Abstract

This review gives an overview of the development of surface acoustic wave (SAW) based gyroscopes. Different types of SAW based gyroscope are first presented, which are categorized into standing-wave based or progressive-wave based gyroscopes according to their respective mechanisms. In addition, multi-axis detectable SAW based gyroscopes are also introduced in this review. Different principles, structures, production methods, and control technologies are analyzed.

Similar content being viewed by others

Review

A gyroscope is a sensor for measuring an angular rate or angle based on the principles of angular momentum. Early gyroscopes (e.g., ball electrostatic and ring laser gyroscopes) were generally large with poor portability. For several decades, micro-gyroscopes based on MEMS(Micro electro mechanical systems) technology have been studied, and there has been a steady improvement in their performance and in the technology used for their production. Recently, a number of outstanding micro-gyroscopes have demonstrated sufficient inertial grade performance to potentially replace fiber-optic and ring laser gyroscopes [1-4]. The micro-gyroscope has advantages such as a scale of a few millimeters, low-power consumption, scope for mass production, and it is low cost. However, currently available MEMS gyroscopes have suffered from a low mechanical Q-factor due to atmospheric viscosity, production difficulties due to the demand for a three-dimensional construction-suspended mechanical structure, and a large susceptibility to external shock and vibration.

The surface acoustic wave (SAW) gyroscope was proposed by Lao in 1980 [5,6]. Several research groups have worked on this concept, and a number of related studies were published between 2000 and 2011 [7-19]. SAW gyroscopes detect a change in SAW velocity as a function of the angular rate of the medium in which the SAW propagates. When an RF power supply to interdigital transducers (IDT) is deposited on the surface of a piezoelectric substrate, the IDT generates a SAW. The change in SAW velocity due to rotation is then detected as a phase shift between the generated and detected wave velocities. In comparison with conventional MEMS gyroscopes, SAW gyroscopes are very attractive for these reasons. As opposed to the MEMS gyroscope, the SAW gyroscope does not need a suspended vibrating mechanical structure. Therefore, it is more resistant to external shocks and vibrations. Frequency matching between the drive- and sense-mode frequencies in the absence of active tuning and feedback control is very easy to achieve. Finally, temperature effects that cause variations in the Young’s modulus and residual stress can be almost completely eliminated easily.

In this review, an overview of the development of SAW based gyroscopes is provided. According to their functional principles, SAW gyroscopes are categorized into different types such as standing-wave-mode type gyroscopes, progressive-wave-mode type gyroscopes, and multi-axis detectable SAW gyroscopes, all of which are introduced in this article [10-19].

SAW gyroscope using standing wave mode

Kurosawa et al. [10] suggested a novel SAW gyroscope design concept using the standing wave mode, which has a metallic dot array within the cavity, as depicted in Figure 1. When the standing wave is generated by adding two counter-propagating SAWs from the resonators, particles vibrate tangentially to the surface at or near the nodes of the standing wave, whereas those at the anti-node vibrate normal to the surface. With rotation about the x-axis, the Coriolis forces act on the perturbation masses perpendicularly, as shown in Figure 1, resulting in the generation of a secondary wave that propagates in the orthogonal direction of the standing wave. In a typical SAW delay line, one of the IDTs acts as a transmitter that converts the applied voltage variation into acoustic waves while the other IDT receives these acoustic waves and converts them back into an output voltage. This reciprocity allows IDTs to be used either as SAW transmitters or as receivers. For this gyroscope, the IDTs for the sensors are used as receivers to detect the amplitude of the secondary SAWs, which are created by the Coriolis effect when the gyroscope is subject to rotation. Despite their design, they cannot obtain any output signals owing to mismatch of the resonance frequencies.

Schematics and mechanism of the SAW gyroscope with a metallic dot array by Kurosawa et al . [10].

Varadan et al. [11] obtained experimental results using this design concept. Figure 2 shows the measured output voltages from the SAW gyroscope for different angular rates. The SAW gyroscope response was evaluated using a rate table and a geophone setup. The gyroscope signal due to the Coriolis force propagates towards the SAWs, which emerge along with the diffracted signals from the resonator. It may be possible to separate the coupled signal from the gyroscope signal using phase-locked detection. Due to the difficulties in driving the rate table at lower rates, the sensitivity of the gyroscope was further measured using a geophone-pendulum setup. From the output voltage level of the BEI gyroscope, it can be seen that the table oscillation at 3 V excitation is 950° h−1.

Wang et al. [12,13] designed another concept SAW gyroscope using a standing wave. This gyroscope consists of a two-port SAW resonator, with a vibrating mass array within the cavity, and two SAW oscillators, one of which is used as a sensor and the other as a reference. Figure 3 shows a schematic of the structure and the operating principles of the proposed gyroscope. A standing wave, generated by the two-port resonator, creates a metallic dot array at an antinode of the standing wave vibrating normal to the surface (± z-axis). When the SAW gyroscope is subjected to an angular rotation about the x-axis, the induced Coriolis force acts on the vibrating mass. The Coriolis force generates a secondary SAW in the orthogonal direction of the primary standing wave (± y-axis). This secondary SAW then interferes with the Rayleigh SAW propagating in the sensing device, causing a change in the acoustic velocity of the sensing device, and thus creating the resonant frequency of the SAW oscillator, which is used to detect the phase shift. Consequently, the angular rate can be evaluated by measuring the resonant frequency difference between the sensor oscillator and the reference oscillator. As shown in Figure 4, the sensitivity and linearity of the SAW gyroscope with rotation about the x-axis were measured to be 172 Hz/deg/s and 0.98, respectively. Moreover, negligible frequency differences between two delay lines were observed when rotating about the y- and z-axis, and were of lower magnitude than the white noise level. A superior single sensor directivity in the x-axis was observed.

Three years later, Oh et al. [14] proposed a gyroscope using a standing wave mode with a one-port reflective delay line. The gyroscope consists of metallic dots, resonators, and a SAW reflective delay line with an 80 MHz central frequency. As depicted in Figure 5, the operating principle is similar to the concept of Wang et al. [12,13], as previously described, and is as follows. When the gyroscope is rotating, the metallic dots induce a Coriolis force and generate a secondary SAW in the direction orthogonal to the standing wave. This wave interferes with the SAW flowing in the reflective delay line, resulting in a change in the SAW velocity. Figure 6 shows the experimental results for the proposed SAW gyroscope, with a sensitivity of 1.23 deg/deg/s in phase response at an angular rate of up to 2000 deg/s.

Table 1 shows the properties of the SAW gyroscope using standing waves described above. Although Kurosawa et al. [10] failed to obtain experimental results with their device, they suggested using the standing wave mode and metallic dot array to enhance the sensitivity of the SAW gyroscope. Wang et al. [12,13] demonstrated a highly sensitive SAW gyroscope using a standing wave mode with two SAW oscillators to eliminate error sources such as temperature, pressure, and so on.

SAW gyroscope based on progressive wave

Lee et al. [15] proposed a SAW micro rate gyroscope (MRG) using two delay lines in 2007, as shown in Figure 7. The rotation vector perpendicular to the propagating axis causes a velocity change that is proportional to the input rotation through the Coriolis force, because the particles of the Rayleigh wave are elliptically polarized on the sagittal plane. Therefore, these devices detect the frequency rather than the minute amplitude of a SAW and can use a temperature-stable material like ST-cut quartz despite the piezoelectric coupling coefficient. The SAWMRG consists of a delay-line structure, a low temperature co-fired ceramic (LTCC) package, and a cover glass. The oscillator operates at two fundamental frequencies. If the device is subject to rotation around the y-axis, the operating frequency of the oscillator will vary according to the gyroscopic gain factor. Then, the output signals of both oscillators are fed into a multiplier and a band-pass filter to extract the frequency variation. Consequently, the angular rate of the SAWMRG can be sensed by measuring the frequency variation. The experiment was carried out at rotations of up to 2000 deg/s, and the results are shown in Figure 8. The sensitivity of the device and the residual standard deviation from the linear fit are 0.431 Hz/deg/s and 46.5 Hz, respectively.

SAW MRG schematics and gyroscopic effects on the Rayleigh wave, from Lee et al. [15].

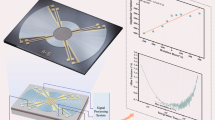

Another type of SAW gyroscope using progressive waves was proposed by Oh et al. [16,17]. Figure 9 shows the schematics and the mechanism of a SAW gyroscope based on a progressive wave which consists of a vibrating mass, an absorber, and a two-SAW delay line; one is used as a sensing element and contains a vibrating mass in a cavity, while the other is used as a reference element. The SAW delay line oscillator operates based on a self-excited oscillator that consists of a delay line, a feedback amplifier, and a phase shifter, as shown in Figure 9(a). The oscillators with a delay line operate at their fundamental frequencies, f 1 (reference part) and f 2 (sensing part). A progressive wave is generated at the input transducer (left transducer) and propagated to the output transducer (right transducer). When the gyroscope is subjected to an angular rotation, the Coriolis force acts on the vibrating metallic dots. The direction of the force is the same as the direction of wave propagation, and the amplitude and velocity of the wave are therefore changed (Δv c), causing a shift in the oscillation frequency (Δf c) of the sensing oscillator. By measuring the frequency difference between the sensing and reference oscillators, the input rotation can be evaluated without errors. The constructed device has been tested at an angular rate in the range of up to 1000 deg/s and the results are shown in Figure 10. The sensitivity was approximately 62.57 Hz/deg/s when metallic dots were positioned near the output IDT.

In [18], Wang et al. demonstrated a novel wireless and passive SAW gyroscope using two parallel broadband reflective delay lines. As shown in Figure 11, these two SAWs follow reflective delay line patterns propagating in opposite directions. If the device is subjected to a rotation, the SAW gyroscopic effect changes the SAW velocity in the SAW reflective delay line, in both directions. The SAW velocity in one direction increases and decreases in the other, as a result of the opposite rotation, causing a doubling of the sensitivity of the device and compensating for the temperature effects. The phase response of the gyroscope was measured at different rotation rates, up to 900 deg/s along the y-axis, and is depicted in Figure 12. According to their results, the sensitivity and linearity of the proposed device are 2.42 deg/deg/s and 0.956, respectively. Therefore, Wang et al. [18] successfully demonstrated the potential of the wireless and passive SAW gyroscope.

Schematics and mechanism of the wireless and passive SAW gyroscope, from Wang et al. [18].

Table 2 shows properties of the various SAW gyroscopes using progressive waves described above. The performance of the SAW gyroscope can be enhanced through the use of two delay lines. Moreover, Lee et al. [15] and Wang et al. [18] have attempted to improve the gyroscope sensitivity by using a differential scheme based on opposing wave propagation directions. Oh et al. [16,17] constructed a SAW gyroscope using a progressive wave with different masses and positions for the metallic dot array on an experimental basis. In particular, Wang et al. [18] successfully demonstrated a wireless and passive SAW gyroscope using two reflective delay lines.

Other gyroscopes using SAW

Figure 13 shows a multi-axis detectable SAW gyroscope utilizing a stacked configuration [19]. It consists of a silicon substrate and two SAW gyroscopes using progressive waves, described in more detail in [16], in which the bottom element is used for y-axis detection and the top element is used for x-axis detection. The silicon substrate is used to protect the SAW gyroscope. The four sides are completely sealed by JSR photoresists (PR) to prevent interference from undesirable factors such as temperature and humidity. The two Si-substrates with SAW gyroscopes are bonded with a conductive silver paste, in which a separation gap of about 200 μm is formed. When the gyroscope is subjected to an angular rotation about the y-axis, a Coriolis force in the x-direction is produced by the vibrating mass. Thus, the bottom SAW gyroscope is affected by the Coriolis force because the wave propagation direction is in the same direction as the Coriolis force. On the other hand, the Coriolis force significantly affects the top SAW gyroscope, because the direction of wave propagation for the top SAW gyroscope is different to the direction of the Coriolis force. Conversely, when the gyroscope is subjected to an angular rotation about the x-axis, the Coriolis force in the y-direction is produced by a vibrating mass. In this case, the top SAW gyroscope is only affected by the Coriolis force.

In this study, as the rotation speed was increased from 0 to 1000 deg/s along the y-axis at 20°C, the mixed oscillator frequency difference of the bottom element increased linearly, as shown in Figure 14(a). However, the mixed oscillator frequency of the top element did not change, and the measured sensitivity and linearity of the SAW gyroscope were found to be 45.32 Hz/deg/s and 0.907, respectively. Next, the device was rotated counterclockwise along the x-axis, from 0 to 1000 deg/s at 20°C. As the rotation speed increased, the mixed oscillator frequency difference of the top element increased linearly, as shown in Figure 14(b). In this case, the difference in signal from the bottom element is negligible, and the measured sensitivity and linearity of the SAW gyroscope were 27.34 Hz/ (deg/s) and 0.837, respectively. The sensitivity of the top element is lower than that of bottom element. This difference can be ascribed to the fact that the applied electric energy to the top device is lower than that supplied to the bottom element, because of the different transmission lines of the electric signal and the highly resistive metal formed by electroplating.

Conclusion

Gyroscopes based on SAW have been reviewed. In comparison to existing silicon-based MEMS gyroscopes, a SAW gyroscope is very attractive for a number of reasons. First, it has no suspended vibrating mechanical structure and is therefore more resistant to external shocks and vibrations. Second, frequency matching between the drive- and sense-mode frequencies in the absence of active tuning and feedback control is very easy. Finally, the temperature effect that causes a variation in the Young’s modulus and residual stress can be almost completely eliminated. By comparing different structures of SAW-based gyroscopes and their mechanisms, we can see that the SAW gyroscope has the potential to be the highest performing gyroscope in the near future.

References

Wang R, Durgam SK, Hao Z, Vahala LL (2009) A SOI-Based Tuning-Fork Gyroscope With High Quality Factors. In: Tomizuka M (ed) Proceeding of SPIE Conference on Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems, vol 7292. SPIE., p 7292

Wang R, Cheng P, Xie F, Young D, Hao Z (2011) A multiple-beam tuning-fork gyroscope with high quality factors. Sensor Actuat A: Phys 166:22–33

Acar C, Schofield AR, Trusov AA, Costlow LE, Shkel AM (2009) Environmentally robust MEMS vibratory gyroscopes for automotive applications. Sensors 9:1895–1906

Liu K, Zhang W, Chen W, Li K, Dai F, Cui F, Wu X, Ma G, Xiao Q (2009) The development of micro-gyroscope technology. J Micromech Microeng 19:113001

Binneg Y, Lao (1983) Surface Acoustic Wave Gyroscope. US patent 24 May 1983

Lao BY (1980) Gyroscopic Effect in Surface Acoustic Waves. Proceeding of IEEE ultrasonic symposium, In, p 687

Jose KA, Suh WD, Xavier PB, Varadan VK, Varadan VV (2002) Surface acoustic wave MEMS gyroscope. Wave Motion 36(4):367–381

Woods RC, Kalami H, Johnson B (2002) Evaluation of a novel surface acoustic wave gyroscope. IEEE Trans Ultrason Ferroelectr Freq Control 49:136–141

Varadan VK, Suh WD, Jose KA, Varadan VV (2001) Hybrid MEMS-IDT-based accelerometer and gyroscope in a single chip. In: Varadan VK (ed) Proceeding of SPIE conference on smart structures and materials 2001: smart electronics and MEMS, vol.4334. SPIE., p 119

Kurosawa M, Fukula Y, Takasaki M, Higuchi T (1998) A surface-acoustic-wave gyro sensor. Sensor Actuat A: Phys 66:33–39

Varadan VK, Suh WD, Xavier PB, Jose KA, Varadan VV (2000) Design and development of a MEMS-IDT gyroscope. Smart Mater Struct 9:898–905

Wang W, Oh H, Lee K, Yoon S, Yang S (2009) Enhanced sensitivity of novel surface acoustic wave microelectromechanical system-interdigital transducer gyroscope. Jpn J Appl Phys 48:06FK09

Oh H, Wang W, Yang S, Lee K (2011) Development of SAW based gyroscope with high shock and thermal stability. Sensor Actuat A: Phys 165:8–15

Oh H, Fu C, Yang SS, Wang W, Lee K (2012) A novel shock and heat tolerant gyrosensor utilizing a one-port surface acoustic wave reflective delay line. J Micromech Microeng 22:045007

Lee SW, Rhim JW, Park SW, Yang SS (2007) A micro rate gyroscope based on the SAW gyroscope effect. J Micromech Microeng 17:2272–2279

Oh H, Yang S, Lee K (2010) Development of SAW-based microgyroscope utilizing progressive wave. Jpn J Appl Phys 49:06GN16

Oh H, Lee K, Yang S, Wang W (2011) Enhanced sensitivity of surface acoustic wave gyroscope using progressive wave. J Micromech Microeng 21:075015

Wang W, Wang W, Liu J, Liu M, Yang S (2011) Wireless and passive gyroscope based on surface acoustic wave gyroscopic effect. Appl Phys Express 4:086601

Oh H, Lee KJ, Yang SS, Lee K (2012) Development of novel dual-axis sensing gyroscope using surface acoustic wave. Microelectron Eng 97:259–264

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF), grant funded by the Korean government (MEST) (No. 2009-0081200).

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

HO carried out research works and writing of the manuscript. KJL carried out research works and KL carried out a survey on the gyroscope based on surface acoustic wave. SSY supervised all research works. All authors read and approved the final manuscript.

Authors’ information

Haekwan Oh was born in Korea in 1981. He received his BS and Ph.D degrees in electrical engineering from Ajou University in 2007 and 2013, respectively. He began working for next generation convergence sensor research center in KETI from 2013.

Ki Jung Lee received the BS, MS degrees in electrical engineering from Ajou University in 2007 and 2009. His major research areas include SAW sensors and micro mass spectrometer. He began working for Micro-system Lab., Ajou University from 2007 as a PhD candidate.

Keekeun Lee was born in Seoul, South Korea, in 1968. He received his MS degree from University of Florida, Gainesville, USA, in 1993 and his PhD degree in electrical engineering from Arizona State University, Tempe, USA, in 2000. After receiving his PhD degree, he worked as a post doctor and an assistant research professor for 4 years in bioengineering department at Arizona State University. In 2004, he joined Ajou University in S. Korea and currently he is a professor in electronics engineering department. He has published more than 60 papers in internationally renowned journal articles, mostly regarding wireless surface acoustic wave (SAW) sensors, microstructured neural probe and its systems, organic-based hybrid solar cells, and so on.

Sang Sik Yang was born in Korea in 1958. He received his BS and MS degrees in mechanical engineering from Seoul National University in 1980 and 1983, respectively. In 1988, he received his PhD degree in mechanical engineering from the University of California, Berkeley. He was then a research assistant professor at New Jersey Institute of Technology. Since 1989, he has been a professor in the Department of Electrical and Computer Engineering at Ajou University. His research interests include the mechanism and actuation of microelectromechanical devices, SAW sensors and micro plasma devices.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit https://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Oh, H., Lee, K.J., Lee, K. et al. Gyroscopes based on surface acoustic waves. Micro and Nano Syst Lett 3, 1 (2015). https://doi.org/10.1186/s40486-015-0009-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40486-015-0009-z