Abstract

Background

Economic benefit has been analyzed for the yield of farming products when designing a farming system, while waste treatment also generates profitable energy products for this system. The economic factor is decisive in decision-making for applying waste treatment solutions for a small-scale farming system. A household farming system in the Mekong Delta generates many kinds of organic wastes, but most of the agricultural waste resources are disposed of into the environment.

Methods

This study approaches an analysis of economic–environmental–energy (EEE) efficiency for waste treatment of an integrated livestock-orchard (LO) system on a household scale in the Mekong Delta. This novel analysis method is based on the energy content of biomass and its cost. The EEE efficiency is optimized to gain objective functions regarding energy yield efficiency, system profit, and CO2 sequestration for the treatment model. The algorithms are built for optimizing these objective functions.

Results

The optimization results show the treatment model of pyrolysis and pelleting gain all the objective functions with high efficiency. The model is efficiently applied for the LO system that generates more than 100 kg of orchard residues and 3000 kg of pig manure. The system with a charcoal oven and pellet machine is capable to gain energy efficiency due to its potential biofuel products, such as biochars and pellet products. A treatment model of composting, pyrolysis, and pelleting gives the best performance of overall EEE efficiency.

Conclusions

This work has proven economic benefits from integrating biogas tank, charcoal oven, and pellet machine in an integrated LO system. The system contributes not only for reducing CO2 emissions but also for supplementing secondary renewable bioenergy, as well as for increasing incomes and thus supporting livelihoods for the local farming households.

Similar content being viewed by others

Introduction

The agricultural sector generates various kinds of biological wastes that have great potential for recycling into useful secondary products as fertilizers or biofuels [1, 2]. Biofuel products from waste have been recognized as an environmentally friendly alternative to coal and fossil fuels [3]. Compared with the characteristics of raw biowaste, biofuel has high bulk density, low moisture content, and high energy content [4]. In addition, they are CO2-neutral and commercially valuable fuels, easy to transport and store [5, 6]. The potential of energy biomass has encouraged research on converting biomass to biofuel products, also attracted by their market values [7]. Jing et al. [8] remarked that economic benefits are the main factor to invest technologies for biofuels.

Analyzing economic benefits is applied for agricultural systems in rural [9,10,11,12,13] and in urban [8, 14, 15]. Not only raw biomass (plant residues) but also intermediate products after treatment (compost and anaerobic digestate) have the potential for energy production [16, 17]. The study of Vadenbo et al. [18] demonstrates the environmental benefits of fecal energy, while also highlights the constraints of technology and economy on the energy potentials of biomass.

Ordinarily, treatment solutions of organic waste are represented by composting and anaerobic digesting that produce products with low energy content. Pyrolysis and pelleting are popular thermochemical processes for generating biofuels [19,20,21]. Pyrolysis decomposes organic materials under non-oxidizing conditions and creates fuels with much energy content [5, 20, 22, 23]. Gas, bio-oil, and biochar are energy products of pyrolysis that can be used to produce energy [19]. In addition, pelleting is another technique of thermochemical conversion. Raw materials for biochar and pellet products are diverse such as rice husks, wood chips, straws, etc. [5, 24, 25], and from secondary products after treatment such as biogas sludge [26] and compost [27]. They are similar to waste sources arising from the livestock-orchard system, so our research prioritizes applying the above two treatment solutions to this system. Besides, the market price of biochar and biomass pellets is many times higher than that of compost [7, 28]. Among biofuels, biomass pellets present many advantages in the great market by the abundant materials with relatively simple processing techniques [5]. Despite the uncertainty of demand and market prices for our case study area and parts of the world, these biofuels would be the primary sources of renewable energy in the context of local perspectives, where people have only seen the role of compost.

An agricultural system with many production components, also known as an integrated farming system [29] such as a livestock-crop system, generates diverse kinds of waste that need multiple treatment solutions [30]. Hai et al. [31, 32] proposed many treatment solutions for biomass from this system, yet overlooks the economic profitability of waste-based energy products. To the best of our knowledge, there is a lack of studies on the energy and economic efficiency of treating organic waste to create energy products for an integrated agricultural system in rural Vietnam. The economic factor is one of the most significant bases to estimate the performance efficiency of a waste treatment system. A small-scale farming household system necessarily takes it into account, especially with the system in the poor countryside areas such as the acidic-soil areas in the Mekong Delta [30]. The lack of research literature calls for further research on the profitability of waste treatment solutions to produce energy in a farming system.

This study aims to build a new approach to the optimal model for waste treatment in terms of EEE efficiency to fulfill the shortcomings of earlier studies. From the point of view of economic benefits, profit determines investment opportunities for a system. It leads this work to focus on waste treatment solutions to create waste-to-energy products for an orchard-livestock (LO) system at a household scale. In this system, organic wastes derived from the orchard and pigsty are used for pyrolysis and pelleting to produce biofuels. Then, input–output data of material and energy flows engaged in each treatment solution are analyzed; thereby, the efficiency of treatment solutions related to energy, profit, and environment is evaluated via multi-objective algorithms.

This study considers some experiments in the field of waste treatment facilities to simulate scenarios for treatment systems, and then applies economic analysis and analysis of material and energy flows that enter these systems. Analysis methods are developed from the work of Chen et al. and Munster et al. [33, 34] to optimize the efficiency of treatment systems. Chen et al. [33] applied energy and economic analysis on integrated treatment technologies for municipal solid waste and sludge. Munster et al. [34] employed a combined method of new cost optimization and a life cycle assessment to optimize costs or greenhouse gas emissions for the domestic waste treatment model.

Since the characteristics of a specific system affect the objectives of optimization assumptions [34], they are different in the treatment models of energy products. Algorithms use the model’s parameters to apply for the objective functions of performance efficiency in the LO system. Generally, our study will design waste treatment solutions for LO systems to optimize their performance efficiency regarding energy yield, profit, and CO2 reduction. Economic analysis is developed from the formulas of Chen et al. [33], which comparing the market price of energy products and their estimated price. The estimated price is calculated by dividing the investment and operating cost by the number of products from the treatment equipment. Energy efficiency is evaluated by the formula of Munster et al. [34] regarding the energy content of inputs and outputs. Finally, mathematical optimization of EEE efficiency is developed for the treatment model of the LO system.

Materials and methods

Case study description

The typical demographic structure of a farming household within an acidic soil area of the Mekong Delta is, on average, from 3 to 4 members or more from 2 generations, or from 5 people or more from 3 generations living together in one household, and there are always at least 2 working laborers in each family. Within a typical farming household there are main components such as homestead and fruit trees orchard, pond, and paddy field/crop field, where the homestead normally includes also the livestock shed. The productive components of a rural farming household in this acidic soil areas are combined types of four components: House–Orchard-Livestock–Pond. Ponds are mainly in the forms of ditches and irrigation canals that cannot be used for aquaculture purpose, because the water is contaminated with acidic components (pH level is lower than 5.0). Livestock are commonly raised in a form of sheds in a local household. The land use for a farming household is commonly above 500 m2, in which orchard land can only grow some kinds of fruit trees such as mango, banana, etc. which are suitable for the acidic soil area under study in Mekong delta [35]. In brief, in the agricultural system of a household there are specific livelihood activities such as orchard cultivation, and livestock (mainly pigs and cows), and the proposed solutions of treating waste for this system would be highly feasible and applicable.

Converting biomass into energy products has not been fully exploited yet for farming households in rural areas, especially in the acidic soils of the Mekong Delta. Because of limited knowledge and skills by rural farmers, biofuels from agricultural waste are often not high interest. Composting and anaerobic digestion are traditional solutions for treating agricultural wastes in these areas. Biogas and compost, the secondary/immediate products after the treatment, are often returned to the system and have limited use in the household. In addition, they have low commercial value. Furthermore, biogas sludge is a potentially valuable renewable resource that is often overlooked. In other words, the various types of wastes derived from the integrated system often cause pressure on treatment solution while they could have potential to be converted into secondary energy products. Livelihood activities of a household in the acid-contaminated soils are constrained to cultivation, animal husbandry, etc. Household income is usually very low, about 100 USD per person a month on average, so it is hard to have any investment in farming activities on a larger scale.

The study was carried out on a typical farming household in acidic soil area in Tien Giang province of the Mekong Delta (latitude of 10°34′45′′ N, and longitude of 106°12′12′′ E). The total area of farming land within the household is 2000 m2 which is used for two activities: raising 10 pigs in a shed and cultivating of a mixed fruit trees in an 1000 m2 orchard. For the household livelihood, breeding of pigs brings the basic income while cultivation in the orchard also gives additional income. The biogas-tank is the only treatment facility here, which is used for treating 20 kg pig manure (including urine) every day. Most of the prunings of fruit trees (twigs, leaves, etc.) are left to be dried naturally, and then used as firewood for cooking.

Methodology for EEE efficiency optimization for waste treatment system

Our research proceeds to identify suitable treatment technologies for a system that generates multiple kinds of organic waste. By applying appropriate treatment solutions, such a typical LO system with diverse types of organic wastes can supply energy containing products, and due to the market value of these products, this will bring additional income for the local household as well. Composting and anaerobic digestion are the “best available” solutions to exploit all potentials for generating bioenergy products. Compost is widely appreciated for its value as organic fertilizer, whereas biofuel products such as biochar or biomass pellet are both biofuels and fertilizers, which can bring additional economic benefits for the farming purposes. Based on such a perspective, a set of potential solutions for treating different types of available wastes needs to be employed for this farming system. In addition to the traditional solutions, pyrolysis and pelleting will be added to this LO system, and they are applied to treat all kinds of biowastes in the system with purpose to produce secondary products with high energy contents, such as biochars and biomass pellets. However, the limitations of the living conditions of the local households somewhat affect the application of expensive waste treatment facilities.

It is hard to find the appropriate parameters and the inputs for the model/system of treatment solutions to apply them to the farming system to regional extents; therefore, the treatment solutions must fix the reference system first [36]. After simulated treatment performances, the system should be modified to support better agricultural practices on the regional scale. The specific parameters for the model/system should meet the demands of local people, for example, the unit cost of the treatment equipment and the quality of the waste resource entering the system. These values need to be optimized under the circumstances of the study area to find out a general model (formulas) for the best treatment practice.

The performance efficiency of treatment model/system is analyzed based on methods of material and energy flows analysis. Input and output flows participating in the treatment models contributes energy and economic benefits to economic and energy efficiency [37]. The ratio of output product and input feedstock for each treatment facility presents the energy efficiency of the treatment [38]. Economic and energy efficiencies of treatment are calculated to balance inflows and outflows, then to solve the energy loss in the system. Besides, the calculation of model efficiency considers all contained energy in the input and output for reducing energy loss and replenishing energy for the system.

The recent studies [34, 39] have applied different analytical methods on economic and energy efficiency for waste treatment. Munster et al. [34] uses energy system analysis for energy efficiency and the OptiWaste tool for economic and environmental efficiency. The efficiencies are related to waste treatment, energy production versus income from recycled material or energy (i.e. heat, electricity, or biofuel). Chen et al. [33] analyzes energy systems on cost, fuel efficiency, CO2 emissions, and other parameters such as initial investment, operating cost, and turnover. Based on methods of EEE efficiency analysis from the mentioned studies, the target parameters for our proposed treatment model are related to the data of inputs (orchard prunings and pig manure) and outputs such as energy yield, profit from energy products, and environmental issues in terms of CO2 emissions.

The efficiency of the treatment model is affected by data of the input and the output, including the energy content (namely, high heating value—HHV), the potential CO2 emissions, and the profit. Three objective functions of the model are developed for optimizing the EEE efficiency of the model. They are represented by the ratio of output energy to input energy (OTI), the ratio of CO2 sequestration to CO2 emission (STE), ratio of market price to predicted price of output unit (MTP) in Table 1. Specific algorithms are applied to quantify the objective functions. They are based on two perspectives, including (1) the household concern about economic profit from the model, (2) considering the treatment system as a production function of Cobb–Douglas [40], which is described by a set of variables for technology, capital stock, labor force, energy consumption, and noise error term. Energy efficiency is based on the energy content of input and output using formula of Munster et al. [34]. Based on the formulas of Chen et al. for calculating common economic values [27], the algorithm in our study develops them to compute the profit of after-treatment products by dividing the products’ market price by their estimated price. The estimated price relates to the expenditures of the treatment facility, operating cost, and the number of the expected output products. The amount of carbon in the secondary products corresponds to the carbon sequestration and is estimated by CO2 equivalent from biomass combustion [36,37,38]. Equation (1) is used for calculating the amount of CO2 gas based on energy in it as follows:

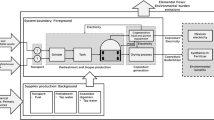

A diagram of the EEE efficiency optimization framework for waste treatment solutions of a LO system is shown in Fig. 1. The multi-objective algorithm is used for the crucial parameters of the EEE efficiency and the initial input [36].

Pre-design of waste treatment techniques for experimental optimization

In this study, the input feedstock for the treatment facilities are pig manure and prunings of mango trees and banana trees (common trees growing in the acidic soils in Mekong delta), and of some unpopular local fruit trees such as longan and jackfruit. The specifications of treatment need to be calibrated for the objective functions as mentioned above. The charcoal oven and the pellet machine are treatment facilities supplemental to the biogas digester (available in the current LO system), so our experiments are conducted at these facilities to Fig. out the ideal factors for objective functions. Slow pyrolysis at low temperatures below 400 ºC [3, 4, 20, 22, 41, 42] is applied for this study to maximize the number of biochars (intermediate product) rather than bio-oil [19, 43]. Our study conducts experiments of pyrolysis by a charcoal oven on the field while this process has been mainly found in the laboratory and demo [19]. The charcoal oven is made of materials, such as recycled metal, or brick, or stainless steel (Fig. 2). This oven can use dried wood, dried orchard prunnings, and biogas as fuel for combustion; and it can load 10 kg of biomass for each operation batch.

According to the recent literature [3, 4, 20, 22, 25, 41, 42] and on-field experiments, three factors are found to influence the effectiveness of pyrolysis, including the moisture content of the prunings, combustion time, and combustion temperature. Pyrolysis of prunings in this LO system shows that biochar from mango prunings reached the highest energy content among that of other tree prunings. The HHV of all kinds of biochar is consistent with the studies of [42, 44]; HHV of biochars from dried leaves of jackfruit and mango is 16 MJ/kg and 18 MJ/kg, respectively. Besides, the HHV of the biomass will increase when biomass is pelleted. Pelleting a mix of biochar with other biomass resources such as fresh manure, biogas sludge, and compost also raises its energy content. The proportion of biochar in these pellet products should account for 10–40%. Therefore, the mango tree prunings would recommend as feedstocks for all the treatment models to compute the predicted objective functions.

Specifications of biomass pellet are based on European and Asian standards in terms of conditions for pelleting such as pressure, particle size, moisture content, material pre-treatment, and consistent equipment [5]. These standards also regulate the pellet values on size, quality, and composition. Pellet is designed as a cylindrical form with a diameter from 6 to 25 mm, and 3 mm to 50 mm in length [20]. This research employs a civil pellet machine, that can load 100 kg biomass per hour, and pellet products from biomass has a diameter of 3 mm, 5 mm, and 8 mm, respectively, with the same length of 3 mm (Fig. 2). Such sizes have little effect on the energy content of the pellet products.

Mathematical optimization for EEE efficiency of treatment models

Mathematical optimization is engaged in the objective functions of waste treatment models regarding EEE efficiency. A set of variables involved in the performance efficiency of the model consists of data of input and output from both biomass and the treatment facilities. Parameters of the objective and input flow are built for each treatment process, and scenario of multiple waste treatment solutions (or waste treatment model) as well. The treatment models connect current existing techniques (biogas digestion and composting) with pyrolysis and pelleting. The parameters of performance efficiency are computed by the mathematical formulas (2 and 3). They are used to compare the models in the discussion part of this article, in which flows of input and output are analyzed separately for each treatment and the combined treatment models. The general equation describes the relationship between the efficiency yα,β (y: OTI, STE, MTP) and the input Rin (IE, PP, ETO) of the energy carrier α and the output Rout (OE, PP, STO) of the energy carrier β. There can be many energy carriers of input and output. This equation is represented as follows:

where conditions of treatment performance optimization are y > 1 and y reaches a maximum value.

The functional objective for product yield is the ratio of energy output to input energy or energy efficiency, wherein the number of output products and input feedstock is based on their HHV when calculating STO. The functional objective for economic benefit is to minimize total costs, in other words, to adjust treatment costs to gain market-competitive pricing for products. Treatment with a low cost for both investment and operation and the higher revenue obtained by output products proves its economic benefit. The estimated price of an output product is calculated simply by dividing the total cost for the period by the number of output products. The functional target for reducing CO2 emissions is based on the carbon content of the input and output biomass. The performance efficiency of a model (E) is the integration of objective parameters, and it is optimized using the expression 3 as.

The algorithms are applied to evaluate the EEE efficiency of the waste treatment model for a LO system. The system boundary covers on an orchard, a pig shed, and a biogas tank. Data of the treatment model are based on either actual information of the current system or calculation. The energy content and carbon content of the biomass in the treatment are shown in Table 2. Mango tree prunings and pig manure are collected every month, and are about 6 kg and 600 kg, respectively. From the total quantity of collected pig manure, about 22 m3 of biogas is generated in the biogas tank within a month. The operating efficiency of biogas tank is 0.036 m3 of biogas per one kilogram of fresh manure, and fresh manure contains 90% of moisture content. The moisture content is reduced by 50% after composting. All fresh manure, biogas sludge, and compost are dried naturally to get the moisture content from 10 to 15% before being used for pyrolysis or pelleting. The efficiency of a charcoal oven yields 35%. The energy content of biochar from orchard prunings is relatively higher than that from compost and biogas sludge, as indicated in the previous studies of [26, 27, 45].

The economic data of the items involving in the treatment are presented in Table 3. They are used to calculate the cost of input parameters and the profit of the output products. The waste treatment of this LO system is considered for calculation in 1 month; it is the time for raw biomass to be converted into compost or to decompose partly in the biogas tank. Thus, the total investment in each treatment facility is equally divided by the lifespan of the facility into the cost for a month. This study chooses the price of the secondary products with the lowest price based on the literature to investigate the potential for the treatment models to bring profit. This profit will be a good source of additional income to support the household's livelihood. The market price of biomass pellets ranges from 90 to 100 USD per ton, which is applied for both biofuel and fertilizer [28]. Biomass pellets are priced from 78 to 120 USD per ton when exported to Asian countries [7]. The international market price of biochar is 2 times higher than compost and 4 times higher than energy products for biomass digested. Besides, the system does not take labor costs into account, because the labor force comes from the family members of the household, and this helps to reduce the predicted price of the output product.

Results and discussion

Scenarios of treatment model

For selecting treatment solutions for the LO system, a large quantity of pig manure can be used as feedstock for most treatment solutions. The quantity of mango tree prunings, however, accounts for 1% of that of pig manure. Thus, the prunings are only used as feedstock for either the charcoal oven or pellet machine. The charcoal oven utilizes biogas from the biogas tank to combust the prunings into biochar; the biochar reduces more CO2 emissions than wood when used as biofuel. With 5 kWh created by one volume of biogas [46], the biogas tank can generate about 110 kWh (400 MJ) in a month, only enough to combust from 10 to 20 kg of mango prunings in a charcoal oven. That causes insufficient biogas to produce electricity for the system.

Due to the advantages of biofuel as mentioned above, biochars and biomass pellets can potentially support income in this LO household system. Thereby, scenarios are developed for treatment models to energy products for the existing LO system. The models show the potentials of utilizing various kinds of biowaste to generate secondary energy products. The scenarios are simulated by models (I) to (XII) and categorized by three groups (Fig. 3), including Group 1: Pyrolysis and pelleting are prioritized for the system as presented in models (I) to (IV); Group 2: All solutions for treating both prunings and pig manure are simulated by the four models from (V) to (VIII); and Group 3: Models from (IX) to (XII) have both pelleting and either composting or anaerobic digestion, and Model (XII) has only pelleting. These proposed models have no treatment of mixing biochar from prunings with other biomass. It is because that the mass of this biochar is 20 times lower than that of other biomass, not enough for the other products.

Estimation of profit for proposed model

The local market has not discovered commercial value for biochar products, but biochar and biomass pellet have high economic value in the international market, as presented in the study of Raviv [7]. Besides, biogas is widely aware of its practical application in a small-scale farming household. Biogas production on a large scale for co-generating electricity to the regional power grid is profitable but requires a large sum of investment capital. Many commercial opportunities for biogas were evaluated by the literature of [7, 28], but they are not feasible for applying to a single household. Therefore, biogas is not considered for its profitability in this study, so biogas is used as combusting fuel for the charcoal oven.

Models (I) are not economically efficient when pig manure is only used for generating biogas for combusting the charcoal oven. In addition, about 10 kg of biochar of prunings BC pr would bring profits. However, to make profits from pelleting this biochar, the system needs more than 100 kg prunings. Thus, the models need over 50 pigs to generate sufficient biogas to combust the quantity of the prunings. Thus, scenario for treating a large volume of prunings are analyzed for the model (XIII) (Fig. 4). Because orchard prunings need to be chopped into small pieces before pelleting and composting, it takes much extra expense for the system. Thus, model (XIII) excludes composting but applies to pelleting biochars from prunings. Besides, this model adds the treatment of mixing biochar from prunings with other biomass. According to Hung [26], biochar from biogas sludge BC bs has lower energy content than other biochars, so the model does not include pyrolyzing biogas sludge.

In terms of profitability MTP, models (II) to (IV) creates pellet products that achieve the profit target. For models (V) to (VIII), economic benefits from compost are higher than the pellet product. Although the amount of manure is halved for treatment solutions in models (V) and (VI), compost and pellet product from the manure give profits. However, only the compost products guarantee profitability in models (VII) to (VIII) when the amount of manure is equally divided for treatment solutions in these models. Models of Group 3 achieve economic benefits from pellet products, whose feedstock is pig manure and compost from pig manure. In this group, both compost and pellet products from prunings are not profitable; thus, only when the quantity of prunings is more than 100 kg, all treatment solutions for prunings obtain economic benefits. Models (II) to (IV) creates pellet products (PL ms, PL bs) that achieve the profit target. For models (V) to (VIII), economic benefits from compost are higher than that from the pellet product. Although the amount of manure is halved for treatment solutions in models (V) and (VI), compost and pellet products from this manure give profits. However, only the compost products guarantee profitability in models (VII) to (VIII) when the amount of manure is equally divided for treatment solutions in these models. Models of Group 3 achieve economic benefits from pellet products, whose feedstock is pig manure and compost from pig manure. In this group, both compost and pellet products from prunings are not profitable; thus, only when the quantity of prunings is more than 100 kg, all treatment solutions for prunings obtain economic benefits. In general, with the same amount of pig manure feedstock for composting, anaerobic digesting, and pelleting, composting achieves the best profit.

It is concluded that two models (III) in group 1 and (VI) in group 3 are highly profitable among models with the same pellet product from biogas sludge. Moreover, profit comes from the pellet product of pig manure by the model (III). The model (VI) has profitable products such as compost from pig manure (CP ms) and pellet product from this compost (PL cpms). Likewise, model (X) without a charcoal oven still gains profits from the same products as the model (VI).

As mentioned, a biomass pellet has a higher HHV content than that of mixing biomass with biochar. Besides, a proportion of biochar in the mixture must be above 10% to increase the HHV of the mixed product. Therefore, model (XIII) is consistent with a volume of prunings higher than 100 kg per month, together with 3000 kg manure to generate sufficient biogas for the charcoal oven. The profits come from all products by this model. Therein, profits from pyrolyzing and pelleting pig manure exceed ten times higher than the investment cost on the treatment.

In case the amount feedstock of biomass for biochar is large enough, as assumed in model (XIII), biochar products are economically viable. MTP of the biochars such as BC pr, BC ms in this model is 4–10 times higher than that in the current system. However, MTP from their pellet products such as PL bcpr, PL bcms lower than 1 indicates ineffective investment. Thus, pelleting biochar will not bring economic benefits due to the high investment cost of a pellet machine to produce pellets of biochar alone.

Energy and environment efficiency

The energy efficiency of the treatment models is evaluated based on the energy contents of biomass. The HHV of pig manure and its secondary products such as biogas sludge and compost range from 11 to 15 MJ, in which biogas sludge has the highest HHV and compost has the lowest HHV. Biochars from these wastes have an increased HHV, except for biochar from biogas sludge [26]. The energy contents of biomass used in our study (Table 2) are lower than those found in the literature. For example, the HHV of pig manure is 19.39 MJ/kg according to Cantrell et al. [45], 16.64 MJ/kg of solid digestate in the study of [26]. Most of the HHV levels are low due to the low carbon content of feeds for pigs. In addition, compared to biochar from compost, biochar from biogas sludge has a higher energy content [27]. The biomass pellet has a higher HHV than raw biomass. Therefore, most of the models with pelleting are efficient in energy yield. It is because the pellet machine creates output products with total energy content higher than the energy of biomass feedstock, except for pelleting compost from pig manure. For pyrolyzing and composting orchard prunings, total energy efficiency on output products is lower than input feedstock. In general, models (III), (VI), (VII), and (VIII) offer higher energy efficiency than the rest models.

Based on the carbon content in biomass, all the biomass give about 0.1 kg CO2 per one megajoule (MJ) of their energy. In other words, the carbon content is positively correlated with the energy content of the biomass in this study. The amount of CO2 captured in both the output product and input biomass depends on the quantities of biomass involved in the treatment. Therefore, the models (III), (VI), (VII), and (VIII) gain CO2 sequestration more than CO2 emission.

Optimization of EEE efficiency

MTP, OTI, and STE of producing biochar products in groups 1 and 2 failed to bring the expected results (< 1), similar to pellet products. It shows that investing in a charcoal oven in the conditions of the existing household is not cost–beneficial. Meanwhile, pellet products from pig waste (PL ms and PL bs) in all groups achieved EEE benefits with MTP, OTI, and STE values > 1 but only ranged from 1 to 2. For group 3, compost from pig manure (CP ms) yielded higher EEE efficiency than all products in the models. Compared with the inefficiencies of the composts from prunings (CP pr), this product has MTP, OTI, and STE of 2–4 times higher. As the investment of a pellet machine mentioned above, a charcoal oven is also unprofitable for small quantities of biomass feedstock to produce biochars.

Among models in group 3, model (X) achieves all EEE efficiency from composting and pelleting pig manure. According to European standards for pellet quality in the literature of [5, 48], the HHV of raw biomass and compost is lower than the standardized HHV level for biofuels. The standard regulates the HHV level of biofuels equal to 16 MJ/kg or more. Thus, the models with a charcoal oven and pellet machine show a high energy efficiency due to their energy products as biochars and pellet products. The results of EEE efficiency analysis for the current LO system show that two models (III) and (VI) give higher overall EEE efficiency than the rest of the models. The EEE efficiency of these models is mainly based on the economic and energy value of the output products and is presented in detail in Fig. 5.

Model (XIII) is applied for a large number of orchard prunings (~ 100 kg). It leads the LO system to get about 3000 kg pig manure to generate enough biogas for pyrolyzing prunings. It proves that all output products from this model are profitable. The model with assumed data of initial discharges makes a good profit of 8–20 times higher than the model with actual data. Besides, for both the hypothetical and current data, the pellet machine in this model yields energy efficiency due to the higher energy content of the output products compared with the energy content of inputs. The analytical results on economic and energy efficiency are presented in Fig. 6. Pyrolyzing is also effective in reducing CO2 emission, where the amount of CO2 gas sequestrated from the output products is higher than CO2 gas exhausted. The charcoal oven, in contrast, is not efficient in both the obtained energy and CO2 reduction. In addition, mixing biochar with biogas sludge in this model is beneficial to both the energy yield and the environment. Therefore, for the LO systems, which discharge a large amount of both orchard prunings and pig manure, the combination of charcoal oven and pellet machine could bring all efficiency to the economy, environment, and energy. With many benefits among the proposed models, model (XIII) is a good choice for LO systems besides models (III) and (VI). However, it is necessary to consider challenges for the system with a large number of orchard prunings. They may include restraints on economic supports and the availability of biomass residues on a regional scale [49].

Optimization of EEE efficiency for waste treatment models in a LO system contributes to CO2 emission reduction and production of secondary biofuels as renewable sources. Analysis of the EEE efficiency is to Fig. out the potential treatment models for this system. The ideal models such as (III) and (VI) would bring additional incomes to enhance the livelihood of the local households. This work has proven economic benefits from integrating biogas tank, charcoal oven, and pellet machine in the same LO system. It shows that pelleting is effective in energy from feedstock such as fresh manure, biogas sludge, and biochar from prunings and pig manure. This treatment makes CO2 gas sequestration rather than CO2 gas exhaust. It also emphasizes the role of treatment solutions to create biofuel products. These products not only bring profitability for a small-scale farming household but also reduce environmental issues. The results indicate that it is possible to optimize EEE efficiency for agricultural waste treatment models through proper analysis and related algorithms.

Conclusions

This work presents the potential of producing biofuel from treating organic wastes of a LO farming system at the household extent. The waste treatment models are designed by supplementing treatment facilities to the LO system to optimize their EEE efficiency. The design focuses on treatment facilities creating biofuel product. The optimal model would achieve objectives related to its performance efficiency in terms of (i) energy yield, (ii) CO2 gas reduction, and (iii) economic benefits. The study also finds that integrating pyrolysis and pelleting maximize the EEE efficiency of the treatment models.

This study prioritizes practical applications for treatment facilities, so it provides a simulation of a set of data of inputs and outputs in treatment models for evaluating their EEE efficiency. Then, we propose an approach of multi-objective optimization by algorithms for the ideal models. Analyzing the EEE efficiency enables solving problems for waste treatment models, especially of economic and environmental issues. The treatment solutions are simple techniques, easy to handle, and free of chemicals. Therefore, similar agricultural systems can apply the results of this study. However, depending on particular conditions of the farming system, they would complete the solutions to support the livelihoods of rural people.

Availability of data and materials

The main data sets on which the results of the manuscript based are presented in the main paper.

Abbreviations

- B:

-

Composting block

- BC bs:

-

Biochar from biogas sludge

- BC cpms:

-

Biochar from compost (from manure slurry)

- BC ms:

-

Biochar from manure slurry

- BC pr:

-

Biochar from prunings

- BC:

-

Biochar

- BG:

-

Biogas

- BS:

-

Biogas sludge

- BS:

-

Biogas sludge

- C:

-

Charcoal oven

- CH4 :

-

Methane gas

- CP ms:

-

Compost from manure slurry

- CP:

-

Compost

- EEE:

-

Economic–environmental–energy

- EL:

-

Electricity

- ETO:

-

Ratio of the weight of exhausted CO2 gas to the output energy

- HHV:

-

High heating value

- IE:

-

Input energy

- LO:

-

Livestock-orchard

- M:

-

Pellet machine

- MP:

-

Market price

- MS:

-

Manure slurry

- MS:

-

Manure slurry

- MTP:

-

Ratio of market price to predicted price of output unit of output unit

- MTP:

-

Ratio of market price to predicted price of output unit

- O:

-

Orchard

- OE:

-

Output energy

- OTI:

-

Ratio of output energy to input energy

- PL bcpr:

-

Pellet from biochar (from prunings)

- PL bs:

-

Pellet from biogas sludge

- PL cpms:

-

Pellet from compost (from manure slurry)

- PL ms:

-

Pellet from manure slurry

- PL:

-

Pellet product

- PP:

-

Predicted price

- PR:

-

Pruning residue

- Pr:

-

Prunings

- S:

-

Pig shed

- STE:

-

Ratio of CO2 sequestration to CO2 emission

- STE:

-

Ratio of CO2 sequestration to CO2 emission

- STO:

-

Ratio of the weight of sequestrated CO2 gas to the output energy

- T:

-

Digestion tank

- U:

-

Unit

References

Bijarchiyan M, Sahebi H, Mirzamohammadi S (2020) A sustainable biomass network design model for bioenergy production by anaerobic digestion technology: using agricultural residues and livestock manure. Energy Sustainabil Soc 10. https://doi.org/10.1186/s13705-020-00252-7

Stupak I, Smith CT, Clarke N (2021) Governing sustainability of bioenergy, biomaterial and bioproduct supply chains from forest and agricultural landscapes. Energy Sustainabil Soc. https://doi.org/10.1186/s13705-021-00288-3

L. et al. (2016) Pelletized carbonized biomass, methods, and apparatuses. US Patent 10,011,799 B2 3 Jul 2018.

García Nieto PJ, García-Gonzalo E, Sánchez Lasheras F, Paredes-Sánchez JP, Riesgo Fernández P (2019) Forecast of the higher heating value in biomass torrefaction by means of machine learning techniques. J Comput Appl Math 357:284–301. https://doi.org/10.1016/j.cam.2019.03.009

Kang K, Qiu L, Sun G, Zhu M, Yang X, Yao Y, Sun R (2019) Codensification technology as a critical strategy for energy recovery from biomass and other resources—a review. Renew Sustain Energy Rev 116:109414. https://doi.org/10.1016/j.rser.2019.109414

Dahmen N, Henrich E, Dinjus E, Weirich F (2012) The bioliq® bioslurry gasification process for the production of biosynfuels, organic chemicals, and energy. Energy Sustainabil Soc. https://doi.org/10.1186/2192-0567-2-3

Raviv O, Broitman D, Ayalon O, Kan I (2018) A regional optimization model for waste-to-energy generation using agricultural vegetative residuals. Waste Manag 73:546–555. https://doi.org/10.1016/j.wasman.2017.10.011

Jing R, Li Y, Wang M, Chachuat B, Lin J, Guo M (2021) Coupling biogeochemical simulation and mathematical optimisation towards eco-industrial energy systems design. Appl Energy 290:116773. https://doi.org/10.1016/j.apenergy.2021.116773

Cortez-Arriola J, Groot JCJ, Rossing WAH, Scholberg JMS, Améndola Massiotti RD, Tittonell P (2016) Alternative options for sustainable intensification of smallholder dairy farms in North-West Michoacán, Mexico. Agric Syst 144:22–32. https://doi.org/10.1016/j.agsy.2016.02.001

Liang Y, Wai Hui C, You F (2018) Multi-objective economic-resource-production optimization of sustainable organic mixed farming systems with nutrient recycling. J Clean Prod 196:304–330. https://doi.org/10.1016/j.jclepro.2018.06.040

Adelhart Toorop R, Ceccarelli V, Bijarniya D, Jat ML, Jat RK, Lopez-Ridaura S, Groot JCJ (2020) Using a positive deviance approach to inform farming systems redesign: a case study from Bihar. India Agric Syst 185:102942. https://doi.org/10.1016/j.agsy.2020.102942

Huong LTT, Takahashi Y, Nomura H, Son CT, Kusudo T, Yabe M (2020) Manure management and pollution levels of contract and non-contract livestock farming in Vietnam. Sci Total Environ 710:136200. https://doi.org/10.1016/j.scitotenv.2019.136200

Song J, Wang Y, Zhang S, Song Y, Xue S, Liu L, Lvy X, Wang X, Yang G (2021) Coupling biochar with anaerobic digestion in a circular economy perspective: a promising way to promote sustainable energy, environment and agriculture development in China. Renew Sustain Energy Rev 144:110973. https://doi.org/10.1016/j.rser.2021.110973

Hosseinalizadeh R, Izadbakhsh H, H. Shakouri G, (2021) A planning model for using municipal solid waste management technologies-considering energy, economic, and environmental impacts in Tehran-Iran. Sustain Cities Soc 65:102566. https://doi.org/10.1016/j.scs.2020.102566

Li L, Li X, Chong C, Wang C-H, Wang X (2020) A decision support framework for the design and operation of sustainable urban farming systems. J Clean Prod 268:121928. https://doi.org/10.1016/j.jclepro.2020.121928

Xu XL, Chen HH, Li Y (2020) Exploring the influencing factors of continuous crop residue supply: from the perspective of a sustainable and bioenergy-oriented crop cultivation. Energy Sustainabil Soc. https://doi.org/10.1186/s13705-020-00267-0

Bautista Angeli JR, Morales A, LeFloc’h T, Lakel A, Andres Y (2018) Anaerobic digestion and integration at urban scale: feedback and comparative case study. Energy Sustainabil Soc. https://doi.org/10.1186/s13705-018-0170-3

Vadenbo C, Tonini D, Burg V, Astrup TF, Thees O, Hellweg S (2018) Environmental optimization of biomass use for energy under alternative future energy scenarios for Switzerland. Biomass Bioenerg 119:462–472. https://doi.org/10.1016/j.biombioe.2018.10.001

Ivona Sigurnjak RVP, Vaneeckhaute C, Michels E, Meers E (2020) Biorefinery of inorganics: recovering mineral nutrients from biomass and organic waste, 1st edn. Wiley, New York

Stelte W, Sanadi AR, Shang L, Holm JK, Ahrenfeldt J, Henriksen UB (2012) Recent developments in biomass pelletization—a review. BioResources 7:4451–4490. https://doi.org/10.15376/biores.7.3.4451-4490

Virmond E, Rocha JD, Moreira RFPM, José HJ (2013) Valorization of agroindustrial solid residues and residues from biofuel production chains by thermochemical conversion: a review, citing Brazil as a case study. Braz J Chem Eng 30:197–229. https://doi.org/10.1590/S0104-66322013000200001

Iwaszko J, Zajemska M, Zawada A, Szwaja S, Poskart A (2020) Vitrification of environmentally harmful by-products from biomass torrefaction process. J Clean Prod 249:119427. https://doi.org/10.1016/j.jclepro.2019.119427

Pehlivan E, Ozbay N, Yargic AS, Sahin RZ (2017) Production and characterization of chars from cherry pulp via pyrolysis. J Environ Manage 203:1017–1025. https://doi.org/10.1016/j.jenvman.2017.05.002

Pradhan P, Mahajani SM, Arora A (2018) Production and utilization of fuel pellets from biomass: a review. Fuel Process Technol 181:215–232. https://doi.org/10.1016/j.fuproc.2018.09.021

Ganzevles J, Asveld L, Osseweijer P (2015) Extending bioenergy towards smart biomass use Issues of social acceptance at Park Cuijk, The Netherlands. Energy Sustainabil Soc. https://doi.org/10.1186/s13705-015-0053-9

Hung CY, Tsai WT, Chen JW, Lin YQ, Chang YM (2017) Characterization of biochar prepared from biogas digestate. Waste Manag 66:53–60. https://doi.org/10.1016/j.wasman.2017.04.034

Meng J, Wang L, Liu X, Wu J, Brookes PC, Xu J (2013) Physicochemical properties of biochar produced from aerobically composted swine manure and its potential use as an environmental amendment. Bioresour Technol 142:641–646. https://doi.org/10.1016/j.biortech.2013.05.086

DiPasquale J (2020) Opportunities and barriers for arizona to supply wood fiber to south korean renewable energy markets. Dissertation, Northern Arizona University

Le TH, Tran VT, Le QV, Nguyen TPT, Schnitzer H, Braunegg G (2016) An integrated ecosystem incorporating renewable energy leading to pollution reduction for sustainable development of craft villages in rural area: a case study at sedge mats village in Mekong Delta. Energy Sustainability and Society, Vietnam, p 6. https://doi.org/10.1186/s13705-016-0088-6

Thao NTT, Van Tung T, Thao NTP, Le Thanh S, Braunegg S, Braunegg G, Schnitzer H, Hai LT (2020) Energy efficiency in an integrated agro-ecosystem within an acidic soil area of the Mekong Delta, Vietnam. Energy Sustainabil Soc. https://doi.org/10.1186/s13705-020-00265-2

Hai LT, Schnitzer H, van Thanh T, Thao NTP, Braunegg G (2016) An integrated eco-model of agriculture and small-scale industry in craft villages toward cleaner production and sustainable development in rural areas – A case study from Mekong delta of Viet Nam. J Clean Prod 137:274–282. https://doi.org/10.1016/j.jclepro.2016.06.146

Hai LT, Tran QB, Tra VT, Nguyen TPT, Le TN, Schnitzer H, Braunegg G, Le S, Hoang CT, Nguyen XC, Nguyen V-H, Peng W, Kim SY, Lam SS, Le QV (2020) Integrated farming system producing zero emissions and sustainable livelihood for small-scale cattle farms: case study in the Mekong Delta, Vietnam. Environ Pollut 265:114853. https://doi.org/10.1016/j.envpol.2020.114853

Chen G, Wang X, Li J, Yan B, Wang Y, Wu X, Velichkova R, Cheng Z, Ma W (2019) Environmental, energy, and economic analysis of integrated treatment of municipal solid waste and sewage sludge: a case study in China. Sci Total Environ 647:1433–1443. https://doi.org/10.1016/j.scitotenv.2018.08.104

Munster M, Ravn H, Hedegaard K, Juul N, Ljunggren Soderman M (2015) Economic and environmental optimization of waste treatment. Waste Manag 38:486–495. https://doi.org/10.1016/j.wasman.2014.12.005

Okubo S, Takeuchi K, Chakranon B, Jongskul A (2003) Land characteristics and plant resources in relation to agricultural land-use planning in a humid tropical strand plain, southeastern Thailand. Landsc Urban Plan 65:133–148. https://doi.org/10.1016/s0169-2046(03)00011-2

Tatsumi K (2016) Effects of automatic multi-objective optimization of crop models on corn yield reproducibility in the U.S.A. Ecol Model 322:124–137. https://doi.org/10.1016/j.ecolmodel.2015.11.006

Kriechbaum L, Scheiber G, Kienberger T (2018) Grid-based multi-energy systems—modelling, assessment, open source modelling frameworks and challenges. Energy Sustainabil Soc. https://doi.org/10.1186/s13705-018-0176-x

Guo B, Yang X, Jin X, Zhou Y (2015) Eco-exergy-based ecological flow accounting of cropland ecosystem and utilisation efficiencies in China. Int J Energy. https://doi.org/10.1504/ijex.2015.069319

Tran TV, Schnitzer H, Braunegg G, Le HT (2017) Development of an optimization mathematical model by applying an integrated environmental indicator for selecting alternatives in cleaner production programs. J Clean Prod 154:295–308. https://doi.org/10.1016/j.jclepro.2017.04.009

Oryani B, Koo Y, Rezania S, Shafiee A (2021) Investigating the asymmetric impact of energy consumption on reshaping future energy policy and economic growth in Iran using extended Cobb-Douglas production function. Energy 216:119187. https://doi.org/10.1016/j.energy.2020.119187

Paolucco (2011) Apparatus for biomass torrefaction, manufacturing a storable fuel from biomass and producing offsets for the combustion products of fossil fuels. US Patent 2012/0093701 A1 19 Apr 2012

Vyavahare G, Jadhav P, Jadhav J, Patil R, Aware C, Patil D, Gophane A, Yang Y-H, Gurav R (2019) Strategies for crystal violet dye sorption on biochar derived from mango leaves and evaluation of residual dye toxicity. J Clean Prod 207:296–305. https://doi.org/10.1016/j.jclepro.2018.09.193

Nomanbhay S, Salman B, Hussain R, Ong MY (2017) Microwave pyrolysis of lignocellulosic biomass––a contribution to power Africa. Energy Sustainabil Soc. https://doi.org/10.1186/s13705-017-0126-z

Gupta A, Thengane SK, Mahajani S (2018) CO2 gasification of char from lignocellulosic garden waste: experimental and kinetic study. Bioresour Technol 263:180–191. https://doi.org/10.1016/j.biortech.2018.04.097

Cantrell KB, Hunt PG, Uchimiya M, Novak JM, Ro KS (2012) Impact of pyrolysis temperature and manure source on physicochemical characteristics of biochar. Bioresour Technol 107:419–428. https://doi.org/10.1016/j.biortech.2011.11.084

Chinnici G, Selvaggi R, D’Amico M, Pecorino B (2018) Assessment of the potential energy supply and biomethane from the anaerobic digestion of agro-food feedstocks in Sicily. Renew Sustain Energy Rev 82:6–13. https://doi.org/10.1016/j.rser.2017.09.018

Kalambe S, Sapkal RS, Sapkal VS (2012) Low pressure separation technique of biogas low pressure separation technique of biogas into CH4 and CO2 employing PDMS membrane. Int J Adv Eng Technol III:311–315. https://citeseerx.ist.psu.edu/

García-Maraver A, Popov V, Zamorano M (2011) A review of European standards for pellet quality. Renewable Energy 36:3537–3540. https://doi.org/10.1016/j.renene.2011.05.013

Lee M, Lin Y-L, Chiueh P-T, Den W (2020) Environmental and energy assessment of biomass residues to biochar as fuel: a brief review with recommendations for future bioenergy systems. J Clean Prod 251:119714. https://doi.org/10.1016/j.jclepro.2019.119714

Acknowledgements

The research is funded by the Vietnam National University–Ho Chi Minh City (VNU–HCM) under Grant Number NCM 2020-24-01. The authors would like to thank to the Department of Natural Resources and Environment (DONRE) in TienGiang province for assistance during site investigation and system demonstration, and the ASEAN-European Academic University network (ASEA-UNINET) for collaboration with IPPE, TU Graz, and Stadtlabor Graz, Austria, to implement this study. Special thanks to Mr. Mark Looney (Environmental Source Samplers, Inc., Wilmington, NC, mark@essknowsair.com) for your elaborative language editing on our manuscript.

Author informations

Le Thanh Hai, Mr., Dr., is a full professor and Director of the Institute for Environment and Resources (IER), VNU-HCM, VN. Nguyen Thi Thu Thao, Ms, is a PhD candidate (under supervision of Prof. LTH), and a lecturer in the Faculty of Chemical and Food Technology, University of Technology and Education, HCM City, VN. Nguyen Thi Phuong Thao (Ms), Tran Thi Hieu (Ms), Le Quoc Vi (Mr), are senior researchers at the Department of Environmental Management, Institute for Environment and Resources (IER), VNU-HCM, VN. Son Le Thanh, Mr., MSc, is a lecturer at the Faculty of Environment, University of Natural Resources and Environment (HCMUNRE), Ho Chi Minh City, VN. Hans Schnitzer, Mr., Dr., is a retired professor at the Institute for Process and Particle Engineering, Graz University of Technology, Austria. Sibylle Braunegg, Mrs., is a senior manager in the StadtLabor Graz, a private research institution in Graz, Austria. Gerhart Braunegg, Mr., Dr., is a retired professor at the Institute of Biotechnology and Biochemical Engineering, Graz University of Technology, Austria, and lead researcher of ARENA, a private research institution.

Funding

The research is funded by the Vietnam National University—Ho Chi Minh City (VNU-HCM) under Grant Number NCM 2020-24-01.

Author information

Authors and Affiliations

Contributions

NTTT initiated the research idea and developed the system under supervision of LTH, and LTH also designed and organized the whole research of this study. NTTT and SLT had a lead role in the literature review and the setup of system. NTTT, LQV, NTPT and a group of coworkers at IER were the site engineers who brought the system into application in a household farm at Tien Giang province, VN. NTPT, TTH were responsible for the communication with the other partner during the site survey and data acquisition. HS, SB and GB contributed in the research idea development, especially about the energy calculation and zero emission application for the system, and they also checked English in the final step. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Thao, N.T.T., Hieu, T.T., Thao, N.T.P. et al. An economic–environmental–energy efficiency analysis for optimizing organic waste treatment of a livestock-orchard system: a case in the Mekong Delta, Vietnam. Energ Sustain Soc 12, 25 (2022). https://doi.org/10.1186/s13705-022-00347-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13705-022-00347-3