Abstract

Cell therapy has emerged as a viable approach for treating damaged organs or tissues, particularly with advancements in stem cell research and regenerative medicine. The innovative technique of cell sheet engineering offers the potential to create a cell-dense lamellar structure that preserves the extracellular matrix (ECM) secreted by cells, along with the cell-matrix and intercellular junctions formed during in vitro cultivation. In recent years, significant progress has been made in developing cell sheet engineering technology. A variety of novel materials and methods were utilized for enzyme-free cell detachment during the cell sheet formation process. The complexity of cell sheet structures increased to meet advanced usage demands. This review aims to provide an overview of the preparation methods and types of cell sheets, thereby enhancing the understanding of this rapidly evolving technology and offering a fresh perspective on the development and future application of cell sheet engineering.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

Cell therapy, a clinical approach with promising potential for treating previously untreatable diseases through the transplantation of living cells, has a long history spanning hundreds of years and has undergone extensive experimentation [1]. With advancements in stem cell research and regenerative medicine, cell therapy has emerged as a viable treatment option and has progressed to clinical trials [2]. Concurrently, researchers have been diligently exploring optimal cell delivery methods for the successful implementation of cell therapy. Cell suspension injection is a commonly utilized cellular transplantation method due to its convenience in facilitating tissue regeneration and functional rehabilitation by injecting a single-cell suspension into the affected area [3]. However, this method may not be suitable for repairing osseous and cartilaginous tissues, as these tissues require the reconstruction of a three-dimensional structure with specific strength [4].

Intercellular interactions and the extracellular matrix (ECM) play crucial roles in the repair of tissue structure and restoration of function. Cell morphology, viability, and function may be compromised when cells are in suspension, leading to uncontrolled localization and non-homogeneous distribution, which can result in the risks of ectopic implantation and inefficacy [5]. These challenges have prompted the advancement of scaffold-free tissue engineering for cell delivery [6], with cell sheet engineering emerging as a promising technique to address these issues [7].

Cell sheet engineering is a scaffold-free tissue engineering technique that enables the formation of cell-dense tissues without the use of enzymes [8]. The assembly of cells into sheet-like structures facilitates the delivery of a large number of cells to targeted areas. Advancements in material science since the 1990s have spurred rapid development in this field. Temperature-responsive materials, photoresponsive materials, magnetic nanomaterials, and other innovative substances have been utilized to achieve enzyme-free cell detachment, resulting in various methods for cell sheet preparation. Additionally, to meet the needs of applications ranging from cell repopulation to functional recovery, different types of cell sheets have been developed, from simple monolayers to complex three-dimensional structures with multiple layers.

To address a variety of applications such as cell repopulation and functional recovery, various types of cell sheets have been developed, ranging from simple monolayers to complex three-dimensional structures with multiple layers. This study aims to consolidate the fabrication methods and classifications of cell sheets by conducting a comprehensive review of recent relevant literature. By doing so, it seeks to provide an overview of the preparation techniques and types of cell sheets, thereby enhancing understanding of this rapidly evolving technology and offering a novel perspective on its advancement and future applications (Table 1).

The fabrication methods of cell sheet

The “sheet-like cell assembly” obtained through cell sheet engineering is an integrated structure that deposits ECM, allowing it to connect directly to the transplant site. Furthermore, essential substances for functional tissue regeneration, such as key membrane proteins (e.g., ion channels and growth factor receptors) and intercellular and ECM connections, are preserved and remain intact due to the use of dispase.

The preparation of cell sheets requires a delicate balance between cell attachment and detachment on the culture surface. With advancements in material science, materials with high biocompatibility and controllable cell adhesion properties have been synthesized and applied to cell sheet formation. Stimuli used for cell sheet release include temperature [9], electrochemical factors [10], mechanical force [11], magnetic force [12], and light [13], among others. Currently, the main methods for cell sheet preparation include: thermally-triggered fabrication using thermo-responsive polymeric surfaces; magnetic force-based fabrication employing magnetite nanoparticles (MNPs) and magnetic force; electrochemical polarization methods with electronic control coatings; pH-controlled fabrication; light-induced fabrication using light-responsive polymeric surfaces; ion concentration-related fabrication; and physical scraping techniques. This summary highlights several strategies for cell sheet fabrication and provides an overview of the technical principles behind each method (Figs. 1, 2, 3, 4 and 5).

Thermally-triggered cell-sheet fabrication

Okano et al. [14] reported their research on preparing a petri dish coated with poly(N-isopropylacrylamide) (PIPAAm) in 1990. They harvested bovine hepatocytes cultured on polystyrene dishes whose surfaces were grafted with PIPAAm by reducing the temperature. They demonstrated the possibility of switching between cell attachment and detachment using thermo-responsive polymer grafted surfaces by altering the culture temperature. In this technique, N-isopropylacrylamide monomers are polymerized simultaneously, and cross-linked polymer chains are uniformly grafted onto polystyrene or amino glass substrates under electron beam (EB) irradiation [15]. The nanometer-thick PIPAAm layer grafted on the petri dish is relatively hydrophobic and thus demonstrates a collapsed, compact conformation under suitable culture conditions at 37°C, facilitating cell attachment and proliferation. As the culture temperature drops to the lower critical solution temperature (LCST, 32°C) or lower, the PIPAAm surface becomes hydrophilic and transforms into a fully expanded chain conformation, resulting in spontaneous cell detachment and enabling the harvest of the “sheet-like cell assembly [16] (Fig. 1A).

Although the PIPAAm surface-based thermo-responsive culture system is the earliest developed and most widely used method for cell sheet fabrication in cell sheet engineering, it faces challenges such as the high cost of EB irradiation or gamma (γ) ray irradiationequipment [17] and the technical difficulty of nanometer-thick layer surface plating. Moreover, the only commercialized product, ‘Thermo Scientific™ Nunc™ UpCell™ Dishes,’ is expensive. These limitations make it impractical for widespread use in average laboratories, leading to numerous studies focused on improving temperature-induced cell sheet fabrication. In 2014, an optimized, simple method for preparing temperature-responsive cell culture surfaces was reported [18]. Researchers applied PIPAAm monomer dissolved in water onto polystyrene (PS) dishes pretreated with thiosalicylic acid, followed by visible light irradiation at a wavelength of 405 nm using a high-pressure mercury lamp or commercially available light-emitting diode light. PIPAAm was successfully grafted onto the PS dishes with the thioxanethone-based photoinitiator. This method enabled the successful fabrication of cell sheets by lowering the temperature to 20 °C, demonstrating a solvent-free, cost-effective surface modification method with potential for cell sheet fabrication and tissue engineering applications (Fig. 1A). Four years later, Yoshikatsu et al. [19] introduced a method to control cell adhesion and detachment through dual stimulation of temperature and mechanical stress. They developed stretchable temperature-responsive cell culture surfaces composed of poly(N-isopropylacrylamide) (PIPAAm) gel-grafted polydimethylsiloxane (PIPAAm-PDMS). This surface exhibited a reversible hydrophilic/hydrophobic change due to the phase transition of PIPAAm chains as the temperature dynamically changed by crossing the LCST. On the other hand, the thickness of the PIPAAm layer affects the adhesion and detachment properties of the cells [15]. In thicker PIPAAm layers, the outermost PIPAAm chains remain hydrated, preventing cell adhesion. Conversely, in thinner PIPAAm layers, the polymer chains near the base substrate can become well dehydrated, but they often fail to show significant temperature-induced transitions, leading to inadequate cell detachment [20]. When PIPAAm-PDMS was subjected to uniaxial stretching, the grafted nanoscale-thick surface became thinner, deformed, and modulated to a more hydrophobic phase, resulting in increased cell adhesion compared to unstretched PIPAAm-PDMS at 37 °C. Consequently, dual stimulation of lowering the temperature and shrinking the stretched PIPAAm-PDMS accelerated cell sheet detachment and harvesting more effectively than single stimulation. Additionally, these new culture surfaces can integrate various stimuli and adjust surface properties to accommodate different cell adhesiveness, meeting the requirements for fabricating various cell sheets (Fig. 1A).

So far, PIPAAm surface-based dishes have become a powerful technology in cell sheet-based tissue engineering. These dishes have been applied to various types of cells, including corneal epithelial cells, retinal pigment epithelial cells (RPE), and oral mucosal epithelial cells (OMECs), among others. However, harvesting and transferring cell sheets fabricated with this material often takes more than 30 min, and prolonged exposure to lower temperatures may potentially deteriorate cellular vitality and affect cellular function [22]. In addition to PIPAAm, several other thermoresponsive materials have been synthesized and developed for relatively nondestructive cell sheet fabrication. These include PNIPAAm, glycidyl methacrylate (GMA)-based thermoresponsive copolymers such as N-isopropylacrylamide-co-glycidyl methacrylate (NGMA) [23], and thermoresponsive nanofabricated substratum (TNFS) [24]. Weinhart et al. presented two glycerol copolymer-based linear thermoresponsive surfaces [25], which exhibited phase transitions after forming self-assembled monolayers (SAM) on gold surfaces and supported reversible cell adhesion and detachment within the physiological range [26]. These switchable, biocompatible copolymer SAM surfaces sustain protein adsorption, leading to cell adhesion and spreading under standard cell culture conditions at 37 °C. Conversely, decreasing the temperature causes the thermoresponsive polymers to become hydrated and repel proteins. Lowering the temperature to ambient allows adherent cells to detach from the functionalized surfaces within 20 min without the need for detachment agents like trypsin/EDTA. Some researchers have attempted to synthesize cell-interactive thermosensitive hydrogels from tyramine-modified Tetronic [27]. During the crosslinking reaction, bioactive molecules can be easily incorporated into the hydrogel, which forms rapidly using HRP/H2O2 as catalysts [28]. The cell-interactive properties of these hydrogels can be readily tuned by adding peptides, such as cell adhesive peptide (RGD), or proteins, such as angiogenic growth factor (bFGF) [29]. Under standard culture conditions at 37 °C, cells can attach to Tetronic-based thermosensitive hydrogels, which are conjugated with bioactive molecules and cultured to form a confluent cell assembly. When the temperature is lowered to 4 °C, the hydrogels expand, disrupting the binding between integrin receptors on the cell membrane and the peptide ligands presented by the hydrogel. Consequently, the cell layer can be easily harvested and transferred to any substrate due to the intact cell-cell junctions [30] (Fig. 1B).

Schematic diagram of PIPAAm-based thermally triggered cell sheet fabrication and Schematic diagram of other thermally triggered cell sheet fabrication methods. A) and B) in Panel A illustrate the PIPAAm-based fabrication process: (a), (b), (c), and (e) represent four methods for preparing PIPAAm-based thermosensitive petri dishes; (d) and (f) depict the processes of cell adhesion and cell sheet detachment. A) in panel B: (a) shows the method for preparing glycerol copolymer-based thermosensitive surfaces, and (b) illustrates the process of cell adhesion and cell sheet detachment. B) in Panel B: (a) shows the method for preparing tyramine-modified Tetronic thermosensitive hydrogels, and (b) depicts the process of cell adhesion and cell sheet detachment. B) in Panel B is reproduced from reference [21] with permission

In summary, thermosensitive materials used for cell sheet fabrication must possess excellent biocompatibility and temperature response characteristics, support the formation of cellular assemblies, and allow phase transitions under biologically non-toxic conditions.

Magnetic force-based cell-sheet fabrication

Since the successful preparation of cell sheets on PIPAAm surface-based culture dishes, the field has rapidly developed, with several new thermosensitive materials synthesized to optimize cell sheet fabrication. However, this method often requires a long time to harvest cell sheets and struggles with the assembly and layering of heterotypic cells, limiting its effectiveness for organizing complex tissues such as tubular constructs. The detailed and precise construction of cellular structures is also challenging to achieve. In response to these limitations, magnetic force-based tissue fabrication methods have emerged. In this approach, MNPs, primarily iron oxide nanoparticles, are incorporated into target cells to enable their attraction by a magnet placed beneath the culture plates. Magnets positioned on the underside of the culture plates provide the magnetic force necessary for this process. Cells can then be assembled and harvested as a sheet through the application and removal of magnetic force (Fig. 2).

Ito et al. first presented their magnetic force-based cell sheet fabrication method in 2004 [31]. This technique utilized magnetite cationic liposomes (MCLs) containing magnetic nanoparticles (MNPs) that could label biomolecules or living cells, demonstrating sufficient safety for widespread application in biological and medical contexts [36]. Specifically, they prepared MCLs using colloidal magnetite (Fe₃O₄; average particle size, 10 nm) and a lipid mixture of N-(α-trimethylammonioacetyl)-didodecyl-D-glutamate chloride. They then magnetically labeled and co-cultured human aortic endothelial cells (HAECs), pre-cultured primary rat hepatocytes [31], and human keratinocytes in Petri dishes. With the magnetic force provided by a magnet placed on the underside of the culture plates, cells were able to adhere under conditions where attachment would generally be difficult [31]. Multilayered keratinocyte sheets could be detached from the bottom of the plates after removing the magnet and then harvested using the magnet [32]. Following this, they extended the technique to create a multilayered heterotypic cell sheet containing HepG2 and mouse fibroblasts NIH3T3 cells in 2007 [33].

Magnetic force-based cell sheet fabrication enables the construction of multilayered structures; however, it does not guarantee adequate nutrient transport and cellular activity in deeper tissues [34]. Ana et al. [35] addressed this limitation by proposing a stratified magnetic-responsive heterotypic cell sheet construction, which involved internalizing iron oxide nanoparticles within cells. They successfully constructed thick bone-like structures composed of heterotypic cell sheets, demonstrating effective osteogenesis due to the synergistic effects of human umbilical vein endothelial cells (HUVECs) and adipose-derived stromal cells (ASCs). The increased activity of Alkaline phosphatase (ALP), matrix mineralization, and elevated levels of osteopontin and osteocalcin further supported the success of the osteogenesis [35]. The inclusion of HUVECs facilitated the pre-vascularization of the entire cell assembly, leading to the formation of thicker tissue that more closely resembles the body’s natural environment.

MNPs are critical in magnetic force-based cell sheet fabrication, involving the internalization of MNPs during cell magnetization labeling pretreatment. However, the direct and long-term interaction of MNPs with cells remains a significant concern due to potential adverse effects on cell viability, phenotype, and function [37]. The biocompatibility and potential cytotoxicity of MNPs are therefore crucial considerations [38]. To evaluate the biocompatibility of MNPs, Tomitaka et al. [39] characterized uncoated and oleic-acid-coated Fe3O4 and NiFe2O4 MNPs and assessed their cytotoxicity using human cervical carcinoma cells (HeLa). They found that NiFe2O4 nanoparticles significantly reduced the number of HeLa cells in a dose-dependent manner, while Fe3O4 MNPs did not exhibit a significant dose-dependent decrease in HeLa cell numbers. This result aligns with findings indicating low cytotoxicity for Fe3O4 nanoparticles coated with biocompatible substances [40, 41]. Although iron oxide nanoparticles have been widely used in tissue engineering due to their relative safety, the long-term effects of these exogenous particles on cell phenotype, viability, proliferation, and function remain uncertain. In response, magneto ferritin, a biological MNP, was introduced in 2014 [42]. This MNP demonstrated stronger magnetic capacity while being safer and causing no adverse cellular effects up to 7 days after incorporation into 3-D cellular spheroids. This provides confidence that magneto ferritin could be a viable alternative to iron oxide MNPs, potentially mitigating the adverse effects associated with metallic MNPs [42].

Dzamukova et al. [43] described a straightforward approach for cell surface engineering using cationic polyelectrolyte-stabilized MNPs. They reported the fabrication of viable layered planar cell sheets and 3-D multicellular spheroids. The MNPs used in this method rendered cells magnetically responsive by being deposited directly onto cellular membranes, creating mesoporous semi-permeable layers. Since the cationic polyelectrolyte-stabilized MNPs did not need to penetrate the cytoplasm, the deposition process was completed under cell-friendly conditions within a few minutes. Consequently, this method did not compromise cell membrane integrity, inhibit enzyme activity, disrupt adhesion or cytoskeleton formation, nor induce cell apoptosis [43].

Polyelectrolyte-based electrochemical controlling cell sheet fabrication

Electrochemical control was another effective method for constructing cell sheets (Fig. 3). Gentil et al. [47] proposed a cell sheet engineering platform using electronically addressable and responsive surfaces, involving polyelectrolyte mono- and multilayered films. Rat calvarial osteoblast (RCO) sheets, NIH3T3 sheets, and human periodontal ligament (PDL) cell sheets were formed on polyelectrolyte-coated electronic control surfaces after application of a positive potential. This method employed biocompatible polymer coatings, specifically RGD-modified poly(L-lysine)-graft-poly (ethylene glycol) (PLL-g-PEG/PEGRGD), to attract cells. The polycation promoted specific interactions between cells and the surface through the α/β-integrin-binding sequence Arg-Gly-Asp (RGD) [44], while the unfunctionalized PEG arms prevented non-specific protein adsorption [45]. Monolayer polyelectrolyte coatings were obtained by simply dipping a charged substrate (e.g., ITO) into a dilute solution of polycationic polymers, which spontaneously adsorbed onto the conducting substrate with the opposite charge (indium tin oxide, ITO) via electrostatic interaction [46]. Multilayered polyelectrolyte coatings were applied layer by layer by alternating dips of the charged surface into dilute solutions of a polycation and a polyanion [47]. Since polyelectrolyte monolayer and multilayer films can be desorbed from the conductive substrate through electrochemical polarization [48], cell sheet detachment was achieved by applying a positive potential to weaken the interactions between the polyelectrolyte and the conductive substrate. At the same time, the electrolysis of water during the electrochemical polarization process can alter the local pH, potentially leading to the dissolution of the polyelectrolyte surface and facilitating the separation of the cell sheet [47]. The PLL-g-PEG/PEG polymer, a weak polyelectrolyte, forms relatively soft and highly hydrated coatings that exhibit poor adhesion to certain types of cells, even after functionalization with bioligands such as fibronectin or RGD (Arg-Gly-Asp) [49] (Fig. 3). Further research by Gentil et al. [50] introduced a novel polyelectrolyte-based platform for the rapid formation of viable human placenta-derived mesenchymal stem cell (PD-MSC) sheets. Coatings achieved through layer-by-layer deposition of cationic poly(allylamine hydrochloride) (PAH) and anionic poly(styrene sulfonate) (PSS) polyelectrolytes on ITO substrates [51] allowed for cell sheet detachment by significantly reducing the stability of the adsorbed protein layers to which cells adhere, through changes in the protein microenvironment, such as decreased pH [52]. When the pH of the culture media was reduced to 4.0, continuous and intact cell sheets grown on PAH/PSS-coated ITO electrodes detached readily within 2 to 3 min [50]. Additionally, this polymer demonstrated better stability, maintaining its integrity after cell sheet detachment and thereby allowing for reusability [51] (Fig. 3).

Seto et al. [53] designed an oligopeptide, CCRRGDWLC, featuring a cell adhesion region (RGD) at the center and cysteine residues (CCR and WLC) at both terminals to facilitate cell attachment and detachment. The thiol group of cysteine can adsorb onto a gold surface via gold-sulfur bonds, mediate cell adhesion, and enable reductive desorption of the oligopeptide and cell detachment when a potential is applied (Fig. 3). They prepared thin gold rods, chemically adsorbed with the oligopeptide CCRRGDWLC. HUVECs were seeded onto the rods, which were subsequently placed within a perfusion culture chamber. Following this, a collagen solution was introduced. Upon the formation of the collagen gel, the cells and rods were dissociated by applying an electric potential. The rods were then removed, creating tubular channels within the collagen gel matrix. The cells that had initially adhered to the rods subsequently attached to the surfaces of these collagen gel tubular channels and underwent spontaneous vascularization under continuous fluid perfusion stimulation. This method is applicable not only to the construction of planar structures but also to various configurations, including cylindrical structures.

Schematic diagram of electrochemical control in cell sheet fabrication. A. A biocompatible polymer, RGD-modified poly(L-lysine)-graft-poly(ethylene glycol) (PLL-g-PEG/PEGRGD), coated charged substrate was used for cell sheet fabrication. B. Multilayered cationic poly(allylamine hydrochloride) (PAH) and anionic poly(styrene sulfonate) (PSS) polyelectrolytes coated charged substrate was used for cell sheet fabrication. C. Oligopeptide CCRRGDWLC was designed and used for cell sheet fabrication. Cells can be harvested as a sheet after applying a potential

Light-induced cell-sheet fabrication

Hong et al. [54] introduced a less invasive method for cell sheet fabrication based on the transition in surface wettability of culture coatings through light illumination. This approach provided an effective and convenient means for cell sheet production. Titanium dioxide (TiO2) was chosen as the raw material for preparing TiO2 nanodot films (TN) due to its biocompatibility [55] and light-induced wettability transition under safe illumination below a wavelength of 380 nm [56]. This nanodot film was coated onto a quartz substrate to support cell attachment under normal culture conditions. Upon exposure to 380 nm ultraviolet (UV) light, the TiO2 nanodot film became hydrophilic, reducing cell adhesion [57]. Consequently, proliferating cells on this surface could be released as a sheet-like structure within 5 min. Additionally, cell sheets from mouse calvaria-derived pre-osteoblastic (MC3T3-E1) cells [54], NIH3T3 cells [58], bone marrow mesenchymal stem cells (BMSCs) [59], and pre-vascularized composite cell sheets consisting of human mesenchymal stem cells and human umbilical vein endothelial cells (MSCs–ECs) [60] have been engineered using UV (365–366 nm) and TiO2-based surfaces.

As a novel approach with significant advantages, light-induced cell sheet technology has seen rapid advancements [13] (Fig. 4). In addition to UV illumination, visible light (400–800 nm) [61], green light (510 nm) [62], and near-infrared (NIR) light (808 nm) [63] have been utilized for the fabrication of MC3T3-E1 cell sheets, hMSCs sheets [64], and human fibroblast (hFCs) sheets, among others.

Schematic diagrams of light-induced cell sheet fabrication. A. UV illumination + TiO2 nanodot film (TN); B. Green light (510 nm) illumination + hematoporphyrin-incorporated polyketone (Hp-PK) film; C. Visible light (400–800 nm) illumination + silicon wafers with a p/n junction [Si(p/n)]; D. NIR light (808 nm) irradiation + poly(3,4-ethylenedioxythiophene) (PEDOT) surface. Panel B is reproduced from reference [62] with permission

Ions concentration-related cell sheet fabrication

Scientists have suggested that the surface energy of the cell culture substrate can affect cell-substrate adhesion and mediate cell sheet fabrication. Baek et al. [65] developed a highly effective and mild surface-tailoring method to regulate the degree of adhesion between cells and their culture surface, achieving intact cell sheets under isothermal conditions for precise modulation of cell-substrate interactions. They prepared a homogeneous copolymer, poly(divinylbenzene-co-4-vinylpyridine) [p(DVB-co-4VP) or pDV], by combining the nonpolar, hydrophobic divinylbenzene (DVB) and the polar, hydrophilic 4-vinylpyridine (4VP) through initiated chemical vapor deposition (iCVD) [66]. The copolymer film deposited onto tissue culture plastic (TCP) allowed for precise control of surface energy and systematic modulation of cell attachment and detachment by adjusting the input flow ratio of DVB to 4VP [65]. Cells seeded onto the culture plate could be harvested after changing the ligand-binding conformation of the integrin-binding domain ECM protein and cell adhesion molecules (CAMs) by soaking in D-PBS without Ca2+ and Mg2+ (Fig. 5A). The entire release process took approximately 100 s and was expected to induce no cytotoxicity. While divalent cations do not affect all transmembrane proteins related to cell-cell junctions, the stability of these proteins in the absence of Ca2+ and Mg2+ contributes to the formation of the sheet-like structure.

Mechanical methods for cell sheet fabrication

Mechanical methods, such as cell scrapers and specialized culture supplements, were used for cell sheet fabrication. These simplified methods can produce intact cell sheets with good flexibility in a short time using tools like cell scrapers, pipette tips, or syringe needles, whereas other methods may require special materials or equipment [11].

In 2009, a large scaffold-free bone was constructed from rabbit BMSCs-derived osteogenic cell sheets harvested using the scraping technique [67]. Researchers cultured rabbit BMSCs under osteogenic conditions and used a gentle roll-up force with a cell scraper to lift a thick cell sheet immediately after formation. Additionally, intact cell sheets of rabbit BMSCs, chondrocytes derived from rabbit BMSCs, human autologous OMECs, and Curcumin-mediated mouse BMSCs were fabricated using the same method [68].

Instead of single-cell suspensions after trypsinization. Jia et al. cocultured smooth muscle cells (SMCs) and endothelial progenitor cells (EPCs) and harvested intact cell sheets by pushing the edge of the confluent cell layer gently with a pipette tip. This finding suggested that cell sheets might be feasible through mechanical methods when cell-cell adherence surpasses cell-substrate adherence. They prolonged the coculture of SMCs and EPCs and obtained an intact, viable, and pre-vascularized SMC sheet by gently tapping the edge of the fused cell layer with a pipette tip [11].

A Vitamin C-mediated procedure assisted in mechanical cell sheet fabrication for certain types of cells. By adding appropriate dexamethasone and ascorbic acid phosphate (vitamin C, Vc) to the culture medium, cells could be scraped off as a sheet structure using a scraper once they were confluent. This approach enhanced the creation of rat BMSCs sheets and bone formation [69]. Later, Wei et al. explored the potential of vitamin C for cell sheet formation due to its properties of biosynthesizing ECM, mimicking the physiological environment, and regulating the proliferation and differentiation of MSCs. They formed cell sheets by adding vitamin C to the culture medium and harvested the sheets using a crooked syringe needle [70]. Maha and Liu et al. [71] also reported the preparation of periodontal ligament stem cell (PLSCs) sheets, BMSCs sheets, and EPCs–BMSCs sheets using this method.

Other approaches to the release of cell sheets

In addition to the methods mentioned above, alternative approaches are available for obtaining cell sheets suitable for specific types of cells (Fig. 5B).

Cellulose-based methods have been employed for cell sheet fabrication, utilizing enzymatic digestion of polysaccharides. Cellulose, a biocompatible and biodegradable polysaccharide with suitable mechanical strength, can be hydrolyzed into beta-glucose by biocompatible cellulase [72]. For cell adherence, cellulose modified to contain different types of ligands is pre-coated onto the culture surface. After the cells form a confluent layer, cellulase-containing culture medium is added, leading to the release of cell sheets within 10 min [73]. Following this principle, fibroblast cell sheets [74], endothelial cell sheets [75], human mesenchymal stem cells (hMSCs) sheets, and corneal limbal epithelial cell (hCLE) sheets [73] have been fabricated using carboxymethyl cellulose conjugates (e.g., carboxymethyl cellulose conjugated with dopamine (CMC-DA) [73] and carboxymethyl cellulose conjugated with tyramine (CMC-Ph) [76]). These cell sheets demonstrated excellent morphology and showed better proliferative activity compared to cells treated with trypsin.

The categories of cell sheets

Cell sheet engineering has emerged as a creative and gentle method for cell harvest in the life sciences. With advancements in this technology, cell sheets have become diverse in shape and structure, meeting various experimental needs. It is now possible to fabricate cell sheets ranging from monolayered to multilayered three-dimensional structures, using single or complex cell types. In this review, we categorize the cell sheet structures developed to date based on their cell type compositions and structural characteristics.

Categories classified by the standards of the number of cell types

Considering the classification standards based on the number of cell types present in cell sheets, they can be divided into two categories as outlined below.

Homeotypic cell sheets

The earliest example of cell sheet construction involved this category, which consists of a single cell type [14]. Due to the simplicity and convenience of this approach, homotypic cell sheets were the primary focus of research and development for some time. Various cells, including autologous oral mucosal cells, mouse BMSCs, NIH3T3 cells, HDFBs, mouse C2C12 cells, human SMCs, hMSCs, and MC3T3-E1 cells [77], have been used to prepare these sheets.

The cell composition in this category is straightforward, and the variables to be controlled during preparation are relatively simple. This simplicity makes it the most basic and easiest category to achieve quality control and mass production, facilitating rapid clinical translation at the top speed [78]. Considering the physiological structure of human organs and tissues, cell sheets composed of a single cell type are particularly valuable for repairing damaged or pathological thin tissues, such as skin, mucosa, and cornea. Additionally, these cell sheets are advantageous for studying the therapeutic effects and mechanisms of specific cells in treating diseases [79]. Cell sheet transplantation allows for the retrieval of grafts from experimental animals [80], whereas cells injected as a suspension are difficult to recover [81].

Heterotypic cell sheets

The advancement of cell sheet engineering has led to the development of cell sheets composed of two or more cell types. Most reported heterotypic cell sheets contain two types of cells, with one type typically being endothelial lineage cells, which are crucial for vascularization and integration in vivo [82]. While the cell composition in these sheets is more complex than in homotypic sheets, this complexity enhances the capacity of the cell sheets to integrate with the host tissue and establish vascular connections [83]. Therefore, multi-cell type sheets are particularly valuable for repairing thicker tissues or those requiring vascularization and functional integration [84]. However, the distribution and arrangement of cells in heterotypic sheets remain relatively disordered, which limits their effectiveness in replacing damaged tissues and in tissue regeneration.

Categories classified by the standards of the number of cell layers

Cell sheets can also be classified based on the number of layers they possess: monolayer cell sheets and multilayer cell sheets. Multilayer cell sheets can be further divided into one-step harvested cell sheets and multi-step harvested cell sheets, depending on the harvesting procedure.

Monolayer cell sheets

Except for certain special cell types (e.g., keratinocytes and stem cells) that may naturally form multilayer sheets, cells seeded on a culture surface typically grow in a monolayer due to contact inhibition [85]. These cells can be harvested as a monolayer once they reach confluence. Monolayer cell sheets do not require complex techniques, only a suitable method and a basic harvesting protocol [86]. Due to their straightforward fabrication, monolayer cell sheets were among the first types constructed and remain prevalent.

Multilayer cell sheets

As most organs and tissues are more than just thin layers but structures of significant thickness, the demand for a large number of cells to achieve therapeutic doses cannot be met by single-layer structures alone. Therefore, multilayer cell sheets were developed, and these multilayered tissues can be categorized based on the harvesting procedure.

Multilayer cell sheets with one-step harvest procedure

To construct multilayer cell sheets using a one-step harvest procedure, the multilayer structure must be established prior to harvesting. Yamato [87] achieved this by plating human keratinocytes on poly(N-isopropylacrylamide)-coated thermo-responsive culture dishes, resulting in intact multilayered human keratinocyte sheets. For other monolayer-adherent cells, there are three main approaches:

The first method involves seeding adherent cells at a much higher density initially or culturing adherent cells for an extended period to achieve a higher density on the culture surfaces, thereby promoting the spontaneous formation of a multilayer cell structure spontaneously [68]. Nishida [78] plated mitomycin C (MMC)-treated NIH3T3 cells onto the culture surfaces one day prior, then seeded human or rabbit limbal stem cells onto these surfaces. After 2 weeks of cultivation, three to five-layered corneal epithelial cell sheets, with flat basal and apical surfaces, were harvested.

Contact inhibition is a characteristic of normal adherent cells that results in a monolayer during in vitro cultivation [88]. To overcome contact inhibition and shape adherent cells into a multilayered sheet, magnetic force was employed as a facilitating device. This approach compels cells to adhere to culture surfaces, promoting intercellular connections between different layers [32]. Yamamoto et al. [89] successfully prepared skeletal muscle tissue constructs expressing muscle-specific markers and exhibiting physiological functions by accumulating MCLs-labeled mouse C2C12 myoblast cells onto an ultralow attachment surface using magnetic force.

Kito et al. [90] labeled induced pluripotent stem cell (iPSCs)-derived fetal liver kinase-1 positive cardiovascular cells (FLK-1+ cells) with MCLs and fabricated an approximately 300 μm thick cell sheet composed of 15 to 20 layers of cells using a magnetic force-based system [31]. Later, Ana et al. [35] constructed a triple-layer sheet with HUVECs sandwiched between two sheets of ASCs with the aid of magnetic force.

The final method relies on time lag. Cells are directly seeded onto a dish that already has an attached and confluent cell layer [71]. The previously attached cell layer serves as a substrate, and the new cell layer adheres to the original layer through cell-cell connections and ECM effects [91]. Repeating this process enables the formation of multilayer structures [92].

Multilayer cell sheets with multi-step harvest procedure

Constructing multilayer cell sheets with a one-step harvest procedure involves applying specific stimulation only once, which is gentler on the cells due to the limited impact of time consumption and changes in culture conditions. However, single cells seeded onto existing cell layers are more prone to migration and harder to control in terms of distribution within the structure. The multi-step harvest procedure addresses these limitations effectively.

This method primarily constructs multilayer cell sheets through the repeated superposition of prepared monolayer cell sheets, utilizing various advanced manipulators [93]. For example, Haraguchi et al. [94] developed a hydrogel-coated, plunger-like manipulator and fabricated triple-layer pulsating cardiac cell sheets by stacking detached monolayer cardiac cell sheets with the aid of this manipulator.

Multilayer cell sheets produced using the multi-step harvest procedure have a relatively defined cell composition and number of layers. These characteristics enhance their ability to mimic the original structure of damaged tissues and provide more effective therapeutic alternatives in tissue and organ regeneration.

Categories classified by the standards of the complexity of the structure

Considering the classification standards for the structural complexity of cell sheets that have been constructed, cell sheets can be classified into three categories ranging from simple to complex structures.

Simple disordered cell sheets

Simple disordered cell sheets are the most basic type of cell sheets. Cells are seeded onto culture surfaces, where they may experience transitions between adherence and detachment under various stimuli. Although the fabrication methods for these cell sheets vary, they share a common characteristic: the arrangement of cells within the sheet is random and disordered. This category offers the advantage of easy operation but has limitations in replicating native structures and specific functions.

Patterned cell sheets

Patterned cell sheets are designed to meet more specific requirements in cell sheet engineering. The fabrication of patterned cell sheets primarily relies on the preparation of patterned culture surfaces. Tsuda et al. [96] reported preparing a patterned surface using EB irradiation and fabricated a patterned cell sheet consisting of rat primary hepatocytes and bovine carotid endothelial cells (HCS-ECs) in 2005. In this method, n-butyl methacrylate (BMA) was grafted onto a PIPAAm-grafted surface using a graphic metal mask. This dual thermoresponsive polymer-grafted surface was patterned as the mask obscured part of the EB [96]. Another advanced patterned thermoresponsive surface was reported, where BMA was replaced by site-selective biofunctionalized carboxyl-functional thermoresponsive polymers [97]. The ‘patterning’ procedures mentioned are closely related to the areas (graphics) modified to achieve specific cell adhesion patterns [98]. The critical process in these methods is the adherence of seeded cells, meaning that patterned cell sheets are already shaped before harvest.

Efforts have also been made to obtain patterned cell sheets during the harvesting procedure [13]. Kim et al. [63] fabricated hFCs sheets with various patterns by diffracting NIR light into a light pattern using a micropatterned optical lens. They generated photothermal patterns on PEDOT, which converts NIR absorption into localized heat, thereby mediating the dissolution of the collagen layer on the PEDOT layer and enabling the rapid harvesting of patterned cell sheets [99].

Additionally, magnetic force-based cell sheet engineering is well-suited for producing patterned cell sheets. The only requirement for ‘patterning’ is the strategic placement of magnets. Pretreated cells seeded on peri dishes will gather and adhere to areas under magnetic control [100].

In contrast to simple disordered cell sheets, patterned cell sheets have a designed and well-aligned cell arrangement or macroscopic shape. This design allows for relatively precise control over the proportion of co-cultured cells, further enabling spatiotemporal regulation of cellular functions and better mimicking of original tissues.

Vascularized and complex configurated cell sheets

Superposing functional cell sheets has been a method for constructing scaffold-free 3D tissues, facilitating the regeneration and repair of tissue defects [87]. In 2006, thick and functionalized myocardial soft tissues [101] were created by stacking monolayered cultured cell sheets confluent with each other. However, fabricating 3D tissue from monolayers is time-consuming. Additionally, simply superimposing monolayer cell sheets may result in a lack of capillaries, which supply oxygen and nutrients. This can lead to cell necrosis in the center of the constructed thick sheets, limiting the number of superimposed cell layers [102]. Sakaguchi et al. used cell sheet engineering and a perfusion bioreactor with collagen-based microchannels to prepare a multi-layer construction of vascularized cell sheets and reported cell viability within them [103]. Sekine et al. also constructed functional vascularized 3D tissues in vitro by stacking cell sheet units [104]. Specifically, every three layers of neonatal rat cardiac cell sheets were considered one unit and cultured on a vascular bed, which consisted of resected tissues with a connectable artery and vein. Endothelial cells within each unit connected with the capillaries on the vascular bed to form lumens. Once lumens were formed, the unit served as the vascular bed for the subsequent unit. Compared to structures with cell sheets superimposed in one step, the pre-vascularized cell sheet units’ superposition is thicker and better mimics heart tissue.

Additionally, tissues usually possess complex 3D geometries, and their special configurations must be accommodated during repair and reconstruction. Recently, Williams et al. [105] reported the formation of a skeletal myotube using a flexible thermoresponsive nanofabricated substratum (TNFS) and a gel casting method [106]. Monolayers of SMCs, skeletal muscle cells, and cardiomyocytes were prepared using TNFS [24], harvested, and neatly stacked on a new TNFS, eventually folding into a cylinder.

With ongoing advancements in cell sheet engineering technology, the construction of more complex and thicker vascularized tissues, curved surfaces, and hollow cavity structures in vitro has become possible. This progress enhances the preservation of cell viability in complex structures or larger-scale tissues and better simulates the functions of natural tissues and organs.

Categories classified by the standards of the degree of hardness and softness

Based on the classification standards for the hardness and softness of in vivo tissues that the fabricated structures correspond to, cell sheets can be classified into soft tissues and hard tissues. The classification primarily depends on the cells used in the cell sheets. So far, soft tissue construction has been more commonly reported. Hepatocytes [107], ASCs [108], human skeletal muscle cells (HSMCs) [109], MSCs, RPE [110], and thyrocytes [111], among others, have been used to construct cell tissues that mimic soft tissues in vivo.

Cell sheet engineering technology also has broad applications in forming hard tissues, such as bone and cartilage structures [112]. Ma et al. [67] prepared BMSCs-derived osteogenic cell sheets using a cell scraping method and constructed large bone tissues by rolling the harvested cell sheets. Additionally, vascularized neotrachea, cartilage sheets, and various dental-derived stem cell sheets [113] have been constructed. These engineered scaffold-free structures offer new strategies for the construction and regeneration of bone and cartilage repair.

Brief summary

The categories of cell sheet types under different classification conditions summarize and evaluate fabricated cell sheets from various dimensions and are not mutually exclusive. For instance, a cell sheet might be classified as a patterned soft tissue cell sheet with multiple cell types and multi-layer structures. Furthermore, different categories of cell sheets may present varying levels of difficulty in construction. For example, monolayer cell sheets composed of single cells are relatively easy to prepare, while cell sheets with pre-vascularized complex structures are more challenging to create. Ultimately, the most suitable type of cell sheet can be selected from the various categories available to meet specific needs. Figures 6 and 7 illustrate some reported cases.

Application examples of basic and relatively simple cell sheets. A. Monolayer human iPSCs-derived hepatocyte sheets [86]. B. Multilayer rat MSCs sheets [95]. C. Multilayer rat EPCs-MSCs sheets [95]. D. a): Schematic diagram of preparing thermo-responsive culture dishes for fabricating patterned cell sheets; b): Co-cultured, patterned monolayer bovine carotid artery endothelial cells (ECs) - rat primary hepatocytes (HCs) sheet [96]. E. a): Schematic diagram of multi-step fabrication of cell sheets using a cell sheet layering manipulator; b): Multi-step stacked homeotypic or heterotypic cell sheets. Sample No. 1: Triple-layered neonatal normal human dermal fibroblasts (NHDFs) sheet. Sample No. 2: Triple-layered NHDF sheet–NHDF sheet–human umbilical vein endothelial cells (HUVECs) sheet. Sample No. 3: NHDF sheet–HUVECs sheet–NHDF sheet. Sample No. 4: Triple-layered HUVECs sheet–NHDF sheet–NHDF sheet. Sample No. 5: Disordered triple-layered HUVECs–NHDFs co-culture sheet [82]. All panels are reproduced with permission

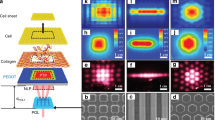

Application examples of advanced prevascularized and complex cell sheets. A. a): Process of preparing prevascularized 3D tissue constructions. “HN” indicates hypoxic hMSCs sheets, normoxic co-cultures, while “NN” indicates normoxic hMSCs sheets, normoxic co-cultures; b): 3D tissues constructed from prevascularized HN hMSCs sheets [83]. B. a): Schematic of constructing vascularized cell-dense tissues by using previously vascularized grafts as the vascular bed for subsequent grafts; b): Thick cell-dense tissues fabricated after 10 surgeries [101]. C. Schematic diagram and example of cell sheet engineering-based tubular tissue fabrication [105]. D. a): Schematic diagram of the culture device and collagen-microchannel-based perfusion culture system for in vitro vascularized tissue engineering; b): Vascularized multi-layer structures consisting of cardiac-endothelial cell sheets fabricated using this system [103]. All panels are reproduced with permission

Conclusions and future outlook

Cell sheet engineering has found broad applications in basic research on regenerative medicine and has even advanced to clinical trials due to its unique characteristics and advantages. Various stimuli, including temperature variations, magnetic force, controllable electrochemical changes, and light, have been utilized to control cell adhesion and detachment. Different types of cell sheets have been fabricated using these stimuli to create diverse 3D tissue constructs without the need for 3D scaffolds.

Thermally triggered cell sheet fabrication involves lowering the culture temperature and has been applied to various cell types. This method is relatively simple and widely used. However, it has a long production time, results in single-layer structures, and imposes stringent requirements on heat-sensitive materials. Magnetic force-based cell sheet fabrication involves impregnating MNPs into target cells, allowing them to be attracted by magnets under culture plates. By adjusting the magnetic force, cells can be assembled into sheets, including multilayer cell sheets. However, long-term exposure to MNPs may adversely affect cell viability. Magneto ferritin has been reported as a safer alternative and is expected to replace metallic MNPs in the future. Polyelectrolyte-based electrochemical cell sheet fabrication and light-induced cell sheet fabrication involve creating petri dishes with special coatings. By altering the culture medium environment (such as pH) and the wavelength of light, the adhesion properties of cells can be changed, leading to their detachment.

In terms of the number of layers, cell sheets can be categorized into monolayer and multilayer cell sheets. Monolayer cell sheets exhibit a single layer of growth due to contact inhibition and are relatively easy to manufacture. In contrast, multilayer cell sheets better mimic the original structure of damaged tissue and can demonstrate synergistic effects when different types are combined, thus enhancing the repair of affected sites.

In vitro vascularization using a vascular bed has been successfully implemented, leading to increased thickness and volume of densely packed cellular tissue. These advancements improve the benefits and effectiveness of this technology. However, simple stacking of cell sheets can result in oxygen and nutrient deficiencies, leading to cell necrosis in the center. Genetically modified cell sheets have been shown to stimulate angiogenesis. Recently, researchers have been exploring advanced vascular engineering techniques to maintain blood supply post-transplantation and improve the survival rate of transplanted cells. The process of cell sheet preparation is flexible, allowing for the selection of appropriate methods based on specific functional requirements. With the development of emerging technologies such as 3D printing and microfluidics, increasingly delicate and personalized cell sheets are being created.

Future advancements will rely on continued development of materials and techniques, a deeper understanding of cellular behavior, clinical translation, customization, and interdisciplinary collaboration. These factors will enable cell sheets to better adapt to complex tissue and organ environments, simplify preparation methods, and effectively replicate the original structure at the transplant site.

Firstly, developing more efficient, cost-effective, and scalable methods is imperative. This involves exploring novel biomaterials with enhanced biocompatibility, mechanical properties, and functionalization capabilities, as well as incorporating advanced manufacturing techniques like 3D printing and microfabrication to create precise and complex tissue structures. Understanding the molecular and cellular mechanisms underlying these processes is also crucial. Detailed investigations into how different fabrication methods impact cellular behavior—including differentiation, proliferation, and function—can help optimize cell sheet engineering for specific applications. This may include gene expression studies and long-term assessments of cell sheet stability and functionality in vivo. Clinical translation is a critical step, requiring rigorous preclinical and clinical trials to evaluate the safety, efficacy, and therapeutic potential of cell sheets in various medical conditions. Additionally, the trend towards personalized medicine necessitates the development of patient-specific cell sheets, which can minimize the risk of immune rejection and enhance therapeutic outcomes. Tailoring cell sheet properties to meet individual patient needs based on unique physiological conditions will further this goal. Finally, the advancement of cell sheet engineering will greatly benefit from interdisciplinary collaboration. By uniting experts from materials science, bioengineering, molecular biology, and clinical medicine, innovative solutions can be fostered, and progress can be accelerated. Continued investment in research and development, along with collaborative efforts across disciplines, will be essential to fully realize the potential of this transformative technology.

Data availability

Not applicable.

Abbreviations

- ECM:

-

Extracellular matrix

- MNPs:

-

Magnetite nanoparticles

- PIPAAm:

-

Poly(Nisopropylacrylamide)

- PNIPAAm:

-

Poly(N-isopropylacrylamide)

- EB:

-

Electron beam

- LCST:

-

Lower critical solution temperature

- PS:

-

Polystyrene

- PDMS:

-

Polydimethylsiloxane

- PIPAAm-PDMS:

-

Poly (Nisopropylacrylamide gel-grafted polydimethylsiloxane

- pH:

-

Potential of hydrogen potential of hydrogen

- RPE:

-

Retinal pigment epithelial cells

- OMECs:

-

Oral mucosal epithelial cells

- GMA:

-

Glycidylmethacrylate

- NGMA:

-

N-isopropylacrylamide-co-glycidylmethacrylate

- TNFS:

-

Thermoresponsive nanofabricated substratum

- SAM:

-

Self-assembled monolayers

- RGD:

-

Cell adhesive peptide

- bFGF:

-

Angiogenic growth factor

- MCL:

-

Magnetite cationic liposomes

- HAECs:

-

Human aortic endothelial cells

- HUVECs:

-

Human umbilical vein endothelial cells

- ASCs:

-

Adipose-derived stromal cells

- RCO:

-

Rat calvarial osteoblasts

- PDL:

-

Periodontal ligament cells

- PLL-g-PEG/PEGRGD:

-

RGD-modified poly(L-lysine)-graft-poly(ethylene glycol)

- ALP:

-

Alkaline phosphatase

- HeLa:

-

Human cervical carcinoma cells

- ITO:

-

Indium tin oxide

- PD-MSCs:

-

Placenta-derived mesenchymal stem cells

- PAH:

-

Poly(allylamine hydrochloride)

- PSS:

-

Poly(styrene sulfonate)

- TN:

-

TiO2 nanodot film

- TiO2 :

-

Titanium dioxide

- UV:

-

Ultraviolet

- MC3T3-E1:

-

Mouse calvaria-derived pre-osteoblastic

- BMSCs:

-

Bone marrow mesenchymal stem cell

- MSCs–ECs:

-

Human mesenchymal stem cells and human umbilical vein endothelial cells

- hFCs:

-

Human fibroblasts

- Hp-PK:

-

Hematoporphyrin-incorporated polyketone

- PEDOT:

-

Poly(3,4-ethylenedi-oxythiophene)

- DVB:

-

Divinylbenzene

- 4VP:

-

4vinylpyridine

- iCVD:

-

Initiated chemical vapor deposition

- TCP:

-

Tissueculture plastic

- CAM:

-

Cell adhesion molecules

- Vc:

-

Ascorbic acid phosphate (vitamin C)

- SMCs:

-

Smooth muscle cells

- EPCs:

-

Endothelial progenitor cells

- hMSCs:

-

Human mesenchymal stem cell

- hCLEs:

-

Corneal limbal epithelial cells

- CMC-DA:

-

Carboxymethyl cellulose conjugation with dopamine

- CMC-Ph:

-

Carboxymethyl cellulose conjugation with tyramine

- MMC:

-

Mitomycin C

- iPSCs:

-

Induced pluripotent stem cells

- FLK-1+ :

-

Fetal liver kinase-1 positive cardiovascular

- HCS -ECs:

-

Hepatocytes and bovine carotid endothelial cells

- BMA:

-

N-butyl methacrylate

- HSMCs:

-

Human skeletal muscle cells

- NHDFs:

-

Normal human dermal fibroblasts

References

Sung S, et al. Biomaterial-assisted macrophage cell therapy for regenerative medicine. Adv Drug Deliv Rev. 2023;199:114979.

Genchi A, et al. Neural stem cell transplantation in patients with progressive multiple sclerosis: an open-label, phase 1 study. Nat Med. 2023;29(1):75–85.

The Lancet H. Updates on blood transfusion guidelines. Lancet Haematol, 2016. 3(12).

Qiao Z, et al. Human adipose-derived mesenchymal progenitor cells plus microfracture and hyaluronic acid for cartilage repair: a phase IIa trial. Regen Med. 2020;15(1):1193–214.

Hu D, et al. The preclinical and clinical progress of cell sheet engineering in regenerative medicine. Stem Cell Res Ther. 2023;14(1):112.

Takagi K, et al. Regeneration of the ureter using a scaffold-free live-cell structure created with the bio-three-dimensional printing technique. Acta Biomater. 2023;165:102–10.

Wystrychowski W, et al. Long-term results of autologous scaffold-free tissue-engineered vascular graft for hemodialysis access. J Vasc Access. 2024;25(1):254–64.

Thummarati P et al. Recent advances in cell sheet Engineering: from fabrication to clinical translation. Bioeng (Basel), 2023. 10(2).

Oie Y, et al. Clinical trial of Autologous Cultivated Limbal epithelial cell sheet transplantation for patients with Limbal Stem Cell Deficiency. Ophthalmology. 2023;130(6):608–14.

Kobayashi Y, et al. Tailored cell sheet engineering using microstereolithography and electrochemical cell transfer. Sci Rep. 2019;9(1):10415.

Jia Z, Guo H, Xie H, et al. Harvesting prevascularized smooth muscle cell sheets from common polystyrene culture dishes. PLoS ONE. 2018;13(9):e0204677.

Vinhas A, et al. Human tendon-derived cell sheets created by magnetic force-based tissue engineering hold tenogenic and immunomodulatory potential. Acta Biomater. 2021;131:236–47.

Jiang Z, et al. Recent advances in light-induced cell sheet technology. Acta Biomater. 2021;119:30–41.

Yamada N, Sakai OT. Thermo-responsive polymeric surfaces; control of attachment and detachment of cultured cells. Macromol Rapid Commun. 1990;11(11):571–6.

Akiyama Y, Yamato KA. Ultrathin poly(\r, N\r, -isopropylacrylamide) grafted layer on polystyrene surfaces for cell Adhesion/Detachment control. Langmuir. 2004;20(13):5506–11.

OKANO T. A novel recovery system for cultured cells using plasma-treated polystyrene dishes grafted with poly (N-isopropylacrylamide). J Biomed Mater res, 1993. 27.

Kumar PRA, Sreenivasan K, Kumary TV. Alternate method for grafting thermoresponsive polymer for transferringin vitro cell sheet structures. J Appl Polym Sci. 2007;105(4):2245–51.

Okano T. New facile method for preparing themperature-resopnsive cell culture surfaces using a thioxantone-based photoinitiator immobilized polystyrene surface. in International Symposium on Micro-nanomechatronics & Human Science. 2014.

Akiyama Y, et al. Poly(N-isopropylacrylamide)-Grafted polydimethylsiloxane substrate for Controlling Cell Adhesion and detachment by dual stimulation of temperature and mechanical stress. Biomacromolecules. 2018;19(10):4014–22.

Okano T. Characterization of Ultra-thin temperature-responsive polymer layer and its polymer thickness dependency on cell Attachment/Detachment properties. Macromol Biosci. 2010;10(10):1117–29.

Jun I, Kim SJ, Lee, Ji-Hye, et al. Transfer Printing of Cell Layers with an Anisotropic Extracellular Matrix Assembly using cell-interactive and thermosensitive hydrogels. Adv Funct Mater. 2012;22(19):4060–9.

Nagamori E, Takezawa NTX. Network formation through active migration of human vascular endothelial cells in a multilayered skeletal myoblast sheet. Biomaterials. 2013;34(3):662–8.

Joseph N, Prasad, Tilak R. A cytocompatible poly(N-isopropylacrylamide-co-glycidylmethacrylate) coated surface as new substrate for corneal tissue Engineering. J Bioactive Compatible Polym. 2010;25(1):58–74.

Jiao A, Trosper NE, Yang H, Seok et al. Thermoresponsive Nanofabricated Substratum for the Engineering of Three-Dimensional Tissues with Layer-by-Layer Architectural Control. Acs Nano, 2014. 8(5): pp. 4430–4439.

Reinicke S, et al. Smart hydrogels based on double responsive triblock terpolymers. Soft Matter; 2009.

Weinhart M, Becherer T, Haag R. Switchable, biocompatible surfaces based on glycerol copolymers. Chem Commun (Camb). 2011;47(5):1553–5.

Park KM, et al. In situ forming hydrogels based on tyramine conjugated 4-Arm-PPO-PEO via enzymatic oxidative reaction. Biomacromolecules. 2010;11(3):706–12.

Park KM, et al. Synthesis and characterizations of in situ cross-linkable gelatin and 4-arm-PPO-PEO hybrid hydrogels via enzymatic reaction for tissue regenerative medicine. Biomacromolecules. 2012;13(3):604–11.

Kim SJ, Jun I, Kim DW, et al. Rapid transfer of endothelial cell sheet using a thermosensitive hydrogel and its effect on therapeutic angiogenesis. Biomacromolecules. 2013;14(12):4309–19.

Fan R et al. Thermosensitive hydrogels and advances in their application in Disease Therapy. Polym (Basel), 2022. 14(12).

Ito A, Honda TY. Tissue Engineering using Magnetite nanoparticles and magnetic force: Heterotypic layers of Cocultured hepatocytes and endothelial cells. Tissue Eng. 2004;10(5):833–40.

Akira Ito MH, Honda H, Hata K-I, Kagami H, Ueda M, Kobayashi T. Construction and Harvest of multilayered keratinocyte sheets using Magnetite nanoparticles and magnetic force. Tissue Eng. 2004;10(5):873–80.

Ito A, Jitsunobu H, Kawabe Y, Kamihira M. Construction of heterotypic cell sheets by magnetic force-based 3-D coculture of HepG2 and NIH3T3 cells.

Moschouris K, Firoozi N. The application of cell sheet engineering in the vascularization of tissue regeneration. Regen Med. 2016;11(6):559–70.

Silva AS, et al. Multi-layer pre-vascularized magnetic cell sheets for bone regeneration. Biomaterials. 2020;231:119664.

Dandamudi S, Campbell RB. The drug loading, cytotoxicty and tumor vascular targeting characteristics of magnetite in magnetic drug targeting. Biomaterials. 2007;28(31):4673–83.

Ito A, et al. The effect of RGD peptide-conjugated magnetite cationic liposomes on cell growth and cell sheet harvesting. Biomaterials. 2005;26(31):6185–93.

Van de Walle A, et al. Ever-evolving identity of magnetic nanoparticles within human cells: the interplay of endosomal confinement, degradation, Storage, and Neocrystallization. Acc Chem Res. 2020;53(10):2212–24.

Tomitaka A, et al. Magnetic characterization of surface-coated magnetic nanoparticles for biomedical application. J Magn Magn Mater. 2011;323(10):1398–403.

Kim M, et al. Amphiphilic comblike polymers enhance the colloidal stability of Fe(3)O(4) nanoparticles. Colloids Surf B Biointerfaces. 2010;76(1):p236–40.

Caizer C et al. Fe(3)O(4)-PAA-(HP-γ-CDs) Biocompatible Ferrimagnetic Nanoparticles for increasing the efficacy in Superparamagnetic Hyperthermia. Nanomaterials (Basel), 2022. 12(15).

Mattix B, et al. Biological magnetic cellular spheroids as building blocks for tissue engineering. Acta Biomater. 2014;10(2):623–9.

Dzamukova MR, et al. Cell surface engineering with polyelectrolyte-stabilized magnetic nanoparticles: a facile approach for fabrication of artificial multicellular tissue-mimicking clusters. Nano Res. 2015;8(8):2515–32.

Muzzio NE, et al. Polyelectrolytes multilayers to modulate cell adhesion: a study of the influence of Film Composition and Polyelectrolyte Interdigitation on the adhesion of the A549 cell line. Macromol Biosci. 2016;16(4):482–95.

Schuler M, et al. Biomimetic modification of titanium dental implant model surfaces using the RGDSP-peptide sequence: a cell morphology study. Biomaterials. 2006;27(21):4003–15.

Jaganathan S. Bioresorbable polyelectrolytes for smuggling drugs into cells. Artif Cells Nanomed Biotechnol. 2016;44(4):1080–97.

Guillaume-Gentil OA, Schuler Y, et al. Polyelectrolyte Coatings with a potential for electronic control and cell sheet Engineering. Adv Mater. 2008;20(3):560–5.

Boulmedais F, et al. Controlled Electrodissolution of Polyelectrolyte multilayers: a platform technology towards the surface-initiated delivery of drugs. Adv Funct Mater. 2006;16(1):63–70.

Maddikeri RR, et al. Reduced medical infection related bacterial strains adhesion on bioactive RGD modified titanium surfaces: a first step toward cell selective surfaces. J Biomedical Mater Res Part A. 2010;84A(2):425–35.

Guillaume-Gentil OS, Zisch OV. H et al pH-controlled Recovery placenta-derived Mesenchymal stem cell Sheets Biomaterials. 2011;32(19):4376–84.

Guillaume-Gentil O et al. Global and local view on the electrochemically induced degradation of polyelectrolyte multilayers: from dissolution to delamination. Soft Matter, 2010. 6(17).

Andrade JD. and H. V., Protein adsorption and materials biocompatibility: a tutorial review and suggested hypotheses. In: Biopolymers/Non-Exclusion HPLC. Adv Polym Sci, 1986. 79.

Seto Y.I., Okuyama R, Sassa T, F, Suzuki H, Fukuda J. Engineering of capillary-like structures in tissue constructs by electrochemical detachment of cells. Biomaterials. 2010;31(8):2209–15.

Hong Y, Yu M, Weng W, et al. Light-induced cell detachment for cell sheet technology. Biomaterials. 2013;34(1):11–8.

Sun Z, et al. Nitrogen-doped titanium dioxide films fabricated via magnetron sputtering for vascular stent biocompatibility improvement. J Colloid Interface Sci. 2022;626:101–12.

Stern RS. The risk of squamous cell and basal cell cancer associated with psoralen and ultraviolet A therapy: a 30-year prospective study. J Am Acad Dermatol. 2012;66(4):553–62.

Cha TG, Moon YJW. M W et al Nanoscale Patterning Microtextured Surf Control Superhydrophobic Robust Langmuir. 2010;26(11):8319–26.

Cheng K, Wan HP, Weng WJ. A facile approach to improve light induced cell sheet harvesting through nanostructure optimization. RSC Adv. 2015;5(108):88965–72.

Jiang Z, et al. Light-controlled BMSC sheet-Implant complexes with Improved Osteogenesis via an LRP5/beta-Catenin/Runx2 Regulatory Loop. ACS Appl Mater Interfaces. 2017;9(40):34674–86.

Zhou Y, Dong, Lingqing, Liu, Chao, et al. Engineering prevascularized composite cell sheet by light-induced cell sheet technology. RSC Adv. 2017;7(52):32468–77.

Wang X, et al. Visible-light-responsive surfaces for efficient, noninvasive cell sheet harvesting. ACS Appl Mater Interfaces. 2017;9(34):28250–9.

Koo MA, et al. Exogenous ROS-induced cell sheet transfer based on hematoporphyrin-polyketone film via a one-step process. Biomaterials. 2018;161:47–56.

Na J et al. Harvesting of living cell sheets by the dynamic generation of Diffractive Photothermal Pattern on PEDOT. Adv Funct Mater, 2017. 27(10).

Jing J, Chen S, Lu Q. Gradient Photothermal Field for precisely directing cell sheet detachment. Adv Biosyst. 2019;3(5):e1800334.

Baek J, Cho Y, Park HJ, et al. A surface-tailoring method for Rapid Non-thermosensitive cell-sheet Engineering via Functional Polymer Coatings. Adv Mater. 2020;32(16):e1907225.

Yang R, et al. Synergistic prevention of biofouling in seawater desalination by zwitterionic surfaces and low-level chlorination. Adv Mater. 2014;26(11):1711–8.

Ma D, et al. Engineering scaffold-free bone tissue using bone marrow stromal cell sheets. J Orthop Res. 2010;28(5):697–702.

Yang Z, He C, He J, et al. Curcumin-mediated bone marrow mesenchymal stem cell sheets create a favorable immune microenvironment for adult full-thickness cutaneous wound healing. Stem Cell Res Ther. 2018;9(1):21.

A N, et al. Cell sheet transplantation of cultured mesenchymal stem cells enhances bone formation in a rat nonunion model. Bone. 2010;46:418–24.

Wei F, Qu C, Song T, et al. Vitamin C treatment promotes mesenchymal stem cell sheet formation and tissue regeneration by elevating telomerase activity. J Cell Physiol. 2012;227(9):3216–24.

Liu H, Jiao Y, Zhou W, et al. Endothelial progenitor cells improve the therapeutic effect of mesenchymal stem cell sheets on irradiated bone defect repair in a rat model. J Transl Med. 2018;16(1):137.

Wang B, Lv, Xiangguo, Chen S, et al. In vitro biodegradability of bacterial cellulose by cellulase in simulated body fluid and compatibility in vivo. Cellulose. 2016;23(5):3187–98.

Hong S, Sunwoo JH, Kim JS, Tchah H, Hwang C. Conjugation of carboxymethyl cellulose and dopamine for cell sheet harvesting. Biomater Sci. 2018;7(1):139–48.

Sakai S, Ogushi Y, Kawakami K. Enzymatically crosslinked carboxymethylcellulose-tyramine conjugate hydrogel: cellular adhesiveness and feasibility for cell sheet technology. Acta Biomater. 2009;5(2):554–9.

K KI, K K. A thin carboxymethyl cellulose culture substrate for the cellulase-induced harvesting of an endothelial cell sheet. J Biomaterials ence. 2005;16:1277–91.

Ogushi Y, Sakai S, Kawakami K. Synthesis of enzymatically-gellable carboxymethylcellulose for biomedical applications. J Biosci Bioeng. 2007;104(1):30–3.

Rovere MR, Rousselle P, Haftek M, et al. Preserving basement membranes during detachment of cultivated oral mucosal epithelial cell sheets for the treatment of total bilateral Limbal Stem Cell Deficiency. Cell Transpl. 2018;27(2):264–74.

Nishida K, et al. Corneal Reconstruction with tissue-Engineered cell sheets composed of autologous oral mucosal epithelium. N Engl J Med. 2004;351(12):1187–96.

Yamaguchi N, Isomoto H, Kobayashi S, et al. Oral epithelial cell sheets engraftment for esophageal strictures after endoscopic submucosal dissection of squamous cell carcinoma and airplane transportation. Sci Rep. 2017;7(1):17460.

Yu J, et al. Cell sheet composed of adipose-derived stem cells demonstrates enhanced skin wound healing with reduced scar formation. Acta Biomater. 2018;77:191–200.

Yamamoto A, et al. A physical biomarker of the quality of cultured corneal endothelial cells and of the long-term prognosis of corneal restoration in patients. Nat Biomed Eng. 2019;3(12):953–60.

Asakawa N, et al. Pre-vascularization of in vitro three-dimensional tissues created by cell sheet engineering. Biomaterials. 2010;31(14):3903–9.

Zhang L, Xing Q, Qian Z, et al. Hypoxia created human mesenchymal stem cell sheet for prevascularized 3D tissue construction. Adv Healthc Mater. 2016;5(3):342–52.

Sasagawa T, et al. Endothelial colony-forming cells for preparing prevascular three-dimensional cell-dense tissues using cell-sheet engineering. J Tissue Eng Regen Med. 2016;10(9):739–47.

Stramer B, Mayor R. Mechanisms and in vivo functions of contact inhibition of locomotion. Nat Rev Mol Cell Biol. 2017;18(1):43–55.

Nagamoto Y, Takayama, Kazuo, Ohashi K, et al. Transplantation of a human iPSC-derived hepatocyte sheet increases survival in mice with acute liver failure. J Hepatol. 2016;64(5):1068–75.

Yamato M, et al. Thermo-Responsive Culture dishes allow the Intact Harvest of multilayered keratinocyte sheets without dispase by reducing temperature. Tissue Eng. 2001;7(4):473–80.

Schnyder SK, Molina JJ, Yamamoto R. Control cell Colony Growth Contact Inhib Sci Rep. 2020;10(1):6713.

Yamamoto Y, Ito A, Fujita H, et al. Functional evaluation of artificial skeletal muscle tissue constructs fabricated by a magnetic force-based tissue engineering technique. Tissue Eng Part A. 2011;17(1–2):107–14.

Kito T, Ishii SR. iPS cell sheets created by a novel magnetite tissue engineering method for reparative angiogenesis. Sci Rep. 2013;3:1418–.

Jun I, Ahmad T, Bak S, Lee JY et al. Spatially assembled Bilayer Cell sheets of Stem cells and endothelial cells using thermosensitive hydrogels for therapeutic angiogenesis. Adv Healthc Mater, 2017. 6(9).

Shudo Y, Cohen JE, Macarthur JW, et al. Spatially oriented, temporally sequential smooth muscle cell-endothelial progenitor cell bi-level cell sheet neovascularizes ischemic myocardium. Circulation. 2013;128(11 Suppl 1):S59–68.

Kim K, Utoh R, Ohashi K, Kikuchi T, Okano T. Fabrication of functional 3D hepatic tissues with polarized hepatocytes by stacking endothelial cell sheets in vitro. J Tissue Eng Regen Med. 2017;11(7):2071–80.

Haraguchi Y, et al. Three-Dimensional Human Cardiac tissue Engineered by Centrifugation of Stacked Cell sheets and Cross-sectional Observation of its synchronous beatings by Optical Coherence Tomography. Biomed Res Int. 2017;2017:p5341702.

Liang Y, Wen L, Shang F, et al. Endothelial progenitors enhanced the osteogenic capacities of mesenchymal stem cells in vitro and in a rat alveolar bone defect model. Arch Oral Biol. 2016;68:123–30.

Tsuda Y, Kikuchi A, Yamato M, et al. The use of patterned dual thermoresponsive surfaces for the collective recovery as co-cultured cell sheets. Biomaterials. 2005;26(14):1885–93.

Hatakeyama H, Kikuchi A, Yamato M, Okano T. Patterned biofunctional designs of thermoresponsive surfaces for spatiotemporally controlled cell adhesion, growth, and thermally induced detachment. Biomaterials. 2007;28(25):3632–43.

Lim J, Jun I, Bin LY, et al. Fabrication of cell sheets with anisotropically aligned myotubes using thermally expandable micropatterned hydrogels. Macromol Res. 2016;24(6):562–72.

Kim JD, et al. Photothermally induced local dissociation of collagens for harvesting of cell sheets. Angew Chem Int Ed Engl. 2015;54(20):5869–73.

Ito A, Akiyama H, Kawabe Y, Kamihira M. Magnetic force-based cell patterning using arg-gly-asp (RGD) peptide-conjugated magnetite cationic liposomes. J Biosci Bioeng. 2007;104(4):288–93.

Shimizu T, Sekine H, Yang J, et al. Polysurgery of cell sheet grafts overcomes diffusion limits to produce thick, vascularized myocardial tissues. Faseb j. 2006;20(6):708–10.

Novosel EC, Kleinhans C, Kluger PJ. Vascularization is the key challenge in tissue engineering. Adv Drug Deliv Rev. 2011;63(4–5):300–11.

Sakaguchi K, Shimizu T, Horaguchi S, et al. In vitro engineering of vascularized tissue surrogates. Sci Rep. 2013;3:1316.

Sekine H, Shimizu T, Sakaguchi K, et al. In vitro fabrication of functional three-dimensional tissues with perfusable blood vessels. Nat Commun. 2013;4:1399.

Williams NP, Rhodehamel M, Yan C, et al. Engineering anisotropic 3D tubular tissues with flexible thermoresponsive nanofabricated substrates. Biomaterials. 2020;240:119856.

Jiao A, Moerk CT, Penland N, et al. Regulation of skeletal myotube formation and alignment by nanotopographically controlled cell-secreted extracellular matrix. J Biomed Mater Res A. 2018;106(6):1543–51.

Asadi M, et al. Hepatic cell-sheet fabrication of differentiated mesenchymal stem cells using decellularized extracellular matrix and thermoresponsive polymer. Biomed Pharmacother. 2021;134:111096.

Cheng NC, et al. Influence of human platelet lysate on Extracellular Matrix Deposition and Cellular characteristics in adipose-derived stem cell sheets. Front Cell Dev Biol. 2020;8:558354.

Thummarati P, Kino-Oka M. Effect of co-culturing fibroblasts in human skeletal muscle cell sheet on angiogenic cytokine balance and angiogenesis. Front Bioeng Biotechnol. 2020;8:578140.

Imafuku A, Oka M, Miyabe Y, et al. Rat mesenchymal stromal cell sheets suppress renal fibrosis via Microvascular Protection. Stem Cells Transl Med. 2019;8(12):1330–41.

Huang Y, et al. Fabrication of functional cell sheets with human thyrocytes from non-tumorous thyroid tissue. Tissue Eng Regen Med. 2019;16(5):491–9.

Chuah YJ, et al. Scaffold-Free tissue engineering with aligned bone marrow stromal cell sheets to recapitulate the microstructural and biochemical composition of annulus fibrosus. Acta Biomater. 2020;107:129–37.

Hu L, et al. Regeneration characteristics of different dental derived stem cell sheets. J Oral Rehabil. 2020;47(Suppl 1):66–72.

Acknowledgements

Not applicable.

Funding

This research work was supported by Key Research and Development Program of Hunan Province (2023SK2069), Health Research Project of Hunan Provincial Health Commission (W20242015), The Natural Science Foundation of Changsha(kq2208260), Natural Science Foundation of Hunan Province (2019JJ40353), Hunan Xiangjiang New District (Changsha High-tech Zone) key core technology research project in 2023, and the National Natural Science Foundation of China (81101510). Postgraduate Scientific Research Innovation Project of Hunan Province (CX20190236).

Author information

Authors and Affiliations

Contributions

Danping Hu: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Project administration, Resources, Validation, Visualization, Writing – original draft, Writing – review & editing. Ce Gao: Data curation, Formal analysis, Investigation, Methodology, Visualization, Writing – review & editing. Jie Li: Data curation, Formal analysis, Investigation, Software, Validation, Visualization, Writing – review & editing. Pei Tong: Investigation, Software, Visualization, Writing – review & editing. Yi Sun: Conceptualization, Data curation, Funding acquisition, Formal analysis, Methodology, Resources, Project administration, Validation, Visualization, Writing – review & editing. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests