Abstract

In the previous paper (Part I), the colorimetry and interferometric microscopy measurements on modern gold leaf models have revealed that the visual appearance of a gilded surface, both burnished and unburnished, depends strongly on the substrate type, surface roughness and texture, but not on the colour of the substrate. In this second part, we investigate the materials compositions and technical specifications of medieval gold leaf through combining literature sources and materials analysis such as scanning electron microscopy coupled with energy dispersive X-ray analysis (SEM–EDX) on samples taken from gilded wooden sculptures. Our study shows that the late medieval gold leaf has a high purity of about 23.7 carat and has an average thickness of 160 nm (with a peak value of 138 nm), purer and thicker than the modern gold leaves studies in Part I. Supportive Rutherford backscattering spectrometry (RBS) measurements on gilded models confirms the accuracy and reliability of the SEM–EDX observations on the medieval gold leaf samples. We additionally present observations of a rarely recorded special variant of medieval gold leaf—“fine reinforced gold leaf”. Combined with the findings from Part I, we conclude that light penetrating the medieval gold leaf and reflected from the gilding substrate could not be a significant, or even perceptible contribution to the visual appearance of the gilding. We argue that the misconception surrounding the correlation between the substrate colour and the gilded surface appearance can be attributed to the historical development of gilding and polychromy technologies.

Similar content being viewed by others

Introduction

In the history of medieval gilding, a popular point of view states that the colour of the gilding substrate influences the visual perception of the gilded surface due to the ultra-thin gold leaf being not completely opaque [1,2,3,4]. This view has been circulated for centuries and often used to explain why particular substrate colours such as red, yellow and white have been frequently observed in medieval gilded artefacts [3, 5,6,7].

In the previous paper (Part I), we have investigated models that were made from modern gold leaves with traditional gilding techniques. Colorimetry measurements on such models show that there is no correlation between the substrate colour and the visual appearance of the gold leaf laid above. Indeed, the modern gold leaves were observed to be far too thick to allow any significant transparency to visible light. Instead, surface burnishing is the most critical factor in determining the colour appearance of a gold leaf through changing the roughness of its surface and thus the proportion of the specular and diffuse light reflections; and the quality of a surface burnishing is strongly dependent on the mechanical support provided by the substrate materials. In addition, the surface roughness and texture of the substrate were also shown to play supplementary roles in determining the appearance, especially for an unburnished gold leaf.

The current paper (Part II) focuses on investigating two technological parameters of medieval gold leaf, namely the gold purity and leaf thickness, which are critical factors for the colour perception of a gold leaf and important to determine whether the findings from Part I apply to the domain of medieval gold leaf. Information regarding these parameters is obtained through literature study in medieval gilding and materials analysis such as scanning electron microscopy coupled with energy dispersive X-ray analysis (SEM–EDX) on samples taken from medieval gilded artefacts. Further literature study in the historical development of medieval polychromy is expected to show the motives for the creation and prevalence of the aforementioned view that the substrate colour influences the appearance of a gilded surface.

In order to assure the accuracy and reliability of SEM observations on the gold leaf samples, a novel sample preparation method through ultramicrotomy has been developed. As supportive data, Rutherford backscattering spectrometry (RBS) is applied to models made from modern gold leaves. The comparison between RBS and SEM investigations on modern gold leaf aims to verify the precision of the sample preparation and experimental methods.

Background

The historical manufacture of gold leaf, known as goldbeating, has not changed much since ancient times [8]. By hammering a lump of gold, a thin gold plate or ribbon is formed; the gold plate/ribbon is then cut into squares and placed within a stack of paper or parchment, and repeatedly beaten until it reaches the desired thickness [8]. In the medieval period, coins served as the most common material source for gold leaf [9,10,11]; especially from the mid thirteenth century, gold coins with stable, high purity such as florins (23.75–24 carat recorded in 1252) and ducats (23.75 carat recorded in 1284) became a reliable source for gold leaf [11]. Evidence of the use of such high-quality gold coins is traceable in some work contracts and guild regulations. For example, in the statutes of the goldsmiths’ guild, the Arte di Por Santa Maria, of 1335, the gold used for artworks is required to be sourced exclusively from florins [12].

The leaf thickness is of great significance in gilding history and denotes the level of metallurgic and goldbeating technologies of the epochs. Nevertheless, the selection of gold leaf sometimes has to face a dilemma: on one hand using thin leaf is critical for artisans to keep a lower cost during the creation process of artworks; while on the other hand a moderate thickness provides mechanical stability, since very thin gold leaf can be easily torn during the burnishing process or worn out. Therefore, some medieval guild regulations and artists’ treaties particularly defined a required leaf thickness by specifying a required number of gold leaves produced from each gold coin. For example, a Florentine guild statute fixes a rate of one florin to one hundred gold leaves [10]; Cennini also suggests 100–145 sheets of gold leaf from a single ducat [11]. In the latter case, combining the weight of ducat (ca. 3.5 g), its gold purity (23.75 carat) and the common sizes of gold leaf in the fourteenth century’s Florence (6.8 × 6.8 cm and 8.2 × 8.2 cm [13]), the leaf thickness is calculated to be in the range of ca. 190–400 nm. Kubersky gives an even thinner and more specific number of 154 nm for the gold leaf of the sixteenth century based on Vasari’s treaties [13]. The National Art Gallery of London [11] provides an average thickness of medieval gold leaf of around 2.69 µm based on the calculation with the given weight of the florin and the number of leaves per coin, which seems significantly thicker than the historical records, indicating the presence of diverse specifications for medieval gold leaf. Indeed, scientific analysis of artefacts has shown that the thickness of medieval gold leaf varies from 100 nm to a few microns [8, 14, 15]. It is interesting to note that while each of these estimates describes the produced gold leaf as having a very regular square or rectangular shape (in agreement with observations), there is no mention of the offcuts necessarily produced from trimming the leaf edges and so the thickness estimates provided above should be considered as an upper bound.

A special variant of medieval gold leaf, called “or fin renforcie” (fine reinforced gold leaf), “d’or fin doubles” (double weight fine gold leaf) and “or doubles renforciez” (gold leaf, double reinforced), which was mentioned in records of the market price of artists’ supplies in Dijon in the turn of 1400 [16], deserves some attention. The two former types were double, and the latter was 1.5 times the price of a normal gold leaf, suggesting a respective leaf thickness of 2 and 1.5 times thicker than the standard. Indeed, the use of gold leaf with different thicknesses is recorded in medieval treatises, for example, Cennini suggests using thicker leaf (e.g. 100 or less sheets produced from one ducat) for flat backgrounds, as it is more suitable for burnishing, and thinner leaf (possibly 145 sheets per ducat) for mordant gilding and frame moulding [7]. Other medieval treatises such as De diversis artibus by Theophilus (twelfth century) and the Montpellier Treatise (fourteenth–fifteenth century) also mention that 2 or 3 layers of gold leaf can be applied through glair if desired [6].

In addition to the leaf thickness, the lateral size of the gold leaf is also an important technical specification of historical gold leaf. It is a critical factor for the traditional method of estimating or calculating the thickness of historical gold leaf, as discussed above with examples of Florentine gold leaf. However, literature records regarding the leaf size and format of medieval gold leaf present a great deal of variety. For example, gold leaf in northern European countries from 1390 till the Reformation is reported to be in either square or rectangular formats with one side of 80–93 mm [17], while other researchers state that gold leaf in northern Germany and Sweden has the sizes of 9.6, 7.2 and 6 cm square [15]. In southern European cities such as Florence, 6.8 × 6.8 and 8.2 × 8.2 cm are recorded for gold leaf in the fourteenth–sixteenth century [13], while in the painters’ statutes of the Florentine Guild of 1403, the size of gold leaf was fixed as one-ninth to one-eighth of a braccio fiorentino per side, corresponding to ca. 6.5–7.3 cm [11]. Therefore, the calculation or estimation of gold leaf thickness can be only performed based on reliable literature sources from specific regions and epochs.

Samples and methods

Samples and sample preparation

33 polychrome wooden sculptures, mainly dated in 1490–1525 and produced in southern Germany, eastern and central Switzerland, were first measured and selected through a Handheld X-ray fluorescence analyser (HHXRF) in the Swiss National Museum (SNM)—Collection Centre. Details of the implementation of HHXRF on gilded artefacts are presented in our previous studies [18, 19]. A total of 34 gold leaf samples with a diameter of maximum 1 mm was taken mainly in the areas of saints’ golden gowns and gown bordures. The sample taking was preferably performed in positions invisible to viewers and difficult to access, in order to maintain the aesthetic integrity of the artefacts and to minimise the chance that the samples have been altered by previous restoration treatments. One example of a selected sculpture as well as its sample taking position is shown in Fig. 1. Detailed information regarding related objects and sample-taking positions are presented in Table 2.

Samples of modern gold leaf including Spezial-Poliergold-Altgold-Dunkel (from Deffner & Johann, Germany) and Dukaten-Doppelgold (from Noris Blattgold, Germany) were taken from the models investigated in Part I for use as controls in the measurements performed in this work. Procedures of the model production are presented in Part I.

Samples were embedded with epoxy resin Araldite 2020 and then cross-sectioned with a Leica UC7 ultra-microtome at the Paul Scherrer Institute (PSI). A DiATOME trimtool 45 diamond knife was used with a clearance angle of 6°. It is worthwhile to point out that producing sample cross-sections for the leaf thickness measurements through SEM requires a precise positioning of the sample during the embedding and cutting. An ideal circumstance is to cut the cross-section perpendicularly to the leaf surface. We have developed a reliable sample preparation method including sample embedding, trimming, cutting and coating, which is summarized and illustrated in Fig. 2. Note that the foil side of the sample needs to be placed face down during the embedding, since this side tends to have a flatter surface than the preparation layer side. Furthermore, the cutting direction should be along the foil, in order to avoid smearing of sample materials, especially the soft gold.

Analytical techniques and experimental conditions

A visual light microscope (VLM) Leica DM4000M, coupled with a uEye UI144xSE-C camera, was used to observe and image the stratigraphy of the sample cross-sections in the conservation laboratory of SNM, in both bright field (BF) and dark field (DF) modes. Through VLM observations, samples containing overlaid Fassungs (German term, refers to a set of polychrome layers applied on sculpture), which usually indicate the presence of overpainting in later time, can be screened out from further SEM–EDX analysis.

The SEM–EDX measurements on sample cross-sections were implemented at the Paul Scherrer Institute (PSI, Switzerland) through a high-resolution Hitachi Regulus 8230 SEM coupled with an EDX X-Max detector, using 5 kV voltage, 10 μA current and Condenser Lens 1 of 2–6 [19]. Samples were coated with ca. 6.5 nm of chromium to increase the sample conductivity and reduce charging issues. A factory standard (5 kV set) was used for EDX quantification analysis. SEM observations on the gold leaf thickness were based on the backscattered electron (BSE) imaging on sample cross-sections.

RBS measurements on models were performed at the Swiss Federal Institute of Technology (ETH Zurich, Switzerland) laboratory for Ion Beam Physics, using both 2 MeV and 5 MeV 4He beams and a silicon PIN diode detector at 168°. The collected RBS data was analysed using simulations by the RUMP code [20].

Results and discussions

SEM–EDX and RBS measurements of modern gold leaf

Table 1 shows that the SEM–EDX observation on the gold (Au) content of modern gold leaf is 96.8±0.2% by weight (w%) for Spezial-Poliergold and 96.6±1.1 w% for Dukaten-Doppelgold, corresponding to the RBS data of 96.6±0.3 w% and 96.2±0.3 w% respectively. Compared to atomic ratios, weight ratios (w%) are preferably used for the quantification of the gold content of the medieval samples, since they can be easily transformed into carat, which is the most important and frequently used unit of gold purity in most literate records regarding medieval gilding leaves/foils. In the case of modern gold leaves used in our study, their gold purity is about 23.1 to 23.2 carat.

SEM-BSE and RBS measurements further show that the Poliergold (96±9; 92±7 nm) appears slightly thinner than the Doppelgold (116±16 nm; 127±7 nm) by ca. 20–30 nm, but both of them are still within the published thickness range of 100–200 nm for modern gold leaf [21, 22]. The high consistency between SEM–EDX and RBS measurements of modern gold leaf samples proves that the samples were precisely prepared, which further confirms the accuracy and reliability of the SEM–EDX observations on the medieval gold leaf samples.

Figure 3 presents one example of the SEM-BSE image (a) and a EDX spot test (a) on a sample taken from a small (ca. 10 × 10 mm), non-burnished gold leaf model made from Dukaten-Doppelgold (laid atop a red bole substrate), compared to the RBS measurements on the same model. Note that the RBS thickness measurement (Fig. 3c) was conducted in the thickness scan mode tracing a 2 meV beam (in a diameter of ca. 1 mm) along the middle line of the model in steps of 1 mm; and its elemental analysis (Fig. 3d) was performed at the central position of the model with a 5 meV beam. Here, it is worth noting that no obvious thickness difference has been observed between the non-burnished and burnished states of gold leaf in both SEM and RBS measurements. Indeed, after the high pressure pressing and rolling during the manufacturing of gold leaf, a manual surface burnishing with agate tools should not generate sufficient pressure to significantly modify the leaf form. The same situation should also apply to the medieval gold leaf, which was produced through the gold-beating process [8].

SEM–EDX measurements of medieval gold leaf

In VLM observations on the sample stratigraphy, two of the 34 medieval gold leaf samples show an overlay of different Fassungs, indicating that they may not have been part of the original artefacts, and so were excluded from further analysis. Figure 4 shows an example of overlaid Fassungs in a sample stratigraphy (b), compared to a normal gold leaf sample (a). Therefore, a total of 32 samples were measured through SEM–EDX.

Table 2 presents details of SEM–EDX measurements on the 32 medieval gold leaf samples with respect to their gold content and leaf thickness. Note that 7 of the 32 samples contain multiple sub-layers. In 3 cases, the sub-layers can be clearly distinguished and hence the average thickness of the individual sub-layers are included in the summary of basic statistics of the leaf thickness and gold content in Table 3. In the remaining 4 multi-layered samples (marked with “*” in Table 2), the sub-layers are poorly defined and difficult to distinguish, and so these 4 samples were excluded from the statistics of leaf thickness, but still used for the statistics of gold content.

Table 3 exhibits the basic statistics of the leaf thickness and gold content of medieval gold leaf samples based on their SEM–EDX data presented in Table 2. Note that the average (avg.), standard deviation (stdev.), median (med.), minimum (min.) and maximum (max.) values in the statistics are based on the averaged measurements of each sample.

Gold content

As shown in Table 3, the average gold purity of the medieval samples is around 23.70 carat, based on 342 measurements of 32 samples, which is close to the historical records of florins (23.75–24 carat) and ducats (23.75 carat). The main alloying elements observed in the sample leaves include copper (Cu) and silver (Ag), with an average content of 0.43 w% and 0.84 w% respectively. However, these are both unevenly distributed in the gold leaf, demonstrated by the relatively high standard deviations. Details regarding the Ag and Cu contents of each sample are presented in Table 2.

It is worth pointing out that 7 of the 32 samples show relatively lower gold quality of 22.02 to 23.26 carat (marked with “**” in Table 2), while the rest of the samples exhibit very high gold purity of 23.62 to 24 carat. We are not certain about the gold source for these 7 samples, which could be some other gold coins such as Rhenish gold with its early compositions. Evidence of using Rhenish gold for gold leaf can be found in some German work contracts of the early sixteenth century [15]. Compared to the florin and ducat, the quality of Rhenish gold was not stable, and its gold content sunk from 98% when it was first minted in 1354 to only 79% by 1419 [15].

Leaf thickness

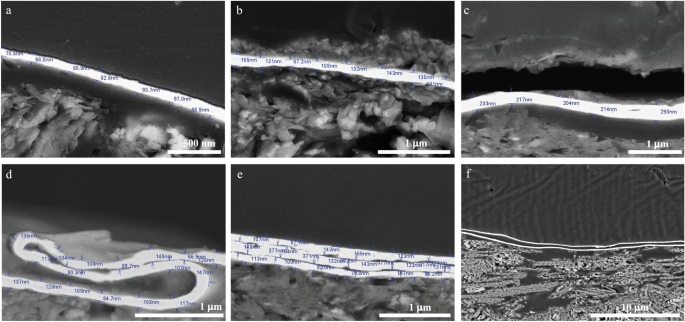

Most of the medieval gold leaf samples (Fig. 5b–d) were observed to be slightly less even than the modern gold leaf (Fig. 5a); and their thickness varies significantly. The basic statistics in Table 3 show that the average thickness of medieval gold leaf is 162 ± 39 nm based on 2235 measurements on 28 gold leaf samples, with a median value of 158 nm, a minimum and a maximum value of 103 nm and 244 nm respectively. This observation is close to the literature record (possibly a calculated leaf thickness) based on Vasari’s treaties (154 nm for gold leaf of the sixteenth century) and ca. 1.4–1.7 times as thick as modern gold leaf that we have observed in Spezial-Poliergold (96 ± 9) and Dukaten-Doppelgold (116 ± 16).

Thickness measurements (indicated with blue numbers) for modern and medieval gold leaf samples based on SEM-BSE images: a modern gold leaf Spezial-Poliergold; b, c normal medieval gold leaves; d a folded normal medieval gold leaf; e a multi-layered medieval gold leaf; f two layers of modern gold leaf Dukaten-Doppelgold overlaid through a 1.5 w% water-based rabbit skin glue

The seven sample gold leaves that contain multiple sub-layers (Fig. 5e) show an overall thickness of 388 ± 45 nm, ca. 2.5 times larger than the average thickness of normal gold leaves. Measurement data of these seven samples are presented in Table 4. Such thick, multi-layered gold leaf can be sometimes misidentified as a folded normal (i.e. single-layered) gold leaf (Fig. 5d), which usually occurs in wrinkled areas of a gilded surface. The observation of the multi-layered gold leaf reminds us of the special type of “fine reinforced gold leaf” recorded in artists’ supplies in Dijon in 1400. Since very little space is observed between these sub-layers, we believe that the artisans must have combined a few thin gold foils in the later stages of beating, in order to ensure a desired final thickness relative to the normal gold leaf. This is different from Cennini’s suggestion of reducing the number of the gold leaves produced from one gold coin for greater leaf thickness, and also unlike Theophilus’s recipe of applying multiple layers of gold leaf with adhesive. SEM observations on a sample taken from a model applied with double layers of modern gold leaf (model produced in Part I) provide evidence supporting our hypothesis. Figure 5f shows that when adhesive (1.5 w% rabbit skin glue in this case) is used for laying one gold leaf above another, a relatively large space is present between these two leaves, even in a burnished state. Based on our experience in the production of models, overlaying gold leaves without adhesive is not practical, as the upper leaf does not adhere and is removed with the lightest touch.

More detailed information is presented in the thickness histogram in Fig. 6, which was constructed by summing the set of clipped normal distributions corresponding to the average, standard deviation, minimum and maximum values calculated from the measurements on each medieval sample shown in Table 2 (four samples marked with “*” were excluded). The histogram of medieval gold leaf samples shows a half-peak range of 85–216 nm with the peak value of 138 nm, indicating a much broader thickness range compared to the modern samples of Spezial-Poliergold (76–115 nm with the peak at 94 nm) and Dukaten-Doppelgold (92–144 nm with the peak at 112 nm).

Further discussions

The SEM–EDX observations of the late medieval gold leaf samples are in high agreement with related literature records, often exhibiting greater leaf thickness and even higher gold purity than some modern gold leaves. Combined with the known optical properties of thin gold films excluding significant transparency in gold films thicker than 100 nm [23] and our findings through modern gold leaf models in Part I, our observations of medieval gold leaf samples indicate that no perceptible reflected light from the substrate could be able to penetrate through the medieval gold leaf to the surface, except for through cracks or holes inside of the leaf. In Part I we determined that such crack and holes in the gilding typically do not make up a significant enough fraction of the surface area to make a perceptible difference to the colour. Therefore, we conclude that the substrate colour does not play any role in the visual appearance of late medieval artefacts gilded with gold leaf. However, why has this misconception been well accepted since at least the Middle Ages and circulated even till now? We believe that the main reason is likely related to the historical development of medieval polychromy. According to Brachert and Kobler [24], in the time period from the second half of the twelfth century till the early fourteenth century, white ground was generally used for glossy gilding in northern Europe, while the use of Armenian bole started in the South. During the trend of “Ideal polychromy” (translated from Ideale Fassung in German), which appeared in the first half of the fourteenth century, differentiated gold effects were preferred: for example, hair was always in matte gold, while gown could show a contrasted effect with glossy gold on white ground and matte gold on yellow substrate. By the end of the fourteenth century, gold leaf was generally applied on a yellow, seldom white substrate, and red Poliment (German term, refers to fine clay bound with organic media and often mixed with pigments, similar to bole [26]) became popular since the middle of this century and dominant in later epochs [17, 24, 25]. Although the “yellow substrate” is not clearly specified by the authors, from its usage for matt gilding we believe that it refers to yellow mordant. Now we see a clear chronological sequence of using different substrates for gilding in the North of medieval Europe: white ground—mixture of white ground and yellow mordant—yellow mordant—red Poliment.

Since ground gilding can only offer a poor surface burnishing and mordant gilding is not burnishable, gold surfaces of North European sculptures in the time periods prior to the introduction of red bole/Poliment, must appear relatively matte and yellowish. Following the wide use of red bole, the quality of the surface burnishing was strongly enhanced, and the gold surface hence exhibited high metal gloss and more depth in its colour appearance, rendering a warmer and more saturated feeling to human eyes. From this perspective of working with a limited set of substrate materials, there is a clear correlation between the substrate colour and the gilding surface, and so it would be easy for medieval artisans to fall victim to the fallacy that the correlation implies causation. However, it is only a coincidence that the colour tone of these substrate materials correlates with the mechanical support and surface roughness properties that are the true cause of the mirror-like smooth surface of the gilding that provides the desired visual appearance. This was demonstrated in Part I with the use of a wider range of substrate material types and colour combinations than would have been available to artisans at the time that the substrate colour theory was being popularised. The occurrence of very fine gold leaf in the late Middle Ages could further strengthen people’s “faith” in using certain substrate colours for gilding, because they believed that the gold leaf was too “thin” to block the substrate colour.

Another contributing factor for artisans’ misconception could have been related to the parallel development of painting techniques in the late medieval period, especially the wide application of stand oil as a pigment binder for the late Gothic’s artworks [26]. Such heat-treated oil (e.g. linseed oil, walnut oil) can be dry within 24–48 h in the paint layers and is thus especially suitable for thin layers over a white grounding [26]. It was also commonly used for the half-transparent colour glazing or varnishes [10], due to its closer refractive index to many pigments for reduced light scattering, compared to water-based binding media [27]. For example, aluminium hydroxide was a common substrate for the organic lake pigments that were extensively used in coloured glaze; its refractive index (ca. 1.5) is very close to that of linseed oil (1.48) and significantly larger than that of glue (ca. 1.35) [27]. Additionally, some mineral pigments and fillers such as ultramarine, smalt, chalk and gypsum also show similar refractive indices as oil (1.5, 1.49–1.52, 1.5–1.64, 1.53–1.62 vs. 1.48) [27]. The practical experience of dealing with oil containing binding media might have helped to build the fallacy in minds of the artisans that a thin gold leaf should behave similarly to the oil paint layers and also be unable to fully block the colour of an underlying layer (e.g. a red bole). The transfer of such ideas could occur especially easily in workshops where gilders and Fassmaler (German term, refers to painters working on sculptures) were working together, which was fairly common at that time.

Conclusions

This study refutes the long-accepted point of view in the history of medieval gilding that the substrate colour can influence the visual appearance of a gilded artefact due to the transparency of the ultra-thin gold leaf laid above. Our investigations combining literature sources and SEM–EDX measurements on samples taken from gilded artefacts show that the medieval gold leaf is of high gold purity of about 23.7 carat and around 160 nm thick (with a peak value of 138 nm), which is only about 1.4–1.7 times as thick as modern gold leaves, indicating a high technological level in the manufacturing of fine gilding materials in the late medieval period.

Since the medieval gold leaves are as pure and at least as thick as the modern gold leaves used in Part I, our previous findings must also be applicable to medieval gilding. Firstly, the gold leaf is too thick to transmit a perceptible amount of visible light reflected from the substrate, and secondly that the visual appearance of the gilded surface is dominated by the proportion of light in the specular and diffuse reflections, which is caused by the roughness of the gold surface and is, in turn, influenced by the roughness and mechanical support provided by the substrate. We argue that the fallacious substrate colour theory may have formed due to two factors: the limited set of material types and colours available at the time (together with their chronological introduction) that coincidentally correlated well with the smoothness of the gilded surfaces, and the analogy with the partial transparency of oil paint layers being used in the same workshops.

Availability of data and materials

The datasets used and/or analysed during this study are available from the corresponding author on reasonable request.

Abbreviations

- Ag:

-

Silver

- Au:

-

Gold

- avg.:

-

Average

- BF:

-

Bright field

- BSE:

-

Backscattered electron

- Cu:

-

Copper

- DF:

-

Dark field

- ETH Zurich:

-

Swiss Federal Institute of Technology, Zurich

- HHXRF:

-

Handheld X-ray fluorescence analyser

- Inv. No.:

-

Inventory number

- max.:

-

Maximum

- med.:

-

Median

- min.:

-

Minimum

- RBS:

-

Rutherford backscattering spectrometry

- SEM–EDX:

-

Scanning electron microscopy coupled with energy dispersive X-ray analysis

- SNM:

-

Swiss National Museum

- stdev.:

-

Standard deviation

- PSI:

-

Paul Scherrer Institute

- VLM:

-

Visible light microscopy

- w%:

-

Percent by weight

References

Hradil D, Hradilová J, Bezdicka P, Serendan C. Late Gothic/early Renaissance gilding technology and the traditional poliment material ‘Armenian bole’: Truly red clay, or rather bauxite? Appl Clay Sci. 2017;135:271–81. https://doi.org/10.1016/j.clay.2016.10.004.

Mounier A, Daniel F. The role of the under-layer in the coloured perception of gildings in medieval mural paintings. Open Journal of Archaeometry. 2013;1:28. https://doi.org/10.4081/arc.2013.e16.

Sandu ICA, de Sá MH, Pereira MC. Ancient ‘gilded’ art object from European cultural heritage: a review on different scales of characterization. Surf Interface Anal. 2011;43(8):1134–51. https://doi.org/10.1002/sia.3740.

Dumazet S, Gentry A, Zymla A, de Contencin F-X, Texier A, Ruscassier N, Bonnet B, Callet P. Influence of the substrate colour of the visual appearance of gilded sculptures. XXI International CIPA Symposium 2007.

Katsibiri O. Investigation of the technique and materials used for mordant gilding on Byzantine and post-Byzantine icons and wall paintings. Diploma thesis, University of Northumbria at Newcastle. 2002; cited by Hradil et al. 2017.

Nadolny JM. The techniques and use of gilded relief decoration by northern European painters, C.1200–1500. Doctor thesis, Courtauld Institute of Art London; 2000.

Cennini C. The Craftsman’s Handbook—The Italian “Il libro dell’arte”, translated by D. V. Thompson. New York: Dover Publications Inc; 1954 (Courier Corporation, 2012).

Pessanha S, Guerra M, Longelin S, Le Gac A, Manso M, Carvalho ML. Determination of gold leaf thickness in a Renaissance illumination using a nondestructive approach. X-Ray Spectrom. 2014;43(2):79–82. https://doi.org/10.1002/xrs.2518.

Thompson DV. The materials and techniques of medieval painting. New York: Dover; 1956.

Dunlop A. On the origin of European painting materials, real and imagined. In: Anderson C, Dunlop A, Smith PH, editors. The matter of art. Materials, practices, cultural logics, c. 1250–1750. Manchester: Manchester University Press; 2015. p. 68–96.

Passeri I. Gold coins and gold leaf in early Italian paintings. In: Anderson C, Dunlop A, Smith PH, editors. The matter of art. Materials, practices, cultural logics, c. 1250–1750. Manchester: Manchester University Press; 2015. p. 97–115.

Dorini U. Statui dell’arte di Por Santa Maria del tempo della Repubblica (Florence: Leo S. Olschki). 1934; cite by Passeri 2015.

Kubersky-Pieredda S. The market for painters’ materials in Renaissance Florence. In: Kirby J, Cannon J, editors. Trade in artists’ materials: markets and commerce in Europe to 1700. London: Archetype Publications; 2010. p. 223–43.

Mastrotheodoros GP, Beltsios KG, Bassiakos Y, Papadopoulou V. On the metal-leaf decorations of post-Byzantine Greek icons. Archaeometry. 2018;60(2):269–89. https://doi.org/10.1111/arcm.12287.

Nadolny JM. Some observations on Northern European Metalbeaters and metal leaf in the late middle ages. In: Materials T, editor. Technology and Arts of Conservations. Conservation Centre of the Institute of Fine Arts: New York University; 1999. p. 134–60.

Nash S. ‘Pour couleurs et autres choses prise de lui...’: the supply, acquisition, cost and employment of painters materials at the Burgundian Court, c.1375–1419. In: Kirby J, Cannon J, editors. Trade in artists’ materials: markets and commerce in Europe to 1700. London: Archetype Publications; 2010. p. 987–182.

Tångeberg P. Mittelalterliche Holzskulpturen und Altarschreine in Schweden: Studien zu Form, Material und Technik Kungl. Stockholm: Vitterhets Historie och Antikvitets Akademien; 1986.

Wu Q, Wörle M, Hubert V, Müller E, Haudenschild M, Wyer P, Scherrer N, Soppa A. The identification of Zwischgold and other metal foils on historical sculptures by handheld XRF spectrometry. Zeitschrift für Kunsttechnologie und Konservierung (ZKK). 2018;32(1):55–68.

Wu Q, Lombardo T, Hubert V, Hildbrand E, Wyer P, Nolting F, Ganz D. New insights into Zwischgold application from a multi-analytical survey of late medieval polychrome sculptures at the Swiss National Museum. Microchemical. 2020;156:104810. https://doi.org/10.1016/j.microc.2020.104810.

Doolittle LR. A semiautomatic algorithm for Rutherford backscattering analysis. Nucl Instrum Methods Phys Res B. 1986;15(1–6):227–31. https://doi.org/10.1016/0168-583X(86)90291-0.

Darque-Ceretti E, Felder E, Aucouturier M. Foil and leaf gilding on cultural artefacts; forming and adhesion. Revista Matéria. 2011;6:1. https://doi.org/10.1590/S1517-70762011000100002.

Eveno M, Ravaud E, Calligaro T, Pichon L, Laval E. The Louvre Crucifix by Giotto—Unveiling the original decoration by 2D-XRF, X-ray radiography Emissiography and SEM-EDX analysis. Herit Sci. 2014;2:7. https://doi.org/10.1186/s40494-014-0017-y.

Loebich O. The optical properties of gold: a review of their technical utilization. Gold Bull. 1972;5:2–10. https://doi.org/10.1007/BF03215148.

Brachert T, Kobler F. Fassung von Bildwerken, In: Gefasste Bildwerke: Untersuchung und Beschreibung von Skulpturenfassungen mit Beispielen aus der praktischen Arbeit der Restaurierungswerkstätten des Bayerischen Landesamtes für Denkmalpflege 1958–1986, Bayerisches Landesamt für Denkmalpfleg, München; 1990. p. 341–48.

Brachert T. Die Techniken der polychromierten Holzskulptur. Maltechnik-Restauro. 1972;3(4):153–204.

Straub RE. Tafel- und Tüchleinmalerei des Mittelalters. In: Reclams Handbuch der künstlerischen Techniken, Band 1. Stuttgart: Philipp Reclam jun.; 1984. p. 131–259.

Kühn H. Farbmittel Buchmalerei Tafel- und Leinwandmalerei. In: Reclams Handbuch der künstlerischen Techniken, Band 1. Stuttgart: Philipp Reclam jun.; 1984. p. 7–54.

Acknowledgements

The authors thank Markus Leuthard and Elke Mürau for helpful discussions and access to the museum objects. We thank Peter Wyer for the sample taking. We also thank Anja Weber, Vera Hubert, Erwin Hildbrand and Rainer Fink for technical assistance. This work was supported by the Swiss National Museum Collection Centre (Switzerland), Paul Scherrer Institute (Switzerland) and University of Zurich (Switzerland).

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

QW designed the work, prepared sample cross-sections, performed SEM–EDX measurements, analysed and interpreted SEM data, and was a major contributor in writing the manuscript. MD performed the RBS experiments and analyzed the data. TL substantively revised the manuscript. KS substantively revised the manuscript. BW performed data visualization and substantively revised the manuscript. FN substantively revised the manuscript. DG designed the work. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Wu, Q., Döbeli, M., Lombardo, T. et al. Does substrate colour affect the visual appearance of gilded medieval sculptures? Part II: SEM–EDX observations on gold leaf samples taken from medieval wooden sculptures. Herit Sci 8, 119 (2020). https://doi.org/10.1186/s40494-020-00456-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40494-020-00456-2