Abstract

Covered tightly by a thin leather skin, three early seventeenth-century cornetts from the collection of the Rijksmuseum were examined with the focus on their construction and manufacturing. One cornett of the three unexpectedly turned out to have a peculiar construction and to be made out of two sections of different wood species. The question arose whether this could be original or is the result of an extensive restoration.

As the internal structure is not accessible for analysis and examination, multi-scale Computed Tomography (CT) scanning was employed to identify the exact regions of interest (ROI) and subsequently perform scans at a sufficiently high resolution in those areas. 3D images of the hollow spaces such as the tunnelling structure caused by the common furniture beetle (Anobium punctatum) criss-crossing the wood species could be computed from the 3D x-ray tomography reconstruction. This allowed to place the occurrence of the insect infestation after the joining of the two sections. Fine tool-marks, signs of construction and potential indications of earlier treatments could be visualized. These results were compared with the other two instruments of the same group and cross-referenced to instruments in other collections, in an attempt to answer questions about the instrument’s authenticity and originality. While the unusual construction out of two wood species might be the result of an extensive repair, another possible hypothesis—based on the combination of the results—is that this unique choice of original manufacturing was intentional, possibly to avoid splitting of the wood when inserting the mouthpiece or to counteract undesired vibrations when played.

Similar content being viewed by others

Introduction

The curved cornett (or zink) is a woodwind instrument which had its peak in popularity in Italy around 1570–1630 and was often played together with string instruments [1, 2]. Venetian cornett makers, in particular the Bassano family of instrument makers [3, 4], played a pioneering role in the sixteenth century when the curved wooden cornett became very popular throughout Europe [1]. The curved shape as it is known today probably is a crossbreed of a more horn-shaped Italian instrument and a straight instrument with a narrow bore made north of the Alps until the sixteenth century [2]. The curved cornett lost its popularity in Italy after 1650. North of the Alps the popularity declined slowly throughout the eighteenth century. In the nineteenth century there were hardly any musical compositions to be found including the cornett until a revival in the 1880s and again in the 1950s [1, 2].

Construction of curved cornetts

Cornetts have a bore, widening towards the bottom (or south) of the instrument into a cone-shape and have (six) finger holes at the front and one thumb hole at the back. Curved cornetts are made by bisecting a piece of wood longitudinally and gouging out the two halves with a conical, curved bore [2, 5]. Rarer and of later date (eighteenth or nineteenth century) are curved cornetts, which are drilled out and bent subsequently with steam [6]. Once the two bisected halves are glued back together, the exterior is shaped octagonally along the body and is decorated with gouged rhombus or diamond shapes between the mouthpiece-insert and the thumb hole. One or more bindings (or ligatures) tie the two halves together inside circumferential grooves, which are visible as imprinted lines in the thin leather covering the entire instrument [1, 7]. Typically, there are four reinforcing ligatures: at the mouthpiece socket, under the diamond-pattern section, between the third and fourth finger hole, and three to four centimetres above the lower endFootnote 1. A thin coating or internal impregnation with oil is applied to the inside of the assembled instrument as a protection against the moisture introduced by the player’s breath [1]. A small cup-mouthpiece with a thin rim and thread-wrapped shank made of ivory or horn is inserted into the socket at the narrow upper end (or north) of the instrument. The vibrations of the lips pressed against the mouthpiece produce the sound, classifying it as a “wooden trumpet” [8, 9] or more specifically: an aerophone where the players lips set the contained air within the instrument in motion and the pitch can be altered using fingerholes, numbered with 423.21 in the “Hornborstel-Sachs Classification of Musical Instruments” [10]. Typically, intonation-corrections were made by the maker undercutting the finger holes on the inside [1].

The wooden pipe

In general, curved cornetts were made of boxwood, yew or fruitwoods, and more rarely in ebony, beech or ivory, without any workshop-specific preferences [5]. However, there seems to be a regional and chronological relationship to the preferred species used: boxwood and yew appear to be used predominately in the sixteenth century in Nürnberg and Venice, and later on fruitwoods were more common north of the Alps [1, 5, 11].

According to Darmstädter et al. [1] the specific density of the wood species itself does not have any impact on the sound. The workability and processing with hand tools however does differ from one wood species to the other. The varying roughness and porosity of the wood species affects the surface texture of the gouged-out bore, which in turn influences the oscillation of the air inside the bore, by altering the degree of acoustic dissipation and damping the soundwaves [12,13,14]. Equally, polishing and impregnating the inner tube with oil has an effect on the smoothness of the surface and hence the acoustic propagation [13, 15]. Whether the internal impregnation was intended to influence the acoustic dissipation is uncertain.

Three early seventeenth-century cornetts in the Rijksmuseum

The collection of historical musical instruments of the Rijksmuseum includes three early seventeenth-century curved cornetts which belonged to the city players of Amsterdam [16] and have been on permanent loan from the city of Amsterdam since 1887 (Fig. 1) [17, 18].

Three cornetts in the collection of Rijksmuseum: Left: BK-AM-62-B (length 560 mm × diameter 35 mm) (http://hdl.handle.net/10934/RM0001.COLLECT.329309), centre: BK-AM-62-A (length 580 mm × diameter 40 mm) (http://hdl.handle.net/10934/RM0001.COLLECT.329307), right: BK-AM-62-C (length 585 mm × diameter 40 mm) (http://hdl.handle.net/10934/RM0001.COLLECT.329310)

One of these cornetts (BK-AM-62-A) bears the mark of the English branch of the famous Bassano family of makers who were active both in London and Venice: a set of silkworm moths, which in some publications are referred to as ‘rabbit’s feet’ but are likely a schematic version of the silkworm moth with open wings (Fig. 2) [3, 4, 7, 19]. The other two (BK-AM-62-B and BK-AM-62-C) are anonymous. The BK-AM-62-B cornett bears a flower-shaped mark. The latter is punched in multiple places on the leather that covers the body of the instrument. So far, this mark has never been found on any other wind instrument and could simply be a decorative element rather than the mark of a specific maker. A fourth cornett belonging to the same group which has recently been given on loan by the City of Amsterdam (Object number: KA 9194) to the Rembrandthuis Museum, is not included in this study.

The cornett BK-AM-62-B

The cornett BK-AM-62-B presents severe infestation by the common furniture beetle (Anobium punctatum) and has been broken in two pieces. On a photograph in the Rijksmuseum archive dating from around 1900 exit holes caused by the woodworm infestation are visible on the otherwise intact instrument [20]. The fracture is first mentioned in a catalogue from 1970 in the Gemeentemuseum in The Hague [17] but not in a catalogue from 1952 [21] nor in the loan agreement from 1959 between the Rijksmuseum and the Gemeentemuseum in The Hague [22]. The authors assume therefore that the fracture occurred between 1959 and 1970. The instrument has been structurally treated in 2018 by Katja Hiller, who reunited the two pieces [23]. Preceding the treatment, in-depth examination and material analysis showed a noteworthy finding: the cornett is not only made in two longitudinal halves, but is also made out of two different sections of wood, one for the top and one for the bottom (Fig. 3). Visible in X-ray, the insect infestation by the common furniture beetle (Anobium punctatum) is mostly limited to the narrow upper end of the instrument, which could be microscopically identified as cherry wood (Prunus avium L.) [24]. The lower section with the finger holes is made of a much denser and more insect-resistant wood, probably boxwood (Buxus L.) [23]. Both sections were split longitudinally and hollowed out before being glued back together and subsequently joined to one another with a wedge-shaped lap-joint in the upper third of the cornett. These observations as well as the condition of the instrument were confirmed during a case-study focussing on explorative CT-scanning workflow for cultural heritage objects, which in turn inspired this further study [25]. After the successful treatment of the fractured section in 2018 the cornett could be exhibited again alongside the other two cornetts in the Special Collections Galleries of the Rijksmuseum [16]. However, the question remained as to why the instrument was made from two sections of two different wood species and whether these are original. All comparable objects known to the authors are made consistently out of one wood species; both boxwood and cherry wood were used independently of one another [1, 5, 8, 18]. The use of two different wood species with significantly different characteristics alongside one another is speculated to be either intentional or a restoration.

Cornett BK-AM-62-B, close-up and X-ray of lap-joint region showing the upper section made of cherry wood (Prunus avium L.) severely damaged by the common furniture beetle (Anobium punctatum) with some detours into the lower section made of boxwood (Buxus L.); faint outlines of the lap-joint are visible

Research aim

It is necessary to discern the exact processing and workmanship of the lap-joint in order to understand the underlying reason for the unusual construction of the cornett BK-AM-62-B of two joined wood sections of different species.

Concealed under the tightly fitting leather, any fine tool-marks, signs of construction, or indications of earlier treatments could offer valuable information. The leather covering neatly follows the complex shape of its core, the seam is practically invisible, and there is no sign of it ever having been removed or altered. Removing it to access the internal structure for inspection would have an unpredictable and potentially high risk of causing damage. High resolution CT scanning offered a powerful alternative, comparable to previous research on other cornetts carried out by Darmstädter et al. [1].

To validate the uncommon construction, the other two cornetts (BK-AM-62-C and BK-AM-62-A) at the Rijksmuseum were investigated, applying the same methodology. Literature research, mostly in German and English, about cornetts from similar periods both from Italy and north of the Alps [1, 2, 5,6,7,8, 18, 19] was undertaken and contemporary instrument makers were consulted.

Material and methods

While CT imaging is no novelty in the field of cultural heritage [26,27,28,29,30,31,32,33,34,35], the challenge arose to identify the exact region of interest (ROI) on this 56 cm long instrument (see Fig. 3), and subsequently obtain a detailed image at a significantly high resolution. The cornett BK-AM-62-B was examined using the Computed Tomography (CT) imaging facility of the Centrum Wiskunde and Informatica (CWI) at their FleX-ray LaboratoryFootnote 2. For the investigation of the internal structure of the other two cornetts (BK-AM-62-A, BK-AM-62-C) CT scans were performed at the X-ray imaging facility at the Rijksmuseum [36]. For the image reconstructions in this paper the FleXbox software [37] was used. An attempt was made to identify key features linked to the process of manufacturing and characteristics of deterioration possibly explaining potential past treatments.

During CT scanning, mounting the object safely on the rotation stage and prevent any movement of the object whilst rotating is paramount to obtain high resolution images. A mount of Ethafoam®Footnote 3 was made to support the cornett in an upright position (Fig. 4).

For BK-AM-62-B, a partial CT scan was made in the area of the joint. The scan consisted of 1200 projections and the tube energy was 70 kV, with voxel size 25 micron. This scan was used to investigate the joint type, and the reconstructed images will be shown in the Results section. To investigate other regions of the cornett and its overall internal structure, a full CT scan consisting of 30 tiles was made, with voxel size 50 micron. For more details on the scanning method and the other scanned regions, the authors refer to previous work [25]. To capture the entire object with the height constraints of the CT setup, the cornett had to be scanned in two sections, flipping it upside down for scanning the second half while the other section would remain outside of the scanner’s range. Three identified regions of interest (ROI) were scanned in the same manner as the region where the two wood species join: the upper section of the instrument, the lower part with the finger holes, and the treated area.

The other two cornettos (BK-AM-62-A, BK-AM-62-C) that were scanned at the X-ray imaging facility at the Atelier-building of the Rijksmuseum only needed vertical tiling (8 tiles) due to the larger size of the detector at this facility. The tube energy was 65 kV.

Results

The CT images obtained made it possible to both identify the exact ROIs on this 56 cm long instrument (BK-AM-62-B) and to collect a sufficiently high-resolution image of the specific areas with a voxel size of 25 micron. The lap-joint region where both sections connect to one another is the ROI where evidence is expected to answer the central questions as stated previously.

The lap-joint

The lap-joint connecting the two sections of the cornett BK-AM-62-B can be clearly visualized in the CT image. While the delicate construction noticeably exhibits the irregularity of a hand-made lap-joint with the lower part of the body fitting into the upper part, there is no sign or flaw indicative of an alteration, and no tool traces were identified. Both the upper sections with rhombus shapes and the lower part with the finger holes are made out of a single piece of wood that was bisected in its length, gouged out and subsequently joined back together (Fig. 5).

By placing a circle on the digital reconstruction matching the tree-ring curvature of the lower boxwood part, the radius could be estimated. It can be assumed that the wood section was located at approximately 10–20 cm from the pith in the transversal section of the tree trunk indicating the exceptionally large diameter of the boxwood tree trunk of at least 20 cm. The longitudinal joint is slightly shifted from the lower to the upper section, indicating that they were bisected separately, before being lap-joined together. It can only be assumed that the joint was cut after a rough shape was determined and before finishing the shape, bisecting the pieces, gouging out the centre, gluing the sections back together etc.

On the inside of the instrument a thin layer of higher density is visible, which is thicker to one side of both the upper and the lower parts of the instrument’s body and continues consistently across the joint. This feature can be explained by the internal impregnation of the instrument after the two sections were joined together and its depositing more on one side when left to dry [1]. The consistent deposit across the joint suggests an injection of the impregnation fluid into the bore and that the fluid was applied only once.

The leather fits tightly around both parts of the cornett and conforms to its intricate detailing and complex embossing. Imprinted circumferential marks in the leather lining with shallow grooves in the wooden substrate suggest the decorative depiction of bindings or ligatures in their four typical locations. No traces of the leather being reapplied during a previous treatment could be discerned on the CT-scan. If that would be the case one would expect to see traces of filling materials or voids between the leather and the diamond-shaped decoration of the newly added wood. Only a replacement of the leather as part of the treatment would result in the tight fit of the leather on both sections of the cornett.

The woodworm infestation took place with all components, including the leather, in their present configuration. Inspection of the tunnelling structure caused by the Anobium punctatum larvae confirmed that the upper section of cherry wood is nearly completely eaten away, in most places just leaving a paper-thin skin on the inside and outside. Only scarce “detours” of the larvae into the significantly harder boxwood of the lower part can be observed (Fig. 6). While boxwood practically never gets infested with Anobium punctatum by itself, none of the corridors stop exactly at the joint between the two wood species or with the leather as confirmed by 3D images of the hollow spaces including the tunnelling structure [38]; moreover, all exit holes in the leather correspond with the tunnelling structure made by the larvae in both species of wood.

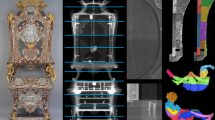

CT reconstruction of lap-joint region. Left in pseudo colours (colour range assigned according to density), centre left indicating the outlines of the individual parts (blue: leather, green: boxwood, yellow: cherry), centre right: 3D image of the hollow space including the tunnelling structure caused by the common furniture beetle (Anobium punctatum), right: 3D image of hollow spaces including the tunnelling structure with slice in pseudo colour representation

Comparison with other cornetts

The scans of the two comparable cornetts BK-AM-62-C and BK-AM-62-A revealed that both are made of a single bisected section of wood with a hollowed out curved bore (Figs. 7 and 8). The finger holes are similarly undercut, and the rope-binding is faintly visible.

So far, the only instance where a similar conical lap-joint could be identified is a replaced mouthpiece-ending of the mute cornett nr. SAM 227 made of boxwood in the collection of the Kunsthistorisches Museum in ViennaFootnote 4. The boxwood cornett of 650.2 mm length and 33.9 mm in diameter is not covered in leather. It bears two pairs of silkworm moths (“!! !!”) as a burn mark near the lower end, which is comparable with the three pairs of silkworm moths on the cornetto BK-AM-62-A and probably is also a mark by the London branch of the Bassano-dynasty [1, 3, 4, 7, 19]. Only the most upper 31 mm of a presumably damaged mouthpiece-ending was replaced in boxwood and is attached in a wedge-shaped lap-joint very similar to the joint of the cornett BK-AM-62-B.

Discussion

The construction of a cornett out of two sections of different wood species joined by a lap-joint is not readily comprehensible and this cornett is until now the only known cornett of this kind [1, 2, 5,6,7,8, 18, 19]. The CT-scans allowed for a highly detailed inspection of the cornett with a focus on the lap-joint. The authors could find no traces of a conservation treatment, other than the recent treatment of the broken upper cherry-wood part: the internal impregnation of the instrument during its manufacturing continues uniformly across the two sections. The embossed leather covering fits tightly onto the diamond decoration on both the upper and lower wooden section of the cornett. The woodworm infestation took place whilst the instrument was in its present form, with continuous tunnelling across the joint and the leather covering. The infestation was therefore not the reason of a possible renewing of one part of the instrument and its leather covering. Given the considerable degree of disintegration the infestation has likely taken place early on in the instruments existence and is also visible on a photograph from c. 1900 [20]. Replacing either the upper or lower section would have involved removing the original leather and would have left traces of its original embossing’s, rhombus shapes and overlapping seams remaining impressed when this was reapplied to the wood—unless the leather has also been replaced altogether.

The instrument makers consulted by the authors have not come across a cornett with a similar construction and are of the opinion that one of the two sections was added during an extensive conservation treatmentFootnote 5. This hypothesis would imply, as argued before, that the leather is likewise dating from the same intervention and is also not original, given that the woodworm infestation postdates the joining of the two sections and hence was not reason for the treatment in question. Mechanical damage would be the most likely reason, and would have occurred to one of the two sections. Another possibility is that the upper section might have split at its end due to regularly inserted mouthpiece by the player. The choice of the new material—cherry wood—turns out to have been detrimental, as it is significantly more prone to insect damage.

While the preservation of part of an important instrument is not uncommon, replicating the entire instrument altogether would have been less laborious. This argument and the lack of evidence of previous interventions as observed during the multi-scale CT scanning may support the theory that the construction in two sections could be original.

The unusual construction out of two wood species, if original, might be explained as an attempt to prevent splitting of the wood when inserting the mouthpiece, or perhaps to counteract undesired vibrations when played. Cornetts made of hard and dense wood species often split at the socket of the upper end holding the mouthpiece. In most cases cornetts with such damages were retrofitted with mouthpiece-ferrules, narrow circular rings often made from metal [18]. The use of a softer and more malleable wood for the upper section could be an attempt to counteract its splitting when inserting the mouthpiece.

Yet another explanation for making the cornett in two sections of different wood species could be linked to the specific qualities of these species. The mouthpiece and the bore have an evident interrelation affecting the sound [1]. And while the individual densities of the varying wood species do not have any direct implications for the sound, the choice appears to have an indirect effect on the oscillation of the air inside the bore, caused by the woods’ specific roughness and porosity [13, 15]. Darmstädter [1] further describes the phenomenon of “impedance turbulences”. Acoustic impedance“ is a measure […] of the motion induced by a pressure applied to a surface is impeded” [39]. When sound impedance is reflected back from the foot of the instrument it can interfere with the vibrations of the mouthpiece and cause turbulences. These imperfections could be adjusted by the maker. Combining two different wood species, a dense wood in the lower section with the finger holes and a softer more malleable wood for the upper section housing the mouthpiece, could have been an attempt to counteract impendence turbulences. However, the only possibility to verify this hypothesis would be by making a replica, as the condition of this intriguing historic instrument would not allow for a representative mechanical study.

Conclusion

Multi-scale CT-scanning proved a powerful tool and allowed for both a general inspection of the three instruments as well as identifying and zooming in at a substantially higher resolution in the ROIs. It was possible to access information of the internal structure without interfering with the instruments’ materials and construction. The novel visualisation of the hollow space in the 3D volume computed from the 3D x-ray tomography reconstruction has made it possible to inspect the tunnelling structure of the insect infestation and on these grounds place its occurrence after the joining of the two sections.

The results of this study are of value to both conservators and curators for a deeper understanding of the object’s state of preservation and interpretation of original manufacturing.

Based on the valuable evidence found during this study, it was possible to approximate the answer to the question whether the construction of cornett BK-AM-62-B in two sections of varying wood species is the result of an extensive restoration or reflects a deliberate choice of materials. To verify the contemporaneity of the individual sections of the cornett Carbon-14 cross-dating could be a possible method to investigate [40, 41]. If the construction is a deliberate, the reason for the choice of materials could be further explored by making a replica for mechanical studies on the implications of the sound.

Data availability

After acceptance, the CT scan data of BK-AM-62-A, recorded at the FleX-ray laboratory will be published on the Zenodo page of the Computational Imaging group at the Centrum Wiskunde and Informatica: https://zenodo.org/communities/ci-cwi/?page=1&size=20.

Notes

Private communication with Claudio Canevari, teacher at the Civica Scuola di Liuteria in Milan and adjunct lecturer at the University of Pavia.

CT for Art: from Images to Patterns. https://www.nicas-research.nl/projects/impact4art/. Accessed: 11 May 2022.

Ethafoam®. http://cameo.mfa.org/wiki/Ethafoam. Accessed: 11 May 2022.

A detailed description of the mute cornett nr. 227 from the Kunsthistorisches Museum Vienna can be found in Darmstädter et al. (2011), pp. 167–172.

Private communication with Claudio Canevari, teacher at the Civica Scuola di Liuteria in Milan and adjunct lecturer at the University of Pavia, and with Andrew Hallock, composer, countertenor, maker and musician of cornetts, The Netherlands.

Abbreviations

- CT:

-

Computed Tomography

- CWI:

-

Centrum Wiskunde and Informatica

- ASI:

-

Amsterdam Scientific Instruments

- ROI:

-

Region of interest

References

Darmstädter B, Salaberger B, Dickey B. Die Zinken und der Serpent der Sammlung alter Musikinstrumente. Sammlungskataloge des Kunsthistorischen Museums, Band 7, Kunsthistorisches Museum Wien. Bergkirchen: PPV Medien; 2011: p. 67–68, 73, 80, 92, 94, 101, 104, 105, 107, 167, 192, 197, 207.

Wilson R. Die Entwicklung des Zinken zwischen 1500 und 1700: neue Erkentnisse. In: Phillipsen Ch, Lustig M, editors. Der Zink - Geschichte, Instrumente und Bauweise 30. Musikinstrumentenbau-Symposium Michaelstein, 23. bis 25. Oktober 2009. Augsburg: Stiftung Kloster Michaelstein; 2015. p. 39.

Ongaro GM. New documents on the Bassano family. Early Music. 1992;20(3):409–13.

Lasocki D. The Bassanos: Venetian musicians and instrument makers in England, 1531–1665. London: Routledge; 1995.

Heyde H. Hörner und Zinken. Musikinstrumenten-Museum der Universität Leipzig. Leipzig: VEB Deutscher Verlag; 1982. p. 55–63.

Carter S. Nicks, kerfs, and joints: the story of the cornett, 1750–1850, in documents and surviving instruments. In: Phillipsen CH, Lustig M, editors. Der Zink – Geschichte, Instrumente und Bauweise 30. Musikinstrumentenbau-Symposium Michaelstein, 23. bis 25 Oktober 2009. Augsburg: Stiftung Kloster Michaelstein; 2015.

McCann J. Snakes, trees and flames: a discussion of venetian curved cornett decorations. Hist Brass Soc J. 1989. https://doi.org/10.2153/FOEG3127.

Baines A. Brass instruments: their history and development. London: Faber and Faber; 1980. p. 19.

Ziegenhals G. Akustische Untersuchungen an Zinken aus dem Instrumentensatz des Freiberger Doms, ihren Nachbauten und modernen Vergleichsinstrumenten. In: Phillipsen CH, Lustig M, editors. Der Zink - Geschichte, Instrumente und Bauweise 30. Musikinstrumentenbau-Symposium Michaelstein, 23. bis 25. Oktober 2009. Augsburg: Stiftung Kloster Michaelstein; 2015. p. 53.

Hornbostel EM, Sachs C. Classification of musical instruments: translated from the original German by Anthony Baines and Klaus P. Wachsmann. Galpin Soc J. 1961;14:28.

Klaus SK. Zinkenbau und Zinkenspiel in Süddeutschland – von der Freien Reichsstadt Nürnberg bis zum Königreich Württemberg. In: Phillipsen CH, Lustig M, editors. Der Zink - Geschichte, Instrumente und Bauweise 30. Musikinstrumentenbau-Symposium Michaelstein, 23. bis 25. Oktober 2009. Augsburg: Stiftung Kloster Michaelstein; 2015. p. 21.

Vaiedelich S, Boutin H, Pathé A, Givois A, Fabre B, le Conte S, Carrou JL. Making historical musical instruments speak. In: Boutin H, Vaiedelich S, Pathé A, Givois A, Fabre B, et al.. FA-RE-MI (Faire parler les instruments de musique du patrimoine): Wooden Musical Instruments Different Forms of Knowledge, 2018. hal-02470016; 325 – 341: 332, 336.

Boutin H, Le Conte S, Vaiedelich S, Fabre B, Le Carrou J-L. Acoustic dissipation in wooden pipes of different species used in wind instrument making: an experimental study. J Acoust Soc Am. 2017. https://doi.org/10.1121/1.4981119.

Boutin H, le Conte S, Vaiedelich S, Fabre B, Carrou JL.Modèle de Propagation Acoustique dans un Tuyau Cylindrique à Paroi Poreuse. 14ème Congrès Français d’Acoustique (CFA’18), Apr 2018, Le Havre, France. hal-01830275 : 685–691.

Boutin H, Le Conte S, Fabre B, Le Carrou J-L. Influence of the surface condition in the bore of woodwind instruments on the accoustic impedance. In. COST FP1302 Woodmusic—annual conference: effects of playing on early and modern musical instruments; London, Royal College of Music, 9–10 September 2015.

Di Stefano GP. Music Parade: A new display at the Rijksmusem. In: ICOM-CIMCIM (International council of museums—International committee for museums and collections of music) Bulletin, April 2020: 30–33.

Plenckers LJ. Haags Gemeentemuseum : catalogus van de muziekinstrumenten, deel I: hoorn- en trompetachtige blaasinstrumenten. Amsterdam: Frits Knuf; 1970. p. 22–3.

Overton FR. Der Zink: Geschichte, Bauweise und Spieltechnik eines historischen Musikinstruments. Mainz: Schott; 1981: 73, 74, 132–133.

Lyndon-Jones M. A checklist of woodwind instruments marked!! Galpin Soc J. 1999;52:243–80.

Rijksmuseum Photo Archive: negative number 1649, 18x24, c. 1900.

Ligtvoet AW. Muziekinstrumenten uit het Rijksmuseum te Amsterdam, 9 October - 24 November 1952, Dienst voor de Schone Kunsten, Gemeentemuseum, ’s-Gravenhage; 1952: 27.

Loan agreement dating from 14 October 1959, signed by D.C. Röell, general director of the Rijksmuseum, addressed to the director of the Gemeentemuseum in The Hague, L.F.J. Wijsenbeek.

Hiller K. Krummer Zink, gerade Stäbchen. Restauro. 2018;8:34–9.

Schoch W, Hellier I, Schweingruber FH, Kienast F. Wood anatomy of central European Species. 2004. www.woodanatomy.ch. Accessed: 11 May 2022.

Bossema FG, Coban SB, Kostenko A, van Duin P, Dorscheid J, Garachon I, Hermens E, van Liere R, Batenburg KJ. Integrating expert feedback on the spot in a time-efficient explorative CT scanning workflow for cultural heritage objects. J Cult Herit. 2021;49:38–47. https://doi.org/10.1016/j.culher.2021.03.004.

Johnson CR, Hendriks E, Berezhnoy IJ, Brevdo E, Hughes SM, Daubechies I, Li J, Postma E, Wang JZ. Image processing for artist identification. IEEE Signal Process Mag. 2008;25(4):37–48. https://doi.org/10.1109/msp.2008.923513.

Cornelis B, Dooms A, Daubechies I, Schelkens P. Report on digital image processing for art historians. In: SAMPTA’09, special session on sampling and (in)painting. Marseille, France; 2009.

Cornelis B, Ružić T, Gezels E, Dooms A, Pižurica A, Platiša L, Cornelis J, Martens M, De Mey M, Daubechies I. Crack detection and inpainting for virtual restoration of paintings: the case of the Ghent Altarpiece. Signal Process. 2013;93(3):605–19. https://doi.org/10.1016/j.sigpro.2012.07.022.

Pintus R, Pal K, Yang Y, Weyrich T, Gobbetti E, Rushmeier H. A survey of geometric analysis in cultural heritage. Comput Graph Forum. 2016;35(1):4–31. https://doi.org/10.1111/cgf.12668.

Legrand S, Vanmeert F, Van der Snickt G, Alfeld M, De Nolf W, Dik J, Janssens K. Examination of historical paintings by state-of-the-art hyperspectral imaging methods: from scanning infra-red spectroscopy to computed X-ray laminography. Herit Sci. 2014;2:13. https://doi.org/10.1186/2050-7445-2-13.

Payne EM. Imaging techniques in conservation. J Conserv Museum Stud. 2013;10(2):17–29. https://doi.org/10.5334/jcms.1021201.

Vandivere A, van Loon A, Dooley KA, Haswell R, Erdmann RG, Leonhardt E, Delaney JK. Revealing the painterly technique beneath the surface of Vermeer’s girl with a pearl earring using macro- and microscale imaging. Herit Sci. 2019;7:64. https://doi.org/10.1186/s40494-019-0308-4.

Yin R, Cornelis B, Fodor G, Ocon N, Dunson D, Daubechies I. Removing cradle artifacts in X-ray images of paintings. SIAM J Imaging Sci. 2016;9(3):1247–72. https://doi.org/10.1137/15M1053554.

Domínguez-Delmás M, Bossema FG, van der Mark B, Kostenko A, Coban SB, van Daalen S, van Duin P, Batenburg KJ. Dating and provenancing the Woman with lantern sculpture—a contribution towards attribution of Netherlandish art. J Cult Herit. 2021. https://doi.org/10.1016/j.culher.2021.04.005.

Domínguez-Delmás M, Bossema FG, Dorscheid J, Coban SB, Hall-Aquitania M, Batenburg KJ, Hermens E. X-ray computed tomography for non-invasive dendrochronology reveals a concealed double panelling on a painting from Rubens’ studio. PLoS ONE. 2021. https://doi.org/10.1371/journal.pone.0255792.

Coban SB, Lucka F, Palenstijn WJ, van Loo D, Batenburg KJ. Explorative imaging and its implementation at the FleX-ray laboratory. J Imaging. 2020;6:18. https://doi.org/10.3390/jimaging6040018.

Kostenko A, Palenstijn WJ, Coban SB, Hendriksen AA, van Liere R, Batenburg KJ. Prototyping X-ray tomographic reconstruction pipelines with FleXbox. SoftwareX. 2020. https://doi.org/10.1016/j.softx.2019.100364.

van Liere R, Batenburg KJ, Garachon I, Wang CL, Dorscheid J. The dual space: concept and applications in cultural heritage. IEEE BITS Inform Theory Mag. 2022. https://doi.org/10.1109/MBITS.2022.3202508.

Rienstra SW, Hirschberg A. An introduction to acoustics. Eindhoven University of Technology. 2012.

Durier M, Bruguière P, Hatté C, Vaiedelich S, Gauthier C, Thil F, Tisnérat-Laborde N. Radiocarbon dating of legacy music instrument collections: example of traditional Indian Vina from the Musée De La Musique, Paris. Radiocarbon. 2019;61(5):1357–66. https://doi.org/10.1017/RDC.2019.71.

Durier M-G, Hatté C, Vaiedelich S, Gauthier C, Noury C, et al.. Radiocarbon dating application to modern musical instruments: an interdisciplinary study. labs, art and relics, Nov. 2018, Bruxelles, Belgium. ⟨hal-02281820⟩.

Acknowledgements

The authors would like to thank for their input and contributions Claudio Carnevari and Andrew Hallock, as well as Willem Jan Palenstijn, Alexander Kostenko and Katja Hiller. The authors are moreover grateful to TESCAN-XRE NV, for their collaboration regarding the FleX-ray Laboratory.

Funding

This collaborative research project was based on the experiences gained from previous interdisciplinary projects and enabled under the umbrella of Impact4Art [22]. The Impact4Art project is supported by the Netherlands Institute for Conservation, Art and Science (NICAS) and NWO, project number 628.007.033. The FleX-ray Laboratory is supported by NWO, project number 639.073.506. The sponsors were not involved in the research and writing process.

Author information

Authors and Affiliations

Contributions

JD and PvD interpreted the results of the conducted research, compiled the surrounding information, drafted the manuscript, and facilitated and assisted with the physical scanning of the instrument. FGB, SBC, RvL and KJB conducted the CT scanning, data evaluation and computed modelling of the results. FGB drafted the Materials and methods section of the manuscript. GPDS contributed with the art historical background and private communications with renowned specialists.

Corresponding author

Ethics declarations

Competing interests

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Dorscheid, J., Bossema, F.G., van Duin, P. et al. Looking under the skin: multi-scale CT scanning of a peculiarly constructed cornett in the Rijksmuseum. Herit Sci 10, 161 (2022). https://doi.org/10.1186/s40494-022-00800-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40494-022-00800-8