Abstract

Background

High-strength wastewater defined by elevated levels of hazardous pollutants measured in BOD, heavy metals, nutrients and other toxic substances. This kind of wastewater discharged to water body without treatment from different industrial sectors that adversely affects aquatic environment and downstream water consumers. The general objective of this study is to investigate efficient substrate with selected plant type for constructed wetland to remove hazardous pollutants from tannery wastewater. This study was conducted at Modjo town, Modjo tannery PLC. Plug flow experimental study design was carried out. The substrate (Pumice) was collected around the study area and chemical characteristics were determined. Chrysopogon zizanioides was planted and grown for 5 months before running tannery wastewater for the treatment. The composite wastewater was introduced to the constructed wetland from Modjo leather industry, Ethiopia. The physicochemical analysis of the sample wastewater was done before and after treatment at four different hydraulic retention time.

Results

Characterization of the untreated tannery wastewater revealed that the mean concentration of BOD5, COD, TSS, PO4-P, TP, NO3-N, TN and total chromium were 1641 ± 373.6, 6953.33 ± 339.4, 1868 ± 863.1, 88.06 ± 40.8, 144.53 ± 20.8, 116.66 ± 26.6, 650.33 ± 93.6 and 18.33 ± 6.7 mg/l respectively beyond the permissible limits. The maximum removal efficiency of the constructed wetland in pumice bed revealed that BOD5 at HRT 7and 9 days (96.42%, 96.30%), COD at HRT 5 and 7 days (96.76%, 96.91%), NO3-N at HRT 5 and 7 days (99.99%, 99.68%), TN (98.67%, 99.00%), PO4-P HRT 7and 9 days (96.97%,100%), TP at HRT 5 and 7 days (94.79%, 96.17%) and total Chromium at HRT 5 and 7 days (98.36%, 98.91%) respectively. Whereas, the removal efficiency of constructed wetland bed with gravel substrate used as a control subject with similar condition to pumice showed lower performance. The result between pumice and gravel bed was tested for their significance difference using two sample t-test statistics. Based on the test statistics, the pumice substrate perform better than the gravel significantly at 95% confidence interval, p-value = 0.01.

Conclusion

Pumice substrate and Chrysopogon zizanioides have a potential ability to remove hazardous pollutants from tannery wastewater in horizontal subsurface constructed wetlands.

Similar content being viewed by others

Background

Industrial wastewater is the most common source of environmental pollution in the current situation. The discharge of high strength wastewaters with high concentration of nutrients and heavy metals from industrial sectors can have harmful consequences on the ecological balance and ecosystem function of the receiving environment as well as the public health of downstream end-users of the polluted water sources (Asamudo et al. 2005).

Tanning is one of the oldest industries in the world. During ancient times, tanning activities were organized to meet the local demands of leather footwear, drums and musical instruments. With the growth of population, the increasing requirement of leather and its products led to the establishment of large commercial tanneries. Two methods are adopted for tanning of raw hide/skin, vegetable tanning, and chrome tanning. Tanneries are typically characterized as pollution intensive industrial complexes which generate widely varying, high-strength wastewaters. Nearly 30 m3 of wastewater is generated during processing of one tone of raw skin/hide (Suthanthararajan et al. 2004).

Tannery operation consists of converting of the raw hide or skin into leather which consume huge amount of water in several stages, generating an enormous amount of liquid effluents which are hazardous to the environment to which they are discharged, consequently, make it as a potentially pollution intensive industry. Tannery effluents again compromise the physical, chemical and biological properties of aquatic environment. Apart from the most toxic heavy metals like Chromium (Cr) chemical impurities of tannery effluents mostly includes the following dissolved substances such as inorganic salt cations (Fe, Zn, Cu, Ca, Na, etc.); anions such as SO42−, NO3−, PO4 3− and parameters such as, Biochemical Oxygen demand (BOD), Chemical Oxygen Demand (COD), Total Suspended Solid (TSS), Total Dissolved Solid (TDS) etc. (Kawser et al. 2011). Therefore treating tannery wastewater using natural adsorbents is very important to protect the surrounding environment.

In Ethiopia currently, there are more than 30 tannery industries in operation. Among them the majority found in Oromia region especially Mojo town and around six established in the capital city Addis Ababa. These tanneries have 153,650 sheep and goat skin soaking capacity and 9,725 cowhides soaking capacity per day. Together they also employ 4577 persons (UNIDO 2012).

Leather is one of the most important export item of Ethiopia earning foreign exchange. On the other hand, the leather tanning industry has been recognized as one of the main causes of water and environmental pollution. With the high adoption of chrome tanning in most of the tanning industries in the country, efficient methods of chromium, nutrients and other pollutant removal from tannery wastewater are important to attain environmental quality standards.

Conventional wastewater treatment processes such as activated sludge and biofilms are used seldom in Africa including Ethiopia due to lack of energy and financial resources. Therefore in this case constructed wetland is sustainable option for industrial wastewater treatment. Because, constructed wetlands can provide an energy-efficient, cost-effective, and low maintenance alternative to conventional wastewater treatment technologies (Kadlec and Knight 1996). They also have additional benefits that include creating habitat for plants and wildlife and an aesthetic green space in communities.

Kivaisi (2001) assured that there is potential for the development of CWs in developing countries like Ethiopia. The author points out this to the location of many developing countries in warm tropical and sub-tropical climates (Ethiopia located in Tropics), which are favorable to higher biological activity and productivity, and hence better treatment performance.

Compared with the conventional wastewater treatment system currently in use the constructed wetland has its own advantage. Constructed wetlands are natural wastewater treatment systems that typically have lower construction, operation and maintenance costs than conventional mechanical treatment systems. Constructed wetlands are therefore cost effective, eco-friendly and technically feasible approach for treating industrial wastewater including high strength tannery wastewater.

Even though literature cannot found in Ethiopia on the cost comparison of constructed wetland and conventional wastewater treatment, Study conducted in Ireland by Reddy (2004) showed that the cost of a typical constructed wetland cheaper by 30% than conventional treatment methods of the same size considering the lifespan and replacement value of the wetland. The above case studies confirmed that the maintenance cost for constructed wetlands was eight times lower than the conventional treatment system. Furthermore, operation and maintenance require only periodic rather than continues.

The result of another study indicated that the total annual cost for waste stabilization pond was 21% more than that of the constructed wetlands (Tomokin 2000). Based on the overall results of the treatment performance and costs, these researchers concluded that the application of constructed wetlands can be considered both technically and economically viable option for wastewater treatment.

Conventional wastewater treatment systems contains energy demanding and mechanical treatment components which require substantial investment and high operating costs. Experience has shown that existing wastewater treatment systems in most of the developing countries failed to treat wastewater effectively it is because of high operating and maintenance costs, lack of local expertise and poor institutional governance. Compared to conventional treatment systems, constructed wetlands are low cost, easy to operate and maintain, and have a strong prospective for application in developing countries (Vymazal 2010).

On the other hand, adsorption has been identified as one of the most promising mechanism for removal of dissolved heavy metal fractions and nutrients from wastewater. Although commercial adsorbents are available for use in adsorption, they are very expensive, resulting in various new low-cost adsorbents being studied by researchers. Babel and Kurniawan (2003), reviewed the technical feasibility of various low-cost adsorbents for heavy metals removal from wastewater and concluded that the use of low-cost adsorbents may contribute to the sustainability of the surrounding environment and offer promising benefits for commercial purpose in the future. Therefore identifying potentially efficient substrate for constructed wetland as an adsorbent is critical for proper practice of environmental management by tanning industries.

Materials and methods

Study area

This study was conducted in Oromia region east Showa zone, Modjo town at Modjo tanning industry PLC (Fig. 1).

Study design

Plug flow experimental study design was carried out to determine the efficiency of pumice substrate and Chrysopogon zizanioides plant species in horizontal subsurface constructed wetland to remove hazardous pollutants from high-strength tannery wastewater.

Experimental materials, Design and setup establishments

Pumice was collected from volcanic cones of refit valley area of Oromia region east showa zone (8° 28′ 36″ N and 39°14′ 29″ E), Ethiopia 20–30 km far from Modjo Tannery (8° 35′ 13″ N and 39° 07′ 23″ E) approximately 70 km East of Addis Ababa (Fig. 1). The chemical characteristics of this substrate was determined by using XRF analysis.

The plant (Chrysopogon zizanioides) was collected from Holeta Agricultural research institute and transported to Modjo tanning industry. It was planted in the horizontal subsurface constructed wetland and grown for 5 months before running high-strength wastewater for the treatment.

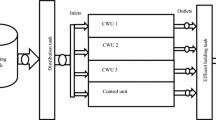

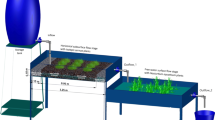

The horizontal subsurface constructed wetland was installed at Modjo tanning industry compound for the treatment of tannery wastewater (Fig. 2). The treatment system consists of: a primary screening and a grit removal tank; sedimentation tank for sludge settling and equalization tank connected with horizontal subsurface flow constructed wetland (HSSFCW), with an effective volume of 1.92 m3 each which is a length of 4 m, width of 0.8 m and effective depth of 0.6 m (Fig. 3).

The CWs are filled with medium-sized gravel, ranging in size from 6 to 20 mm as a control and pumice 10–25 mm grain size substrate vegetated with Chrysopogon zizanioides in separate constructed wetland cell with similar size and dimensions (Fig. 4). The pumice substrate was crushed and graded. Effective size was determined by using standard sieve. Based on the analysis the effective size (ES) (d10) of the media was 1.5–4.5 and the uniformity coefficient (UC) (d60/d10) was 3.5–4.

The raw wastewater is fed into a sedimentation tank from the factory after 24 h retention time pumped to the equalization tank with volume of 5000 L then the CWs fed from this tank through 3/4th inch pipe with control valve for each cell. Performance of this constructed wetland was recorded for two years based on four different hydraulic retention time (3, 5, 7 and 9 days).

Sample collection and laboratory analysis

The on-site measurement of the physicochemical parameters was undertaken. The physicochemical analysis of wastewater samples was done before and after the treatment with the two different hydraulic retention time, using standard methods. The analytical parameters were pH, BOD5, COD, Ammonium N, Nitrite N, Nitrate N, Total N, Phosphate, Total P, TSS, TDS, Salinity and Chromium. On-site measurement of the wastewater like temperature, pH and DO were carried out at the site in the tannery environmental quality control laboratory using portable pH meter (Wagtech International N374, M128/03IM, USA) and DO meter (Hach P/N HQ30d, Loveland. CO, USA) for Dissolved oxygen and temperature.

COD, Ammonium-nitrogen, Nitrite-nitrogen, Nitrate-nitrogen, Phosphate, Chloride, Sulfide and Sulfate were measured by using spectrophotometer (Hach model DR/3900 portable spectrophotometer, Germany) according to Hach instructions. BOD5 and total Chromium were analyzed using BOD sensor and inductive stirring system AQUA LYTIC model type ET618-4 and Flame Atomic Absorption Spectrophotometer (AAS), (model AAS NOUA-400, Germany) respectively. Total suspended solids (TSS) were determined according to the Standard Methods for the Examination of Water and Wastewater gravimetric method. Heavy metal uptake capacity of the plant and adsorption potential of the pumice were determined by Ash-Modified AOAC 923.03 and Minerals-Modified AOAAC 985.35 (APHA 2005).

The removal efficiency of the filter media for the selected parameters were calculated as:

where Ci is the parameter concentration in the untreated wastewater and Cf is the parameter concentration in the treated wastewater.

Statistical data analysis

Mean and standard deviations were calculated to estimate the concentration of each parameter of the samples. The hypothesis has been tested by two sample t-test using R statistical software: R version 3.2.2 (2015–08-14), Platform: x86_64-w64-mingw32/ × 64 (64-bit) and Originlab pro 2017 to determine whether an observed difference between the means of the groups is statistically significant or not, based on the two hydraulic retention time.

Data quality management

To assure quality of the data by minimizing the errors the following measures had been undertaken: Apparatuses were calibrated; expiry date of reagents had been checked before starting the real analysis and standard control also prepared. Each test had been triplicated.

Result and discussion

Physicochemical characteristics of Modjo Tannery wastewater

The raw wastewater was taken from Modjo tannery for physicochemical analysis. Based on this investigation the mean concentration of selected physicochemical parameters were presented at Table 1.

This study revealed that the mean concentration of BOD5, COD and TSS were 1641 ± 375.6, 6953 ± 339.4 and 1868 ± 863.1 mg/l respectively (Table 1). This result is basically similar to different studies in Ethiopia with slight difference for different parameters for example a study done at the same tannery industry indicated that the mean concentration of COD was laid between 7950 and 15,240 mg/l with the mean of 11,123 ± 563.9 mg/l (Seyoum Leta et al. 2003). Another study also undertaken with same tannery wastewater showed that the mean concentration of BOD5 was 1054 ± 448 mg/l (Tadesse Alemu and Seyoum Leta 2015) and the concentration of total suspended solid was found from 1217 to 2847 (Table 3.1) this is a bit greater than some studies for instance a study done in India indicated that 1244 mg/l (Tamal et al. 2010).

Nutrients like orthophosphate, ammonium, nitrite and nitrate concentration of Modjo tannery were characterized in this study, the result revealed that 88 ± 40.8, 253.3 ± 11.6, 1.9 ± 0.12, 116.7 ± 26.6 mg/l respectively. This result is comparable to a study done by Sivakumar et al. (2015) which indicates the concentration of nitrate in untreated tannery effluent was 116 mg/l. The result of ammonium is also similar to that of the results done at Bahir Dar tannery wastewater characterization (96–420 mg/l) (Wosnie and Wondie 2014). According to Arasappan and Kalyanaraman (2015), the nitrite concentration of untreated tannery wastewater was 1.3 mg/l almost parallel to this study finding which accounts 1.9 ± 0.12 mg/l (Table 1). Some variation have been seen in some parameters. This variation may be due to the utilization of chemicals for different purposes and different tanning activities among tanneries.

In terms of chromium concentration, Modjo tannery comprised 18.33 ± 6.7 mg/l is similar to other different results presented from same tannery wastewater by Tadesse Alemu et al. (2016) the mean influent wastewater to the constructed wetland was 18.67 mg/l. Likewise a variation exists in values of physicochemical parameters in general like BOD5, COD, TSS, phosphate, sulfide, sulfate, etc. in every tannery wastewater characteristics, this may be because of different tanning process, methods, technology and raw material utilization by various tanning industries.

Tannery wastewater treatment efficiency of horizontal subsurface flow constructed wetland with pumice substrate planted with Chrysopogon zizanioides(CZ)

The pollutant removal efficiency of horizontal subsurface constructed wetland under this investigation was high this may be due to the high adsorption capacity of pumice and the uptake potential of Chrysopogon zizanioides from tannery wastewater. The characteristics of tannery wastewater after treatment was alongside with the standard guideline value of the Ethiopian environmental protection authority and WHO irrigation water quality standard (Table 2).

BOD5, COD and TSS removal efficiency of HSSFCW with pumice substrate and planted with Chrysopogon Zizanioides

The three important pollutant of the tannery wastewater were analyzed before and after treatment of four hydraulic retention time, based on the finding the final effluent concentration of BOD5, COD and TSS in mg/l were (273 ± 91, 532.50 ± 177.5 and 99.72 ± 80.93) for 3 days HRT, (74 ± 2, 225.41 ± 11.13 and 79 ± 13.53) for 5 days HRT, (58.67 ± 6.5, 214.67 ± 32.33 and 80 ± 4.58) for 7 days HRT and (60.67 ± 4.93, 234.67 ± 38.79 and 74 ± 21.65) for 9 days HRT (Table 2). Both BOD and COD result of 5, 7 and 9 HRT were met the standard value of WHO water quality for irrigation and EEPA (200 and 500 mg/l) but they are beyond the standard at hydraulic retention time of 3 days this is because of the time shortage to degrade organic matter. In all the allotted hydraulic retention time TSS was not achieved good result as compared to the Both WHO and EEPA guideline (50 mg/l) (EEPA 2003;WHO 1996).

The removal efficiency of this horizontal flow subsurface constructed wetland filled with pumice substrate and planted with Chrysopogon zozanioides was high for the purification of tannery wastewater considering the three polluting agents with specific hydraulic retention time. During the first 3 and 5 days retention time BOD5, COD and TSS were reduced by (83.36%, 92.34% and 94.66%) and (95.49%, 96.76% and 95.77%) respectively. After the second 7 and 9 days retention time also it reduced by (96.42%, 96.91% and 95.72%) and (96.30%, 96.62% and 96.02%) respectively (Table 3).

The result achieved due to the activities of the microorganisms and the networked and spongy tuft roots of the plant to make comfortable environment for the growth of the organism in addition to absorption. The aerobic condition in the superficial wetland bed and anaerobic condition in the bottom allow for efficient removal of organic pollutants and the filtration of the wastewater is the main reason for the removal of suspended solids. A vertical subsurface wetland planted with Scirpus Alternifolios and red ferralitic soil substrate was evaluated by scholars for its wastewater purification capacity and reported as BOD, COD and TSS were reduced by (84.9%, 89.8% and 98.1%) respectively (Villara et al. 2012), the result is almost similar to this investigation especially with the first 3 and 5 h retention time.

Nutrient removal efficiency of HSSFCW with pumice substrate and planted with Chrysopogon Zizanioides (NH4-N, NO3-N, TN, PO4-P, TP)

The plant (Chrysopogon zizanioides) used in this study possesses unique characteristics suitable for wastewater purification. Now a days various research findings showed its exceptional ability to absorb and to tolerate extreme levels of nutrients, to consume large quantities of water in the process of producing a massive biomass growth. These attributes indicated that this plant is highly suitable for treating high strength wastewater from different industries like tanning industries. In addition to the plant type, selection of best efficient substrate based on the selection criteria including its chemical composition is important for effective application of horizontal subsurface flow constructed wetland for the treatment of high strength industrial wastewater.

The main nutrient component concentrations like NH4-N, NO3-N, TN, PO4-P and TP in Modjo tannery wastewater were determined before and after treatment using this horizontal subsurface constructed wetland to evaluate its treatment performance at four different hydraulic retention time. In the final effluent, the concentration of NH4-N, NO3-N, TN, PO4-P and TP in mg/l become (26.83 ± 2.93, 10.83 ± 2.75, 42 ± 15.72, 6.33 ± 2.1 and 19.67 ± 3.05) at 3 days HRT, (5.00 ± 4.36, 0 ± 0, 8.67 ± 5.7, 3.04 ± 1 and 7.53 ± 2.33) at 5 days HRT, (4.67 ± 1.53, 0.37 ± 0.15, 6.50 ± 1.32, 2.67 ± 1.26 and 5.53 ± 0.5) at 7 days HRT and (6.83 ± 1.44, 0.57 ± 0.21, 9.33 ± 2.1, 0 ± 0 and 83.87 ± 11.37) at 9 days HRT respectively (Table 2).

When the result finding evaluated with the standard guideline value of WHO water quality standard and EEPA at different hydraulic retention time, NH4-N and TN were under the maximum permitable limit at all retention time and NO3-N and PO4-P were met the specified limit value at 5, 7 and 9 days retention time only. But TP removal was good only at 5 and 7 days retention time. Therefore contact time of 5 days and greater are efficient retention time for the removal of major nutrients from tannery wastewater using horizontal subsurface constructed wetland filled with pumice substrate and planted with Chrysopogon zizanioides. Substrate composition, plant type and some microorganisms in the constructed wetland were play great role for the reduction of those nutrient components.

As various scholars reported, the removal of pollutants from wastewater are achieved by different mechanisms like sedimentation, filtration, chemical precipitation, adsorption, microbial interactions, and uptake of vegetation. The nutrient removal efficiency of this subsurface constructed wetland was generally effective. The maximum removal efficiency was seen at 5, 7 and 9 days retention time. The minimum (89.41%) and maximum (98.16%) of NH4-N removal efficiency was achieved at 3 and 7 days retention time respectively. Almost all of NO3-N also removed after 5 days treatment, more than 93.5% of TN was removed, PO4-P and TP were also effectively removed in this constructed wetland, a minimum of 92.81% at 3 days HRT and maximum of 100% at 9 days HRT of PO4-P was removed likewise TP from 41.97% at 9 days HRT up to 96.17% at 7 days HRT was removed (Fig. 5).

This effective result was seen mainly because of the adsorption capacity of the substrate pumice and uptake potential ability of the plant. Especially pumice is effective to remove phosphate since it contains sufficient amount of aluminum and iron that favors for the removal of phosphorus (Villara et al., 2012). This study results again shows that the same trend to a study done by Nese and Ennil (2004) that indicates more than 95% nitrate removal efficiency from aqueous solution by adsorption mechanism.

On the other hand Chrysopogon zizanioides has high level of tolerance for high strength wastewater and very effective in removing pollutants from landfill leachates, particularly N and P. Nitrogen and Phosphorus absorption is also expedited because roots have direct exposure to effluents (Xia et al. 2000). Another study report which could support this findings also indicated that, the vetiver system is based on the use of vetiver grass (Chrysopogon zizanioides), which was first recognized early in the 1990s for having “super absorbent” characteristics suitable for the treatment of wastewater and leachate generated from landfill (Truong and Stone 1996).

The efficiency of this constructed wetland in this pilot study to remove most of the hazardous pollutants from tannery wastewater was excellent. The reason may be due to the cumulative effect of the plant’s ability and the substrate potential. The use of plants for wastewater treatment is not a new fashion. But the issue is how to improve pollutant removal efficiency. For example a project was done to examine the phytoremediation potential of water hyacinth (Eichhornia crassipes), water lettuce (Pistia stratiotes) and Vetiver (chrysopogon zizanioides) for the removal of Total dissolved solids from brine solution of textile industry by shallow pond system. The result reported after 10 days of operational period, water hyacinth showed maximum removal of 55.6% on 6th day, 48.7% using water lettuce on 7th day and 39.6% on 3rd day under Vetiver treatment system (Abinaya et al. 2018). Another study also was carried on constructed wetland to treat an aquaculture effluent using four species, Cyperus giganteus Vahl, Typha domingensis Pers., Pontederia cordata L. e Eichhornia crassipes in Brazil, in this study the constructed wetland perform 85.5% removal of total dissolved solid (Travaini and Sipauba 2012).

Chromium removal efficiency of HSSFCW with pumice substrate and planted with Chrysopogon zizanioides

Chromium is a toxic heavy metal which is found in tannery wastewater and causes serious environmental problem. Constructed wetland recently used for the removal of wastewater pollutants including heavy metals like chromium, the result of this investigation presents the chromium removal efficiency of horizontal subsurface flow constructed wetland from tannery wastewater. Based on the finding the concentration of total chromium in the tannery wastewater effluent after 3 and 5 days treatment time was (0.88 ± 0.03 mg/l and 0.30 ± 0.1 mg/l) respectively and this concentration further reduced to 0.20 ± 0.1 mg/l and 0.35 ± 0.13 mg/l after 7 and 9 days retention time respectively (Table 2). The effluent concentration at all retention time was under the standard guideline value of 2 mg/l set by WHO.

The total chromium removal efficiency of this constructed wetland with pumice substrate and Chrysopogon zizanioides was calculated and become 95.20%, 98.36%, 98.91% and 98.09% at 3,5,7 and 9 days retention time respectively (Fig. 6). In previous study it was observed that through increasing contact time, the removal efficiency of chromium in predetermined optimum dose of substrate powder increased significantly from 73.28 to 86.63% (Moradi et al. 2015). In this investigation the chromium adsorption capacity of pumice was analyzed, the result showed that 58.15 mg of total chromium was adsorbed per one kilogram of pumice substrate. This result is similar to the previous research finding on phytoremediation of chromium by model constructed wetland which accounts 97–99.6% at all system of the constructed wetland with different plant species (Catherine et al. 2006).

The mechanism of heavy metals removal in horizontal subsurface constructed wetlands is a combination of different processes mainly physicochemical and biological which includes filtration, sedimentation, straining on the substrate, plant uptake, and precipitation as insoluble forms (Kadlec and Wallace 2009). The most important reaction zone in constructed wetlands is the root zone (rhizosphere) where physicochemical and biological processes take place (Stottmeister et al. 2003). For this reason, this high chromium removal efficiency was achieved because of the metal adsorption potential ability of pumice substrate and the uptake capacity of the plant Chrysopogon zizanioides. Various research works and experiments were done in both laboratory and full scale on the chromium removal efficiency of constructed wetland, for example Dotro et al. (2011) reported that 90–99% of chromium removed from tannery wastewater by subsurface constructed wetland with pea gravel substrate and Typha spp.

Comparison between Pumice (test substrate) and Gravel (Control substrate) on the Tanner wastewater treatment efficiency of HSSFCW Planted with CZ

The treatment efficiency of constructed wetland varied according to the type of substrate, plant type, seasonal variation, climatic change and other factors. Even though the plant type is similar in both two beds (control and study), the result of this investigation also varied between the gravel and pumice substrate (Table 4). In this investigation at the first 3 days HRT only BOD5 and COD were removed by gravel substrate (89.05% and 93.82%) better than pumice substrate (83.36% and 92.34%) but in all other retention time the pumice substrate showed better result than gravel (Table 4; Fig. 7).

The result between the study and control bed was tested using Two-Sample t-Test, the result showed that significantly differ at 95% confidence interval, p-value = 0.01and hence, this substrate can be useful for the treatment of high strength wastewater in horizontal subsurface constructed wetland better than the conventional gravel substrate. Chromium removal efficiency of pumice substrate was better than gravel at all hydraulic time except the first three days that pumice achieved 95.2% while gravel achieved 96.4% (Table 4 and Fig. 8).

The plant biometry and chromium uptake capacity of CZ in Gravel and Pumice substrate beds

The biometry data of the plant Chrysopogon zizanioides was analyzed for both gravel and pumice substrate. The result showed that the growth of the plant at the sixth month above the ground in cm was 58.66 and 113.33 and below the ground was 43.33 and 24.33 in gravel and pumice substrate bed respectively. The plant dry weight also indicate that 77, 130.8 gm above ground and 80, 89 gm below the ground in gravel and pumice substrate respectively (Table 5). The chromium uptake capacity of the plant in both substrate beds was evaluated and revealed that, the plant below the ground uptake more chromium than above the ground that was (8.88, 36.62 mg/kg) and 10.24, 39.72 gm/kg) in gravel and pumice substrate bed respectively (Table 5).

Based on the result found from the biometry data, The Cr bioaccumulation factor (BAF) and Translocation factor (TF) of Chrysopogon Zizaniodes plant species was estimated, (as a method described by Baker et al. (2000) and Shanker et al. (2004)):

Translocation factor of Cr was also calculated as:

Therefore BAF of this plant were above the ground (0.48, 0.56 Lkg−1) and below the ground (1.99, 2.17 Lkg−1) in gravel and pumice substrate beds respectively. Whereas TF were (0.24 and 0.26) in gravel and pumice substrate bed respectively. Plants with more BAF and TF values can remove metals like chromium from the wastewater in the constructed wetland that may be due to the harvesting the areal part of the plant removes chromium from the bed. Plant species with high capacity to translocate chromium from below the ground to above the ground enhances absorption of chromium from the constructed wetland bed (Skiffington, et al., 1976; Perk, 2006). Translocation can reduce again chromium concentration and hence that reduce toxicity potential of the metal ions to the root.

Conclusion

Modjo tannery wastewater characteristics was very high strength wastewater with different hazardous pollutants. The bioaccumulation and translocation factor of Chrysopogon zizanioides were greater in pumice substrate bed than the gravel which means that this plant can remove more chromium in pumice media than gravel one. The tannery wastewater treatment efficiency of pumice substrate was better than gravel substrate.

Horizontal subsurface flow constructed wetland with pumice substrate and Chrysopogon zizanioides plant species has a potential to treat high strength tannery wastewater by different mechanisms including adsorption, filtration, microbial activities and plant uptake. Therefore the use of such kind of constructed wetland with locally-available low-cost substrate and potential plant type may contribute to the low technology solution for sustainable industrial wastewater management in ecofriendly manner.

Availability of data and materials

The dataset and materials used for this manuscript is available and can be shared whenever necessary. Data was generated by the author from the field substrate and plant sample collection, Constructed wetland design, construction and laboratory analysis.

Abbreviations

- APHA:

-

American Public Health Association

- BOD:

-

Biological oxygen demand

- COD:

-

Chemical oxygen demand

- DO:

-

Dissolved oxygen

- EPA:

-

Environmental protection authority

- ES:

-

Effective size

- FAAS:

-

Flame atomic absorption spectrophotometer

- HRT:

-

Hydraulic retention time

- HSSFCW:

-

Horizontal subsurface flow constructed wetland

- TSS:

-

Total suspended solids

- TWW:

-

Tannery wastewater

- UC:

-

Uniformity coefficient

- UNIDO:

-

United Nations Industrial Development Organization

References

Abinaya S, Saraswathi R, Rajamohan S, Mohammed SAM (2018) Phyto-remediation of total dissolved solids (TDS) by Eichhornia Crassipes, Pistia Stratiotes and Chrysopogon Zizanioides from second stage RO-Brine solution. Res J Chem Environ 22(5):36–41

Alemu T, Leta S (2015) Evaluation of selected wetland plants for removal of chromium from tannery wastewater in constructed wetland Ethiopia. Environ Sci Technol 9(5):420–427

Alemu T, Lemma E, Mekonnen A, Leta S (2016) Performance of Pilot Scale Anaerobic-SBR System Integrated with Constructed Wetlands for the Treatment of Tannery Wastewater. Environ Process 3:815–827. https://doi.org/10.1007/s40710-016-0171-1

APHA (2005) Standard Methods for the Examination of Water and Wastewater, 21stedn. American Public health association, Washington

Arasappan S, Kalyanaraman R (2015) Characterization of physicochemical parameters and heavy metal analysis of tannery effluent. Int J Curr Microbiol App Sci 4(9):349–359

Asamudo NU, Daba AS, Ezeronye OU (2005) Bioremediation of textile effluent using Phanerochaete chrysosporium. Afr J Biotechnol 4(13):1548–1553

Babel S, Kurniawan TA (2003) Low-cost adsorbents for heavy metal uptake from contaminated water: a review. J Hazard Mat 97:219–243

Baker ATM, Reeves RD, Smith JAC (2000) Metal Hyper Accumulator Plants. A review of the Ecology and Physiology of Biochemical Resource for Phytoremediation of Contaminated Soil and Water. pp. 85–107

Catherine M, Sylvia C, John W, Elias T (2006) Phytoremediation of chromium by model constructed wetland. Biores Technol 97:1767–1772

Dotro G, Larsen D, Paul P (2011) Preliminary evaluation of biological and physical chemical chromium removal mechanisms in gravel Media used in constructed wetlands. Water Air Soil Pollut 215:507–515

EEPA (Federal Environmental Protection Authority of Ethiopia) (2003) Standards for industrial pollution control in Ethiopia, Part Three: Standards for Industrial effluents. ESIS project US/ETH/99/ 068/ETHIOPIA, EPA/UNIDO, Addis Ababa

Kadlec RH, Knight RL (1996) Treatment Wetlands. Lewis Publishers, Boca Raton, FL

Kadlec RH, Wallace S (2009) Treatment Wetlands, 2nd edn. CRC Press, Boca Raton, Florida, USA, Boca Raton

Kawser AM, Monika D, Monirul IM, Mosammat SA, Shahidul I, Muhammad AA (2011) Physicochemical Properties of Tannery and Textile Effluents and Surface Water of River Buriganga and Karnatoli, Bangladesh. World Appl Sci J 12(2): 152–159, ISSN 1818–4952

Kivaisi AK (2001) The potential for constructed wetlands for wastewater treatment and reuse in developing countries: a review. Ecol Eng 16:1

Leta S, Asefa F, Gunnel D (2003) Characterization of tannery wastewater and assessment of downstream pollution profiles along ModjoRiver in Ethiopia. Ethiopian J Biol Sci 2(2):157–168

Moradi M, Hemati L, Pirsaheb M, Sharafi K (2015) Removal of hexavalent chromium from aqueous solution by powdered scoria-equilibrium isotherms and kinetic studies. World Appl Sci J 33(3):393–400

Nese and Ennil (2004) Nitrate removal from aqueous solution by adsorption onto various materials. J Hazard Mater B112:155–162

Perk MVD (2006) Soil and Water Contamination: From Molecular to Catchments Scale. JK, London

Reddy K (2004): Phosphorus Cycling in Wetlands Associated with Agricultural Water Shades. Nutrient Management in Agricultural Watersheds–A wetland Solution- ‘A symposium conducted at Teargases Research Center, Johnstown Castle, Cowexfored, Ireland. pp 24–25

Shanker AK, Djanaguiraman M, Sudhagar R, Chandrashekar CN, Pathmanabhan G (2004) Plant Sci 166:1035

Sivakumar P, Kanagappan M, Sam MDS (2015) Physicochemical characteristics of untreated effluent from tannery industries in Tamil Nadu: a comparative study. Int J Pharm Bio Sci. 6(1):446–451

Skeffington R, Shwery PA, Peterson PJ (1976) Chromium uptake and transport in barely seedlings (Hordeum vulgare L.). Plantrta (ber) 132:209–214

Stottmeister U, Wiebner A, Kuschk P, Kappelmeyer U, Kastner M, Bederski O, Muller RA, Moormann H (2003) Effects of plants and microorganisms in constructed wetlands for wastewater treatment. Biotechnol Adv 22:93–117

Suthanthararajan R, Ravindranath E, Chits K, Umamaheswari B, Ramesh T, Rajamam S (2004) Membrane application for recovery and reuse of water from treated tannery wastewater. Desalination 164:151–156

Tamal M, Dalia D, Subhasis M, Siddhartha D (2010) Treatment of leather industry wastewater by aerobic biological and Fenton oxidation process. J Hazardous Materials 180:204–211

Tomokin O (2000) A Pilot Study on Municipal Wastewater Treatment Using a Constructed Wetland in Uganda. UNESCO-IHE Dissertation, Serious Information J.Taylor & Francis Engineering, Water and Earth Sciences. www.blakema.nl/series

Travaini LF, Sipauba TLH (2012) Efficiency of a constructed wetland for wastewaters treatment. Acta Limnol Bras 24(3):255–265

Truong P, Stone R (1996) Vetiver grass for landfill rehabilitation: Erosion and leachate control, Report to DNR and Redland Shire Council, Queensland, Australia

UNIDO (2012) Technical assistance project for the upgrading of the Ethiopian leather and leather products industry, Independent Evaluation Report Ethiopia. https://www.unido.org/fileadmin/user/Evaluation/Ethiopia_leather_valuation FINAL_report_131302.pdf. Accessed Sep 2016

Villara MM, Domíngueza ER, Tackb F, Ruiza JM, Moralesa RS, Arteaga LE (2012) Vertical subsurface wetlands for wastewater purification, 20th International Congress of Chemical and Process Engineering CHISA 2012, 25–29 August 2012, Prague, Czech Republic, Procedia Engineering 42: 1960 -1968, Available online at www.sciencedirect.com

Vymazal J. (2010): Constructed wetlands for wastewater treatment: five decades of experience. Environmental Science and Technology, vol. 45.

WHO (1996): Guidelines for drinking water quality, vol 2: Health criteria and other supporting information, WHO, Geneva

Wosnie A, Wondie A (2014) Bahir Dar tannery effluent characterization and its impact on the head of Blue Nile River. Afr J Environ Sci Technol 8(6):312–318

Xia H, Liu S, Ao H (2000) Study on purification and uptake of garbage leachate by vetiver grass. In: Proc. of the 2nd International Conference on Vetiver, Thailand

Acknowledgements

The principal investigator would like to thank Dilla and Addis Ababa University for financial support.

Funding

The first author is grateful to Dilla and Addis Ababa University in supporting for expenditures during laboratory analysis.

Author information

Authors and Affiliations

Contributions

All authors have made an essential intellectual contribution to this study. MBA designed the study, conducted the experiments, Collected, analyzed and interpreted the data and wrote the manuscript. SLA supervised the experiment, provided comments and suggestion for the whole work. MMK supervised and provided pertinent comments and suggestion on the manuscript. All authors read and approved the final manuscript.

Authors' information

Mekonnen Birhanie Aregu is Assistant professor of Environmental health, school of public health, college of health science and medicine, Dilla University. He has given Public health, Environmental health science and technology courses and also contribute in community services and problem solving applied research activities and published several articles in the internationally peer reviewed journals. He is also a senior consultant in environmental health, waste management and emission control.

Seyoum Leta Asfaw (PhD) is an Associate professor of environmental pollution and sanitation stream, Center for environmental sciences, Addis Ababa University. He has given various courses in the stream. He is also supervising and monitoring several PhDs and MSc students in the areas of environmental biotechnology, wastewater treatment and water quality studies, waste to energy (resource recovery and climate change mitigation and adaptation studies), bioremediation, phytoremediation, microbial ecological studies, environmental sanitation. He has published several peer reviewed papers in different international reputable journals. Currently, he is also executive Director for Horn of Africa Regional Environmental Centre and Network (HOARECN).

He has more than 20 years of experience in environmental science and technology studies and management. He had also been a regional program manager for the Bio-resources innovation network for Eastern Africa development. He has also been the principal investigator for a number of research projects such as “Development of innovative technologies for the sustainable treatment of high strength wastewater in East Africa”, a regional research program involving Ethiopia, Kenya, Tanzania and Uganda funded by Sida. He developed an innovative, integrated pilot technology for the treatment of agro-process wastewater, generating biogas, biofertilizer, and clean water at Modjo Tannery, Addis Ababa, Ethiopia.

Professor Mohammed Mazharuddin Khan (PhD) is a professor of Environmental Science at Center for Environmental Sciences, Addis Ababa University. He is the CHARLES DARWIN GOLD MEDAL was conferred on the 27th day of June, 2009 towards the contribution made in the field of Life Science by International society for Ecological communication at Vinoba Bhave university, Hazaribagh, Jharkhand, India. He has given several courses like Botany, Biotechnology, Environmental sciences, Ecology, Microbiology, and Environmental Microbiology at postgraduate and undergraduate level. He is also a founder of different organizations, moreover he is a member of more than eight international professional associations and societies and served in different positions. Professor Khan has published several internationally peer reviewed papers.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Aregu, M.B., Asfaw, S.L. & Khan, M.M. Developing horizontal subsurface flow constructed wetland using pumice and Chrysopogon zizanioides for tannery wastewater treatment. Environ Syst Res 10, 33 (2021). https://doi.org/10.1186/s40068-021-00238-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40068-021-00238-0