Abstract

Background

Teneligliptin is a new FDA approved drug for treating Diabetes Mellitus. There are no reported evidences for its degradation products during stability studies and their effects on humans.

Methods

A simple and new stability indicating RP-HPLC method was developed and validated for identification of Teneligliptin and its degradants on Kromasil 100- 5C18 (250 × 4.6 mm, 5 μm) column using pH 6.0 phosphate buffer and acetonitrile (60:40 v/v) as a mobile phase in isocratic mode of elution at a flow rate of 1.0 mL/min. The column effluents were monitored by a variable wavelength UV detector at 246 nm. The method was validated as per ICH guidelines. Forced degradation studies of Teneligliptin were carried out under acidic, basic, neutral (peroxide), photo and thermal conditions for 48 hours at room temperature. The degradation products were identified by HPLC and characterized by UPLC with tandem mass spectroscopy (LC/MS/MS).

Results

UPLC MS/MS data shown major peaks, observed at 375.72, 354.30, 310.30, 214.19, 155.65, 138.08 and 136.18 m/z. Their structural elucidation was depicted.

Conclusion

Degradation was observed in base, peroxide and thermal stressed samples, but not in acid and photolytic stressed samples.

Similar content being viewed by others

Background

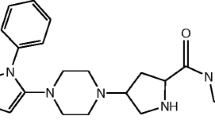

Teneligliptin is a novel drug, which is used for the treatment of type 2 diabetes mellitus. It is an anti-diabetic drug that belongs to dipeptidyl peptidase-4 inhibitors or “gliptins” (Kishimoto 2013). Chemically, it is {(2S, 4S)-4-[4-(3-Methyl-1-phenyl-1H-pyrazol-5-yl)-1-piperazinyl]-2-pyrrolidinyl} (1, 3-thiazolidin-3-yl) methanone (Fig. 1). Teneligliptin exerts its activity for 24 h, with elevation of activated glucagon-like peptide 1 (GLP-1) levels by suppressing postprandial hyperglycemia after the meals (Goda and Kadowaki 2013; Ideta et al. 2015; Bronson et al. 2013). Significant decrease in hemoglobin A1c (HbA1c), fasting blood glucose, and postprandial blood glucose levels was observed in type 2 diabetic patients taking teneligliptin for 12 weeks (Goda and Kadowaki 2013). This drug showed promising effect in stabilizing the glycemic fluctuations throughout the day and suppressing the diabetic complications (Ideta et al. 2015). Teneligliptin is approved for use in India, Japan, and Korea in 2012 (Bronson et al. 2013). Although the drug entered the market, there is no much information available about its degradation studies and its degraded products. Few have reported its metabolism and pharmacokinetic studies (Halabi et al. 2013; Reddy et al. 2014; Luhar et al. 2016; Shanthikumar et al. 2015). Identification of the degraded products helps in future metabolic studies and also related impurity determination during its bulk synthesis. In the present study, we have focused our research into two stages: (1) To develop and validate a RPHPLC method for identifying teneligliptin and its degradation products formed during various forced conditions as per the ICH guidelines (Asian Guideline for Validation of Analytical Procedure Adopted from ICH guideline and Q2A27, ICH Q2B 1994) and (2) Identification of the degraded products obtained and their characterization using UPLC with tandem mass spectroscopy (LC/MS/MS).

Experimental

Materials and Methods

HPLC grade acetonitrile (Lichrosolv®, Merck life sciences, Pvt. Ltd, Mumbai, India), HPLC water (Lichrosolv®, Merck life sciences, Pvt. Ltd. Mumbai, India), formic acid, potassium dihydrogen o-phosphate (Thermo fisher scientific Pvt. Ltd. Mumbai, India), and sodium hydroxide (S D Fine-chem. Ltd. Mumbai, India) were used for the study and filtered through 0.45-μm-pore-size membrane filters (Millipore, Mumbai, India). Teneligliptin pure drug and its tablet formulation were obtained from Ajanta Pharma Limited, Mumbai, India.

Apparatus

The HPLC system (Agilent technologies, compact LC-G4286A made in Germany) with variable wavelength UV-detector was used. Reversed phase Kromasil® 100-5C18 (250 × 4.6 mm, 5 μm particle size) column was used for chromatographic separation. The chromatographic and integrated data were recorded using EZchrom Elite Compact Software in computed system (Version: 3.30B, Sr. no 08051601100, Scientific Software. Inc.). For the LCMS studies, UPLC system consisting of gradient mode pump with column Acquity UPLC@ BEH C18 (1.7 μm, 2.1 × 50 mm) detected using photodiode array (PDA) detector range 200–400 nm was used. The mass spectrum with ESI mode of ionization was used for the study (LC/MS/MS (Waters, XEVO-TQD).

Chromatographic conditions

Chromatographic separation was achieved on Kromasil® 100-5C18 using a mobile phase consisting mixture of pH 6.0 phosphate buffer and acetonitrile (60:40 v/v) under isocratic mode of elution. The mobile phase was prepared and filtered through membrane filters (0.45 μm) and sonicated for 30 min prior to use. Separation was performed using 1 mL/min flow rate at room temperature, and the run time was 25 min. The injection volume was 20 μL and the detection wavelength set at 246 nm.

LC/MS conditions

Chromatographic separation was achieved on Acquity UPLC@ BEH C18 1.7 μm, 2.1 × 50 mm using the gradient mobile phase consisting of A (10% acetonitrile in water with 0.1% formic acid) and B (90% acetonitrile with 0.1% formic acid). A flow rate of 0.3 mL/min is maintained for the study. The eluted components were detected using PDA at range of 200–400 nm. The products were ionized by ESI mode for their mass data.

Sample preparation

One thousand microgram per milliliter solution of teneligliptin was prepared by dissolving required amount of drug in methanol. The solution was adequately diluted with methanol for accuracy, precision, linearity, limit of detection, and quantification studies.

Stability sample preparation

The collected samples of acid and base hydrolysis were neutralized with sodium hydroxide and hydrochloric acid, respectively. Further dilution was carried out with methanol and the remaining stressed samples also diluted with methanol. All the samples were filtered before analysis.

Degradation studies

Acid degradation

Teneligliptin was subjected to forced degradation by acid hydrolysis using 0.1N HCl maintained at 35 °C for 48 h. The sample after the stress was neutralized with sodium hydroxide and diluted with methanol and filtered through 0.45-μm membrane before its analysis.

Base degradation

Teneligliptin was subjected to forced degradation by base hydrolysis using 0.1N NaOH maintained at 35 °C for 48 h. The sample after the stress was neutralized with hydrochloric acid and diluted with methanol and filtered through 0.45-μm membrane before its analysis.

Hydrogen peroxide (neutral) degradation

Forced degradation of teneligliptin was studied under the influence of (3%) hydrogen peroxide maintained at 35 °C for 48 h. The stressed sample was diluted with methanol and filtered through 0.45-μm membrane before its analysis.

Photolytic degradation

The influence of UV light on the stability of teneligliptin was studied by exposing the sample in UV light at 365 nm for 48 h. The stressed sample was diluted with methanol and filtered through 0.45-μm membrane before its analysis.

Thermolysis degradation

The effect of increased temperature on teneligliptin was studied by heating the sample at 69 °C for 48 h in refluxing apparatus. The stressed sample was diluted with methanol and filtered through 0.45-μm membrane before its analysis.

Validation

System suitability

The system suitability was determined by six injections of teneligliptin (300 μg/mL). The developed method was found to be suitable for use as the tailing factor and peak resolution for teneligliptin were within the limits.

Linearity

The linearity of teneligliptin was studied from the standard concentrations ranging from 100–500 μg/mL. The calibration curve of peak intensity versus concentration was plotted, and correlation coefficient and regression line equation were determined.

Precision

The precision of the method was determined by six (n = 6) injections of teneligliptin (300 μg/mL), and the % RSD of peak areas were calculated. The obtained RSD was within the range (≤2). Both intraday and interday precision were determined.

Accuracy

The recovery of the method was determined by adding known amount of drug to the standard concentration. The recovery was performed at three levels 80, 100, and 120% of teneligliptin standard concentration. The three samples were prepared for each recovery level and % recoveries were calculated.

Limits of detection (LOD) and limit of quantification (LOQ)

The LOD and LOQ are the lowest level and lowest concentration of the analyte respectively in a sample that would yield signal-to-noise ratios of 3.3 for LOD and 10 for LOQ. These are determined from the standard deviation of the peak response and the slope of the calibration curve.

Robustness and ruggedness

The robustness of developed method is identified by taking the drug sample and analyzing at lower and upper wavelengths and flow rates than actual by changing the conditions in method and calculated the % RSD.

The ruggedness of the method is identified by changing the analyst and performing the analysis with the developed method and calculated the % RSD.

Results

Method development and optimization of chromatographic conditions

Initially, 50:50%v/v of methanol and water was tried on Kromasil® 100-5C18 as mobile phase at 1 mL/min flow rate and we observed that the peak was not eluted in this mobile phase. Then, 50:50%v/v pH 7.4 phosphate buffer (basic) and acetonitrile was tried as mobile phase on same column at 1 mL/min flow rate. The peak was eluted with poor resolution and low intensity for high concentration (1000 μg/mL) of drug. Then, 50:50%v/v pH 6 phosphate buffer (acidic) and acetonitrile was tried as mobile phase on Kromasil® 100-5C18, grater intensity and peak broadening were observed. Then for better resolution, 60:40%v/v pH 6 phosphate buffer and acetonitrile was modified as mobile phase at 1 mL/min flow rate. Sharp peak, good intensity, and good retention time were observed in isocratic mode of elution. The system suitability was performed, and the results were found to be within the limits (Table 1). Linearity with 0.99 regression coefficient was observed at the concentration range of 100–500 μg/mL, and residual sum of squares were tabulated in Table 2. As per the ICH guidelines, minimum of 5-point calibration and any term which implies the concentration is sufficient for linearity, hence 5-point linearity and the peak height were studied. The method was validated for the parameters, precision (intraday and interday), accuracy, LOD and LOQ, and robustness and ruggedness as per the guidelines and tabulated the results in Tables 3, 4, 5, and 6, respectively. The results of validation were within the limits.

Stability studies

Teneligliptin was stressed under different conditions, and the samples were subjected to HPLC separation. Significant degradation product peaks were observed in basic, neutral (hydrogen peroxide), and thermolysis conditions. The stability studies were performed for 48 h. After the time of study, the samples were neutralized except for thermal-, UV-, and peroxide-treated samples and diluted with methanol. The samples were filtered through 0.45-μm Millipore membrane filters. Teneligliptin was found to be stable under acidic and photolysis conditions. The chromatograms of pure drug and its stressed samples were shown in Figs. 2 and 3. The peak intensities and retention times of degraded product peaks during stress conditions were tabulated in Table 7. The percentage degradation of teneligliptin in various stress conditions were tabulated in Table 8. The UPLC data was depicted in Figs. 4, 5, and 6 for base-, hydrogen peroxide-, and thermally stressed samples, respectively. The respective mass spectra were shown in Figs. 7, 8, and 9. From the mass spectral data, the fragmentation pattern of teneligliptin was depicted. The fragmentation patterns of base-, peroxide-, and thermal-stressed teneligliptin were depicted in Figs. 10, 11, and 12, respectively.

UPLC/MS conditions

Chromatographic isolation is acquired using Acquity column UPLC @ BEH C18 1.7 μm, 2.1 × 50 mm. The mobile phase in gradient fashion consisting of A (10% acetonitrile in water with 0.1% formic acid) and B (90% acetonitrile with 0.1% formic acid) was used for the liquid chromatography. The temperature of the system was kept constant at 25 °C. Uniform flow rate of 0.3 mL/min is used. The eluted components were detected using photodiode array at range of 200–400 nm. The products were ionized by electrospray ionization mode for their mass data.

Characterization of degradation products

The molecular ion peak for teneligliptin was observed at 427.22 in ESI mode. In base-stressed sample, the major intense fragments with M+ of 354.30 at a retention time of 1.195 min, 310.30 and 214.19 at a retention time of 1.345 min, and 178.73 and 155.65 at a retention time of 1.205 min were observed. In peroxide-stressed sample, the fragments with M+ of 138.08 and 136.18 were observed at a retention time of 1.666 and 1.467 min, respectively. In thermal-stressed sample, the fragments with M+ of 375.72 at a retention time of 0.455 min and fragments 214.20, 310.31, and 155.69 at a retention time of 1.325 min were observed. There is no degradation peaks for teneligliptin in acid- and UV-stressed conditions. The scan mode is PDA with both positive (E+) and negative (E−) scans at total ion current (TIC) chromatogram. Both the scans were compared with diode array spectra.

Discussion

Teneligliptin is an antidiabetic drug recently approved by FDA. There are no reports available for the stability of the drug and their possible degraded products till date. In the present research work, we aimed to perform stability studies on teneligliptin and develop and validate a method for its estimation and identification by RPHPLC. A new RPHPLC method was developed and validated for teneligliptin as per the ICH guidelines and used as a stability indicating method. The linearity range for teneligliptin drug was found to be 100–500 μg/mL. The intraday and interday precision for the developed method was found to be 0.807 and 0.810 respectively and are within the limits. The LOD and LOQ for teneligliptin were found to be 4.04 and 12.25 μg/mL respectively for the developed method. The robustness and ruggedness were found to be 1.000 ± 0.200 and 0.9 ± 0.04 respectively and are within the limits. Teneligliptin pure drug was used for the study and stressed under acid, base, neutral (hydrogen peroxide), UV photolysis, and thermal conditions. The base-stressed sample has shown an extra peak other than drug peak at retention time of 2.966 with an intensity of 312.12 mAV. The oxidative-stress sample has shown two extra degraded peaks at retention time of 2.519 and 2.979 with an intensity of 846.61 and 87.45 mAV, respectively. The thermal-stressed samples have shown a very small degraded peak with a retention time of 3.033 having intensity of 46.65 mAV. The HPLC analysis of stressed samples have shown that no degradation has occurred under the influence of acid and UV light. But the stressed samples under base, peroxide, and thermal have presence of degraded products, which observed as separate peaks in HPLC other than teneligliptin. From the AUC, it is observed that the highest percentage of degradation was observed in oxidative stress followed by base stress and thermal. Although no prominent peaks were observed in the acid and photolytic stress samples, the percentage degradation was limited to 9.18% and 2.61%, respectively. The obtained degraded samples were further analyzed by UPLCMS/MS, to identify the products formed. It is observed that a change in retention times and mass analysis in LCMS is due to the time lag between the sample elution from LC and undergoing ionization in MS. The major molecular ion fragments formed for all the three stress conditions are different except 310.30 ((4-(4-(1-aminovinyl) piperazin-1yl) pyrrolidin-2-yl) (thiazolidin-3-yl) methanone), 214.19 (N,N-diethyl-1-phenyl-1H-pyrazol-5-amine), and 155.65 (1-(pyrrolidin-3-yl) piperazine) were observed in both base and thermal stress conditions. A characteristic of 354.30 (4-(4-(1ethyl-3-methyl-1H-pyrazol-5-yl)piperazin-1-yl)-N-(mercaptomethyl)-N-methylpyrrolidine-2-carboxamide) and 375.72 ((4-(4-(3-methyl-1-vinyl-1H-pyrazol-5-yl)piperazin-1-yl)pyrrolidin-2-yl) (thiazolidin-3-yl)methanone) molecular ion peaks was observed in base condition and thermal condition, respectively. The products formed with photolytic stress were completely different with molecular ions at 138.08 (N,N-diethyl-1H-pyrazol-5-amine) and 136.18 (2-aminoN-(mercaptomethyl)-N-methylacetamide) which are not observed in other stress conditions. From the data, it is observed that comparatively less degradation occurred for photolysis stress than for base and thermal stress. The fragmentation pattern shows that the degraded products are similar for the base and thermal stress samples. Further study is required for determining the degraded products toxicity by quantifying the samples.

Conclusions

The present study helps in identifying the degraded products of teneligliptin in bulk and formulations, during their storage and transport conditions. This research work is the first to report its stability studies with degraded product identification, which is helpful for determining the toxicity of degraded products and also to caution the storage conditions. The products formed could also be the starting materials during its synthesis, which has to be studied. Further study is required for establishing the toxicity profile of degraded products, which is under process.

References

Asian Guideline for Validation of Analytical Procedure Adopted from ICH guideline, Q2A27, and ICH Q2B. 1994.

Bronson J, Black A, Murali Dhar TG, Ellsworth BA, Robert Merritt J. Teneligliptin (antidiabetic), chapter: to market, to market—2012. Annu Rep Med Chem. 2013;48:523–4.

Goda M, Kadowaki T. Teneligliptin for the treatment of type 2 diabetes. Drug today (Barc). 2013;49:615–29.

Halabi A, Maatouk H, Siegler KE, Faisst N, Lufft V, Klause N. Pharmacokinetics of teneligliptin in subjects with renal impairment. Clin Pharmacol Drug Development. 2013;2:246–54.

Ideta T, Shirakami Y, Miyazaki T, Kochi T, Sakai H, Moriwaki H, Shimizu M. The dipeptidyl peptidase-4 inhibitor teneligliptin attenuates hepatic lipogenesis via AMPK activation in non-alcoholic fatty liver disease model mice. Int J Mol Sci. 2015;16:29207–18.

Kishimoto M. Teneligliptin: a DPP-4 inhibitor for the treatment of type-2 diabetes. Diabetes Metab Syndr Obes: targets and therapy. 2013;6:187–95.

Luhar SV, Pandya KR, Jani GK, Sachin B, Narkhed S. Simultaneous estimation of teneligliptin hydrobromide hydrate and its degradation product by RPHPLC method. J Pharm Sci Bioscientific Res. 2016;6:254–61.

Reddy BR, Rao NV, Saraswathi K. Stability indicating RP-HPLC method for development and validation of teneligliptin hydrobromide hydrate in pure and tablet dosage forms. IJPROnline. 2014.

Shanthikumar S, Sateeshkumar N, Srinivas R. Pharmacokinetic and protein binding profile of peptidomimetic DPP-4 inhibitor—teneligliptin in rats using liquid chromatography–tandem mass spectrometry. J Chromatogra B. 2015;1002:194–200.

Acknowledgements

The authors are thankful to Chebrolu Hanumaiah Institute of Pharmaceutical Sciences, Guntur, and CSIR-Indian Institute Integrative Medicine, Mumbai, for providing the facilities and timely support for carrying out this research work.

Authors’ contributions

TNVGK contributed to the main idea and implementation of the work by selecting the drug, performing the wet lab study, analyzing the degradation products, and interpreting the results from LCMS/MS data. SV helped in analyzing the results of RPHPLC method development and validation. NAN performed the LCMS study of the samples and helped in the UPLC method development. YSS performed the wet lab study of hydrogen peroxide stress and thermal stress work for the drug sample and helped in adjusting the pH of mobile phase during the HPLC study. MRL performed the wet lab study of collecting the dilutions of the sample after stress conditions for the drug sample and helped in the mobile phase preparation during the HPLC study. All authors read and approved the final manuscript.

Competing interests

The authors declare that they have no competing interests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kumar, T.N.V.G., Vidyadhara, S., Narkhede, N.A. et al. Method development, validation, and stability studies of teneligliptin by RP-HPLC and identification of degradation products by UPLC tandem mass spectroscopy. J Anal Sci Technol 7, 27 (2016). https://doi.org/10.1186/s40543-016-0107-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40543-016-0107-4