht DS, Grüner G. Percolation in transparent and conducting carbon nanotube networks. Nano Lett. 2004;4:2513–7.

Hu C, Yang DP, Zhu F, Jiang F, Shen S, Zhang J. Enzyme-labeled Pt@BSA nanocomposite as a facile electrochemical biosensing interface for sensitive glucose determination. ACS Appl Mater Interfaces. 2014;6:4170–417.

Hu Y, Cheng H, Zhao X, Wu J, Muhammad F, Lin S, He J, Zhou L, Zhang C, Deng Y, Wang P, Zhou Z, Nie S, Wei H. Surface-enhanced raman scattering active gold nanoparticles with enzyme-mimicking activities for measuring glucose and lactate in living tissues. ACS Nano. 2017;11:5558–66.

Hwang JY, Kim HS, Kim JH, Shin US, Lee SH. Carbon nanotube nanocomposites with highly enhanced strength and conductivity for flexible electric circuits. Langmuir. 2015;31:7844–51.

Iijima S. Helical microtublules of graphitic carbon. Nature. 1991;354:56–8.

Jacobs CB, Peairs MJ, Venton BJ. Review: Carbon nanotube based electrochemical sensors for biomolecules. Anal Chim Acta. 2010;662:105–27.

Kul D, Ghica ME, Pauliukaite R, Brett CM. A novel amperometric sensor for ascorbic acid based on poly(Nile blue A) and functionalised multi-walled carbon nanotube modified electrodes. Talanta. 2013;111:76–84.

Lee J, Lim M, Yoon J, Kim MS, Choi B, Kim DM, Kim DH, Park I, Choi SJ. Transparent, flexible strain sensor based on a solution-processed carbon nanotube network. ACS Appl Mater Interfaces. 2017;9:26279–85.

Li J, Lee EC. Functionalized multi-wall carbon nanotubes as an efficient additive for electrochemical DNA sensor. Sens Actuators B Chem. 2017;239:652–9.

Liu L, Ma W, Zhang Z. Macroscopic carbon nanotube assemblies: preparation, properties, and potential applications. Small. 2011;7:1504–20.

Liu JW, Luo Y, Wang YM, Duan LY, Jiang JH, Yu RQ. Graphitic carbon nitride nanosheets-based ratiometric fluorescent probe for highly sensitive detection of H2O2 and glucose. ACS Appl Mater Interfaces. 2016;8:33439–45.

Mathur A, Roy SS, Hazra KS, Wadhwa S, Ray SC, Mitra SK, Misra DS, McLaughlin JA. Oxygen plasma assisted end-opening and field emission enhancement in vertically aligned multiwall carbon nanotubes. Mater Chem Phys. 2012;134:425–9.

Park JS, Choi JS, Han DK. Platinum nanozyme-hydrogel composite (PtNZHG)-impregnated cascade sensing system for one-step glucose detection in serum, urine, and saliva. Sens Actuators B Chem. 2022;359:131585.

Park S, Vosguerichian M, Bao Z. A review of fabrication and applications of carbon nanotube film-based flexible electronics. Nanoscale. 2014;5:1727–52.

Park OK, Kim WY, Kim SM, You NH, Jeong Y, Lee HS, Ku BC. Effect of oxygen plasma treatment on the mechanical properties of carbon nanotube fibers. Mater Lett. 2015;156:17–20.

Paul RK, Badhulika S, Saucedo NM, Mulchandani A. Graphene nanomesh as highly sensitive chemiresistor gas sensor. Anal Chem. 2012;84:8171–8.

Powell HM, Lannutti JJ. Nanofibrillar surfaces via reactive ion etching. Langmuir. 2003;19:9071–8.

Savk A, Özdil B, Demirkan B, Nas MS, Calimli MH, Alma MH, Asiri AM, Şen F. Multiwalled carbon nanotube-based nanosensor for ultrasensitive detection of uric acid, dopamine, and ascorbic acid. Mater Sci Eng C. 2019;1(99):248–54.

Schroeder V, Savagatrup S, He M, Lin S, Swager TM. Carbon nanotube chemical sensors. Chem Rev. 2019;119:599–663.

Shi J, Claussen JC, McLamore ES, Haque A, Jaroch D, Diggs AR, Calvo-Marzal P, Rickus JL, Porterfield DM. A comparative study of enzyme immobilization strategies for multi-walled carbon nanotube glucose biosensors. Nanotechnol. 2011;22: 355502.

Shrestha S, Mascarenhas RJ, D’Souza OJ, Satpati AK, Mekhalif Z, Dhason A, Martis P. Amperometric sensor based on multi-walled carbon nanotube and poly (Bromocresol purple) modified carbon paste electrode for the sensitive determination of L-tyrosine in food and biological samples. J Electroanal Chem. 2016;778:32–40.

Su Y, Pei S, Du J, Liu WB, Liu C, Cheng HM. Patterning flexible single-walled carbon nanotube thin films by an ozone gas exposure method. Carbon. 2013;53:4–10.

Sun X, James TD. Glucose sensing in supramolecular chemistry. Chem Rev. 2015;115:8001–37.

Vashist SK, Zheng D, Al-Rubeaan K, Luong JHT, Sheu FS. Advances in carbon nanotube based electrochemical sensors for bioanalytical applications. Biotechnol Adv. 2011;29:169–88.

Wang J. Electrochemical glucose biosensors. Chem Rev. 2008;108:814–25.

Wang C, Li SJ, Wu ZQ, Xu JJ, Chen HY, Xia XH. Study on the kinetics of homogeneous enzyme reactions in a micro/nanofluidics device. Lab Chip. 2010;10:639–46.

Wang X, Lu X, Liu B, Chen D, Tong Y, Shen G. Flexible energy-storage devices: design consideration and recent progress. Adv Mater. 2014;26:4763–82.

WHO, Diabetes. https://www.who.int/health-topics/diabetes#tab=tab_1, 2022 (accessed 26 August 2022).

Wu Z, Chen Z, Du X, Logan JM, Sippel J, Nikolou M, Kamaras K, Reynolds JR, Tanner D, Hebard AF, Rinzler AG. Transparent, conductive carbon nanotube films. Science. 2004;305:1273–6.

Xu W, Jiao L, Yan H, Wu Y, Chen L, Gu W, Du D, Lin Y, Zhu C. Glucose oxidase-integrated metal-organic framework hybrids as biomimetic cascade nanozymes for ultrasensitive glucose biosensing. ACS Appl Mater Interfaces. 2019;11:22096–101.

Yang H, Zhu Y, Chen D, Li C, Chen S, Ge Z. Electrochemical biosensing platforms using poly-cyclodextrin and carbon nanotube composite. Biosens Bioelectron. 2010;26:295–8.

Zhang Y, Wang J, Xu M. A sensitive DNA biosensor fabricated with gold nanoparticles/ploy (p-aminobenzoic acid)/carbon nanotubes modified electrode. Colloids Surf B: Biointerfaces. 2010;75(1):179–85.

Acknowledgements

Not applicable.

Funding

This research was supported by a grant from the Korea Basic Science Institute (C380300 and C330110). This research was also supported by the Basic Science Research Program through the National Research Foundation (NRF) of Korea (2018R1A6A1A03024231 and 2021R1A2C1003566). This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (2019R1A6A1A03032988).

Author information

Authors and Affiliations

Contributions

DKH, CAL, and GHS contributed to the conceptualization and methodology of the study. DKH and CAL performed the investigation, validation, and data analysis. DKH wrote the original draft. SES assisted in the investigation and data analysis. SHS, KC, JSC, and GHS contributed to the data interpretation and writing—review and editing. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

There are no competing interests to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1: Fig S1.

Microscope images of GOx/FCA/PEG-modified SWCNT electrode. Fig S2. SEM images of SWCNT patterns on PET plastic substrate treated by O2 plasma etching. Table S1. Comparison of analytical performances with other reported methods.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Han, D.K., Li, C.A., Song, S.H. et al. Electroanalytical biosensor based on GOx/FCA/PEG-modified SWCNT electrode for determination of glucose. J Anal Sci Technol 14, 9 (2023). https://doi.org/10.1186/s40543-023-00371-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40543-023-00371-8