Abstract

Background

A cost-effective pretreatment and saccharification process is a necessary prerequisite for utilizing lignocellulosic biomass (LCB) in biofuel and biomaterials production. Utilizing a multifunctional enzyme with both pretreatment and saccharification functions in a single step for simultaneous biological pretreatment and saccharification process (SPS) will be a green method of low cost and high efficiency. Manganese peroxidase (MnP, EC 1.11.1.13), a well-known lignin-degrading peroxidase, is generally preferred for the biological pretreatment of biomass. However, exploring the role and performance of MnP in LCB conversion will promote the application of MnP for lignocellulose-based biorefineries.

Results

In this study, we explored the ability of an MnP from Moniliophthora roreri, MrMnP, in LCB degradation. With Mn2+ and H2O2, MrMnP decomposed 5.0 g/L carboxymethyl cellulose to 0.14 mM of reducing sugar with a conversion yield of 5.0 mg/g, including 40 μM cellobiose, 70 μM cellotriose, 20 μM cellotetraose, and 10 μM cellohexaose, and degraded 1.0 g/L mannohexaose to 0.33 μM mannose, 4.08 μM mannotriose, and 4.35 μM mannopentaose. Meanwhile, MrMnP decomposed 5.0 g/L lichenan to 0.85 mM of reducing sugar with a conversion yield of 30.6 mg/g, including 10 μM cellotriose, 20 μM cellotetraose, and 80 μM cellohexose independently of Mn2+ and H2O2. Moreover, the versatility of MrMnP in LCB deconstruction was further verified by decomposing locust bean gum and wheat bran into reducing sugars with a conversion yield of 54.4 mg/g and 29.5 mg/g, respectively, including oligosaccharides such as di- and tri-saccharides. The catalytic mechanism underlying MrMnP degraded lignocellulose was proposed as that with H2O2, MrMnP oxidizes Mn2+ to Mn3+. Subsequently, it forms a complex with malonate, facilitating the degradation of CMC and mannohexaose into reducing sugars. Without H2O2, MrMnP directly oxidizes malonate to hydroperoxyl acetic acid radical to form compound I, which then attacks the glucosidic bond of lichenan.

Conclusion

This study identified a new function of MrMnP in the hydrolysis of cellulose and hemicellulose, suggesting that MrMnP exhibits its versatility in the pretreatment and saccharification of LCB. The results will lead to an in-depth understanding of biocatalytic saccharification and contribute to forming new enzymatic systems for using lignocellulose resources to produce sustainable and economically viable products and the long-term development of biorefinery, thereby increasing the productivity of LCB as a green resource.

Similar content being viewed by others

Introduction

With the rising concerns about fossil fuel exhaustion and environmental pollution, it is urgent to explore sustainable green resources for bioenergy production [1]. Lignocellulosic biomass (LCB) is a viable resource for biofuel and biomaterials production due to its low cost, abundance, and often availability as agro-industrial by-products or wastes [2, 3]. It is mainly composed of cellulose, hemicellulose, and lignin rigidly assembled. Each of these three major constituents can be bioconverted to value-added products using a biorefinery approach through biomass conversion consisting of pretreatment, enzymatic hydrolysis, and fermentation [4]. However, the highly complex structure and rigid recalcitrant nature of LCB is the main barrier to effectively converting LCB to bio-products [5]. To process LCB into biofuel, pretreatment is needed to efficiently remove lignin, making cellulose and hemicelluloses exposed for enzymatic hydrolysis [6, 7]. Furthermore, several classes of enzymes are required to completely convert LCB into fermentable sugars [8]. Therefore, a cost-effective pretreatment and saccharification process are prerequisites for utilizing the LCB in biofuel production.

In contrast to conventional physical and chemical pretreatment methods, biological pretreatment using ligninolytic enzymes (laccase, manganese peroxidase, lignin peroxidase, and versatile peroxidase) is a greener and cleaner method due to its higher safety, milder process conditions, and higher reaction specificity [9]. Combining the biological pretreatment with the subsequent saccharification steps will be a lower energy and less time process than sequential steps, which can be achieved by mixing ligninolytic enzymes with cellulolytic enzymes in a single step for simultaneous biological pretreatment and saccharification process (SPS) [10]. Although several successful enzymatic SPS methods have been reported [11,12,13], poor efficiency and higher production cost make the enzymatic SPS process unpopular. These issues can be solved by utilizing more robust and multifunctional enzyme systems. Except for laccase, other ligninolytic enzymes have seldom been reported to be used for delignification in SPS [14, 15]. While the conventional cellulolytic enzymes for saccharification are glycosidic hydrolases. However, the recently identified lytic polysaccharide monooxygenases (LPMOs) can cleave recalcitrant polysaccharides by oxidation [16,17,18,19], revolutionizing the understanding of enzyme-based saccharification. Given that ligninolytic enzymes are also oxidoreductases, it is worth exploring the cellulose degradation ability of ligninolytic enzymes, which can significantly improve the SPS efficiency for biomass conversion.

Manganese peroxidase (MnP, EC 1.11.1.13), a well-known lignin-degrading peroxidase, can oxidatively depolymerize lignin in an H2O2-assisted reaction by oxidizing Mn2+ to Mn3+, which is subsequently chelated by organic acids forming a diffusible oxidant to degrade lignin [20, 21], aromatic compounds [22, 23], pollutants and dyes [24,25,26]. MnPs are promising biocatalysts for converting lignin-based feedstock into high-value products, such as bioethanol and others, through lignin deconstruction/delignification [27]. However, their role in cellulose decomposition has not been thoroughly studied yet. Exploring the role and performance of MnP in LCB conversion will facilitate the utilization of MnP for lignocellulose-based biorefineries.

Most studies of MnPs focus on their ability to biodegrade organic pollutants, toxins, etc. This study explored its ability in LCB decomposition by using an MnP from Moniliophthora roreri, MrMnP, distinguished from other enzyme counterparts by its high-level secretory expression with a strong potential application prospect [28, 29]. The effects of buffer components, pH, and H2O2 on MrMnP activity were first examined. Then the optimal reaction conditions were performed to examine its ability in cellulose (CMC and lichenan) and hemicellulose (xylan and mannan) degradation. It was found that the MnP-driven Mn3+-malonate complex hydrolyzed CMC and Mannohexaose to reducing sugars, and MrMnP decomposed lichenan independently of Mn2+ and H2O2. The versatility of MrMnP in LCB deconstruction was further verified by decomposing locust bean gum and wheat bran into oligosaccharides such as di- and tri-saccharides. This study demonstrated previously unknown cellulolytic and hemicellulolytic activities of MrMnP. This new function of MrMnP in the hydrolysis of cellulose and hemicellulose, coupled with its known delignification activity, makes this enzyme a versatile enzyme for SPS of lignocellulosic biomass. The results will lead to an in-depth understanding of biocatalytic saccharification and contribute to forming new enzymatic systems for producing environmentally friendly products from lignocellulose and the long-term development of biorefinery.

Results and discussion

Characterization of the MrMnP

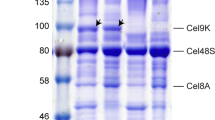

MrMnP can be heterologously expressed in Pichia pastoris at a high level (132 mg/L) [28]. In this study, the MrMnP, expressed in P. pastoris as before [29], was purified using hydrophobic-interaction chromatography (Fig. 1a). SDS-PAGE revealed that the purified MrMnP had a single band with a molecular mass of about 45 kDa (Fig. 1b), which was slightly higher than the theoretical molecular weight of 39.5 kDa. This is most likely due to post-translational glycosylation. UV–visible absorption spectrum scanning analyses showed an absorbance peak at 408, indicating the correct heme incorporation (Fig. 1b). The RZ (A408/A280) value was about 2.4, indicating the high purity of the enzyme, which was consistent with SDS-PAGE results. MrMnP can oxidize phenolic substrate DMP with the specific activity of 4.2 ± 0.2 U/mg, as well as ABTS (34.9 ± 4.4 U/mg) and MnSO4 (36.2 ± 5.1 U/mg), exhibiting the characteristics of short MnPs which can oxidate low-redox-potential substrates (ABTS, 2,6-DMP) [28].

Purification of MrMnP. a FPLC elution profile of the purification step of MrMnP performed on a HiTrapTM Phenyl HP FPLC column. Heme absorption at 407 nm (blue line), total protein at 280 nm (red line), (NH4)2SO4 concentration (brown line), percentage of 10 mM McIlvaine buffer (green line). b UV–Vis absorption spectra of MrMnP. The inset shows SDS-PAGE analysis of purified MrMnP. Lane M: protein ladder; lane 1: crude extract showing expressed MrMnP; lane 2: purified MrMnP (~ 45 kDa)

Effects of buffer components on MrMnP activity

Due to the importance of organic acids (the enzymatically generated Mn3+ chelator) in MnP-catalyzed oxidation [30], four different buffer solutions (malonate buffer, citric acid buffer, phosphate buffer, acetate buffer, 50 mM, pH 5) were selected to investigate the effects of buffer components on MrMnP activity (Fig. 2a). For both substrates ABTS and MnSO4, the highest activity was obtained in malonate buffer, which is in agreement with the previous study that malonate is the most effective chelator [31]. Unlike ABTS, MrMnP could not oxidize Mn2+ to Mn3+ in phosphate buffer and acetic acid–sodium acetate buffer. No Mn3+ was detected in the phosphate buffer, confirming that C2 and C3 dicarboxylic or a-hydroxyl acids are needed to stimulate the MnP activity [32]. Besides, the Mn2+ was not oxidized to Mn3+ in the acetate buffer, probably because H2O2 may reduce the resulting Mn3 + -acetate complex without a phenolic terminal substrate [33]. The oxidation rate of Mn2+ by MnP was also extremely slow in the reaction system containing acetate [34]. Thus, malonate buffer is used for all the following reactions unless otherwise specified.

Effects of pH and H2O2 on MrMnP activity

The pH–activity profile was significantly narrower, consistent with the data for most reported fungal MnP [26]. For the ABTS oxidation activity, it exhibited a maximum at pH 4 and retained more than 80% of its maximum activity between pH 4 and 5, but it was completely lost at pH 3 and 8 (Fig. 2b); For the Mn2+ oxidation activity, it exhibited a maximum at pH 5 and was completely lost at pH 3. It was reduced to 34%, 23%, and 7% at pH 4, 6, and 7, respectively (Fig. 2b). Considering that MnP functions through oxidizing Mn2+ and MrMnP is most stable at pH 5 [28], the following reactions were conducted at pH 5.

As an essential factor in initiating the MnP catalytic cycle, the concentration of H2O2 also affected the activity of MrMnP (Fig. 2c). When the concentration of H2O2 was 2 mM, the residual ABTS oxidation activity was less than 40%. This may be because excessive H2O2 can convert MnP into MnP compound III [35], a superoxide anion (O2·−) having Fe3+ species, which cannot participate in normal substrate oxidation reactions [36]. The enzyme retained > 60% ABTS oxidation activity as H2O2 concentration was 0.05 ~ 1 mM, especially 0.1 mM. The effect of H2O2 concentration on the oxidation activity of MnSO4 was greater than that of ABTS. The optimum concentration for Mn2+ oxidation activity was 0.1 mM, and the activity decreased by more than 30% when the concentration was increased to 0.2 mM. When the concentration was greater than or equal to 0.4 mM, the activity decreased to less than half. Thus, the optimum concentration for Mn2+ oxidization, 0.1 mM, was used for the following reactions.

MrMnP catalyzes the degradation of cellulose

To examine whether MrMnP can catalyze cellulose decomposition, CMC and lichenan were used as cellulosic substrates. As seen in Fig. 3a, 0.14 mM of reducing sugar was released from CMC after treatment by MrMnP with MnSO4 and H2O2 in malonate buffer (50 mM, pH 5) at 37 °C for 24 h. The reducing sugar conversion yield from CMC was 5.0 mg/g. MrMnP alone or MrMnP and H2O2 had no cellulolytic activity. MnP from P. chrysosporium (PcMnP) was first reported to produce reducing sugar from CMC in 50 mM acetate buffer (pH 4.5). However, the product's composition was not analyzed in detail [37]. We further analyzed the products using HPAEC-PAD. The results showed that 0.04 mM CE2, 0.07 mM CE3, 0.02 mM CE4, and 0.01 mM CE6 were produced, a total of 0.13 mM, which was lower than the reducing sugars by DNS method, indicating that some polysaccharides, which were not detected by HPAEC-PAD, were still present (Fig. 3c).

Analysis of the degradation products from CMC, lichenan, and mannohexaose. a Reducing sugar from CMC (0.5% (m/V)). b Reducing sugar from lichenan (0.5% (m/V)). c HPAEC analysis of hydrolysates of CMC and lichenan. d HPAEC analysis of hydrolysates of mannohexaose (1.0 g/L). The reaction was conducted in 50 mM malonate buffer (pH 5) containing 2.5 mg MrMnP, 1.0 mM MnSO4, and 0.1 mM H2O2 at 37 °C for 24 h. Error bars represent standard deviation calculated based on triplicate experiments. CE1: glucose, CE2: cellobiose, CE3: cellotriose, CE4: cellotetraose, CE5: cellopentaose, CE6: cellohexaose, M1: mannose, M2: mannobiose, M3: mannotriose, M4: mannotetraose, M5: mannopentaose, M6: mannohexaose

MrMnP also degraded lichenan but was different from CMC (Fig. 3b). MrMnP itself shocked us by producing 0.85 mM of reducing sugar from lichenan with a conversion yield of 30.6 mg/g. The control group containing the same amount of BSA did not detect any reducing sugar, suggesting that this resulted from MrMnP rather than the self-degradation of lichenan. After adding MnSO4, the increment of reducing sugar in the experimental and control groups was similar (0.11 and 0.14 mM, respectively). Similarly, adding H2O2 and MnSO4 simultaneously increased the reducing sugar by 0.41 mM in the experimental group and 0.40 mM in the control group, respectively. The HPAEC-PAD result showed that the degradation product by MrMnP contained 0.01 mM CE3, 0.02 mM CE4, and 0.08 mM CE6 (Fig. 3c), a total of 0.11 mM, indicating that the polymerization degree of the product is very high, which is not detected by HPAEC-PAD. Overall, these results suggest that MnP decomposed lichenan independently of Mn2+ and H2O2, which differs from CMC's.

MrMnP catalyzes the degradation of hemicellulose

To examine whether MrMnP can catalyze hemicellulose decomposition, xylan and mannan, two important hemicellulose components, were used as hemicellulosic substrates. Although the amount of substrate was reduced, no reducing sugar was detected in the reaction products. Interestingly, when the concentration of MrMnP was adjusted from 2.5 mg/mL to 25 μg/mL, it produced 0.33 μM M1, 4.08 μM M3, and 4.35 μM M5 in 24 h from mannohexaose with H2O2 and MnSO4 (Fig. 3d). A possible explanation for this might be that high concentrations of MrMnP have higher oxidation activity, which may directly oxidize substrates into other non-reducing sugar products. MrMnP could not decompose xylan; on the one hand, it might be because it had very low xylanase activity as PcMnP reported by Min et al. [37]; on the other hand, it might be because the reaction condition was not suitable as Min et al. found that the optimal temperature and pH for xylan decompose by PcMnP was different from that of Mn2+ oxidation [37]. Since the hydrolysis products can only be formed by adding H2O2 and MnSO4, MrMnP may degrade mannohexaose and CMC similarly.

MrMnP catalyzes the degradation of the raw material substrate

Given the ability of (hemi)cellulose degradation, we evaluated whether MrMnP can decompose LCB using the raw material wheat bran and locust bean gum as substrates. In the presence of MnSO4 and H2O2, 1.51 and 0.82 mM of reducing sugars were released from wheat bran and locust bean gum after treatment with MrMnP at 37 °C for 24 h, respectively. The reducing sugar conversion yield from wheat bran and locust bean was 54.4 mg/g and 29.5 mg/g, respectively. The degradation products were further analyzed using UHPLC–HRMS in negative ion mode. In the wheat bran degradation product, peaks with mass-to-charge ratio (m/z) of 340.94 and 342.96 were visible, and this substance may be a disaccharide composed of two hexose units. To further determine the structure of this substance, fragment patterns were further analyzed. As shown in Fig. 4a, the fragment ions C1 (m/z, 179.05) and Z1 (m/z, 161.04) combined precisely to form intact disaccharides. The degradation products of locust bean gum also contain disaccharides. Moreover, trisaccharide was also present. The fragment ions C1 (m/z, 179.05), C2 (m/z, 341.11), Z1 (m/z, 161.04), and Z2 (m/z, 323.09) are the characteristic fragments of trisaccharide (Fig. 4b). These results indicated that MrMnP could hydrolyze raw material substrates to reducing sugars. As MrMnP has cellulolytic, hemicellulolytic, and delignification activities, it has excellent potential for SPS of lignocellulosic biomass in biorefinery.

Mass spectra of the degradation products from wheat bran and locust bean gum. a Disaccharide released from wheat bran and locust bean gum (0.5% (m/V)). b Trisaccharide released from locust bean gum (0.5% (m/V)). The reaction was conducted in 50 mM malonate buffer (pH 5) containing 2.5 mg MrMnP, 1.0 mM MnSO4, and 0.1 mM H2O2 at 37 °C for 24 h

Proposed catalytic mechanism

The detection of monosaccharides and oligosaccharides in the CMC, lichen, and mannohexaose degraded products formed by MrMnP suggested that MrMnP has cellulolytic and hemicellulolytic activity, which is different from LPMO catalyzing oxidative cleavage of glycosidic bonds [19, 38]. H2O2 and Mn2+ were required for the degradation of CMC and mannohexaose, as well as lignin. In addition, MnP from P. chrysosporium was found to release peroxidized glucose and glucose from cellobiose [37]. Thus, we proposed that the catalytic mechanism underlying MrMnP decomposed CMC and mannohexaose is the normal peroxidase catalytic cycle [35], wherein the native MnP is oxidized by H2O2 in a two-electron transfer step to form reactive intermediate MnP Compound I (Fe4+ oxo-porphyrin radical cation), and the native MnP is recovered through reducing the compound I with Mn2+ in two single one-electron transfer steps with the intermediate formation of MnP Compound II. The generated Mn3+, chelated with an organic acid such as malonate, then degraded CMC and mannohexaose into reducing sugars (Fig. 5).

However, the degradation of lichen polysaccharides catalyzed by MrMnP was independent of H2O2 and Mn2+, completely different from ordinary MnP's mechanism. MrMnP was regarded as a short MnP due to its 343 amino acid length and ability to oxidize low redox potential [28, 39]. The short MnPs are capable of directly oxidizing low-redox-potential compounds such as phenols, amines, and small dye compounds, without Mn2+, through an additional active site containing an exposed heme edge to indirect contact with the δ-position of the porphyrin macrocycle by compound I and II [40]. Furthermore, it has been reported that MnP can oxidize the organic acid to stimulate MnP activity without H2O2 [41, 42]. Thus, we proposed that MrMnP can directly oxidize malonate to hydroperoxyl acetic acid radical (COOH–CH2OO.), which is transformed to a hydroperoxide (COOH–CH2OOH) using by MrMnP to form compound I [42]. The MrMnP compound I then attack the glucosidic bond of lichenan. To further elucidate the proposed mechanism experimentally, isotope-labeling experiments are required in future studies.

Conclusion

As cost-effective pretreatment and saccharification are vital steps for the LCB convention, a multifunctional enzyme that can function in both pretreatment and saccharification phases will significantly improve the efficiency of lignocellulosic-based biorefinery. In this study, we report MrMnP's unknown cellulolytic and hemicellulolytic activity. Being a lignin-degrading enzyme, MnP can hydrolyze CMC, Mannohexaose, and lichenan to reducing sugars, suggesting its versatility in LCB decomposition. This was verified by decomposing locust bean gum and wheat bran into oligosaccharides such as di- and tri-saccharides. With its lignin degradation properties, MrMnP is a super enzyme with great potential for lignocellulosic degradation. It would contribute to forming an economic cellulolytic cocktail for producing sustainable and economically viable products from lignocellulose and the long-term development of biorefinery.

Materials and methods

Strains and chemicals

The P. pastoris X33 transformant bearing the MrMnP manganese peroxidase gene from Moniliophthora roreri (GenBank accession number: ESK95360.1) was constructed by our lab [29], and this construct was used for MrMnP production. The substrates carboxymethyl cellulose (CMC), locust bean gum, 2,2’-azinobis(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS), 2,6-dimethylphenol (2,6-DMP), and the standard substances glucose (CE1), cellobiose (CE2) and mannose (M1) were purchased from Sigma-Aldrich (St. Louis, MO). The substrates lichenan, mannohexaose, and the standard substances cellotriose (CE3), cellotetraose (CE4), cellopentaose (CE5), cellohexaose (CE6), mannobiose (M2), mannotriose (M3), mannotetraose (M4), mannopentaose (M5) and mannohexaose (M6) were purchased from Megazyme (Bray, Wicklow, Ireland). The other chemicals used in this research are of analytical grade and commercially available.

Enzyme expression and purification

MrMnP was produced in a 6-L fed-batch fermentation process as described before [29]. The fermentation supernatant, which was concentrated by a 10-kDa ultrafiltration membrane, was purified using a HiTrapTM Phenyl HP FPLC column (GE Healthcare, Uppsala, Sweden), followed by a RESOURCETM Q (6 mL) FPLC column (GE Healthcare) as described previously [43]. The enzyme concentration was determined by the Bradford assay. The purified MrMnp were analyzed by sodium dodecyl sulfate–polyacrylamide gel electrophoresis (SDS-PAGE) using a 12% polyacrylamide gel and scanned by UV–visible absorption spectrum with a microplate reader in the wavelength range of 250 − 700 nm. The protein purity was evaluated by calculating the RZ value, where RZ = A407/A280.

Biochemical characterization

MrMnP activity was determined spectrophotometrically by monitoring the oxidation of 1.0 mM ABTS (ϵ420 = 36,000 /M/cm), 2,6-DMP (ϵ468 = 49,600 /M/cm), and MnSO4 (ϵ270 = 11,590 /M/cm) at 420, 468, and 270 nm, respectively, using UV Vis spectrophotometer (Hitachi, model 8543). Reactions were performed in 200 μL of 50 mM malonate buffer containing 5 μg/mL MrMnP and 1 mM MnSO4. The Reactions were initiated by the addition of 0.1 mM H2O2. The data were recorded every 30 s for 3 min at 30 °C. One unit (U) of enzyme activity was defined as the amount of enzyme oxidizing 1 μmol substrate or producing 1 μmol oxidation product per minute under the assay conditions. Optimum conditions for oxidation of ABTS and MnSO4 were determined. To determine optimum pH and H2O2 concentration, 50 mM malonate buffer (pH 3.0 − pH 7.0) and H2O2 (0.01 − 2 mM) were used. To determine the buffer, the pH and H2O2 concentration are maintained at the determined optimum.

Enzymatic hydrolysis of (hemi)cellulosic substrates and raw material substrate

To investigate the (hemi)cellulosic decomposing ability of MrMnP, various (hemi)cellulosic substrates (5.0 g/L of CMC, lichenan, and 1.0 g/L of mannohexaose) were reacted with 2.5 mg MrMnP in 1 mL malonate buffer (50 mM, pH 5) containing 1.0 mM MnSO4, and 0.1 mM H2O2 at 37 °C for 24 h, respectively. To investigate the lignocellulose decomposing ability of MrMnP, the locust bean gum and sulfuric acid pretreated (2% H2SO4, 121 °C, 1 h, the ratio of straw to liquid 10%) wheat bran were used as raw material substrate. The reaction system and condition were consistent with (hemi)cellulose substrates. The BSA was served as the control.

Hydrolysates analysis

The total reducing sugar liberated from enzymatic hydrolysis was measured using the 3,5-dinitrosalicylic acid (DNS) assay [44] with glucose as the standard. The hydrolysates of (hemi)cellulosic substrates were separated and quantified using high-performance anion-exchange chromatography with pulsed amperometric detection (HPAEC-PAD; ThermoFisher, Sunnyvale, CA) equipped with a CarboPac™ PA-100 (4 mm × 250 mm) column. A multi-step gradient was performed to analyze the hydrolysates of CMC and lichenan using the previous method [45]. The substances CE1, CE2, CE3, CE4, CE5, and CE6 were used as the standards. To analyze the hydrolysates of mannohexaose, the eluents were deionized water (eluent A) and 0.1 M sodium hydroxide (eluent B) at a flow rate of 0.45 mL/min, using the multi-step procedure as follows: 0–4 min, isocratic, 20% B; 4–5 min, linear, 20%–100% B; 5–25 min, isocratic, 100% B; 25–28 min, linear, 100%–20% B; and 28–31 min, isocratic, 20% B. The substances M1, M2, M3, M4, M5, and M6 were used as the standards. The hydrolysates of raw material substrate were analyzed by ultra-high-performance liquid chromatography–high-resolution mass spectrometry (UHPLC–HRMS; TripleTOF™ 5600 + , AB SCIEX, USA) with Poroshell 120 EC-C8 (100 mm × 4.6 mm, 4 μm, Agilent) as described previously [45].

Availability of data and materials

All data generated or analyzed during this study are included in this manuscript.

Abbreviations

- LCB:

-

Lignocellulosic biomass

- SPS:

-

Simultaneous biological pretreatment and saccharification process

- LPMOs:

-

Lytic polysaccharide monooxygenases

- CMC:

-

Carboxymethyl cellulose

- ABTS:

-

2,2’-Azinobis(3-ethylbenzothiazoline-6-sulfonic acid)

- 2,6-DMP:

-

2,6-Dimethylphenol

- CE1:

-

Glucose

- CE2:

-

Cellobiose

- CE3:

-

Cellotriose

- CE4:

-

Cellotetraose

- CE5:

-

Cellopentaose

- CE6:

-

Cellohexaose

- M1:

-

Mannose

- M2:

-

Mannobiose

- M3:

-

Mannotriose

- M4:

-

Mannotetraose

- M5:

-

Mannopentaose

- M6:

-

Mannohexaose

- SDS-PAGE:

-

Sodium dodecyl sulfate–polyacrylamide gel electrophoresis

- DNS:

-

3,5-Dinitrosalicylic acid

- HPAEC-PAD:

-

High-performance anion-exchange chromatography with pulsed amperometric detection

- UHPLC–HRMS:

-

Ultra-high-performance liquid chromatography–high-resolution mass spectrometry

References

Raj T, Chandrasekhar K, Naresh Kumar A, Rajesh Banu J, Yoon J-J, Kant Bhatia S, et al. Recent advances in commercial biorefineries for lignocellulosic ethanol production: current status, challenges and future perspectives. Bioresour Technol. 2022;344:126292. https://doi.org/10.1016/j.biortech.2021.126292.

Singh N, Singhania RR, Nigam PS, Dong CD, Patel AK, Puri M. Global status of lignocellulosic biorefinery: challenges and perspectives. Bioresour Technol. 2022;344:126415. https://doi.org/10.1016/j.biortech.2021.126415.

Saini R, Osorio-Gonzalez CS, Hegde K, Brar SK, Magdouli S, Vezina P, Avalos-Ramirez A. Lignocellulosic biomass-based biorefinery: an insight into commercialization and economic standout. Curr Sustain Renew Energy Rep. 2020;7:122–36. https://doi.org/10.1007/s40518-020-00157-1.

Velvizhi G, Goswami C, Shetti NP, Ahmad E, Kishore Pant K, Aminabhavi TM. Valorisation of lignocellulosic biomass to value-added products: paving the pathway towards low-carbon footprint. Fuel. 2022;313:122678. https://doi.org/10.1016/j.fuel.2021.122678.

Zoghlami A, Paës G. Lignocellulosic biomass: understanding recalcitrance and predicting hydrolysis. Front Chem. 2019;7:874. https://doi.org/10.3389/fchem.2019.00874.

Zhao L, Sun ZF, Zhang CC, Nan J, Ren NQ, Lee DJ, Chen C. Advances in pretreatment of lignocellulosic biomass for bioenergy production: Challenges and perspectives. Bioresour Technol. 2022;343:126123. https://doi.org/10.1016/j.biortech.2021.126123.

Ahmed SF, Mofijur M, Chowdhury SN, Nahrin M, Rafa N, Chowdhury AT, et al. Pathways of lignocellulosic biomass deconstruction for biofuel and value-added products production. Fuel (Lond). 2022;318:123618. https://doi.org/10.1016/j.fuel.2022.123618.

Adsul M, Sandhu SK, Singhania RR, Gupta R, Puri SK, Mathur A. Designing a cellulolytic enzyme cocktail for the efficient and economical conversion of lignocellulosic biomass to biofuels. Enzyme Microb Technol. 2020;133:109442. https://doi.org/10.1016/j.enzmictec.2019.109442.

Masran R, Zanirun Z, Bahrin EK, Ibrahim MF, Lai Yee P, Abd-Aziz S. Harnessing the potential of ligninolytic enzymes for lignocellulosic biomass pretreatment. Appl Microbiol Biotechnol. 2016;100:5231–46. https://doi.org/10.1007/s00253-016-7545-1.

Rathankumar AK, Ravindran S, Saikia K, Arvind V, Batista-Garcia RA, Folch-Mallol JL, Kumar VV. Simultaneous pretreatment and saccharification process for fermentable sugars production from Casuarina equisetifolia biomass using transgenic Trichoderma atroviride. J Air Waste Manag Assoc. 2020;70:1244–51. https://doi.org/10.1080/10962247.2020.1749730.

Dhiman SS, Haw J-R, Kalyani D, Kalia VC, Kang YC, Lee J-K. Simultaneous pretreatment and saccharification: green technology for enhanced sugar yields from biomass using a fungal consortium. Bioresour Technol. 2015;179:50–7. https://doi.org/10.1016/j.biortech.2014.11.059.

Masran R, Bahrin EK, Ibrahim MF, Phang L-Y, Abd-Aziz S. Simultaneous pretreatment and saccharification of oil palm empty fruit bunch using laccase-cellulase cocktail. Biocatal Agric Biotechnol. 2020;29:101824. https://doi.org/10.1016/j.bcab.2020.101824.

Terasawat A, Phoolphundh S. Simultaneous biological pretreatment and saccharification of rice straw by ligninolytic enzymes from Panus neostrigosus I9 and commercial cellulase. J Fungi (Basel). 2021. https://doi.org/10.3390/jof7100853.

Kumar S, Gujjala LK, Banerjee R. Simultaneous pretreatment and saccharification of bamboo for biobutanol production. Ind Crops Prod. 2017;101:21–8. https://doi.org/10.1016/j.indcrop.2017.02.028.

Kumar S, Banerjee R. Enzymatic delignification and saccharification of Bambusa bambos for biobutanol production. Ind Crops Prod. 2018;125:386–94. https://doi.org/10.1016/j.indcrop.2018.09.015.

Rani Singhania R, Dixit P, Kumar Patel A, Shekher Giri B, Kuo CH, Chen CW, Di Dong C. Role and significance of lytic polysaccharide monooxygenases (LPMOs) in lignocellulose deconstruction. Bioresour Technol. 2021;335:125261. https://doi.org/10.1016/j.biortech.2021.125261.

Vandhana TM, Reyre JL, Sushmaa D, Berrin JG, Bissaro B, Madhuprakash J. On the expansion of biological functions of lytic polysaccharide monooxygenases. New Phytol. 2022;233:2380–96. https://doi.org/10.1111/nph.17921.

Johansen KS. Lytic polysaccharide monooxygenases: the microbial power tool for lignocellulose degradation. Trends Plant Sci. 2016;21:926–36. https://doi.org/10.1016/j.tplants.2016.07.012.

Forsberg Z, Sørlie M, Petrović D, Courtade G, Aachmann FL, Vaaje-Kolstad G, et al. Polysaccharide degradation by lytic polysaccharide monooxygenases. Curr Opin Struct Biol. 2019;59:54–64. https://doi.org/10.1016/j.sbi.2019.02.015.

Yao M, Li W, Duan Z, Zhang Y, Jia R. Genome sequence of the white-rot fungus Irpex lacteus F17, a type strain of lignin degrader fungus. Stand Genomic Sci. 2017;12:55. https://doi.org/10.1186/s40793-017-0267-x.

Qin X, Sun X, Huang H, Bai Y, Wang Y, Luo H, et al. Oxidation of a non-phenolic lignin model compound by two Irpex lacteus manganese peroxidases: evidence for implication of carboxylate and radicals. Biotechnol Biofuels. 2017;10:103. https://doi.org/10.1186/s13068-017-0787-z.

Yang S, Yang J, Wang T, Li L, Yu S, Jia R, Chen P. Construction of a combined enzyme system of graphene oxide and manganese peroxidase for efficient oxidation of aromatic compounds. Nanoscale. 2020;12:7976–85. https://doi.org/10.1039/d0nr00408a.

Baborová P, Möder M, Baldrian P, Cajthamlová K, Cajthaml T. Purification of a new manganese peroxidase of the white-rot fungus Irpex lacteus, and degradation of polycyclic aromatic hydrocarbons by the enzyme. Res Microbiol. 2006;157:248–53. https://doi.org/10.1016/j.resmic.2005.09.001.

Thampraphaphon B, Phosri C, Pisutpaisal N, Thamvithayakorn P, Chotelersak K, Sarp S, Suwannasai N. High potential decolourisation of textile dyes from wastewater by manganese peroxidase production of newly immobilised Trametes hirsuta PW17-41 and FTIR analysis. Microorganisms. 2022. https://doi.org/10.3390/microorganisms10050992.

Lumbaque EC, Dallegrave A, Baldassari LL, Lüdtke DS, Bussamara R, Sirtori C, Yuan Q. Degradation of imatinib mesylate by manganese peroxidase (MnP): Optimization, identification of transformation products, pathway proposal and in silico predictions. J Environ Chem Eng. 2021;9:106246. https://doi.org/10.1016/j.jece.2021.106246.

Kumar A, Arora PK. Biotechnological applications of manganese peroxidases for sustainable management. Front Environ Sci. 2022. https://doi.org/10.3389/fenvs.2022.875157.

Bilal M, Zdarta J, Jesionowski T, Iqbal HMN. Manganese peroxidases as robust biocatalytic tool—an overview of sources, immobilization, and biotechnological applications. Int J Biol Macromol. 2023. https://doi.org/10.1016/j.ijbiomac.2023.123531.

Bronikowski A, Koschorreck K, Urlacher VB. Redesign of a new manganese peroxidase highly expressed in Pichia pastoris towards a lignin-degrading versatile peroxidase. ChemBioChem. 2018;19:2481–9. https://doi.org/10.1002/cbic.201800500.

Wang S, Wang X, Penttinen L, Luo H, Zhang Y, Liu B, et al. Patulin detoxification by recombinant manganese peroxidase from Moniliophthora roreri expressed by Pichia pastoris. Toxins (Basel). 2022. https://doi.org/10.3390/toxins14070440.

Chan JC, Paice M, Zhang X. Enzymatic oxidation of lignin: challenges and barriers toward practical applications. ChemCatChem. 2020;12:401–25. https://doi.org/10.1002/cctc.201901480.

López C, García-Monteagudo JC, Moreira MT, Feijoo G, Lema JM. Is the presence of dicarboxylic acids required in the MnP cycle? Enzyme Microb Technol. 2007;42:70–5. https://doi.org/10.1016/j.enzmictec.2007.08.002.

Chowdhary P, Shukla G, Raj G, Ferreira LFR, Bharagava RN. Microbial manganese peroxidase: a ligninolytic enzyme and its ample opportunities in research. SN Appl Sci. 2019;1:1–12. https://doi.org/10.1007/s42452-018-0046-3.

Wariishi H, Valli K, Gold MH. Manganese(II) oxidation by manganese peroxidase from the basidiomycete Phanerochaete chrysosporium. Kinetic mechanism and role of chelators. J Biol Chem. 1992;267:23688–95. https://doi.org/10.1016/S0021-9258(18)35893-9.

Deguchi T, Matsubara M, Nishida T. NADH oxidation by manganese peroxidase with or without alpha-hydroxy acid. Biosci Biotechnol Biochem. 2002;66:717–21. https://doi.org/10.1271/bbb.66.717.

Kumar A, Chandra R. Ligninolytic enzymes and its mechanisms for degradation of lignocellulosic waste in environment. Heliyon. 2020;6:e03170. https://doi.org/10.1016/j.heliyon.2020.e03170.

Valle-Altamirano RG, Baratto MC, Badillo-Ramírez I, Gasteazoro F, Pogni R, Saniger JM, Valderrama B. Identification of Fe(III)–OH species as a catalytic intermediate in plant peroxidases at high H2O2 concentration. New J Chem. 2022;46:4579–86. https://doi.org/10.1039/D1NJ04837F.

Min K, Kim YH, Kim J, Kim Y, Gong G, Um Y. Effect of manganese peroxidase on the decomposition of cellulosic components: Direct cellulolytic activity and synergistic effect with cellulase. Bioresour Technol. 2022;343:126138. https://doi.org/10.1016/j.biortech.2021.126138.

Moon M, Lee JP, Park GW, Lee JS, Park HJ, Min K. Lytic polysaccharide monooxygenase (LPMO)-derived saccharification of lignocellulosic biomass. Bioresour Technol. 2022;359:127501. https://doi.org/10.1016/j.biortech.2022.127501.

Fernández-Fueyo E, Acebes S, Ruiz-Dueñas FJ, Martínez MJ, Romero A, Medrano FJ, et al. Structural implications of the C-terminal tail in the catalytic and stability properties of manganese peroxidases from ligninolytic fungi. Acta Crystallogr D Biol Crystallogr. 2014;70:3253–65. https://doi.org/10.1107/S1399004714022755.

Knop D, Yarden O, Hadar Y. The ligninolytic peroxidases in the genus Pleurotus: divergence in activities, expression, and potential applications. Appl Microbiol Biotechnol. 2015;99:1025–38. https://doi.org/10.1007/s00253-014-6256-8.

Urzúa U, Kersten PJ, Vicuña R. Manganese peroxidase-dependent oxidation of glyoxylic and oxalic acids synthesized by Ceriporiopsis subvermispora produces extracellular hydrogen peroxide. Appl Environ Microbiol. 1998;64:68–73. https://doi.org/10.1128/AEM.64.1.68-73.1998.

Hofrichter M, Ziegenhagen D, Vares T, Friedrich M, Jäger MG, Fritsche W, Hatakka A. Oxidative decomposition of malonic acid as basis for the action of manganese peroxidase in the absence of hydrogen peroxide. FEBS Lett. 1998;434:362–6. https://doi.org/10.1016/S0014-5793(98)01023-0.

Ding S, Liu X, Hakulinen N, Taherzadeh MJ, Wang Y, Wang Y, et al. Boosting enzymatic degradation of cellulose using a fungal expansin: Structural insight into the pretreatment mechanism. Bioresour Technol. 2022;358:127434. https://doi.org/10.1016/j.biortech.2022.127434.

Miller GL. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem. 1959;31:426–8. https://doi.org/10.1021/ac60147a030.

Wang S, Ding S, Meng K, Liu X, Wang Y, Wang X, et al. Preparation of methyl-esterified pectin oligosaccharides with antibacterial activity using fungus-derived bifunctional pectinase. J Clean Prod. 2022;333:130110. https://doi.org/10.1016/j.jclepro.2021.130110.

Acknowledgements

Not applicable.

Funding

The authors are grateful to the National Key Research and Development Program of China (2021YFC2102400, 2021YFC2103002), the State Key Laboratory of Animal Nutrition Project (2004DA125184G2101), and the China Agriculture Research System of MOF and MARA (CARS-41).

Author information

Authors and Affiliations

Contributions

XL and SD contributed equally to this work. XL and TT conceived the research and interpreted the data. XL and SD conducted experiments and wrote the manuscript. FG purified the protein. TT and MJ revised the manuscript. HL and TT supervised the project. YW, YW, XQ and XW were involved in formal analysis. BY, HH and TT received the funding. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Liu, X., Ding, S., Gao, F. et al. Exploring the cellulolytic and hemicellulolytic activities of manganese peroxidase for lignocellulose deconstruction. Biotechnol Biofuels 16, 139 (2023). https://doi.org/10.1186/s13068-023-02386-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13068-023-02386-0