Abstract

Background

Duke cherry is a non-climacteric fruit but deteriorates quickly during storage due to thin pericarp and succulent fruit tissue. The application of edible coatings, essential oils, or their combination is an appropriate technique to maintain the quality characteristics and reduce the deterioration of fruits during storage. This research assessed the effect of Aloe vera gel (AVG), thymol, and their combined use on the physicochemical and qualitative properties of duke cherries kept at 5 °C and 80% relative humidity for 28 d.

Results

Compared to the uncoated fruits, duke cherries coated with a combination of AVG and thymol, showed more values of firmness (12.76–100.32%), total phenol (9.99–45.09%), antioxidant activity (7.90–84.56%), and sensory scores(50.15–100.00%), as well as the activity of guaiacol peroxidase (GPX) (12.03–185.11%) and catalase (CAT) (10.20–243.66%) enzymes during cold storage. Moreover, duke cherries coated with a combination of AVG and thymol had remarkably lower values of weight loss (32.57–42.67%), respiration rate (34.96–49.78%), stem browning (24.50–50.53%), spoilage percentage (84.55–100%), anthocyanin (14.21–23.16%), and total soluble solids/titratable acidity (TSS/TA) (35.64–50.15%), as well as hydrogen peroxide (H2O2) (16.66–32.35%) and malondialdehyde (MDA) (15.23–31.05%).

Conclusion

The application of AVG and thymol, particularly their combination, can have a high practical potential to extend shelf-life and preserve the quality of duke cherries during cold storage. This treatment has various advantages including natural, edible, cost-effective, and efficient.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

Sweet and sour cherry, the two main species of cherries, originated from Iran, Iraq, and Syria [1]. Duke cherry (P. × gondouinii Rehd.) is a natural hybrid between sweet and sour cherries and has trees and fruits that are intermediate between these two cherry species [2]. Duke cherry, as a popular fruit, is commercially important in temperate zones; and recent awareness of its health benefits has helped increase consumption [3]. Duke cherry has been widely cultivated in Iran, the most important duke cherry-producing countries are Turkey, Russia, Ukraine, Poland, and Iran [4].

Sweet and sour cherry are non-climacteric fruits; however, they deteriorate quickly during storage due to thin pericarp and succulent tissue that is greatly susceptible to weight loss, softening, surface pitting, color changes, and loss of acidity [5, 6]. According to Benichou et al. [7], approximately one-third of fresh fruits are lost before they reach the consumer. The shelf life of cherries is 7–10 d under ambient and 14–21 d under storage at − 1 to 0 °C with RH in the range of 90 to 95% [8, 9]. A main approach to increase the storage life and maintain the quality of fresh fruits is the use of synthetic chemicals. However, in most countries, the use of post-harvest chemicals to extend the storage life of fruits is restricted. Another effective method to extend the storage life of fruits is storage at low temperatures, although this approach is not sufficient to maintain fruit quality during the postharvest period [10]. Thus, alternative, safe, and cost-effective strategies, combined with low temperatures are needed.

The use of edible coatings is accepted as a very suitable option for extending the storage life of fruits [11]. Natural coatings are composed of waxes, carbohydrates, proteins, and their composites, which create a semi-permeable coating on fruits [12]. Among edible coatings, Aloe vera gel has been widely applied to preserve the quality characteristics and prolong the storage life of several fresh fruits, including strawberry [12], apple [13], cornelian cherry [14], cherry laurel [15], jujube [16], plums [17], sapodilla [18], and apricots [19]. Aloe vera coating is an effective barrier against moisture and gas, which reduces weight loss, color changes, softening of tissues, oxidative browning, the proliferation of microorganisms, respiration rate, and production of ethylene in fruits [12, 20]. Furthermore, it is odorless, invisible, edible, safe for human health, and eco-friendly [21]. However, Aloe vera gel has low barrier efficacy due to its low lipid content [22]. It is possible to enhance the barrier efficacy of Aloe vera gel by adding lipids such as essential oils to the coating [12, 23]. Thymol is one of the most important essential oils of thyme (Thymus vulgaris L. thymoliferum) and is well known for its antimicrobial, and antioxidant properties. Furthermore, plant essential oils have shown the excessive potential to prolong the storage life of several fruits [24]. However, the use of essential oils to extend the shelf-life of fruits is often limited by their application costs and other disadvantages, such as pungent aroma and potential toxicity. An alternative to decrease the dose of essential oils while retaining their efficiency can be their combination in the formulation of edible coatings [24].

There are reports concerning the effect of edible coating and essential oils on the storage life of sweet and sour cherries [5, 25, 26]. In addition, a mixture of AVG and essential oils is widely studied as edible coatings for various fruits [12, 17]. However, as far as we know, no work has been reported on the effect of Aloe vera gel and thymol on the storage life of ‘Majari’ duke cherries during cold storage. Thus, the main purpose of the present research was to evaluate the effects of Aloe vera gel, thymol, and their combined use on quality characteristics, storage life extension, physicochemical characteristics, antioxidant enzyme activity as well as H2O2, and MDA levels of ‘Majari’ duke cherries during 28 d of storage at 5 °C and 80% relative humidity. ‘Majari’ is the most important commercial variety in Lorestan province with high performance and quality.

Materials and methods

Plant material and treatments

Duke cherries cv. ‘Majari’ were picked at the commercial maturation time (25 July 2021) from a commercial 6-year-old orchard at Borujerd, Lorestan province, Iran. The trees were grafted on ‘Mazzard’ rootstocks. On the same day of harvesting, the fruit was transferred by a refrigerated vehicle (3–6 °C and 80% relative humidity) to the postharvest laboratory at Arak University. Duke cherries with similar size, shape, color, and healthy green stems were selected; whereas those with visible defects (bruised, diseased, injured, and sunburned fruits) were thrown away. The healthy fruits were divided into four groups of 300 fruits for the subsequent treatments in three replicates (each replicate included 100 individual fruits).

The treatments included three types of solutions: 33% AVG (v/v)., 200 mg L−1 thymol (Sigma Chemical Co., St. Louis, MO, USA, Minimum 99.5%), and 33% AVG + 200 mg L−1 thymol. The mixture of AVG and thymol was prepared by dissolving thymol in water, with the use of Tween-80, followed by the addition of AVG under vigorous shaking. The concentrations of AVG and thymol were chosen based on the preliminary experiments done in the laboratory. Duke cherries were dipped for 2 min in the prepared solutions. Fruits immersed in distilled water were considered as controls. All samples were air-dried for 60 min before packaging in polyethylene terephthalate and kept at 5 °C and 80% relative humidity in permanent darkness for 28 d. On days 0, 7, 14, 21, and 28, five fruit from each replicate were analyzed for all parameters.

After washing the Aloe vera leaves with distilled water, the colorless gel of the middle parts of the leaves was removed and mixed in a blender. Finally, the resulting mixture was filtered to remove the fibers.

Weight loss

The weight loss of fruits was concluded using the equation [(A‒B)/A] × 100, where A was the weight of fruits following treatment (day 0), and B was the weight of fruits at 7-day intervals (days 7, 14, 21, and 28) during storage [24].

Respiration rate

Three fruit were placed in a 1-L gas tight plastic for 2 h. Afterward, 1 ml gas samples were removed from the main space with a syringe to determine CO2 using a gas chromatograph (model: Agilent 7890A). The column, detector, and injector temperatures were 90, 100, and 120 °C, respectively. Helium was used as a carrier gas with a flow rate of 60 mL min−1. The respiration rate was stated as mg CO2 kg−1 h−1 [27].

Stem browning

The percentage of stem browning was calculated using the equation [(A‒B)/A] × 100, where A was fruits with visible symptoms of stem browning and B was the total number of fruits [26].

Spoilage percentage

The spoilage percentage was calculated using the equation [(A‒B)/A] × 100, where A was fruits with spoilage and B was the total number of fruits [27].

Firmness

A penetrometer (STEP SYSTEM, Germany) was used to measure the firmness of duke cherries. A plunger tip with an 8 mm diameter and 21 mm height was used to measure the fruit's firmness. Results were stated as kg cm−2 [27].

Total soluble solids (TSS) and titratable acidity (TA)

Using a digital refractometer (Atago, PAL-1, Japan) TSS concentration of duke cherries was measured, and results were stated as % (°Brix). A pH meter (Az 86502, Taiwan) was used to measure the pH of fruit juice. Afterward, TA was specified by titration with 0.1 N NaOH up to pH of 8.1, using 1 mL of diluted juice in 25 mL distilled water, and the results were stated as % malic acid. TSS/TA was calculated by dividing TSS by TA percent [27].

Anthocyanin

The total anthocyanin content in the juice of duke cherries was determined according to the pH differential method as reported by Kim et al. [28]. Absorbance was measured using a spectrophotometer (Cary Win UV 100; Varian, Sydney, Australia) at 520 and 700 nm and readings expressed as mg cyanidin-3-glycoside equivalent (CGE) per 100 g of fresh weight (FW).

Total phenol

The total phenolic content in the juice of duke cherries was obtained using the Folin–Ciocalteau method according to the approach presented by Singleton et al. [29]. Absorbance was determined using a spectrophotometer (Cary Win UV 100; Varian, Sydney, Australia) at 765 nm, and total phenolic contents were calculated by applying a calibration curve drawn for the gallic acid standard solution and exhibited as mg gallic acid equivalent (GAE) per 100 g of fresh weight (FW).

Total antioxidant activity

Antioxidant activity in the juice of duke cherries was obtained based on the radical scavenging ability in reacting with DPPH (2,2-diphenyl-1- picrylhydrazyl) according to the approach presented by Brand-Williams et al. [30] with some modifications. Briefly, 100 μL of the methanol extract was mixed adequately with a 1900 μL DPPH (Sigma Aldrich, USA) solution. After 30 min, the absorbance was read against a blank (methanol) at 517 nm using a spectrophotometer (Cary Win UV 100, Varian, Australia). Total antioxidant activity as inhibition percentage of free radical DPPH was calculated by the subsequent equation:

Hydrogen peroxide (H2O2)

The H2O2 concentration of duke cherries was measured according to the approach presented by Irani et al. [31] method. H2O2 concentration was exhibited as μmol g−1 FW.

Malondialdehyde (MDA)

According to the method recommended by Heath and Packer [32], lipid peroxidation of the membrane was determined. Lipid peroxidation was measured in terms of MDA concentration and exhibited as μmol g−1 FW.

GPX and CAT activity

Briefly, 0.5 g of duke cherries was powder powdered in a mortar with liquid nitrogen. Afterward, 100 mg of the frozen fruit powder was homogenized in 1.0 mL of sodium phosphate buffer (0.5 M, pH 7.8), containing 1 mM EDTA and PVP-40 (2% w/v). Samples were centrifuged at 12,000 ×g for 20 min at 4 °C, and the supernatant was used to determine the activity of GPX and CAT enzymes.

Following the oxidation of guaiacol by H2O2, GPX activity was measured at 470 nm [33]. By measuring the absorption drop of H2O2, the activity of CAT was determined at 240 nm [34]. The readings were shown as a unit of mg−1 protein.

Sensory attributes evaluation

Throughout the post-harvest period, evaluation of kept duke cherries was done by five experts on a hedonic scale ranging from 0 to 5, where 1 = very bad, 2 = bad, 3 = medium, 4 = suitable, and 5 = excellent. Color, taste, appearance, and overall acceptability were evaluated by consumers, and average values were considered [27].

Storage life

The storage life was determined by recording the days that duke cherries remained in good condition without spoilage and deterioration. The end of storage life was when the deterioration of fruits exceeded 50% [24].

Statistical analysis

This experiment was carried out as a factorial in a completely randomized design (CRD) with two factors: the first factor was the storage period (0, 7, 14, 21, and 28 d) and the second factor was the edible coating (AVG, thymol, and their combination). Data were analyzed using the GLM procedure of SAS software (Version 9.1). Significant differences were evaluated at P ≤ 0.05 using Duncan’s multiple ranges. All the treatments were replicated three times.

Results and discussion

For all measured parameters, significant interactions were observed between storage time and edible coating; hence only mean comparisons related to interactions are shown.

Weight loss

Throughout cold storage, the weight loss of duke cherries increased for all treatments; however, coated fruits had lower weight loss than controls (Table 1). The effect of AVG + thymol was significantly greater than sole AVG or thymol coating. After 7, 14, 21, and 28 d of storage, duke cherries treated with AVG + thymol had 40.10%, 42.67%, 32.57%, and 36.28% lower weight loss than nontreated fruits, respectively (Table 1).

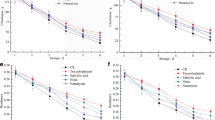

Cherries lose a lot of water during the storage period due to their low skin diffusion resistance and high surface-to-volume ratio [9, 35]. Water losses due to transpiration and respiration processes are the main reasons for weight loss in fruits [36]. Edible coatings create a transparent film around the fruit and seal small wounds; therefore, a decrease in weight loss of coated fruits during the storage period can be related to the effects of coatings on the reduction of transpiration and respiration rate, as recognized in this study (Fig. 1). Delaying in weight loss of fruits with the application of AVG and essential oils have been reported for tomatoes [11], strawberries [12], and apricots [19], which is consistent with the results of the present work.

Respiration rate

Respiration rate is a good index of metabolic activity and can be used for evaluating the storage life of fruits [27]. The obtained results revealed that the respiration rate increased throughout the storage, although coated duke cherries with AVG, thymol, and their combination showed lower respiration rates than uncoated fruits (Fig. 1). At all sampling times, a combination of AVG and thymol was more effective than the application of AVG or thymol alone. Compared to the uncoated duke cherries, the respiration rate of fruits coated with AVG + thymol was 34.96%, 35.01%, 58.96%, and 49.78% lower after 7, 14, 21, and 28 d of storage, respectively (Fig. 1). Similar to our findings, it was found that coating sour cherries with AVG [5], strawberries with essential oils [37], and stone fruits with a combination of AVG and essential oils [22, 38] decreased respiration rate compared with uncoated fruits. The decrease in the respiration rate of fruits as the result of AVG application is likely to be because AVG, as a semi-permeable barrier, reduces the gas exchange resulting in decreases in O2 and increases in CO2 concentration [22, 38]. Since the lipid content of AVG is very low, the incorporation of a source of lipids such as essential oils into the coating could result in the formation of a coating with higher barrier efficacy [23], and in turn lower respiration rate, as documented in this research (Fig. 1).

Stem browning

Stem browning is a serious issue in the marketing of fresh cherries and affects buyer and consumer acceptance [39]. Our findings showed that stem browning rose during the storage period. However, duke cherries treated with AVG, thymol, and their combination, had lower stem browning than controls, where the effect of AVG + thymol was significantly greater than the other treatments except for AVG at day 7 (Table 1). In fruits treated with AVG + thymol, the stem browning was 50.53%, 38.53%, 24.50%, and 32.97% lower than nontreated ones after 7, 14, 21, and 28 d of storage, respectively (Table 1). The positive effects of edible coatings on reducing stem browning of sweet cherries during the storage period have been recognized [26, 40], which is consistent with the findings of the present research. Higher water loss is observed in the cherry pedicel than in the fruit [41], and desiccation is responsible for stem browning in the cherry [42]. The decrease in stem browning as the result of coating application can be due to decreased water loss from the stems [26]. There was no evidence regarding the influence of essential oils on the stem browning of cherries during the storage period.

Spoilage percentage

As shown in Table 1, the application of AVG and thymol was not only effective in controlling the spoilage of duke cherries but also in postponing the beginning of spoilage symptoms and deceleration the growth of microbes during cold storage. Nontreated control duke cherries exhibited spoilage after 14 d of storage, whereas spoilage was recognizable in coated fruits after 21 d (Table 1). The addition of thymol to AVG was more effective in controlling spoilage than AVG and thymol alone. By the end of storage, duke cherries treated with AVG, thymol, and AVG + thymol had 68.61%, 77.39%, and 84.55% lower spoilage than uncoated fruits, respectively (Table 1).

The results of the current study agree with those obtained by Hassan et al. [12] on strawberries, Martínez-Romero et al. [40] on cherries, and Rasouli et al. [43] on oranges, reporting that microbial infection of AVG-coated fruits was lower than controls during storage. The inhibitory effects of AVG on the growth of postharvest pathogens can be due to the presence of Aloe-emodin, aloenin, and other active compounds in the coating [40]. Similarly, decreases in postharvest decay with the application of thymol have been described for figs [27], avocados [44], and kiwifruits [45]. Thymol inhibits the pathogen's growth and spore germination by affecting the pathogen's cellular metabolism and the active sites of enzymes [46]. The obtained results in this study (Table 1) also confirm previous reports that combining essential oils and AVG presents a much better effect on controlling microbial infection than essential oils or AVG alone [12, 44].

Fruit firmness

Fruit firmness is one of the most important quality features of cherries. The firmness of duke cherries decreased with an extension in the storage period, with greater levels in coated compared with uncoated fruits (Table 2). At all sampling times, the highest firmness was related to AVG + thymol, although there were no statistically significant differences among edible coatings at day 7, and between AVG + thymol and AVG at days 14 and 28. On days 7, 14, 21, and 28, duke cherries coated with AVG + thymol had 12.76%, 20.03%, 50.98%, and 100.32% higher firmness than uncoated fruits, respectively (Table 2).

Consistent with our findings, a decrease in the firmness of cherries during the storage period has been reported [38, 40, 47], which could be associated with the activity of cell wall degrading enzymes, dehydration due to water loss, and pathogen infection [27]. Furthermore, similar findings on the positive effects of AVG, essential oils, and their combination on fruit firmness have been obtained for tomatoes [11], strawberries [12], plums [17], and peaches [38]. The decrease in the softening of fruits as the result of coating application can be due to the role of coatings in reducing respiration rates, enzyme activities, metabolic activity, and the ripening process [48].

TSS, TA, and TSS/TA

With an extension in the storage period, the levels of TSS and TSS/TA increased while TA decreased (Table 3), although these changes in TSS, TA, and TSS/TA were less noticeable in duke cherries coated with AVG, thymol, and particularly AVG + thymol. No statistically significant differences were found in TSS values of coated and uncoated fruits at day 7, among edible coatings at days 14 and 21, and between AVG + thymol and AVG at day 28 (Table 3). Moreover, coated and uncoated duke cherries did not show significant differences in TSS/TA values on days 7 and 21, but after that, fruits under AVG + thymol treatment showed the lowest TSS/TA value (9.51), although no significant difference was found between AVG + thymol and AVG regarding this trait (Table 3). On the other hand, the decline in TA was lower in duke cherries treated with coatings; the highest advantage was for AVG + thymol. Nevertheless, there were no statistically significant differences between coated and uncoated fruits on day 7, among edible coatings on day 14, and between AVG + thymol and AVG on days 21 and 28 (Table 3).

The TSS/TA is an important parameter determining cherry acceptability by consumers. Similar to the results of this work, an increase in TSS and a decrease in TA of fruits during the storage period has been described for strawberries [12], mangos [49], and apricots [50] which could be due to the increase in respiration rate and consumption of organic acids, water losses, breakdown of glycoside into sub-units, and the catabolism of polysaccharides into simple sugars [24]. Furthermore, the positive effects of AVG, essential oils, and their combination on TSS, TA, and TSS/TA have been reported for tomatoes [11], strawberries [12], and plums [17], which is consistent with our findings. The lower changes in TSS and TA of coated fruits can be due to a decrease in respiration rate and water loss by coatings [27], as shown in the present research (Fig. 1 and Table 1).

Anthocyanin content

The anthocyanin content of duke cherries increased over the cold storage (Fig. 2). The increase in anthocyanin content was less in coated fruits than in those untreated. The lowest anthocyanin content was obtained for AVG + thymol; however, there were no statistically significant differences between coated and uncoated fruits on day 7, among edible coatings on day 14, and between AVG + thymol and AVG on days 21 and 28 (Fig. 2). In duke cherries coated with AVG + thymol, the anthocyanin content was 14.21%, 21.88%, and 23.16% lesser than uncoated fruits after 14, 21, and 28 d of cold storage, respectively (Fig. 2).

Our findings agree with those achieved by Shehata et al. [37] on strawberries, and Hu et al. [47] on sweet cherries, describing that the anthocyanin content of fruits increases during storage. This increase, especially in control, can be justified regarding the increases in respiration rate, sugar accumulation, and weight loss [24, 37]. Moreover, the results obtained in this work confirm previous research that the application of AVG, essential oils, and their combination decelerated anthocyanin synthesis in coated fruits during the storage period [12, 17]. The lower anthocyanin contents in coated fruits during the storage period may be due to the inhibitory effects of coatings on fruit ripening, which leads to a decrease in the activity of enzymes and biochemical reactions responsible for anthocyanin biosynthesis [26, 51].

Total phenol content

With increasing storage time, the total phenolic content of duke cherries decreased. The decline in total phenolic content was lesser in coated duke cherries than those uncoated (Fig. 3). At all sampling times, the highest total phenolic content was related to AVG + thymol, although there were no statistically significant differences among edible coatings at days 7 and 14, and between AVG + thymol and AVG at day 21 (Fig. 3). After 7, 14, 21, and 28 d of storage, duke cherries coated with AVG + thymol showed 9.99, 25.66, 32.20%, and 45.09% greater total phenolic content than uncoated ones, respectively (Fig. 3).

Phenolic compounds not only improve the quality and nutritional value of the cherries [47] but also play a major role in the defense mechanism against the invasion of plant pathogens [52]. Therefore, maintaining a high level of phenolic compounds in fruits during their storage life can be very beneficial. The findings of the current study are consistent with Petriccione et al. [53] who described that the total phenolic content of fruits was decreased during storage. On the contrary, the results of this study are dissimilar to reports that showed the total phenolic content of fruits increased during storage [12, 19, 54]. Furthermore, our findings are similar to Nourozi and Sayyari [19] for apricots and Hu et al. [38] for sweet cherries, who indicated total phenolic content of fruits treated with coatings, was greater than nontreated fruits during storage. The results of this work are also in agreement with those obtained by Gol et al. [51] who detected that total phenolic content was higher in coated fruit with a combination of chitosan and essential oils than in uncoated fruits. In contrast, Hassan et al. [12] reported that strawberries coated with AVG, lemongrass essential oil, and their combination had lower total phenolic content than uncoated fruits, which is contrary to the results of this research (Fig. 3).

Antioxidant activity

The antioxidant activity of duke cherries decreased with an extension in the storage time; however, coated fruits had greater antioxidant activity than uncoated fruits (Fig. 4). The combination of AVG and thymol was more effective than the application of AVG or thymol alone, although there were no statistically significant differences among edible coatings at day 7, and between AVG + thymol and AVG at day 14 (Fig. 4). On days 7, 14, 21, and 28, duke cherries coated with AVG + thymol had 7.90%, 20.03%, 39.57%, and 84.56% higher antioxidant activity than uncoated fruits, respectively (Fig. 4).

Decreases in the antioxidant activity of fruits during storage have been found in strawberry [12], table grape [24], and sweet cherry [53], which is consistent with the results of this work. Antioxidant activity can be associated with the contents of phenolic compounds and pigments such as anthocyanins. Degradation of anthocyanins and phenolic compounds results in a reduction of antioxidant activity [55]. In this regard, a continuous decrease in the level of anthocyanins and phenolic compounds of duke cherries during the storage period, as previously mentioned (Figs. 2 and 3) showed similar trends to the antioxidant activity of fruits (Fig. 4). Alternatively, the higher antioxidant activity with the application of AVG, essential oils, and their combination have been reported for strawberries [12], plum [17], and avocados [44], which is in agreement with our findings. The positive impact of essential oils on the antioxidant activity of coated fruits during storage can be associated with the fact that most of them comprise relative amounts of antioxidant compounds [56]. In addition, one of the main constituents of AVG is aloe-emodin, which leads to increased antioxidant activity in coated fruits [57].

H2O2 and MDA concentration

H2O2 and MDA concentrations increased throughout the storage (Figs. 5 and 6), although this increase was less noticeable in coated duke cherries. The edible coatings significantly affected the H2O2 and MDA concentration of fruits on days 14, 21, and 28, whereas they had no significant effect on H2O2 and MDA concentration on day 7 (Figs. 5 and 6). The lowest H2O2 concentration was recorded in fruits coated with AVG + thymol; however, the effect of AVG + thymol was only statistically greater to the control treatment at day 14 and to the control and thymol treatments at days 21 and 28 (Fig. 5). In addition, duke cherries coated with AVG + thymol had the lowest MDA concentration, although there were no statistically significant differences among edible coatings at day 14, and between AVG + thymol and AVG at day 21 (Fig. 6).

The results of this research agree with reports that showed H2O2 and MDA concentrations of fruits increased during storage [24, 58]. Furthermore, our findings are consistent with ValizadehKaji et al. [24], who indicated H2O2 and MDA concentration of fruits treated with an edible coating, the essential oils, and their combination was significantly lower than nontreated controls during storage. The lower concentrations of H2O2 and MDA in duke cherries coated with AVG, thymol, and their combination, might be related to the high antioxidant activity [24] and the high activity of antioxidant enzymes [59], as documented in the present study (Figs. 4, 7 and 8).

GPX and CAT activity

Over the cold storage, the GPX and CAT activity of duke cherries decreased; however, coated fruits showed more GPX and CAT activity compared to uncoated ones, and the maximum values were related to AVG + thymol which was significantly greater than the other treatments (Figs. 7 and 8). GPX activity of fruits under AVG + thymol treatment was 12.03%, 43.93%, 83.88% and 185.11% greater than controls after 7, 14, 21, and 28 d of the storage, respectively (Fig. 7). In addition, fruits coated with AVG + thymol had 10.20%, 30.34%, 82.97% and 143.66% higher CAT activity than uncoated ones at days 7, 14, 21, and 28, respectively (Fig. 8).

The results of the current study are consistent with those obtained by Shehata et al. [37] but contrary to the results of Ghorbani et al. [59], who stated that the antioxidant enzyme activity of fruits increased during storage. Moreover, the findings of this work support those achieved by ValizadehKaji et al. [24] and Bill et al. [44], who described that the activity of antioxidant enzymes in fruits coated with edible coatings, essential oils, and their combination was greater than in nontreated fruits during storage. The production of reactive oxygen species in fruits increases during storage [60]. Antioxidant enzymes play a role in keeping plant cells from oxidative damage by reactive oxygen species. Since the increase in the activity of antioxidant enzymes leads to an increase in the tissue's ability to remove H2O2 and MDA, the levels of H2O2 and MDA were lower in the duke cherries (Figs. 5 and 6).

Sensory attributes evaluation

During the cold storage period, the sensory attributes of duke cherries decreased; with better sensory scores in coated compared with uncoated fruits (Table 2; Fig. 9). The edible coatings had no statistically significant effect on the sensory attributes of duke cherries at days 7 and 14, but after that, coated fruits had significantly higher sensory scores than nontreated ones (Table 2). Application of AVG + thymol was more effective in maintaining sensory attributes of duke cherries than AVG and thymol alone, although AVG + thymol and AVG were not statistically different at day 21 (Table 2). By the end of storage, duke cherries coated with thymol, AVG, and AVG + thymol had 28.75%, 57.08%, and 100.00% higher sensory scores than nontreated fruits, respectively (Table 2). Similar findings on the positive effects of edible coatings, essential oils, and their combination on sensory attributes of fruits during storage have been described for tomato [11], fig [27], and stone fruits [38].

Storage life

The edible coatings had a statistically significant effect on the storage life of duke cherries (Fig. 10). Fruits coated with AVG + thymol showed the highest storage life (27.00 d), which was significantly greater than the other treatments, whereas uncoated fruits had the lowest storage life (15.66 d) (Fig. 10). The higher storage life with the application of edible coatings, essential oils, and their combination have been reported for strawberry [12], sweet cherry [26], and fig [27], which is in agreement with our findings.

Conclusion

Duke cherries coated with AVG, thymol, and particularly AVG + thymol, showed lower values of weight loss, respiration rate, stem browning, fungal infection, and TSS/TA, as well as H2O2 and MDA, whereas they had higher values of firmness, anthocyanin, total phenol, antioxidant activity, antioxidant enzyme activity, and sensory scores during cold storage. Therefore, applying AVG, thymol, and particularly AVG + thymol, for prolonging the shelf storage of duke cherries has revealed great practical potential. This combined treatment has various advantages including natural, edible, and efficient. Despite considerable findings of the present research, further work is needed to be done on a combination of other coatings and essential oils to preserve the quality of duke cherries. In addition, combined treatments must be tested for infected fruits to provide an effective decay control measure to the organic duke cherry industry.

Availability of data and materials

Not applicable.

Abbreviations

- TSS:

-

Total soluble solids

- TA:

-

Titratable acidity

- H2O2 :

-

Hydrogen peroxide

- MDA:

-

Malondialdehyde

- GPX:

-

Guaiacol peroxidase

- CAT:

-

Catalase

References

Vavilov NI, Starr CK. The origin, variation, immunity and breeding of cultivated plants. NewYork: Ronald Press; 1951.

Höfer M, Peil A. Phenotypic and genotypic characterization in the collection of sour and duke cherries (Prunus cerasus and ×P. ×gondouini) of the Fruit Genebank in Dresden-Pillnitz, Germany. Genet Resour Crop Evol. 2015;62:551–66. https://doi.org/10.1007/s10722-014-0180-8.

Toydemir G, Capanoglu E, Kamiloglu S, Boyacioglu D, de Vos R, Hall RD, Beekwilder J. Changes in sour cherry (Prunus cerasus L.) antioxidants during nectar processing and in vitro gastrointestinal. J Funct Foods. 2013;5:1402–13. https://doi.org/10.1016/j.jff.2013.05.008.

Pérez-Sánchez R, Morales-Corts MR, Gómez-Sánchez MA. Quality evaluation of sour and duke cherries cultivated in South-West Europe. J Sci Food Agric. 2013;93:2523–30. https://doi.org/10.1002/jsfa.6069.

Ravanfar R, Niakousari M, Maftoonazad N. Postharvest sour cherry quality and safety maintenance by exposure to hot-water or treatment with fresh Aloe vera gel. J Food Sci Technol. 2014;51(10):2872–6. https://doi.org/10.1007/s13197-012-0767-z.

Guler SK, Karakaya O, Karakaya M, Ozturk B, Aglar E, Yarılgac T, Gün S. Combined treatments of modified atmosphere packaging with aminoethoxyvinylglycine maintained fruit quality in sweet cherry throughout cold storage and shelf life. Acta Sci Pol Hortorum Cultus. 2019;18(5):13–26. https://doi.org/10.24326/asphc.2019.5.2.

Benichou M, Ayour J, Sagar M, Alahyane A, Elateri I, Aitoubahou A. Postharvest technologies for shelf life enhancement of temperate fruits. In: Mir S, Shah M, Mir M, editors. Postharvest biology and technology of temperate fruits. Cham: Springer; 2018. https://doi.org/10.1007/978-3-319-76843-4_4.

Paull RE. Effect of temperature and relative humidity on flesh commodity quality. Postharvest Biol Technol. 1999;15:263–77. https://doi.org/10.1016/S0925-5214(98)00090-8.

Wani AA, Singh P, Gul K, Wani MH, Langowski HC. Sweet cherry (Prunus avium): critical factors affecting the composition and shelf life. Food Packag Shelf Life. 2014;1:86–99. https://doi.org/10.1016/j.fpsl.2014.01.005.

Huang W, Wang X, Zhang J, Xia J, Zhang X. Improvement of blueberry freshness prediction based on machine learning and multi-source sensing in the cold chain logistics. Food Control. 2023;145:109496. https://doi.org/10.1016/j.foodcont.2022.109496.

Tzortzakis N, Xylia P, Chrysargyris A. Sage essential oil improves the effectiveness of Aloe vera gel on postharvest quality of tomato fruit. Agronomy. 2019;9(10):635–51. https://doi.org/10.3390/agronomy9100635.

Hassan HS, El-Hefny M, Ghoneim IM, El-Lahot MS, Akrami M, Al-Huqail AA, Ali HM, Abd-Elkader DY. Assessing the use of Aloe vera gel alone and in combination with lemongrass essential oil as a coating material for strawberry fruits: HPLC and EDX analyses. Coatings. 2022;12:489. https://doi.org/10.3390/coatings12040489.

Öztürk B, Karakaya M, Karakaya O, Gün S. Effects of aminoethoxyvinylglycine (AVG) and Aloe vera treatments on cold storage and shelf life of Piraziz apple. Akad Ziraat Derg. 2018;7(2):121–30. https://doi.org/10.29278/azd.476107.

Öztürk B, Ağlar E. Effects of modified atmosphere packaging (MAP) and Aloe vera treatments on quality characteristics of cornelian cherry fruits during cold storage. Akad Ziraat Derg. 2019;8(1):1–8. https://doi.org/10.29278/azd.592897.

Ozturk B, Karakaya O, Yıldız K, Saracoglu O. Effects of Aloe vera gel and MAP on bioactive compounds and quality attributes of cherry laurel fruit during cold storage. Sci Hortic. 2019;249:31–7. https://doi.org/10.1016/j.scienta.2019.01.030.

Islam A, Acıkalın R, Ozturk B, Aglar E, Kaiser C. Combined effects of Aloe vera gel and modified atmosphere packaging treatments on fruit quality traits and bioactive compounds of jujube (Ziziphus jujuba Mill.) fruit during cold storage and shelf life. Postharvest Biol Technol. 2022;187:111855. https://doi.org/10.1016/j.postharvbio.2022.111855.

Martínez-Romero D, Zapata PJ, Guillén F, Paladines D, Castillo S, Valero D, Serrano M. The addition of rosehip oil to Aloe gels improves their properties as postharvest coatings for maintaining quality in plum. Food Chem. 2017;217:585–92. https://doi.org/10.1016/j.foodchem.2016.09.035.

Khaliq G, Ramzan M, Baloch AH. Effect of Aloe vera gel coating enriched with Fagonia indica plant extract on physicochemical and antioxidant activity of sapodilla fruit during postharvest storage. Food Chem. 2019;286:346–53. https://doi.org/10.1016/j.foodchem.2019.01.135.

Nourozi F, Sayyari M. Enrichment of Aloe vera gel with basil seed mucilage preserve bioactive compounds and postharvest quality of apricot fruits. Sci Hortic. 2020;262:109041. https://doi.org/10.1016/j.scienta.2019.109041.

Barman K, Sharma S, Siddiqui MW. Heat treatments for enhancing storability of fruits and vegetables. In: Barman K, Sharma S, Siddiqui MW, editors. Emerging postharvest treatment of fruits and vegetables. Waretown: Apple Academic Press; 2018. https://doi.org/10.1201/9781351046312.

Hasan MU, Riaz R, Malik AU, Khan AS, Anwar R, Rehman RNU, Ali S. Potential of Aloe vera gel coating for storage life extension and quality conservation of fruits and vegetables: an overview. J Food Biochem. 2021;45: e13640. https://doi.org/10.1111/jfbc.13640.

Zapata PJ, Serrano M, Martínez-Romero D, Valero D, Guillén F, Paladines D, Castillo S. The addition of rosehip oil to Aloe gels improves their properties as postharvest coatings for maintaining quality in plum. Food Chem. 2016;217:585–92. https://doi.org/10.1016/j.foodchem.2016.09.035.

Guillén F, Díaz-Mula HM, Zapata PJ, Valero D, Serrano M, Castillo S, Martínez-Romero D. Aloe arborescens and Aloe vera gels as coatings in delaying postharvest ripening in peach and plum fruit. Postharvest Biol Technol. 2013;83:54–7. https://doi.org/10.1016/j.postharvbio.2013.03.011.

ValizadehKaji B, Seyfori P, Abbasifar A. Effect of chitosan and thymol on physicochemical and qualitative properties of table grape fruits during the postharvest period. Biologia. 2023;78:279–89. https://doi.org/10.1007/s11756-022-01249-7.

Nabifarkhani N, Sharifani M, Daraei Garmakhany A, Ganji Moghadam E, Shakeri A. Effect of nano-composite and Thyme oil (Tymus Vulgaris L) coating on fruit quality of sweet cherry (Takdaneh Cv) during storage period. Food Sci Nutr. 2015;3(4):349–54. https://doi.org/10.1002/fsn3.226.

Mujtaba M, Ali Q, Yilmaz BA, Seckin Kurubas M, Ustun H, Erkan M, Kaya M, Cicek M, Oner ET. Understanding the effects of chitosan, chia mucilage, levan based composite coatings on the shelf life of sweet cherry. Food Chem. 2023;416:135816. https://doi.org/10.1016/j.foodchem.2023.135816.

Saki M, ValizadehKaji B, Abbasifar A, Shahrjerdi I. Effect of chitosan coating combined with thymol essential oil on physicochemical and qualitative properties of fresh fig (Ficus carica L.) fruit during cold storage. J Food Meas Charact. 2019;13(2):1147–58. https://doi.org/10.1007/s11694-019-00030-w.

Kim D, Jeong S, Lee C. Antioxidant capacity of phenolic phytochemicals from various cultivars of plums. Food Chem. 2003;81:321–6. https://doi.org/10.1016/S0308-8146(02)00423-5.

Singleton VL, Orthofer R, Lamuela-Raventós RM. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol. 1999;299:152–78. https://doi.org/10.1016/S0076-6879(99)99017-1.

Brand-Williams W, Cuvelier ME, Berset C. Use of a free radical method to evaluate antioxidant activity. Food Sci Technol. 1995;28(1):25–30. https://doi.org/10.1016/S0023-6438(95)80008-5.

Irani H, ValizadehKaji B, Naeini MR. Biostimulants-induced drought tolerance in grapevine is associated with physiological and biochemical changes. Chem Biol Technol Agric. 2021;8:1–13. https://doi.org/10.1186/s40538-020-00200-9.

Heath RL, Packer L. Photo-peroxidation in isolated chloroplasts: I. Kinetics and stoichiometry of fatty acid peroxidation. Arch Biochem Biophys. 1968;125:189–98. https://doi.org/10.1016/0003-9861(68)90654-1.

Herzog V, Fahimi HD. Determination of the activity of peroxidase. Anal Biochem. 1973;55:554–62.

Bergmeyer N. Methoden der enzymatischen analyse. Berlin: Academic Verlag; 1970.

Serrano M, Guillén F, Martínez-Romero D, Castillo S, Valero D. Chemical constituents and antioxidant activity of sweet cherry at different ripening stages. J Agric Food Chem. 2005;53:2741–5. https://doi.org/10.1021/jf0479160.

Zhu X, Wang Q, Cao J, Jiang W. Effects of chitosan coating on postharvest quality of mango (Mangifera indica L. cv. Tainong) fruits. J Food Process Preserv. 2008;32:770–84. https://doi.org/10.1111/j.1745-4549.2008.00213.x.

Shehata SA, Abdeldaym EA, Ali MR, Mohamed RM, Bob RI, Abdelgawad KF. Effect of some citrus essential oils on post-harvest shelf life and physicochemical quality of strawberries during cold storage. Agronomy. 2020;10(10):1466. https://doi.org/10.3390/agronomy10101466.

Paladines D, Valero D, Valverde JM, Díaz-Mula HM, Serrano M, Martínez-Romero D. The addition of rosehip oil improves the beneficial effect of Aloe vera gel on delaying ripening and maintaining postharvest quality of several stonefruit. Postharvest Biol Technol. 2014;92:23–8. https://doi.org/10.1016/j.postharvbio.2014.01.014.

Schick JL, Toivonen PMA. Reflective tarps at harvest reduce stem browning and improve fruit quality of cherries during subsequent storage. Postharvest Biol Technol. 2002;25:117–21. https://doi.org/10.1016/S0925-5214(01)00145-4.

Martinez-Romero D, Alburquerque N, Valverde JM, Guillén F, Castillo S, Valero D, Serrano M. Postharvest sweet cherry quality and safetymaintenance by Aloe vera treatment: a new edible coating. Postharvest Biol Technol. 2006;39:93–100. https://doi.org/10.1016/j.postharvbio.2005.09.006.

Seske L. Respiration and storage potential in Norwegian-grown sweet cherries. Acta Hortic. 1996;410:357–62. https://doi.org/10.17660/ActaHortic.1996.410.56.

Drake SR, Kupferman EM, Fellman JK. ‘Bing’sweet cherry (Prunus avium L.) quality as influenced by wax coatings and storage temperature. J Food Sci. 1988;53:124–6.

Rasouli M, Saba MK, Ramezanian A. Inhibitory effect of salicylic acid and Aloe vera gel edible coating on microbial load and chilling injury of orange fruit. Sci Hortic. 2019;247:27–34. https://doi.org/10.1016/j.scienta.2018.12.004.

Bill M, Sivakumar D, Korsten L, Thompson AK. The efficacy of combined application of edible coatings and thyme oil in inducing resistance components in avocado (Persea americana Mill.) against anthracnose during post-harvest storage. Crop Prot. 2014;64:159–67. https://doi.org/10.1016/j.cropro.2014.06.015.

Shirzad H, Hassani A, Ghosta Y, Abdollahi A, Finidokht R, Meshkatalsadat MH. Assessment of the antifungal activity of natural compounds to reduce postharvest gray mould (Botrytis cinerea Pers.: Fr.) of kiwifruits (Actinidia deliciosa) during storage. J Plant Prot Res. 2011;51:1e6. https://doi.org/10.2478/v10045-011-0001-4.

Arrebola E, Sivakumar D, Bacigalupo R, Kortsen L. Combined application of antagonist Bacillus amyloliquefaciens and essential oils for the control of peach postharvest diseases. Crop Prot. 2010;29:369–77. https://doi.org/10.1016/j.cropro.2009.08.001.

Hu W, Feng K. Effect of edible coating on the quality and antioxidant enzymatic activity of postharvest sweet cherry (Prunus avium L.) during storage. Coatings. 2022;12(5):581. https://doi.org/10.3390/coatings12050581.

Severino R, Ferrari G, Vu KD, Donsì F, Salmieri S, Lacroix M. Antimicrobial effects of modified chitosan based coating containing nanoemulsion of essential oils, modified atmosphere packaging and gamma irradiation against Escherichia coli O157:H7 and Salmonella Typhimurium on green beans. Food Control. 2015;50:215–22. https://doi.org/10.1016/j.foodcont.2014.08.029.

Khalil HA, Abdelkader MF, Lo’ay AA, El-Ansary DO, Shaaban FK, Osman SO, Shenawy IE, Osman HE, Limam SA, Abdein MA, Abdelgawad ZA. The combined effect of hot water treatment and chitosan coating on mango (Mangifera indica L. cv. Kent) fruits to control postharvest deterioration and increase fruit quality. Coatings. 2022;12:83. https://doi.org/10.3390/coatings12010083.

Hosseinifarahi M, Mousavi SM, Radi M, Jowkar MM, Romanazzi G. Postharvest application of hot water and putrescine treatments reduce brown rot and improve shelf life and quality of apricots. Phytopathol Mediterr. 2020;59(2):319–29. https://doi.org/10.14601/Phyto-10751.

Gol NB, Patel PR, Rao TVR. Improvement of quality and shelf-life of strawberries with edible coatings enriched with chitosan. Postharvest Biol Technol. 2013;85:185–95. https://doi.org/10.1016/j.postharvbio.2013.06.008.

Beckman CH. Phenolic-storing cells: key to programmed cell death and periderm formation in wilt disease resistance and in general defense response in plants. Physiol Mol Plant Pathol. 2000;57:101–10. https://doi.org/10.1006/pmpp.2000.0287.

Petriccione M, De Sanctis F, Pasquariello MS, Mastrobuoni F, Rega P, Scortichini M, Mencarelli F. The Effect of chitosan coating on the quality and nutraceutical traits of sweet cherry during postharvest life. Food Bioproc Tech. 2015;8:394–408. https://doi.org/10.1007/s11947-014-1411-x.

Hassanpour H. Effect of Aloe vera gel coating on antioxidant capacity, antioxidant enzyme activities and decay in raspberry fruit. LWT - Food Sci Technol. 2015;60:495–501. https://doi.org/10.1016/j.lwt.2014.07.049.

Maqbool M, Ali A, Alderson PG, Mohamed MTM, Siddiqui Y, Zahid N. Postharvest application of gum arabic and essential oils for controlling anthracnose and quality of banana and papaya during cold storage. Postharvest Biol Technol. 2011;62(1):71–6. https://doi.org/10.1016/j.postharvbio.2011.04.002.

Martínez K, Ortiz M, Arrieta ARA, Castañeda CG, Valencia ME, Tovar CD. The effect of edible chitosan coatings incorporated with thymus capitatus essential oil on the shelf-life of strawberry (Fragaria x ananassa) during cold storage. Biomolecules. 2018;8:155. https://doi.org/10.3390/biom8040155.

Ni Y, Turner D, Yates KM, Tizard I. Isolation and characterization of structural components of Aloe vera L. Leaf pulp. Int Immunopharmacol. 2004;4:1745–55. https://doi.org/10.1016/j.intimp.2004.07.006.

Nguyen HT, Boonyaritthongchai P, Buanong M, Supapvanich S, Wongs-Aree C. Postharvest hot water treatment followed by chitosan-and κ-carrageenan-based composite coating induces the disease resistance and preserves the quality in dragon fruit (Hylocereus undatus). Int J Fruit Sci. 2020;20:S2030–44. https://doi.org/10.1080/15538362.2020.1851314.

Ghorbani B, Pakkish Z, Najafzadeh R. Shelf life improvement of grape (Vitis vinifera L. cv. Rish Baba) using nitric oxide (NO) during chilling damage. Int J Food Prop. 2017;20:2750–63. https://doi.org/10.1080/10942912.2017.1373663.

Meitha K, Pramesti Y, Suhandono S. Reactive oxygen species and antioxidants in postharvest vegetables and fruits. Int J Food Sci. 2020;2020:8817778. https://doi.org/10.1155/2020/8817778.

Acknowledgements

The support of this research provided by Arak University has been acknowledged.

Author information

Authors and Affiliations

Contributions

BV designed the experiment. NF performed the experiments. BV and NF conducted the laboratory measurements. BV analyzed the data and wrote the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

All authors contributed in design and preparation of the research, and they have read the final version of the manuscript.

Consent for publication

We declare our agreement.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

ValizadehKaji, B., Fakhri, N. Postharvest application of Aloe vera gel and thymol enhances shelf-life of duke cherries via altering physiochemical parameters. Chem. Biol. Technol. Agric. 10, 85 (2023). https://doi.org/10.1186/s40538-023-00453-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40538-023-00453-0