Abstract

The problem of management and treatment of wastewater from commercial laundries is a matter of concern. The present study provides an effective and eco-friendly solution to the treatment of wastewater from commercial laundries in Quebec (Canada) by using the extracellular polymeric substance (EPS) as a bio-flocculant. EPS was produced from the valorization of crude glycerol and paper mill sludge by a bacterial strain (BS-04). Two different types of EPS: Slime EPS (S-EPS) and Broth EPS (B-EPS) were used for the treatment of commercial laundry wastewater (CLWW). This is the first study for the treatment of CLWW using bio-flocculant EPS. A comparison between the conventional treatment of laundry wastewater (LWW) by chemical coagulants (FeSO4, CaCl2, Alum) and enhanced treatment by bio-flocculant EPS has been drawn in the study. Moreover, LWW treatment by a combination of EPS and chemical coagulants was also investigated. It was observed that S-EPS (0.6 g/L) gave better flocculation activity (FA) than B-EPS. S-EPS alone can remove 83.20% of turbidity, 77.69% of suspended solids (SS), and 76.37% of chemical oxygen demand (COD). The best results were obtained by combining S-EPS (0.6 g/L) with alum (300 mg/L) at pH 7 for a treatment time of 30 min. This combination was able to remove 98% of turbidity, 95.42% of SS, and 83.08% of COD from LWW. When treatment time has been increased to 4 h at pH 7, it resulted in more than 88% COD removal from CLWW.

Graphical Abstract

Similar content being viewed by others

Introduction

There has been a persistent presence of contaminants in the water that leads to its pollution, because of which treating this polluted water has been a huge concern, all over the globe. Commercial laundries have been contributing to this pollution over the years as 1 kg of clothing requires about 15 L of water for washing, which in turn produces approximately 400 m3 of wastewater on daily basis (Ciabattia et al. 2009). Laundry wastewater (LWW) has been composed of organic contaminants that include surfactants, fats, and detergents along with inorganic contaminants such as sand and soil dust (Zhu et al. 1998). Linear alkylbenzene sulfonates (LAS) and nonylphenol ethoxylates (NPEOs) are the most used surfactants in laundry detergent formulations, which often lead to environmental degradation causing health problems for animals and humans both. It has a serious negative impact on the aquatic biota as well (Jardak et al. 2016). Many studies have found the presence of microplastics in LWW (Akarsu & Deniz 2021; Conley et al. 2019). It must be noted that such emerging contaminants are of great concern due to their endocrine and hormonal disrupting nature. These emerging contaminants can also lead to a genetic mutation in aquatic animals (Lissens et al. 2003). Therefore, the urgent demand of the hour is to treat this polluted water.

Various physicochemical processes such as electrocoagulation (Chou et al. 2009; Elazzouzi et al. 2018; Estahbanati et al. 2021; Gomes et al. 2007; Han et al. 2002; Holt et al. 2005; Hu et al. 2003; İrdemez et al. 2006; Janpoor et al. 2011; Kabdaşlı et al. 2009; Kumar et al. 2004; Larue et al. 2003; Mollah et al. 2001; Yüksel et al. 2009; Zaroual et al. 2006), membrane filtration (Ahn & Song 1999; Bhattacharyya et al. 1978; Bilad et al. 2020; Carbonell-Alcaina et al. 2016; Corbatón-Báguena et al. 2015; Gitis et al. 2006; Guilbaud et al. 2010; Manouchehri & Kargari 2017), adsorption (Ahmad et al. 2012; Chen et al. 2008; Corona et al. 2021; Veli et al. 2019, 2021); biological processes (Andersen et al. 2002; Ashfaq et al. 2017; Bagheri & Mirbagheri 2018; Deowan et al. 2015; Emaminejad et al. 2019; Hamedi et al. 2019; Hoinkis et al. 2012; Iorhemen et al. 2016; Lohaus et al. 2018; Madaeni et al. 1995; Mahmoudi et al. 2020; Paris & Schlapp 2010) and combined treatment processes (Bokhary et al. 2018; ElSherbiny et al. 2019; Emaminejad et al. 2019; Fan et al. 2001; Hamedi et al. 2019; Howe & Clark 2006; Huang et al. 2019; Jia et al. 2014; Kamarudin et al. 2003; Kim et al. 2014; Mostafazadeh et al. 2019; Siswoyo et al. 2019) have been applied for the treatment of LWW. Biological processes are inefficient in eliminating persistent organic pollutants. Also, the availability of excessive chemical oxygen demand (COD) makes biological processes incompatible with an explicit application for LWW treatment (Bokhary et al. 2018; Kumar et al. 2021).

Anaerobic treatment and membrane bioreactors are potential methods for the treatment of CLWW (Braga et al. 2015; Delforno et al. 2020; Faria et al. 2019; Moura et al. 2019). However, challenges associated with them consist of the expensive treatment process, the existence of excessive ammoniacal nitrogen in the effluents, and membrane clogging in membrane filtration makes them less effective for industrial-scale application (Corbatón-Báguena et al. 2015; Hamedi et al. 2019; Howe & Clark 2002). The treatment of LWW by utilizing chemical flocculants has been found in the literature (Šostar-Turk et al. 2005; Terechova et al. 2014). The removal of particulate matter along with phosphorus and heavy metals has been effectively performed by the easy and economical coagulation (alum and ferrous sulfate) and flocculation processes. The chemical flocculants are not considered eco-friendly despite the advantages of being cost-effective. On the other hand, environment-friendly biopolymers like extracellular polymeric substance (EPS) can be used for LWW treatment as they are sustainable and environmentally friendly, and they minimize the harmful risks posed by the chemical flocculants such as their carcinogenic nature with low biodegradability.

Bio-flocculants originate from the natural secretions of bacteria, and cell lysis which is harmless, sustainable, biodegradable, and poses no secondary pollution risk. The predominant constituents of bio-flocculant (or extracellular polymeric substances or EPS) such as protein, glycoprotein, polysaccharide, and nucleic acid are generated by microbes during the growth phase. They have been investigated as a flocculating agent for dewatering and sludge settling (Huang et al. 2019; Kaur et al. 2019; Liu et al. 2009). EPS is present both outside of cells and in the interior of microbial aggregates. The forms of EPS that occur outside of microbial cells can be divided into bound EPS (loosely bound polymers, sheaths, condensed gels, capsular polymers, and attached organic matters) and soluble EPS or loosely bound EPS (soluble macromolecules, colloids, and slimes) (Laspidou & Rittmann 2002).

The use of EPS as a flocculating agent has been used by other researchers in the biological treatment of wastewater (Kaur et al. 2019; Ndao et al. 2022), but the application of EPS to treat LWW is not reported in the existing literature. In recent studies, EPS was effectively used to treat composting and landfill leachate (Kaur et al. 2019; Ndao et al. 2022). The study achieved a removal efficiency of 84% for COD, 96% for phosphorus, 97% for nitrates-nitrites, 75% for ammoniacal nitrogen, 29–99% for metals, and 95% for colors (Kaur et al. 2019). In another study, when EPS was used in combination with FeSO4 for the treatment of landfill leachate. During the Jar test study, FeSO4 was added to the glass beaker and stirred fast at 120 rpm for 90 s. Thereafter at adjusted pH, the process effectively removed 82.00% of COD, 44.00% of total nitrogen, 50.00% of phosphorus and 64.30% of Ca, and 62.40% of Mg (Ndao et al. 2022). However, there is a lack of studies using bio-flocculants. Resulting in negligible utilization of bio flocculants for the treatment of LWW (Mohan 2014).

Therefore, the purpose of this study was to use bacterial EPS produced by the use of waste streams as substrate (crude glycerol in combination with industrial pulp and paper mill sludge) with chemical coagulants for LWW treatment. Three chemical coagulants (Alum, FeSO4, and CaCl2) were selected and used for the treatment of commercial laundry wastewater (CLWW).

Materials and methodology

Origin and characterization of commercial laundry wastewater (CLWW)

Raw laundry wastewater (LWW) sample was collected from commercial laundry by VEOSwater (Terrebonne, Quebec) and the samples were supplied to the INRS laboratory. The effluents have been collected at the water outlet point of the commercial laundry room (Montreal, Quebec). The 100 L of LWW effluent was stored in 5 buckets of 20 L each, over a period of 24 h for further analysis. The samples were stored in a cold room at a temperature of – 4 ºC.

The commercial laundry wastewater was characterized to measure pH, turbidity, conductivity, suspended solids (SS), total solids (TS), chemical oxygen demand (COD), total nitrogen (TN), total phosphorous (TP), nonylphenolethoxylate (NPEOs), and metals.

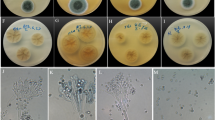

EPS Production using crude glycerol and industrial sludge

EPS was produced using the bacterial strain BS-04 (isolated from wastewater sludge), which was grown on crude glycerol and secondary sludge (from pulp and paper mill wastewater treatment) as carbon substrates (Subramanian et al. 2010). The process involved 96 h of fermentation at controlled pH, temperature, and dissolved oxygen. The fermented broth obtained after the fermentation process is called broth EPS (B-EPS). Centrifugation was done to the fermented broth at 4 °C for 20 min at 6000 g to obtain slime EPS (S-EPS) in the supernatant (Nouha et al. 2016a).

To measure the dry weight of S-EPS the supernatant obtained was mixed with ethanol (95%v/v) in a 1:2 ratio and kept at − 20 °C overnight for phase separation. The precipitates (solid phase) of S-EPS were collected by centrifuging at 6000 g at 4 °C for 20 min. The centrifuged pallet of S-EPS was dried at 60 °C to a constant weight.

The concentration of EPS was calculated using Eq. (1):

where W1 = initial weight of the empty container (in g); W2 = final dry weight of the container with dried sample (in g); and V = volume of the sample (in L).

The dry weight of capsular EPS (C-EPS) was determined by mixing the biomass pellets (obtained by centrifugation of fermented broth) with water in equal volume and then the mixture was heated at 60ºC in the water bath for 60 min to release the C-EPS in the liquid phase. Released C-EPS in the liquid phase was then collected by centrifugation at 6000 g at 4 °C for 20 min.

The total EPS concentration or broth EPS (B-EPS) concentration contains was calculated by using Eq. (2):

The collected S-EPS and B-ESP in liquid form were used for LWW treatment. Figure 1 shows the mechanism of CLWW treatment using EPS as a bio-flocculant. During the process of charge neutralization, the bio-flocculant particles get adsorbed on the surface of colloidal particles, resulting in reducing the repulsive force between the adjacent particles. This causes the particles to combine by increasing van der Waals interaction. During the bridging process, high molecular weight bio-flocculants are adsorbed on colloidal particles. Due to their large sizes, the bio-flocculants bridge particles and hence creates large flocs. During the patching mechanism, bio-flocculant particles come in contact with colloidal particles and neutralize a portion of the particle's surface. The opposite charge makes adsorbed bio-flocculants act as patching points for nearby particle.

CLWW treatment

Identification of optimized pH for chemical coagulants

The jar test experiments were conducted for ferrous sulfate, alum, and calcium chloride to study flocculation activity at different pH (3, 5, 7, 9, and 11). During the experiment, 300 mL of LWW sample was taken into 1 L glass beaker and different pH were maintained by adding acid (1 M H2SO4) or base (2 M NaOH). A fixed concentration (300 mg/L) of each coagulant was added to different beakers, followed by rapid mixing (120 rpm) for 90 s. Then beakers were kept for agitation at 40 rpm for 30 min. Subsequently, the liquid mixture was shifted into a 1 L glass cylinder for 30 min settling, after that, the supernatant was taken and tested for FA.

Flocculation activity can be determined by using Eq. (3):

where A = turbidity of the sample (with added coagulant) after settling for 30 min, and B = turbidity of the control (without coagulant) after settling for 30 min.

Effect of coagulant concentration

Jar test experiments were performed at suitable pH, and different coagulant doses (100 mg/L, 300 mg/L, 600 mg/L, 900 mg/L, 1200 mg/L, 1500 mg/L, and 2000 mg/L) were added to the glass beakers containing CLWW, respectively. Followed by 90 s of rapid mixing (120 rpm) and 30 min of slow agitation (40 rpm) in the jar test, the liquid mixture was transferred to a 1 L glass cylinder for settling. After 30 min of settling, the supernatant was collected and analyzed for flocculation activity.

Identification of optimum pH using EPS (S-EPS or B-EPS)

Experiments were performed for S-EPS and B-EPS. The pH of the LWW samples was adjusted to different values (3, 5, 7, 9, and 11). Rapid agitation (120 rpm) was done for 90 s to stabilize pH. Then fixed concentration (0.2 g/L of LWW) of S-EPS and B-EPS were added to different beakers containing LWW. Following the addition of EPS, slow agitation (40 rpm) was carried out for 30 min. After the agitation, the liquid mixture was transferred to a glass cylinder for settling to determine the flocculation activity.

Identification of optimum EPS concentration

In search of the optimal dose of EPS for maximum treatment efficiency, different concentrations (0.1 g/L, 0.2 g/L, 0.3 g/L, 0.4 g/L, 0.5 g/L, and 0.6 g/L) of S-EPS and B-EPS were used to perform the flocculation experiments. Each type of EPS was added to the glass beakers containing LWW and then jar tests were performed separately (as mentioned in the above sections) to determine the treatment efficiency. The concentration at which the visible flocs can be seen was considered for further optimization. After the jar test experiment followed by 30 min settling, the supernatant was analyzed (Turbidity, SS, TS, COD, nitrogen, phosphorous, metals, and NPEOs) to determine the pollutant removal efficiency.

Combination of EPS and chemical coagulant

Aluminum salt (alum) is as of now the most favored coagulant due to its efficiency and economics; however, traces of aluminium residuals in treated water are a strong agent for Alzheimer’s disease (Campbell 2002). Another environmental risk associated with the widespread use of aluminium salt as a primary coagulant is sludge disposal (Priya et al. 2017). The use of natural coagulants such as bio-flocculants is a cost-effective and efficient remediation strategy for the treatment of extremely turbid water, but its composition tends to increase the organic content in water (Verma et al. 2012). They also have insignificant flocculant activity in low turbid water because of limited repulsive force between dispersed colloidal particles. As a result, low flocculating properties, insignificant yields, and high production costs have limited the usage of only natural coagulants in water treatment plants (Huang et al. 2014). Therefore, it was a scientific and economic approach to use metal coagulants along with the bio-flocculants.

Flocculation activity is improved while combining metal coagulant and bio-flocculant owing to three main mechanisms taking place simultaneously: (i) the charge neutralization; (ii) the sweep coagulation and (iii) flocs bridging (Bo et al. 2012). The ionic nature of metal and its size and charge density regulate its interaction with negatively charged EPS. The mechanism behind the removal of organic matter and other contaminants is that the introduction of positively charged coagulants destabilizes the stable negative charge of the target particles by compressing the double layer. This upset decreases the distance or repulsion between particles, in turn decreasing the zeta potential. The particles are then able to get close enough together due to Vander Waals forces. As a result, van der Waals interactions are predominant, allowing aggregation of suspended fine particles and subsequent flocculation.

The association of EPS with coagulants leads to a better particle aggregation due to high molecular weight and structure of EPS. EPS has hydroxyl sites, amine and carboxyl functional groups. In fact, a previous study has shown the presence of these functional sites in EPS structure produced from glycerol and activated sludge by using FTIR (Nouha et al. 2016a). Also, EPS molecules can attach to neutralized particles in solutions and simultaneously cross-link other EPS molecules which are also attached to other neutralized colloids (More et al. 2014). All these phenomena under combination of EPS and coagulant resulted in enhanced treatment of LWW. To enhance the performance of EPS, a chemical coagulant was used in combination with EPS. During the LWW treatment process, suitable pH (as determined in the section on optimization of pH for EPS) and chemical coagulant (as determined in the section effect of chemical coagulant) were used to carry out the experiments. Different concentrations (0.1 g/L, 0.2 g/L, 0.3 g/L, 0.4 g/L, 0.5 g/L, and 0.6 g/L) of each type of EPS were added to the glass beakers containing LWW. Rapid mixing was done for 90 s for each set followed by 30 min of slow mixing at 40 rpm. Treated water was kept for settling in a glass cylinder for 30 min. The collected supernatant was then analyzed to determine the removal efficiency of different parameters (Turbidity, SS, COD, nitrogen, phosphorous, metals, and NPEOs).

Effect of treatment time

After the determination of suitable pH and EPS concentration, experiments were performed to determine the treatment time to achieve the maximum treatment efficiency. During the treatment process, 300 mL of commercial LWW was added to each of the glass beakers. Then the suitable concentration of S-EPS (as determined in the section on optimization of EPS concentration) was added to each beaker. Then pH was adjusted to a suitable value (as determined in the section on optimization of pH) by using 1 M H2SO4 or base 2 M NaOH. After 90 s of rapid agitation, agitation speed was reduced from 120 to 40 rpm and kept for incubation. The jar test experiments were performed for different time periods (0.5, 1, 2, 4, 6, and 12 h), and treated water was set aside to settle by gravity for 30 min. After settling, the supernatant sample was analyzed to determine the treatment efficiency for each treatment time.

Analytical methods

The methods used for the analysis of samples are certified methods by CEAEQ (Center of Expertise in Environmental Analysis of Quebec) (l’Environnement and climatiques 2014) under the responsibility of the Government of Quebec. The mission of CEAEQ is to standardize the methods and analytical tools used in environmental analysis. Table 1 depicts the analytical methods for different parameters.

Results and discussion

Characteristics of CLWW

The LWW samples collected from the discharge basin (raw LWW) were characterized for turbidity, pH, conductivity, SS, TS, COD, NPEOs, TN, TP & metals. The characterization results are depicted in Table 2. It was found that LWW contained high amount of turbidity, SS, TS, COD, and NPEOs. The presence of a high amount of turbidity and SS was a result of residual dirt/soil in the dirty clothes/fabrics. The analysis was also carried out to detect the amount of NPEO present in the laundry wastewater. A significant amount of NPEO (570–720 µg/L) was found in the sample. The CLWW also contained a significant amount of metals like calcium (Ca), magnesium (Mg), aluminum (Al), sodium (Na), and potassium (K). A small amount of heavy metals were also detected in the CLWW.

The characteristics of CLWW were compared with the standards for water discharge outlined by Health Canada and Ville de Quebec. It was found (Table 2) that the concentration of different parameters (turbidity, SS, TS, COD, NPEO, metals) of CLWW was almost 5 times higher than the recommended value. Hence it was necessary to treat CLWW before discharge to the water bodies.

Treatment of CLWW using chemical coagulants

Identification of optimized pH for chemical coagulants

The chemical coagulants (alum, FeSO4, and CaCl2) were investigated for the treatment of CLWW. The results were compared based on zeta potential and FA. The treatment of CLWW by alum resulted in an initial increase in zeta potential (during pH 3–7) and then it gradually decreased with an increase in pH from 7 to 11 (Additional file 1: Figure S1). The increase in zeta potential (pH 3–7) is probably due to the surface charge neutralization (Cosa et al. 2013). Zeta potential values of − 7.7 mV, − 2.7 mV, 0.4 mV, − 4.7 mV, and − 11.9 mV were obtained at pH 3, 5, 7, 9, and 11 respectively. Similarly, the FA also increased with an increase in pH up to pH 7, and then it decreased with a further increase in pH. At pH 3, only small FA (12.55%) was observed. FA increased to 97.00% at pH 7 and then decreased to 27.00% at pH 11. However, when FeSO4 was used as a coagulant the zeta potential value varied from pH 3 to 11. Zeta potential values of − 7.7 mV, − 8.3 mV, − 9.4 mV, − 9.7 mV, and − 3.9 mV was found at pH 3, 5, 7, 9, and 11 respectively. The maximum FA of 89.00% was observed at pH 11.

However, when CaCl2 was used as a chemical coagulant, it was observed that the value of zeta potential initially increased with an increase in pH (3 to 5) and then became almost constant (from pH 7 to 9). Zeta potential values of − 10.7 mV, − 10.3 mV, − 10.7 mV, − 11.7 mV, and − 13.2 mV were found at pH 3, 5, 7, 9, and 11 respectively. The maximum FA of 29% was observed at pH 5. Figures 2a, b show the impact of pH on flocculation activity using chemical coagulants and EPS, respectively.

The results for FA for different coagulants indicate that pH has a significant role in flocs formation and removal of pollutants from CLWW. It has been identified that the suitable pH for Alum, FeSO4, and CaCl2 were 7, 11, and 5, respectively. From the results, it is evident that the coagulation-flocculation process is widely dependent on the pH. It imparts a huge effect on the ionization and solubility of chemical coagulants. However, the optimized pH will depend upon the type of chemical coagulant used. Considering the optimized pH for chemical coagulant alum (pH = 7), it was decided to keep pH 7 as the optimized pH for future experiments.

The main factors behind the removal of pollutants by coagulation-flocculation are charge neutralization, double-layer compression, bridging, and particle entrapment. During the process, positively charged chemical coagulants neutralize the negatively charged contaminants present in the wastewater sample. It destabilizes the stable particles by compressing the double layer (Kaur et al. 2019).

Due to a decrease in the distance between the double layer, the repulsive forces between the particles also decrease which results in a decrease in zeta potential. Once the particle comes closer, it starts bridging with the other adjacent particles and results in flocs formation. This process of flocs formation followed by settling helps in the removal of pollutants from the wastewater sample.

Effect of coagulant concentration

To identify the optimum concentration of each coagulant, jar test experiments were performed by using different coagulant doses (100, 300, 600, 900, 1200, 1500, and 2000 mg/L of LWW). When alum concentration was raised from 100 to 2000 mg/L at pH 7, the zeta potential value also increased from − 12.8 to 1.8 mV, respectively. With the increase in alum concentration, FA also increased from 21.82% to 99.18%. However, when FeSO4 concentration increased from 100 to 2000 mg/L at pH 11, the value of zeta potential increased from − 14.7 to − 5.8 mV, respectively. Similarly, FA also improved from 14.09% to 91.09% by increasing the FeSO4 dosage. When the concentration of CaCl2 was increased from 100 to 2000 mg/L, the zeta potential value increased from − 13.9 mV to − 8.3 mV, respectively. With the increase in zeta potential value, the flocculation activity also improved from 4.55% to 22.45%. It has been clear that the concentration of chemical coagulants used for the treatment depends upon the properties of laundry wastewater samples (Huang et al. 2019; Mahvi et al. 2015). A reported study indicates that the appropriate coagulant dosage can produce stable and consistent flocs due to adsorption and stable interaction between particles (Huang et al. 2019; Mahvi et al. 2015). However, a lower coagulant dose may result in the formation of small flocs and can interfere with the settling of the particles. This may also result in a decrease in flocculation activity. Similarly, a higher coagulant dose may result in unstable flocs due to particle repulsion and weak flocs formation.

Table 3 shows the removal of pollutants by using different chemical coagulants. It is indicated from Table 3 that alum and FeSO4 provided higher turbidity, SS, and TS removal as compared to CaCl2. Alum (2000 mg/L) alone was effective in removing 99.18% turbidity, 98.00% SS and 91.33% TS. Similarly, 91.09% turbidity, 78.67% SS and 68.09% TS were removed from CLWW at 2000 mg/L dose of FeSO4. However, for CaCl2, the maximum removal efficiency was achieved at 1500 mg/L dose. The removal of turbidity, SS, and TS for CaCl2 (1500 mg/L) was found to be 36.18%, 29.17%, and 36.09% respectively.

COD removal of 85.10, 42.60and 47.80% COD was achieved using alum (2000 mg/L), CaCl2 (1500 mg/L), and FeSO4 (2000 mg/L), respectively. It was seen that when the dosage of alum and FeSO4 increased from 100 mg/L to 2000 mg/L, corresponding COD removal was increased from 8.17% to 85.10% for alum and 6.23% to 47.80% for FeSO4, respectively. However, CaCl2 gave a slightly different performance. When the dosage of CaCl2 was increased from 100 to 1500 mg/L, COD removal was enhanced. But when the dosage of CaCl2 increased further from 1500 to 2000 mg/L, COD removal decreased. The maximum COD removal (42.60%) was obtained at a CaCl2 concentration of 1500 mg/L. The reason behind the lower COD removal in the case of CaCl2 at higher concentration (> 1500 mg/L) was due to an excessive increase in positive charge, which increased the repulsive forces between the pollutant particles and resulted in a tendency of lower flocs formation. Since FA and pollutant removal rates were the highest for alum when compared to the other coagulants, a combination of EPS with coagulant was tested only with alum.

Treatment of CLWW using EPS (S-EPS and B-EPS)

Identification of optimum pH for CLWW treatment

To determine the best pH for CLWW treatment using EPS, experiments were conducted at various pH (3, 5, 7, 9, and 11). The EPS concentration was fixed at 0.2 g/L to conduct the jar test experiments. The results were compared based on flocculation activity and zeta potential. The treatment of CLWW using S-EPS resulted in an initial increase in zeta potential (from pH 3 to 5) and then it gradually decreased with an increase in pH from 5 to 11. Zeta potential values of − 8.9, − 1.4, − 2.1, − 8.7, and − 10.9 mV were obtained at pH 3, 5, 7, 9, and 11, respectively. Similarly, the FA also increased while increasing the pH from 3 to 5. Then, FA remained almost constant till pH 7 and decreased with a further increase in pH. At pH 3, only small FA (38.73%) was observed. FA increased to 68.8% at pH 7 and then decreased to 34.09% at pH 11. The isoelectronic point (IEP) seems to be reached at pH 5. When IEP is reached, the positive and negative charges of particles get neutralized, resulting in a higher probability of combining the dispersed and/or colloid particles. However, when B-EPS was used as a bio-flocculant the zeta potential value increases with an increase in pH up to 5, is almost constant from 5 to 7 pH, and then decreases with an increase in pH 11. Zeta potential values of − 11.2 mV, − 8.1 mV, − 8.3 mV, − 10.9 mV, and − 13.1 mV were found at pH 3, 5, 7, 9, and 11 respectively. Similarly, the FA also increased with an increase in pH up to pH 5 and after that remains almost constant up to pH 7 and decreased with further increase in pH up to pH 11. At pH 3 it was observed that B-EPS shows only small FA (18.73%), at pH 5 it shows maximum FA (30.70%) and then decreased to 15.20% at pH 11. The results indicated that S-EPS showed higher FA (68.80%) when compared to B-EPS (30.70%) at pH 5. However, at pH 7 the S-EPS and B-EPS showed a huge difference in the flocculation activity (65.90% and 29.50% respectively). Figure 2a, b, c, and d shows the flocculation activity of chemical coagulants at different pH, EPS (S-EPS and B-EPS) at different pH, EPS (S-EPS and B-EPS) in combination with alum at various EPS concentrations and EPS (S-EPS and B-EPS) in combination with alum at different treatment time.

The results for FA for EPS indicate that pH has a significant role in floc formation and removal of pollutants from CLWW. The bio-flocculant adsorbed on the surface of colloidal particles during the charge neutralisation process, lowering the repulsive force between the nearby particles. High molecular weight bio-flocculants are adsorbed on colloidal particles during the bridging process. The bio-flocculants bridge particles because of their huge diameters, resulting in massive flocs. Bio-flocculant particles interact with colloidal particles during the patching mechanism, neutralising a section of the surface. Adsorbed bio-flocculants function as patching points for surrounding particles due to the opposite charge. The suitable pH for S-EPS and B-EPS is pH 5. However, FA at pH 7 is almost similar to pH 5 (Fig. 2b). Therefore, pH 7 can also be considered, because it will reduce the consumption of chemicals to adjust the pH. By adding H2SO4 and NaOH, the pH of the CLWW sample can be adjusted to the desired optimized value. At these optimized pH values (pH 7), the visible flocs were formed efficiently, resulting in the removal of pollutants from the wastewater.

The variation in FA of S-EPS and B-EPS is possibly caused by the existence of various types of proteins and carbohydrates moiety. These compounds are complex molecules, which are structurally different and contain many functional groups. The structure and functional groups may change with the microorganism used for fermentation, the type of carbon substrate, and the time of fermentation (Higgins and Novak 1997).

Also, another possible reason may be the fact that B-EPS is the combination of S-EPS and C-EPS. C-EPS can affect the FA of B-EPS because it contains a hydrophilic compound (hydroxyl groups) (Tian et al. 2006). B-EPS also contains organic, inorganic, dead cells, etc. which may also affect the overall performance of B-EPS.

Effect of EPS concentration

Different concentrations of S-EPS and B-EPS were used at the optimum pH. Various concentrations (0.1, 0.2, 0.3, 0.4, 0.5, and 0.6 g/L) of S-EPS and B-EPS were used to remove the contaminants from CLWW. The zeta potential and FA were studied at different EPS concentrations. It was observed that when S-EPS concentration increased, the zeta potential value also increased. The values of zeta potential in mV were − 7.7 mV, − 3.4 mV, − 1.4 mV, − 0.6 mV, 0.4 mV, and 1.2 mV at corresponding S-EPS concentrations of 0.1 g/L, 0.2 g/L, 0.3 g/L, 0.4 g/L, 0.5 g/L, and 0.6 g/L, respectively. Similarly, the FA also increased with the increase in S-EPS concentration. The maximum FA of 83.27% was attained at an S-EPS dose of 0.6 g/L (Fig. 2c). However, when B-EPS was used the zeta potential value was − 16.3 mV, − 8.1 mV, − 6.5 mV, − 4.3 mV, − 3.7 mV, and, − 3.5 mV at corresponding B-EPS concentration of 0.1 g/L, 0.2 g/L, 0.3 g/L, 0.4 g/L, 0.5 g/L, and 0.6 g/L. Similarly, the FA was raised with the rise in the B-EPS doses. The maximum FA (51.64%) was achieved when 0.6 g/L B-EPS was used. The results indicated that S-EPS displayed higher (83.27%) FA when compared to B-EPS (51.64%) at an EPS concentration of 0.6 g/L.

Combining EPS and chemical coagulant for the treatment of CLWW

Experiments were also conducted using EPS in the combination of alum (300 mg/L) at pH 7. When S-EPS is combined with alum for the treatment of CLWW it gives better FA as compared to S-EPS alone (Fig. 2c). This indicates that EPS with or without alum plays a significant role in the removal of pollutants from CLWW samples. The FA increased with an increased in S-EPS concentration (Fig. 2c). The maximum FA of 98.09% was achieved by using S-EPS (0.6 g/L) and alum (300 mg/L. The flocculation activity for the combination of EPS and alum has been depicted in Fig. 2c. Similarly, when B-EPS was used in combination with alum, it gave better FA as compared to B-EPS alone. The maximum FA of 76.36% was achieved using 0.6 g/L B-EPS and 300 mg/L of alum. The outcomes of the experiments were compared for the removal of pollutants (turbidity, SS, TS, COD, metals, etc.).

Removal of turbidity, SS, and TS

When EPS (S-EPS and B-EPS) were used alone for the treatment of CLWW, it resulted in slightly lower removal efficiency as compared to chemical coagulants (Table 4). The results indicated that the removal efficiency of turbidity, SS, and TS increased with the increase in EPS dosage. It was also observed that S-EPS gave better removal efficiency than B-EPS. S-EPS (0.6 g/L) alone can remove 83.27% turbidity, 77.69% SS and 78.66% TS. However, B-EPS (0.6 g/L) was able to remove only 51.64% turbidity, 48.38% SS and 46.15% TS from CLWW. Statistical analysis of the results obtained under optimum conditions by combining S-EPS with alum (analysis done in triplicate) indicates that the percentage of turbidity removal had a mean value of 98.09% with a standard deviation of 0.09, which means that it can be considered as constant with 0.09% accuracy. Also, the percentage TSS removal had a mean value of 95.42% with a standard deviation of 0.58 with accuracy 0.61%, and the percentage TS removal had a mean value of 94.80% with a standard deviation of 1.56 with accuracy 1.64%.

A higher removal of turbidity, SS, and TS was achieved by using S-EPS (0.6 g/L) in combination with alum (300 mg/L). S-EPS and alum together effectively removed 98.09% turbidity, 95.42% SS and 94.80% TS from CLWW. Similarly, B-EPS (0.6 g/L) in combination with alum (300 mg/L) removed 76.36% turbidity, 67.76% SS and 65.57% TS. From the outcomes, it can be easily determined that the combination of S-EPS with alum gave higher removal efficiency for turbidity, SS, and TS when compared to S-EPS alone.

Removal of COD

When EPS (S-EPS and B-EPS) were used alone for the treatment of CLWW it gave lower COD removal (Table 4). During the treatment process, 76.37% COD removal was obtained at 0.6 g/L S-EPS concentration. However, 43.64% of COD removal was achieved using B-EPS (0.6 g/L) alone. An increase in EPS concentration increased the COD removal efficiency. The reason behind the lower COD removal at lower EPS dosage (< 0.2 g/L) may be due to the less availability of bio-flocculant, which leads to the insufficient bridging of the particles and results in low settling of the suspended material. These results are in agreement with those reported on composting leachate treatment with EPS (Kaur et al. 2019).

The combination of EPS (S-EPS and B-EPS) with alum enhanced the COD removal from CLWW. The combination of S-EPS (0.6 g/L) and alum (300 mg/L) facilitated COD removal (83.08%). Similarly, the combination of B-EPS (0.6 g/L) and alum (300 mg/L) was able to remove 67.20% of COD from the wastewater sample. The Statistical analysis shows that the percentage COD removal had a mean value of 83.08% with a standard deviation of 1.1 with accuracy 1.32%.

Removal of metals

CLWW contains a significant amount of metals like Al, Na, Mg, K, and Ca (Table 2). A small amount of heavy metals was also detected in the wastewater sample. When CLWW was treated alone with S-EPS, it displayed considerable removal of metals. At the initial S-EPS dose of 0.1 g/L, only a small concentration of Al (5.2%), Na (6.3%), Mg (5.7%), K (2.1%), and Ca (10.8%) was removed from the wastewater sample (Table 5). When S-EPS concentration was increased, it displayed considerable removal of metals from wastewater. When S-EPS concentration increased to 0.6 g/L, removal of Al, Na, Mg, K, and Ca was 72.2%, 94.3%, 92.6%, 85.3%, and 98.4% respectively. Table 5 indicates data for the metal removal at different EPS concentrations. For the treatment of CLWW using B-EPS, the elimination of metals enhanced with the rise in B-EPS concentration (Table 5). At the initial B-EPS dose of 0.1 g/L, the removal of Al, Na, Mg, K, and Ca was 3.12%, 4.41%, 3.76%, 1.85%, and 8.32% respectively. When the concentration of B-EPS was raised to 0.6 g/L the elimination of metals enhanced to 45.32% (Al), 68.01% (Na), 63.12% (Mg), 77.06% (K), and 78.77% (Ca).

When EPS was used in combination with alum, the metal removal was increased significantly with the increase in EPS concentration. For the combination of S-EPS and alum (0.1 g/L and 300 mg/L), only a small concentration (2–13%) of metals was removed. When the dose of S-EPS was raised to 0.6 mg/L the removal of Al, Na, Mg, K, and Ca was increased to 87.08 84.76, 97.3, 92.68, and 96.2%, respectively.

When B-EPS was used in combination with alum, it also shows a significant impact on metals removal. For the initial B-EPS dose of 0.1 g/L, the elimination of Al, Na, Mg, K, and Ca was 3.49%, 4.94%, 4.1%, 1.76%, and 9.4% respectively. When the concentration of B-EPS was increased to 0.6 g/L, the removal of Al, Na, Mg, K, and Ca increased to 52.52%, 75.93%, 69.62%, 73.31%, and 81.62% respectively. It was observed that the removal of Na (75.93%) and Ca (81.62%) was better than the removal of Al (52.52%) and Mg (69.62%).

The removal of metals is because EPS possesses several adsorption sites for metals, which consist of proteins with aromatics and aliphatic sites and carbohydrates with hydrophobic sites (More et al. 2014). The EPS contains a high amount of polysaccharides and proteins, which play a very important role in metal removal. Studies indicate that C=O (carbonyl groups), amides groups, and -OH (hydroxyl group) present in the proteins can effectively eliminate heavy metals by electrostatic interaction (Nouha et al. 2016a, 2016b; Ruan et al. 2013). In addition to that other functional groups like the C–O–C group (ether) with polysaccharides, C=O group with phenolic alcohol, − OH group with alcohol, and phosphorous and sulfur groups also contributes to complex reactions. Apart from this, the presence of a phosphorus group in a nucleic acid (particularly DNA) which is present in EPS also provides additional binding sites for metals. Additionally, nucleotides and uronic acids containing phosphorous groups available in EPS are having a negative charge and they can effectively attach with multivalent positive charged ions resulting in metal removal (Nouha et al. 2018). It has been also reported that S-EPS contains a higher portion of proteins as compared to B-EPS (Pan et al. 2010). Therefore, the amount of protein and its types play a significant role in the flocculation process.

Effect of treatment time for CLWW treatment

The impact of treatment time on flocculation activity is depicted in Fig. 2d. It was observed that as the treatment time increased, it has a significant impact on the removal of contaminants like turbidity, SS, TS, COD, and metals.

When S-EPS (0.6 g/L) was used in combination with alum (300 mg/L), it was found that the value of turbidity decreased from 2.1 NTU to 1.1 NTU after 12 h of treatment. It was observed that treatment time (after 0.5 h) did not have a significant impact on the turbidity removal rate for S-EPS (Fig. 3a). Similarly, the concentration of SS, TS, and COD also decreased with an increase in treatment time. The concentration of SS, TS, and COD after 12 h of treatment was 1 mg/L, 18.18 mg/L, and 58.2 mg/L, respectively. It was also found that the removal of metals like Al and Mg increased significantly with an increase in treatment time (Fig. 3d, e). The removal of Al and Mg increases from 72.2% and 92.6% (30 min of treatment time) to 92.15% and 97.11%, respectively (Fig. 3d, e). For metals like Na and Ca, only small removal (2–5%) was observed.

When B-EPS (0.6 g/L) was used in combination with alum (300 mg/L), it was found that with the increase in treatment time, better removal of turbidity, TS, TSS, COD, and metals was observed as compared to S-EPS and alum treatment. The value of turbidity decreases from 26 NTU to 12.2 NTU after 12 h of treatment. Similarly, the concentration of SS, TS, and COD also decreased from 19.34, 214.13, and 190 mg/L to 6.99, 90.43, and 132.9 mg/L respectively after 12 h of treatment time. It was also observed that a significant amount of metal removal was achieved with an increase in treatment time (Fig. 3d–f). The removal of Al, Na, Mg, K, and Ca was increased from 45.32, 68.01, 63.12, 77.06% (30 min of treatment time) and 78.77 to 72.15, 83.14, 80.34, 87.12, and 85.46%, respectively (12 h of treatment time).

Comparison with previous studies

To the best of our knowledge this is the first time that a process using EPS has been used for the treatment of LWW. However, EPS produced by different bacterial strains has been used as a bio-flocculent to treat landfill leachates. We compare below the present study with other studies mentioned in the literature using EPS for the treatment of composting leachate and landfill leachate.

For this study, we used EPS produced by the bacterial strain BR04. The S-EPS (0.6 g/L) when combined with alum (0.3 g/L) at pH 7 gave the best results for LWW treatment after 30 min. The removal efficiency for turbidity, SS, COD and TS were recorded as 98%, 95.42%, 83.08% and 65.57%, respectively. COD removal efficiency increased to 88% after the treatment time of 4 h.

By comparison, Rajwinder et al., 2019 (Kaur et al. 2019) used EPS (produced by bacterial strain BS04) in order to treat composting leachate. Up to 69% of COD, 92% of phosphorus, 65.7% of ammonia and 63.32% of colour could be removed simultaneously removed from landfill leachate using a combination of S-EPS (0.5 g/L) and FeSO4 (2 g/L) at pH 8 for a treatment time of 8 h.

Another study carried out by Adama et al., 2022 (Ndao et al. 2022) used EPS (obtained from bacterial strain BS04) for the treatment landfill leachate. The best results from this study were obtained when S-EPS (0.015 g/L) and FeSO4 (2 g/L) were used together at pH 8 for 2 h. 83% COD, 50% Phosphorus, 44% nitrogen and 64–79% of metal removal were obtained.

The discrepancy of these results can be attributed to two main reasons: (i) the type of wastewater having different initial characteristics; (ii) the EPS is produced by different bacterial strains.

Conclusion

This work concludes that the biopolymer (EPS) produced from the bacterial fermentation process using BS-04 bacterial strain and waste streams (crude glycerol and secondary sludge from pulp and paper mill) can be used for the treatment of commercial laundry wastewater. Out of the three common chemical coagulants (Alum, FeSO4, and CaCl2), alum (2000 mg/L) achieved the highest flocculation activity (99.18%) and pollutant removal rates (SS-98%, TS- 91.33%, COD-85.1%) for CLWW treatment at pH 7 and treatment time of 30 min. It was observed that S-EPS (0.6 g/L) gave better FA than B-EPS. S-EPS alone can remove 83.20% of turbidity, 77.69% SS, and 76.37% COD. When S-EPS (0.6 g/L) was used in combination with alum (300 mg/L) at pH 7 and a treatment time of 30 min, the removal of turbidity, SS, and COD reached 98.00%, 95.42%, and 83.08%, respectively. When treatment time has been increased to 4 h, it resulted in more than 88.00% COD removal) from CLWW.

Availability of data and materials

All data generated or analyzed during this study are included in this published article.

References:

Ahmad M, Lee SS, Dou X, Mohan D, Sung J-K, Yang JE, Ok YS (2012) Effects of pyrolysis temperature on soybean stover-and peanut shell-derived biochar properties and TCE adsorption in water. Bioresour Technol 118:536–544

Ahn K-H, Song K-G (1999) Treatment of domestic wastewater using microfiltration for reuse of wastewater. Desalination 126(1–3):7–14

Akarsu C, Deniz F (2021) Electrocoagulation/electroflotation process for removal of organics and microplastics in laundry wastewater. Clean 49(1):2000146

Andersen M, Kristensen GH, Brynjolf M, Grüttner H (2002) Pilot-scale testing membrane bioreactor for wastewater reclamation in industrial laundry. Water Sci Technol 46(4–5):67–76

Ashfaq M, Wang T, Qiblawey H, Reesh IA, Judd S (2017) Recycling of hospital laundry wastewater using membrane technology. Desalination Water Treat 60:122–128

Bagheri M, Mirbagheri SA (2018) Critical review of fouling mitigation strategies in membrane bioreactors treating water and wastewater. Bioresour Technol 258:318–334

Bhattacharyya D, Jumawan A Jr, Grieves R, Witherup S (1978) Ultrafiltration of complex wastewaters: recycling for nonpotable use. J Water Pollut Control Fed 50:846–861

Bilad MR, Nawi NIM, Subramaniam DD, Shamsuddin N, Khan AL, Jaafar J, Nandiyanto ABD (2020) Low-pressure submerged membrane filtration for potential reuse of detergent and water from laundry wastewater. JWPE 36:101264

Bo X, Gao B, Peng N, Wang Y, Yue Q, Zhao Y (2012) Effect of dosing sequence and solution pH on floc properties of the compound bioflocculant–aluminum sulfate dual-coagulant in kaolin–humic acid solution treatment. Bioresour Technol 113:89–96

Bokhary A, Tikka A, Leitch M, Liao B (2018) Membrane fouling prevention and control strategies in pulp and paper industry applications: a review. J Membr Sci Res 4(4):181–197

Braga JK, Motteran F, Macedo TZ, Sakamoto IK, Delforno TP, Okada DY, Silva EL, Varesche MBA (2015) Biodegradation of linear alkylbenzene sulfonate in commercial laundry wastewater by an anaerobic fluidized bed reactor. J Environ Sci Health A 50(9):946–957

Campbell A (2002) The potential role of aluminium in Alzheimer’s disease. Nephrol Dial Transplant 17(suppl_2):17–20

Carbonell-Alcaina C, Corbatón-Báguena M-J, Álvarez-Blanco S, Bes-Piá MA, Mendoza-Roca JA, Pastor-Alcañiz L (2016) Determination of fouling mechanisms in polymeric ultrafiltration membranes using residual brines from table olive storage wastewaters as feed. J Food Eng 187:14–23

Chen B, Zhou D, Zhu L (2008) Transitional adsorption and partition of nonpolar and polar aromatic contaminants by biochars of pine needles with different pyrolytic temperatures. Environ Sci Technol 42(14):5137–5143

Chou W-L, Wang C-T, Huang K-Y (2009) Effect of operating parameters on indium (III) ion removal by iron electrocoagulation and evaluation of specific energy consumption. J Hazard Mater 167(1–3):467–474

Ciabattia I, Cesaro F, Faralli L, Fatarella E, Tognotti F (2009) Demonstration of a treatment system for purification and reuse of laundry wastewater. Desalination 245(1–3):451–459

Conley K, Clum A, Deepe J, Lane H, Beckingham B (2019) Wastewater treatment plants as a source of microplastics to an urban estuary: removal efficiencies and loading per capita over one year. Water Res X 3:100030

Corbatón-Báguena M-J, Álvarez-Blanco S, Vincent-Vela M-C (2015) Fouling mechanisms of ultrafiltration membranes fouled with whey model solutions. Desalination 360:87–96

Corona RR, Sad CM, da Silva M, Lopes DL, Leite JS, Viegas GMdF, Gonçalves GR, Filgueiras PR, de Castro EV (2021) Adsorption of anionic surfactant in graphite oxide: a study for treatment of laundry wastewater. J Environ Chem Eng 9(6):106858

Cosa S, Ugbenyen AM, Mabinya LV, Rumbold K, Okoh AI (2013) Characterization and flocculation efficiency of a bioflocculant produced by a marine Halobacillus. Environ Technol 34(18):2671–2679

Delforno TP, Belgini DR, Hidalgo K, Centurion VB, Lacerda-Júnior GV, Duarte IC, Varesche M, Oliveira V (2020) Anaerobic reactor applied to laundry wastewater treatment: Unveiling the microbial community by gene and genome-centric approaches. Int Biodeterior Biodegradation 149:104916

Deowan S, Bouhadjar S & Hoinkis J (2015) Membrane bioreactors for water treatment. Advances in membrane technologies for water treatment, Elsevier. p 155–184

Elazzouzi M, El Kasmi A, Haboubi K, Elyoubi M (2018) A novel electrocoagulation process using insulated edges of Al electrodes for enhancement of urban wastewater treatment: techno-economic study. PSEP 116:506–515

ElSherbiny I, Khalil AS, Ulbricht M (2019) Influence of surface micro-patterning and hydrogel coating on colloidal silica fouling of polyamide thin-film composite membranes. Membranes 9(6):67

Emaminejad SA, Avval SS, Bonakdarpour B (2019) Gaining deeper insights into the bioflocculation process occurring in a high loaded membrane bioreactor used for the treatment of synthetic greywater. Chemosphere 230:316–326

Estahbanati MK, Kumar S, Khajvand M, Drogui P & Tyagi RD (2021) Environmental Impacts of Recovery of Resources From Industrial Wastewater. Biomass, Biofuels, Biochemicals, Elsevier. p 121–162

Fan L, Harris JL, Roddick FA, Booker NA (2001) Influence of the characteristics of natural organic matter on the fouling of microfiltration membranes. Water Res 35(18):4455–4463

Faria CVd, Delforno TP, Okada DY, Varesche MBA (2019) Evaluation of anionic surfactant removal by anaerobic degradation of commercial laundry wastewater and domestic sewage. Environ Technol 40(8):988–996

Gitis V, Haught RC, Clark RM, Gun J, Lev O (2006) Nanoscale probes for the evaluation of the integrity of ultrafiltration membranes. J Membr Sci 276(1–2):199–207

Gomes JA, Daida P, Kesmez M, Weir M, Moreno H, Parga JR, Irwin G, McWhinney H, Grady T, Peterson E (2007) Arsenic removal by electrocoagulation using combined Al–Fe electrode system and characterization of products. J Hazard Mater 139(2):220–231

Guilbaud J, Massé A, Andrès Y, Combe F, Jaouen P (2010) Laundry water recycling in ship by direct nanofiltration with tubular membranes. Resour Conserv and Recycl 55(2):148–154

Hamedi H, Ehteshami M, Mirbagheri SA, Rasouli SA, Zendehboudi S (2019) Current status and future prospects of membrane bioreactors (MBRs) and fouling phenomena: a systematic review. The Can J Chem Eng 97(1):32–58

Han M, Song J, Kwon A (2002) Preliminary investigation of electrocoagulation as a substitute for chemical coagulation. Water Sci Technol 2(5–6):73–76

Higgins MJ, Novak JT (1997) Characterization of exocellular protein and its role in bioflocculation. J Environ Eng 123(5):479–485

Hoinkis J, Deowan SA, Panten V, Figoli A, Huang RR, Drioli E (2012) Membrane bioreactor (MBR) technology–a promising approach for industrial water reuse. Procedia Eng 33:234–241

Holt PK, Barton GW, Mitchell CA (2005) The future for electrocoagulation as a localised water treatment technology. Chemosphere 59(3):355–367

Howe KJ, Clark MM (2002) Fouling of microfiltration and ultrafiltration membranes by natural waters. Environ Sci Technol 36(16):3571–3576

Howe KJ, Clark MM (2006) Effect of coagulation pretreatment on membrane filtration performance. J Am WATER Work Assoc 98(4):133–146

Hu C, Lo S, Kuan W (2003) Effects of co-existing anions on fluoride removal in electrocoagulation (EC) process using aluminum electrodes. Water Res 37(18):4513–4523

Huang X, Bo X, Zhao Y, Gao B, Wang Y, Sun S, Yue Q, Li Q (2014) Effects of compound bioflocculant on coagulation performance and floc properties for dye removal. Bioresour Technol 165:116–121

Huang AK, Veit MT, Juchen PT, da Cunha GG, Palacio SM, de Oliveira CC (2019) Sequential process of coagulation/flocculation/sedimentation-adsorption-microfiltration for laundry effluent treatment. J Environ Chem Eng 7(4):103226

Iorhemen OT, Hamza RA, Tay JH (2016) Membrane bioreactor (MBR) technology for wastewater treatment and reclamation: membrane fouling. Membranes 6(2):33

İrdemez Ş, Demircioğlu N, Yıldız YŞ, Bingül Z (2006) The effects of current density and phosphate concentration on phosphate removal from wastewater by electrocoagulation using aluminum and iron plate electrodes. Sep Purif Technol 52(2):218–223

Janpoor F, Torabian A, Khatibikamal V (2011) Treatment of laundry waste-water by electrocoagulation. J Chem Technol Biotechnol 86(8):1113–1120

Jardak K, Drogui P, Daghrir R (2016) Surfactants in aquatic and terrestrial environment: occurrence, behavior, and treatment processes. Environ Sci Pollut Res 23(4):3195–3216

Jia S, Han H, Hou B, Zhuang H, Fang F, Zhao Q (2014) Treatment of coal gasification wastewater by membrane bioreactor hybrid powdered activated carbon (MBR–PAC) system. Chemosphere 117:753–759

Kabdaşlı I, Keleş A, Ölmez-Hancı T, Tünay O, Arslan-Alaton I (2009) Treatment of phthalic acid esters by electrocoagulation with stainless steel electrodes using dimethyl phthalate as a model compound. J Hazard Mater 171(1–3):932–940

Kamarudin S, Daud W, Mohammad A, Som AM, Takriff M (2003) Design of a tubular ceramic membrane for gas separation in a PEMFC system. Fuel Cells (weinh) 3(4):189–198

Kaur R, Roy D, Yellapu SK, Tyagi RD, Drogui P, Surampalli RY (2019) Enhanced composting leachate treatment using extracellular polymeric substances as bioflocculant. J Environ Eng 145(11):04019075

Kim H-C, Shang X, Huang J-H, Dempsey BA (2014) Treating laundry waste water: cationic polymers for removal of contaminants and decreased fouling in microfiltration. J Membr Sci 456:167–174

Kumar PR, Chaudhari S, Khilar KC, Mahajan SP (2004) Removal of arsenic from water by electrocoagulation. Chemosphere 55(9):1245–1252

Kumar S, Talan A, Boyle K, Ormeci B, Drogui P & Tyagi RD (2021) Water recycling: economic and environmental benefits. Biomass, Biofuels, Biochemicals, Elsevier. p 91–120

Larue O, Vorobiev E, Vu C, Durand B (2003) Electrocoagulation and coagulation by iron of latex particles in aqueous suspensions. Sep Purif Technol 31(2):177–192

Laspidou CS, Rittmann BE (2002) A unified theory for extracellular polymeric substances, soluble microbial products, and active and inert biomass. Water Res 36(11):2711–2720

l'Environnement Md & climatiques edlLclc (2014) Center of Expertise in Environmental Analysis of Quebec. Quebec,Canada).

Lissens G, Pieters J, Verhaege M, Pinoy L, Verstraete W (2003) Electrochemical degradation of surfactants by intermediates of water discharge at carbon-based electrodes. Electrochim Acta 48(12):1655–1663

Liu W, Yuan H, Yang J, Li B (2009) Characterization of bioflocculants from biologically aerated filter backwashed sludge and its application in dying wastewater treatment. Bioresour Technol 100(9):2629–2632

Lohaus J, Perez YM, Wessling M (2018) What are the microscopic events of colloidal membrane fouling? J Membr Sci 553:90–98

Madaeni S, Fane A, Grohmann G (1995) Virus removal from water and wastewater using membranes. J Membr Sci 102:65–75

Mahmoudi E, Ng LY, Ang WL, Teow YH, Mohammad AW (2020) Improving membrane bioreactor performance through the synergistic effect of silver-decorated graphene oxide in composite membranes. J Water Process Eng 34:101169

Mahvi A, Feizabadi GK, Dehghani M, Mazloomi S (2015) Efficiency of different coagulants in pretreatment of composting plant leachate. J Biodivers Environ Sci 6(6):21–28

Manouchehri M, Kargari A (2017) Water recovery from laundry wastewater by the cross flow microfiltration process: a strategy for water recycling in residential buildings. J Clean Prod 168:227–238

Mohan SM (2014) Use of naturalized coagulants in removing laundry waste surfactant using various unit processes in lab-scale. J Environ Manage 136:103–111

Mollah MYA, Schennach R, Parga JR, Cocke DL (2001) Electrocoagulation (EC)—science and applications. J Hazard Mater 84(1):29–41

More T, Yadav JSS, Yan S, Tyagi RD, Surampalli RY (2014) Extracellular polymeric substances of bacteria and their potential environmental applications. J Environ Manage 144:1–25

Mostafazadeh AK, Benguit AT, Carabin A, Drogui P, Brien E (2019) Development of combined membrane filtration, electrochemical technologies, and adsorption processes for treatment and reuse of laundry wastewater and removal of nonylphenol ethoxylates as surfactants. J Water Process Eng 28:277–292

Moura AdL, Centurion V, Okada D, Motteran F, Delforno T, Oliveira V, Varesche M (2019) Laundry wastewater and domestic sewage pilot-scale anaerobic treatment: microbial community resilience regarding sulfide production. J Environ Manage 251:109495

Ndao A, Drogui P, Tyagi RD (2022) Enhancement of landfill leachate treatment using extracellular polymeric substances as bio-flocculants. J Environ Sci Health B 57(1):62–70

Nouha K, Hoang N, Song Y, Tyagi RD, Surampalli R (2016) Characterization of extracellular polymeric substances (EPS) produced by Cloacibacterium normanense isolated from wastewater sludge for sludge settling and dewatering. J Civil Environ Eng. https://doi.org/10.4172/2165-784X.1000191

Nouha K, Kumar RS, Tyagi RD (2016b) Heavy metals removal from wastewater using extracellular polymeric substances produced by Cloacibacterium normanense in wastewater sludge supplemented with crude glycerol and study of extracellular polymeric substances extraction by different methods. Bioresour Technol 212:120–129

Nouha K, Kumar RS, Balasubramanian S, Tyagi RD (2018) Critical review of EPS production, synthesis and composition for sludge flocculation. J Environ Sci 66:225–245

Pan X, Liu J, Zhang D, Chen X, Song W, Wu F (2010) Binding of dicamba to soluble and bound extracellular polymeric substances (EPS) from aerobic activated sludge: a fluorescence quenching study. J Colloid Interface Sci 345(2):442–447

Paris S, Schlapp C (2010) Greywater recycling in Vietnam—application of the HUBER MBR process. Desalination 250(3):1027–1030

Priya T, Mohanta VL, Mishra BK (2017) Performance evaluation of zirconium oxychloride for reduction of hydrophobic fractions of natural organic matter. Sep Purif Technol 174:104–108

Ruan X, Li L, Liu J (2013) Flocculating characteristic of activated sludge flocs: Interaction between Al3+ and extracellular polymeric substances. J Environ Sci 25(5):916–924

Siswoyo E, Utari AW, Mungkari LGN (2019) Adsorption combined phytoremediation system for treatment of laundry wastewater. MATEC Web Conf. https://doi.org/10.1051/matecconf/201928005002

Šostar-Turk S, Petrinić I, Simonič M (2005) Laundry wastewater treatment using coagulation and membrane filtration. Resour Conserv Recycl 44(2):185–196

Subramanian SB, Yan S, Tyagi RD, Surampalli R (2010) Extracellular polymeric substances (EPS) producing bacterial strains of municipal wastewater sludge: isolation, molecular identification, EPS characterization and performance for sludge settling and dewatering. Water Res 44(7):2253–2266

Terechova E, Zhang G, Chen J, Sosnina N, Yang F (2014) Combined chemical coagulation–flocculation/ultraviolet photolysis treatment for anionic surfactants in laundry wastewater. J Environ Chem Eng 2(4):2111–2119

Tian Y, Zheng L, Sun D-z (2006) Functions and behaviors of activated sludge extracellular polymeric substances (EPS): a promising environmental interest. J Environ Sci 18(3):420–427

Veli S, Arslan A, Gülümser Ç, Topkaya E, Kurtkulak H, Zeybek Ş, Dimoglo A, İşgören M (2019) Advanced treatment of pre-treated commercial laundry wastewater by adsorption process: experimental design and cost evaluation. J Ecol Eng 20(10):165

Veli S, Arslan A, Topkaya E, Gülümser Ç, Kurtkulak H, Belat B, Zeybek Ş, Zor S, Dimoglo A (2021) Deep purification of pretreated laundry wastewater through the adsorption by polymeric composites and optimisation of the process. Int J Environ Anal Chem. https://doi.org/10.1080/03067319.2021.1889530

Verma AK, Dash RR, Bhunia P (2012) A review on chemical coagulation/flocculation technologies for removal of colour from textile wastewaters. J Environ Manage 93(1):154–168

Yüksel E, Şengil İA, Özacar M (2009) The removal of sodium dodecyl sulfate in synthetic wastewater by peroxi-electrocoagulation method. Chem Eng J 152(2–3):347–353

Zaroual Z, Azzi M, Saib N, Chaînet E (2006) Contribution to the study of electrocoagulation mechanism in basic textile effluent. J Hazard Mater 131(1–3):73–78

Zhu YP, Rosen MJ, Morrall SW, Tolls J (1998) Surface properties of linear alkyl benzene sulfonates in hard river water. J Surfactants Deterg 1(2):187–193

Acknowledgements

The authors would like to acknowledge the financial support from the National Sciences and Engineering Research Council of Canada (NSERC) by the CREATE-TEDGIEER program. We would like to acknowledge financial support from our industrial partner VEOS water. We would also like to thank Lalit R Kumar for helping with grammatical correction and, INRS technicians for their help in sample analysis.

Funding

The authors received financial support from the National Sciences and Engineering Research Council of Canada (NSERC) by CREATE-TEDGIEER program (Grant number- 498017-2017), and by industrial partner VEOS water (Grant number-RDCPJ 531664-18).

Author information

Authors and Affiliations

Contributions

SK, AKM, PD, and RDT conceived and planned the idea of the study. SK experimented and collected the data. All authors carried out the analysis and contributed to the interpretation of the results. SK wrote the manuscript in consultation with AKM, PD, and RDT. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

All authors read and approved the final manuscript and mutually agreed that it should be submitted to Environmental System Research.

Competing interests

The authors declare that they have no competing interests to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1: Figure S1

. Effect of pH on Zeta Potential.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kumar, S., Mostafazadeh, A.K., Drogui, P. et al. Treatment of laundry wastewater using extracellular polymeric substances (EPS). Environ Syst Res 12, 10 (2023). https://doi.org/10.1186/s40068-023-00289-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40068-023-00289-5