Abstract

Chlorpheniramine maleate–paracetamol–caffeine tablet formulation is one of the common over-the-counter drugs used for the treatment of cold and cough. A reversed-phase high-performance liquid-chromatography method has been successfully developed for the simultaneous determination of chlorpheniramine maleate, paracetamol and caffeine in a drug formulation. The RP-HPLC method employed a Phenomenex C18 reversed phase column (Luna 5µ, 250 × 4.6 mm) with an isocratic mixture of methanol and 0.05 M dibasic phosphate buffer pH 4.0 in the ratio of (30:70; v/v) as the mobile phase. The column temperature was kept at 30 °C. The flow rate was 1.0 mL/min and detection was by means of a UV detector at wavelength of 215 nm. All the active components were successfully eluted with mean retention times of 2.4, 4.2, 7.2 min for chlorpheniramine maleate, paracetamol and caffeine respectively. The method was found to be linear (R2 > 0.99), precise (RSD < 2.0 %), accurate (recoveries 97.9–102.8 %), specific, simple, sensitive, rapid and robust. The validated method can be used in routine quality control analysis of fixed dose combination tablets containing chlorpheniramine maleate, paracetamol and caffeine without any interference by excipients.

Similar content being viewed by others

Background

Drug combinations are single preparations containing two or more active pharmaceutical ingredients (APIs) for the purpose of their concurrent administration as a fixed dose mixture combinations drug. Most multi-component drug formulations usually contain two or more active ingredients which are responsible for a combined therapeutic activity of the drug. This concept is beneficial when the selective agents have different mechanisms of action that provide additive or synergistic efficacy (Li et al. 2010). There is increased production of multicomponent drugs formulation due to increased efficacy, increased resistance of microorganisms to single component formulations and dependency and/or tolerance, and this has further led to increased drug counterfeiting and adulteration (Mackey and Liang 2011; Newton et al. 2006).

However, monographs in most official pharmacopoeia are for single component drugs, hence local Pharmaceutical manufacturing companies in the analysis of multi-component drug formulations use methods that involve multiple and repeated extractions to extract each active component before their quantification using spectrophotometry or titrimetry. Such methods are thus laborious and cumbersome. This has led to researchers developing various methods to help facilitate easy and quick analysis of multi-component drugs. With HPLC being a method of choice, many researchers have worked at developing various RP-HPLC methods for the simultaneous estimation of various active components in multi-component drugs (Sawyer and Kumar 2003; Okine et al. 2006; Cesar et al. 2008; Suresh et al. 2010; Tsvetkova et al. 2012; Chandra and Sharma 2013; Malakar et al. 2013, Acheampong et al. 2015).

There are many multi-component tablet formulation available in the market that contain chlorpheniramine maleate (CPM), paracetamol (PARA) and caffeine (CAF) as the only active components or as part of the many active components of the drug. Such drugs are usually used against nausea and motion sickness, common cold, and cough (Sawant and Borkar 2012). For this reason, researchers have worked at developing methods that can be used to simultaneously identify and quantify some or all the active ingredients in tablet formulations. Various analytical techniques have been employed in such methods including voltammetry (Shekappa et al. 2011; Saeed and Reyhaneh-Sadat 2011), fluorimetry (Hossein and Yahya 2011), colorimetry (Shihana et al. 2010), UV-spectrophotometry (Hadad et al. 2007; Ghulam et al. 2011; Khoshayand et al. 2010; Maryam and Mehdi 2005; Kuldeep et al. 2011), quantitative thin-layer chromatography (TLC) (Atul et al. 2008; Misra et al. 2009), high-performance liquid chromatography (HPLC) (Heydari 2008; Prasanna and Reddy 2009; Godse et al. 2009; Franeta et al. 2002; Pattan et al. 2009; Suryan et al. 2011; Viswanath et al. 2011), gas chromatography (GC) (Belal et al. 2009), RP-HPLC (Mukesh et al. 2010; Şenyuva and Özden 2002), and LC–MS–MS (Lou et al. 2010).

In developing countries where the challenge of sub-standard drugs and drug counterfeiting is enormous, there is the need for methods which are accurate, cost effective, easy to use, rapid and require the use of non-sophisticated equipment in order to facilitate easy identification and quantitation of the active components in multi-component formulations. The main objective of this work, therefore, is to develop and validate a new, simple, accurate, linear, precise, specific, robust, sensitive and cost effective RP-HPLC method for simultaneous estimation of chlorpheniramine maleate, paracetamol and caffeine in multi-component tablets.

Results and discussion

Method development and optimization

Mobile phase selection

Preliminary studies with several solvent systems were performed to select the most effective solvent system for the separation of the three APIs. The selection of these solvents as possible mobile phase(s) depended on factors such as cost of solvent(s), polarities of solvent(s) and that of the analyte(s) of interest and the solubility of the analyte(s) (Rasmussen and Ahuja 2007; Skoog et al. 2004). Solvents such as methanol, isopropyl alcohol, chloroform, and some phosphate buffers at various pH values, as well as combinations of these solvents were tried. The mobile phase of methanol and dibasic phosphate buffer was tried in different proportions and different pH values. However, an isocratic mixture of methanol and 0.05 M dibasic phosphate buffer (pH 4.0) in the ratio of (30:70; v/v) was chosen as the mobile phase because it produced the best resolution of peaks, peak symmetry and separation of all components within the least retention times. Mean retention times of 2.4 ± 0.0, 4.2 ± 0.01 and 7.2 ± 0.0 were recorded for chlorpheniramine maleate, paracetamol and caffeine respectively as depicted in Fig. 1.

Stationary phase selection

The polarities of the analytes of interest were taken into consideration when choosing the stationary phase. As the drug molecules are polar or moderately polar, reversed phase stationary phases were tried (Sawyer and Kumar 2003; Chandra and Sharma 2013). A Phenomenex C18 reversed phase column (Luna 5µ, 250 × 4.6 mm) was chosen in order to reduce the time of interaction between the stationary phase and the analytes. This helped to reduce analysis time as there is reduced affinity of the analytes for the stationary phase, and increased interaction of the analytes with the mobile phase (Rasmussen and Ahuja 2007; Skoog et al. 2004).

Chromatographic conditions

The established chromatographic conditions included a mobile phase of methanol: 0.05 M dibasic phosphate buffer (pH 4.0) (30:70; v/v), a C18 (Luna 5µ, 250 × 4.6 mm) stationary phase and a flow rate of 1 mL/min. Wavelength of detection was 215 nm and mode of elution was isocratic. Temperature was kept constant at 30 °C. These conditions gave the best resolution of peaks and separation of components. This is illustrated in Fig. 1. Figure 2 depicts the resolution of the internal standard from all the three APIs.

Method validation

Linearity

Regression analysis of the standard calibration graphs was used to determine the linearity of the developed method. The results obtained showed that the method is linear for the three APIs in the range of 1–50, 1–500 and 1–150 μg/mL for CPM, PARA and CAF respectively with their coefficient of correlation (R2) all approximately equal to 1 (R2 = 1). The results are presented in Table 1.

Accuracy

The results obtained from the determination of accuracy, expressed as percentage recovery, are summarized in Table 2. The mean recovery values of 100.76 ± 2.10 for chlorpheniramine maleate, 98.66 ± 1.72 for paracetamol and 100.13 ± 1.39 for caffeine depicts the accuracy of the method. The method was also accurate in the presence of tablet excipients as shown in Table 3. The mean recoveries and standard deviations at all three levels of determination were very good for all three APIs.

Precision

Precision of the developed method was determined based on inter and intra-day precisions. Results are presented in Table 4. The method was found to be precise since the RSD values for both inter-day and intra-day precision were below 2.0.

Selectivity

Each analyte chromatographic peak was not found to be attributable to more than one component which indicates that the method is selective. There were no interfering peaks from the tablet excipients. Selectivity of the current method was demonstrated by good resolution of the peaks of the three APIs and the internal standard as shown in Fig. 2.

Limit of detection and limit of quantification

LOD and LOQ give a measure of the sensitivity of the developed method and the HPLC equipment (Varian Prostar Corporation, LC-20 AD single pump) used for the method development. The lowest amount of chlorpheniramine maleate, paracetamol and caffeine that could be detected were 1.444 × 10−2, 1.415 × 10−4, 4.694 × 10−5 µg/mL respectively. Also the lowest amount of chlorpheniramine maleate, paracetamol and caffeine that could be quantified were 4.376 × 10−2 µg/mL, 4.289 × 10−4, 1.423 × 10−4 µg/mL respectively. These values are very low and indicate that even very small amount of the analyte(s) can be detected using the developed method and the HPLC equipment under consideration. Hence the method and the equipment are very sensitive. The results are presented in Table 4.

Robustness

Changes in mobile phase pH (±0.2 pH units), methanol composition in mobile phase (±2 %), wavelength (±2 nm), and temperature (±3°) did not adversely affect the developed method, meaning the developed method showed a high level of robustness. There were no significant difference between the results obtained with these changes in chromatographic conditions and those from the original chromatographic conditions.

Specificity

Peak purities higher than 99 % were obtained for all three APIs in the chromatograms of sample solutions depicting that the method was very specific to the three APIs under consideration. There were no interfering peaks on the retention times of the APIs in the presence of excipients. This was very evident in the chromatograms of the tablet sample (Fig. 2).

Selection of internal standard

Having developed and validated the method using external standards, the authors decided to go further to find an appropriate internal standard that could be used for the analysis of the three APIs. Even though external standard method is effective, internal standard method tends to yield the most accurate and precise results (Kupiec 2004). Cyanocobalamin was chosen as the best internal standard as its peak was very well resolved from that of all three APIs with its retention time falling in between those of paracetamol and caffeine. This is illustrated in Fig. 2. Calibration graphs of MPAR against concentration of each API were linear in the concentration ranges of 1–50, 1–500, and 1–150 μg/mL respectively for chlorpheniramine maleate, paracetamol and caffeine respectively. The regression coefficients, R2, were 0.9985, 0.9998 and 0.9988 respectively for CPM, PARA and CAF. Recovery values obtained (98–100 %) showed that the internal standard of cyanocobalamin is an excellent internal standard for determining the concentration of the APIs.

Application

Analysis of marketed formulation

The developed method was used for the simultaneous quantification of the APIs in fixed dose combination tablets. To determine the content of CPM, PARA and CAF in commercial drugs, Coldrid™ tablets were analyzed with the proposed method and the results are presented in Table 5. The content (mg) and percentages of each API in the tablet sample was computed using peak areas and the regression equations from the calibration curves. The mean contents obtained for chlorpheniramine maleate, paracetamol and caffeine in the formulated product were in the acceptable range of 90–110 % of the label amount (BP 2009). The results show that the method is accurate in determining the content of the three active ingredients in fixed dose combination tablets. The mean contents of the three APIs were also computed using the internal standard, cyanocobalamine. The results are presented in Table 6.

Conclusions

An accurate, simple, linear, specific and precise reversed phase HPLC method with UV detection for the simultaneous quantification of chlorpheniramine maleate, paracetamol and caffeine has been developed and validated. A second method employing internal standard was also proposed which is also very effective in determining the quantity of the three APIs in fixed dose combination drugs. The proposed method is rapid and convenient for laboratory quality control analysis of tablet dosage forms containing the three APIs. The brand of tablet containing the three APIs analyzed by the validated method had contents of the three APIs in the acceptable limits of the British Pharmacopoeia, and therefore showed adequate quality.

Methods

Materials and chemical

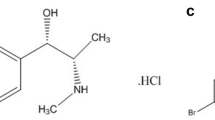

Reference standards of CPM (100.45 %) (Alta Labs Ltd, India), PARA (100.46 %) (Hebei Jiheng (group) Pharmaceutical Co. Ltd, China), and CAF (100.65 %) (AARTI Industries Ltd, India), cyanocobalamin (100.60) were obtained from the Food and Drugs Authority (FDA) in Ghana. Tablet formulation (COLDRID™) containing 4 mg CPM, 500 mg PARA and 30 mg CAF were obtained commercially. HPLC grade methanol (Fluka) was procured from the Chemical Store, KNUST. All chemical reagents were of analytical grade.

Preparation of mobile phase

The mobile phase was a mixture of Phosphate buffer: methanol (70:30 v/v) (pH = 4.0). The mobile phase was prepared by mixing 700 mL of the phosphate buffer with 300 mL of methanol to produce 1 dm3 of mobile phase.

Preparation of buffer solution

A phosphate buffer solution of pH 4.0 and of the buffer strength of 50 mM (0.05 M) was prepared by weighing accurately 0.68 g of potassium dihydrogen phosphate (KH2PO4) and dissolving it in 100 mL redistilled water and adjusting to pH 4.0 with 85 % orthophosphoric Acid (H3PO4).

Preparation of standard solutions

Standard stock solutions of CPM, PARA and CAF were prepared by accurately weighing and dissolving 10 mg of chlorpheniramine maleate, 100 mg of paracetamol and 20 mg of Caffeine, in redistilled water to form a 100 mL of solution containing 100 µg/mL of chlorpheniramine maleate, 1000 µg/mL of paracetamol and 200 µg/mL of caffeine. Standard solutions of concentrations ranging from 2 to 10 µg/mL for chlorpheniramine maleate, 40–200 µg/mL for paracetamol and 4–20 µg/mL for caffeine were prepared from the stock solution for standard curves.

The internal standard solution was prepared by weighing 1 mg of the internal standard (cyanocobalamine) and dissolving in distilled water to form 100 mL of solution, with concentration of 10 µg/mL of cyanocobalamin.

Preparation of sample solution

Twenty (20) tablets of coldrid™ tablets were powdered and 150 mg equivalent of the powdered sample was taken and dissolved in mobile phase to produce 100 mL of solution of concentration 1500 µg/mL.

1.0 mL of the stock solution was pipette into a 100 mL volumetric flask and 12.5 mL of the stock solution of internal standard (cyanocobalamine) added and made up to the mark with distilled water. The final concentration of chlorpheniramine maleate, paracetamol, caffeine and cyanocobalamine were 0.10, 12.50, 0.75 and 1.25 µg/mL respectively in the resultant solution. The resultant solution was then injected into the LC system. Three replicate injections were performed and the average percentage content calculated.

Instrumentation and chromatographic condition

A high performance liquid chromatographic system Varian Prostar 325 (Varian Prostar Corporation, LC-20 AD single pump) with autosampler and Varian Prostar SPD-20A UV/VIS detector was used for analysis. Separation was carried out at 30 °C, using an octadecylsilane (ODS), Phenomenex Luna, C18 (2) 100A, 250 × 4.6 mm, 5µ analytical column.

Internal standard selection

Various compounds that do not react with the three APIs were mixed with standard solutions of the three APIs and ran using the established chromatographic conditions. The compound that produced a peak that was well resolved from those of the APIs was chosen as the internal standard.

Obtaining concentration of APIs using internal standard

Various concentrations of the APIs were injected together with known concentrations of the internal standard and the mean peak area ratios (MPAR) were recorded. Calibration graphs of MPAR against concentration of each API was plotted to relate peak area ratios to concentrations (Kupiec 2004; Okine et al. 2006). The actual concentrations of the APIs were interpolated from the required calibration graphs using the respective MPAR. Similarly, recovery was performed by injecting mixtures containing known concentrations of the three APIs and the internal standard and the MPAR was used to verify the concentrations of the APIs.

Method validation

The method was validated based on International Conference on Harmonization (ICH) guidelines (ICH 2005). Validation parameters included accuracy, linearity, precision, specificity, robustness, limit of detection (LOD) and limit of quantification (LOQ).

Linearity

Standard calibration graphs for the APIs were obtained by plotting peak areas produced by injection of standard solutions against the concentrations used. The calibration graphs were analyzed by regression analysis. The equation, correlation coefficient, slope, and y-intercept were then calculated.

Accuracy

The accuracy of method was determined by studying recovery at three different concentrations for all active pharmaceutical ingredients, by replicate analysis (n = 3). Samples of known concentration (reference standard solutions) were analyzed and the measured values, from the respective peak areas, were compared with the true values.

Precision

Precision of the developed method was determined based on inter and intra-day precisions. The intra-day precision was evaluated by analysing six sample solutions (n = 6) at three concentration levels of 10, 20 and 50 µg/mL for CPM, 10, 50 and 100 µg/mL for PARA and 10, 20 and 50 µg/mL for CAF, and calculating the actual concentrations of these standard solutions. Three replicate injections were performed for each sample within a day and the mean concentrations determined. The inter-day precision was evaluated in three consecutive days (n = 18) using the same concentrations of the APIs as in the intra-day precision. The concentrations of the three APIs were determined and relative standard deviations (RSD) were calculated.

Selectivity

Selectivity of the method was assessed by the peak purity test. Each analyte chromatographic peak must not be found to be attributable to more than one component.

Limit of detection and limit of quantification

The LOD and LOQ of the developed method were determined by progressively injecting low concentrations of the standard solutions using the method developed. The smallest amount of the analyte which produces a measurable response is the LOD (signal-to-noise ratio of 3). The LOQ is the lowest concentration of the analyte which gives a response that be quantified accurately (signal-to-noise ratio of 10).

Robustness

Robustness of the method was assessed by examining changes in different experimental conditions. Six sample solutions were prepared and analyzed using the established conditions and by varying some of the chromatographic conditions. Changes in mobile phase pH (±0.2 pH units), methanol composition in mobile phase (±2 %), wavelength (±2 nm), and temperature (±3°) were made and data obtained. Data obtained was subjected to statistical analysis using analysis of variance (ANOVA test).

Specificity

Specificity of the developed method was evaluated by preparing a solution of the reference standards of the three APIs in the presence of excipients. Five injections of this solution were carried out to observe any interfering peaks.

References

Acheampong A, Addai-Arhin S, Apau J, Gyasi WO (2015) Development and validation of a RP-HPLC method with PDA detection for the simultaneous estimation of acetylsalicylic acid, paracetamol and caffeine in fixed dose combination tablets. Int J Chem Biomol Sci 1(4):211–217

Atul AS, Afsar MS, Sanjay JS (2008) Simultaneous determination of paracetamol and piroxicam in tablets by thin layer chromatography combined with densitometry. Eurasian J Anal Chem 3(2):258–267

Belal T, Awad T, Clark CR (2009) Determination of paracetamol and tramadol hydrochloride in pharmaceutical mixture using HPLC and GC-MS. J Chromatogr Sci 47(10):849–854

British Pharmacopoeia Commission (2009) British pharmacopoeia. British Pharmacopoeia Commission, London

Cesar IC, Nogueira FHA, Pianetti GA (2008) Simultaneous determination of artemether and lumefantrine in fixed dose combination tablets by HPLC with UV detection. J Pharm Biomed Anal 48:951–954

Chandra R, Sharma KD (2013) Quantitative determination of paracetamol and caffeine from formulated tablets by reversed phase-HPLC separation technique. Int J Chromatogr Sci 3(2):31–34

Franeta JT, Agbaba D, Eric S, Pavkov S, Aleksic M, Vladimirov S (2002) HPLC assay of acetylsalicylic acid, paracetamol, caffeine and phenobarbital in tablets. Farmaco 57(9):709–713

Ghulam M, Shujaat AK, Arham S, Arshad M, Muhammad Hassham Hassan BA, Kalsoom F, Nadia SM, Izhar H (2011) Development of a UV-spectrophotometric method for the simultaneous determination of aspirin and paracetamol in tablets. Sci Res Essays 6(2):417–421

Godse VP, Deodhar MN, Bhosale AV, Sonawane RA, Sakpal PS, Borkar DD, Bafana YS (2009) Reverse phase HPLC method for determination of aceclofenac and paracetamol in tablet dosage form. Asian J Res Chem 2(1):37–40

Hadad GM, El-Gindy A, WmM Mahmoud (2007) Development and validation of chemometrics-assisted spectrophotometry and liquid chromatography methods for the simultaneous determination of the active ingredients in two multicomponent mixtures containing chlorpheniramine maleate and phenylpropanolamine hydrochloride. J AOAC Int 90(4):957–970

Heydari R (2008) A new HPLC method for the simultaneous determination of acetaminophen, phenylephrine, dextromethorphan and chlorpheniramine in pharmaceutical formulations. Anal Lett 41:965–976

Hossein T, Yahya H (2011) Spectrofluorometric determination of paracetamol in pharmaceutical formulations. Asian J Biochem Pharm Res 2(1):684–689

International Conference on Harmonization of Technical Requirements for Registration of Pharmaceuticals for Human use (eds) (2005) Validation of analytical procedures: text and methodology. Geneva

Khoshayand MR, Abdollahi H, Ghaffari A, Shariatpanahi M, Farzanegan H (2010) Simultaneous spectrophotometric determination of paracetamol, phenylephrine and chlorpheniramine in pharmaceuticals using chemometric approaches. DARU 18(3):292–297

Kuldeep D, Ritu K, Prachi K, Sunil K, Pratik P (2011) Spectrophotometric simultaneous analysis of paracetamol, propyphenazone and caffeine in tablet dosage forms. Int J Pharm Pharm Sci 3(3):170–174

Kupiec T (2004) Quality-control analytical methods: high-performance liquid chromatography. Int J Pharm Compd 8:223–227

Li S, Zhang BO, Zhang N (2010) Network target for screening synergistic drug combination with application to traditional Chinese medicine. BMC Syst Biol 5(1):1–13

Lou H-G, Yuan H, Ruan Z, Jiang B (2010) Simultaneous determination of paracetamol, pseudoephedrine, dextrophan and chlorpheniramine in human plasma by liquid chromatography–tandem mass spectrometry. J Chromatogr B 878(7):682–688

Mackey TK, Liang BA (2011) The global counterfeit drug trade: patient safety and public health risks. J Pharm Sci 100(11):4571–4579

Malakar P, Deb AR, Adhikary S, Ahmed S, Maloth R (2013) Simultaneous estimation of phenylephrine hydrochloride, paracetamol, caffeine and cetirizine dihydrochloride from tablet dosage form using RP-HPLC. Int J Biol Pharm Res 4:368–376

Maryam K, Mehdi A (2005) Derivative spectrophotometry for simultaneous analysis of chlorpheniramine maleate, phenylepherine hydrochloride, phenylpropanolamine hydrochloride in ternary mixture and pharmaceutical dosage forms. Iran J Pharm Res 4(3):147–153

Misra H, Mehta D, Mehta BK, Soni M, Jain DC (2009) Study of extraction and HPTLC-UV method for estimation of caffeine in marketed tea (Camellia sinensis) granules. Int J Green Pharm 3(1):47–51

Mukesh M, Richa R, Vertika G, Dharmendra K, Amrendra KC, Anand G, Ranjit S (2010) Development and validation of a RP-HPLC method for the determination of chlorpheniramine maleate and phenylephrine in pharmaceutical dosage form. Pharm Glob Int J Compr Pharm 5(5):1–4

Newton PN, Green MD, Fernandez FM, Day NPJ, White NJ (2006) Counterfeit and anti-infective drugs. Lancet Infect Dis 6(9):602–613

Okine NNA, Asare-Nkansah S, Acheampong A (2006) Simultaneous determination of sulphamethoxazole and trimethoprim in co-trimoxazole tablets using RP-LC analysis. J Sci Technol 26(3):66–74

Pattan SR, Jamdar SG, Godge RK, Dighe NS, Daithankar AV, Nirmal SA, Pai MG (2009) RP-HPLC method for simultaneous estimation of paracetamol and etoricoxib from bulk and tablets. J Chem Pharm Res 1(1):329–335

Prasanna RB, Reddy MS (2009) RP-HPLC method for simultaneous estimation of paracetamol and ibuprofen in tablets. Asian J Res Chem 2(1):70–72

Rasmussen H, Ahuja S (eds) (2007) HPLC method development for pharmaceuticals. Academics Press, London

Saeed S, Reyhaneh-Sadat S (2011) voltammetric determination of acetaminophen in the presence of codeine and ascorbic acid at layer-by-layer MWCNT/hydroquinone sulfonic acid-overoxidized polypyrrole modified glassy carbon electrode. Int J Electrochem. doi:10.4061/2011/764294

Sawant S, Borkar N (2012) Review of simultaneous determination of analytes by high performance liquid chromatography (HLPC) in multicomponent cough and cold oral drug products. Int J Pharm Tech Res 3(3):1339–1345

Sawyer M, Kumar V (2003) A rapid high-performance liquid chromatographic method for the simultaneous quantitation of aspirin, salicylic acid, and caffeine in effervescent tablets. J Chromatogr Sci 41(8):393–397

Şenyuva H, Özden T (2002) Simultaneous high-performance liquid chromatographic determination of paracetamol, phenylephrine HCl, and chlorpheniramine maleate in pharmaceutical dosage forms. J Chromatogr Sci 40(2):97–100

Shekappa DL, Rajesh NH, Anita PS, Sharanappa TN (2011) Voltammetric determination of chlorpheniramine maleate based on the enhancement effect of sodium-dodecyl sulfate at carbon paste electrode. Electroanalysis 23(2):347–354

Shihana F, Dissanayake P, Dargan P, Dawson AA (2010) A modified low-cost colorimetric method for paracetamol (acetaminophen) measurement in plasma. Clin Toxicol (Phila) 48(1):42–46

Skoog DA, West DM, Holler JF, Crouch SR (eds) (2004) Fundamentals of analytical chemistry, 8th edn. David Harris, Belmont

Suresh SK, Latif JD, Krishnamurthy B, Prashant B, Vasantharaju SG, Udupa N (2010) Analytical method development and validation for aspirin. Int J Chem Tech Res 2(1):389–399

Suryan AL, Bhusari VK, Rasal KS, Dhaneshwar SR (2011) Simultaneous quantitation and validation of paracetamol, phenylpropanolamine hydrochloride and cetirizine hydrochloride by RP-HPLC in bulk drug and formulation. Int J Pharm Sci Drug Res 3(4):303–308

Tsvetkova B, Pencheva I, Zlatkov A, Peikov P (2012) Simultaneous high-performance liquid chromatography determination of paracetamol and ascorbic acid in tablet dosage forms. Afr J Pharm Pharm 6(17):1332–1336

Viswanath RP, Useni RM, Varaprasad B, Somasekhar P (2011) A novel RP-HPLC method for analysis of paracetamol, pseudoephedrine, caffeine and chlorpheniramine maleate in pharmaceutical dosage forms. J Pharm Res 4(4):1225–1227

Authors’ contributions

AA conceived the study and participated in the design as well as analysis and interpretation of data and the drafting of the manuscript. WOG was involved in the acquisition of data, its analysis and interpretation as well as drafting of the manuscript. JA was involved in analysis of the data and drafting of the manuscript. GD was involved in critically revising the manuscript for important intellectual content. SAA was involved in acquisition of the data as well as its analysis and interpretation. All authors read and approved the final manuscript.

Acknowledgements

The authors will like to acknowledge the leadership role of Professor D. K. Dodoo of the University of Cape Coast in Ghana for his critical assessment of the research findings. We will also like to acknowledge the staff of Ayrtons Drug Pharmaceuticals (Ghana), especially the quality control department for permitting some aspects of the work to be carried out in their laboratory space. We will like to acknowledge, Mr. Stephen Boandoh, MPhil. student in the Department of Chemistry, KNUST, for the role he played in the data acquisition.

Competing interests

We have read and understood SpringerPlus’ policy on declaration of interests. The authors declare that they have no competing interests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Acheampong, A., Gyasi, W.O., Darko, G. et al. Validated RP-HPLC method for simultaneous determination and quantification of chlorpheniramine maleate, paracetamol and caffeine in tablet formulation. SpringerPlus 5, 625 (2016). https://doi.org/10.1186/s40064-016-2241-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40064-016-2241-2