Abstract

Recently, green analytical chemistry (GAC) is a key issue towards the idea of sustainability, the analytical community is focused on developing analytical methods that incorporate green chemistry principles to minimize adverse impacts on the environment and humans. Herein, we present 2 sustainable, selective, and validated chromatographic methods. Initially, lidocaine hydrochloride (LDC) and miconazole nitrate (MIC) with two preservatives; methyl paraben (MTP) and saccharin sodium (SAC) were chromatographed via TLC–densitometric method which employed ethyl acetate: methanol: formic acid (9:1:0.1, by volume) as the mobile phase with UV detection at 220.0 nm, good correlation was obtained in the range of 0.3–3.0 µg/band for MIC and LDC. Following that, RP-HPLC was successfully applied for separating quinary mixture of LDC, MIC, MTP, SAC along with LDC impurity; dimethyl aniline (DMA) using C18 column, and a gradient green mobile phase composed of methanol and phosphate buffer (pH 6.0) in different ratios with a flow rate 1.5 mL/min and UV detection at 210.0 nm, linearity ranges from 1.00 to 100.00 µg/mL for MIC, 2.00–100.00 µg/mL for LDC and 1.00–-20.00 µg/mL for MTP and DMA. No records to date regarding the determination of the two drugs, besides MTP and DMA. The proposed methods were validated according to the ICH guidelines and applied successfully to the analysis of the compounds. The methods' results were statistically compared to those obtained by applying the reported one, indicating no significant difference regarding both accuracy and precision. The methods' greenness profiles have been assessed and compared with those of the reported method using different assessment tools.

Graphical Abstract

Similar content being viewed by others

Introduction

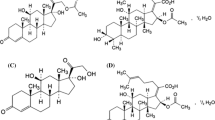

Lidocaine hydrochloride (LDC) is chemically designed as 2-(diethyl amino)-N-(2,6-dimethylphenyl) acetamide hydrochloride, Fig. 1a, it is a local anesthetic, LDC combination can be directly applied to the skin and mucous membranes to make the area numb via suppressing the inward Na.+current upon depolarization at the sodium ionophore, which inhibits the axonal action potential propagation, it usually begins functioning within a few minutes and lasts for 30 min to three hours when used for local anaesthesia or in nerve blocks [1, 2]. It is on the WHO list of essential medicines [3] Miconazole nitrate (MIC) is 1-[(2RS)-2-[(2,4-dichlorobenzyl) oxy]-2-(2,4-dichlorophenyl) ethyl)]-1H-imidazole nitrate, Fig. 1b, MIC is an imidazole antifungal, it’s one of the most extensively utilized azoles on the market [1]. MIC has dual mechanisms of actions, the first mechanism involves the suppression of ergosterol production and the other one includes the inhibition of peroxidases, which results in a buildup of peroxide inside the cell and eventually causes cell death [4]. Its combination with LDC, is marketed as antifungal oral gel used for treatment of candidal infection of the gastrointestinal tract and the oropharyngeal cavity [5]

Methyl paraben (MTP) is methyl 4-hydroxybenzoate, Fig. 1c. Parabens are utilized extensively in a variety of industries, as preservatives and antimicrobial agents [6, 7]. Parabens are effective substances, but their widespread use is under debate among a number of organizations and the scientific community due to their reputation of being harmful to several aquatic creatures, in addition, these substances have a number of health concerns, because of the endocrine disrupting impact, including breast cancer and reproductive system issues, added to some publications claim that they are carcinogenic substances as they can exhibit estrogenic and antiandrogenic activity, these molecules have been linked to cancers, specifically breast tumors and male infertility [8]. Parabens also showed the ability to be passed from mother to child via trans placental transmission, the impact of prenatal paraben exposure on thyroid function in newborns and birth weight has been studied and also, several research studies have suggested that parabens are to blame for persistent urticaria or angioedema, as a result, parabens are now being considered a possible health danger [9]. This type of emergent chemical is becoming more prevalent in ecosystems causing harm to the environment, wildlife, and even people. The presence of this sort of chemical in ecosystems is increasing the environment, animals, and even humans [10]. Thus, antimicrobial preservatives as parabens in medical products need to be justified and they must be controlled during the analysis and batch release and there are acceptance criteria that have to be fulfilled. MTP is utilized in oral preparations at concentrations ranging from 0.015 to 0.2% [9].

Saccharin sodium (SAC) chemically named as 2H-1λ6,2-benzothiazol-1,1,3-trione (SAC), Fig. 1d, SAC is a pharmacologically inactive substance, it is used as a non-nutritive sweetener in oral pharmaceutical formulations, separation of SAC was crucial, as it’s extracted with the active ingredients in the oral gel. Dimethylaniline (DMA) the major impurity of LDC chemically named as N, N-Dimethylaniline, Fig. 1e, it is a pharmacologically inactive metabolite, regarded as a major degradation product of LDC [1], Hence, it is crucial to be identified in pharmaceutical formulations, as it is absorbed through the mucosa of the mouth and the skin affecting organs such as the kidneys, liver, and heart [11]. The BP claimed that the impurity limit was 0.01 percent [1]

A review of the literature in hand revealed a number of approaches which were applied to determine the studied drugs separately or combined with other compounds using various analytical techniques. For LDC determination either alone or in combination with other drugs chromatographic [12, 13] capillary electrophoretic [14] and spectrophotometric [15, 16] have been reported, in addition, for the estimation of LDC with DMA, spectrophotometric [17] voltammetric, [18] and electrochemical approaches [19] approaches have been published. MIC was determined individually or combined with other compounds by stability indicating High Performance Thin Layer Chromatography (HPTLC) [20, 21], High Performance Liquid Chromatography (HPLC), Chemometrics-assisted UV spectrophotometry [22, 23] and voltammetry [24] On the other hand, for the determination of MTP, stability indicating- HPTLC [25], electrochemical [26] and spectrophotometric [27] methods have been published, besides for SAC determination HPLC [28, 29] methods have been reported. According to what we know, there was only one reported method, which is HPLC–DAD for the determination of LDC and MIC in their co-formulated gel dosage form [30].

After reviewing the literature, no records so far for the separation and the determination of the binary mixture of LDC and MIC along with MTP and DMA in presence of SAC.

Green analytical chemistry (GAC) is a novel approach that emerged in 2000s [31]. This emerging discipline is concerned with establishing analytical processes that limit the use of harsh chemicals or reagents while also increasing analyst and environmental safety [32,33,34]. Significant advancements in methodological tools have been developed in latest years to minimize the negative impacts of analytical methods [35, 36]. Following GAC's principles and recommendations is essential to achieving balance between attaining maximum results and minimizing the environmental issues related with analytical methodologies [37]. The word SIGNIFICANCE represents the GAC principles [31]:

The approaches for evaluating an analytical method's greenness should be dependable assessment tool. A tool like this should be evaluated, assessed, and used as the primary parameter for building a green analytical approach [37]. These include, for example, National Environmental Methods Index (NEMI), this is regarded as the most traditional form of evaluation [38], Green Analytical Procedure Index (GAPI) [39] and the recently established “Analytical Greenness metric” (AGREE)[40,41,42].

Hence, In the current work, authors target to develop green, simple, and rapid TLC method for determination of LDC and MIC, which has the advantages of being accurate, selective, and quick for routine quantitative analysis, also it minimizes sample preparations, laboratories consumption and cost materials [43, 44], it is commonly utilized in the pharmaceutical industry's research and quality-control labs [45]. Considering that it was necessary to identify and quantify the hazardous impurity related to LDC that might be present in the stated combination and also the endocrine disruptor MTP, RP-HPLC method was a step forward as it managed to separate and determine LDC, MIC, and MTP in their gel formulation along with DMA in presence of SAC with greater precision, accuracy, and sensitivity.

Experimental

Instrumentation

TLC method

CAMAG TLC Scanner model 3S/N 1302139 operated with winCATS software (CAMAG, Switzerland) was used for scanning, CAMAG TLC autosampler Linomat (CAMAG, Muttenz, Switzerland) with a 100.0 µL microsyringe. Aluminum TLC plates precoated with 0.25 mm silica gel with florescent indicator F254 size 20 × 20 cm (Merck, Germany),

RP-HPLC method

An HPLC system (model 1260 infinity series; Agilent, Germany) consists of an Agilent quaternary pump (model G1311C, serial No. DEAB816766) with different flow rates, equipped with a photodiode array detector (model G1315D, Agilent, Germany, serial No. DEAAX06967) and a manual injector (model G1328C, serial No. DEABG03628) with 20-µL injection loop, and the system is operated by Agilent ChemStation software. Waters X Select® CSHTMC18 column (250 mm × 4.6 mm I.D, particle size 5 µm) was used as stationary phase. A Soniclean 160 T sonicator (Soniclean, Thebarton, Australia) was used for extraction of drugs from pharmaceutical dosage form. pH-meter (Jenway model 3505, UK) was also used.

Materials and reagents

Pure standards

Miconazole, methyl paraben, lidocaine, and saccharin their purities were certified to be 99.5%, 98%, 99.9%, and 98% respectively, were kindly provided by Amriya Pharmaceutical Industries (Alexandria, Egypt). 2, 6-Dimethylaniline was supplied by Sigma-Aldrich (Egypt), with a purity of 99.9%.

Pharmaceutical formulation

Micoban® oral gel (25 mg/6.6 mg), batch no 5875003, labelled to contain 2.5% (w/w) MIC and 0.66% (w/w) LDC per gram, as well as the inactive ingredients: MTP and SAC, manufactured by Amriya Pharmaceutical Industries, Alexandria, Egypt and obtained from the local Egyptian market.

Chemicals and reagents

The chemicals utilized were of analytical reagent grade, and the solvents used were of an HPLC grade; Methanol, sodium hydroxide (Sigma Aldrich, Darmstadt, Germany), potassium dihydrogen phosphate (E. Merck, Darmstadt, Germany), ethyl acetate, formic acid (El-Nasr Pharmaceutical Chemicals Co., Cairo, Egypt) and double distilled deionized water (Otsuka, Cairo, Egypt). Phosphate buffer solution pH 6.0 (made by dissolving 2.72 g of potassium dihydrogen phosphate in 1 L of double distilled deionized water, its pH was adjusted with 10% sodium hydroxide to pH 6.0) [1].

Stock standard solutions

TLC method

Stock standard solutions for LDC, MIC, MTP and SAC were prepared in methanol, by accurately weighing and transferring 10.0 mg of each standard into a 10-mL volumetric flask to attain 1.0 mg/mL final concentrations for each drug individually.

RP-HPLC method

Stock standard solutions for LDC, MIC, MTP, DMA and SAC were prepared, each at a concentration of 1.0 mg/mL in methanol, by accurately weighing and transferring 25.0 mg of each of the pure standards to 25-mL volumetric flask. Working standard solutions (100.00 µg/mL) were prepared by transferring 10.0 mL of stock standard solution separately into 100- mL volumetric flasks and completing to the mark with methanol.

Procedures

Chromatographic conditions

TLC method

Samples were individually applied in triplicates as bands onto TLC plates, the band length was 3.0 mm. The bands were placed 15 mm from the plate's bottom edge and at intervals of 10 mm. The chromatographic chamber was previously saturated with the developing system [ethyl acetate: methanol: 0.1% formic acid (9:1:0.1, by volume] for about 30 min at room temperature. After then, the plates were developed by ascending chromatography (for 7.5 cm). The plates were air dried after development, then they were scanned at 220.0 nm.

RP-HPLC method

Using a gradient mobile phase of methanol (A) and phosphate buffer pH 6.0 (B), which was ultrasonically degassed before injection, the separation was accomplished in the following manner: starting at (80:20, v/v) for 2 min, ramping up to (90:10, v/v) for the following 2 min, this ratio was kept till the end of the run and 3 min of reconditioning was applied in between runs. We performed the chromatographic separation on Waters X Select® CSHTMC18 column (250 mm × 4.6 mm I.D, particle size 5 µm), the flow rate was 1.5 mL/min, and detection wavelength was 210.0 nm, both mobile phase and samples were filtered through 0.24 m filters. The injection volume was 20.0μL, all measurements were conducted at ambient temperature.

Construction of calibration curve

For TLC

Accurately measured aliquots of LDC, and MIC equivalent to (0.3–3.0 µg/band) for both drugs were transferred from their stock standard solutions (1.00 mg/mL) and applied onto three different TLC plates in the form of bands using with a 100.0 µL microsyringe. After the plates were developed using the previously mentioned optimized conditions, they were air dried, bands were visible at 254 nm under a UV lamp, and the chromatogram was scanned at 220.0 nm. Calibration curves illustrating the relation between the mean integrated peak area and the corresponding concentration of each of LDC, and MIC (0.3–3.0 µg/band), were plotted.

For HPLC

Different volumes equivalent to 1.00 –100.00 µg /mL for MIC, 2.00 –100.00 µg /mL for LDC and 1.00 -20.00 µg /mL for MTP and DMA, separately, were accurately transferred from their stock solutions into 10-mL measuring flasks, diluted to the mark with a solution of methanol–phosphate buffer pH 6.0 (50:50, v/v). In triplicate, a 20.0 µL of these solutions were injected into the column and chromatographed using the optimized conditions described earlier. The calibration curves were created by plotting the average area under the peak against the relevant concentration and then computing the regression equations.

Application to pharmaceutical formulation

Into a 50-mL beaker, a 1.0 g of the oral gel preparation was accurately weighed and sonicated for 15 min in methanol, filtered into 100-mL volumetric flask, and the volume is completed with methanol. For TLC method 10.0 μL was applied onto TLC plates. For RP-HPLC method 2.0 mL aliquots claimed to contain (50.00 µg/mL MIC and 13.20 µg/mL LDC) were transferred to 10-mL measuring flasks and completed with a solution of methanol–phosphate buffer pH 6.0 (50:50, v/v). The prepared solutions were chromatographed under the chromatographic conditions described above and the concentrations were calculated from the corresponding regression equations.

Results and discussion

A survey of the literature revealed that, the only reported method for determination of LDC and MIC in their gel dosage form is HPLC–DAD and there was no reported technique available for simultaneous MTP and DMA determination besides the two active ingredients LDC and MIC in laboratory mixture and dosage form. Initially, the development of the proposed TLC method is used for quantification the two drugs in presence of the two inactive ingredients: MTP, and SAC.

Given that the effect of parabens on people, animals, and ecosystems is a debatable issue and that DMA has negative health effects, there is an increasing need for DMA and MTP quantification. As a result, we present an eco-friendly, precise, sensitive, and gradient RP-HPLC technique to assess the opportunities presented by this separation technique for determination the toxic MTP and DMA besides LDC and MIC.

Methods Development and optimization

Optimization of the TLC method

Developing system

There have been attempts at various development systems with various ratios for the maximum separation of LDC, MIC, MTP and SAC. Initially, butanol: water: acetic acid (6:2:2, by volume) system was tried but analysis time was too long. Second, a good separation was accomplished using chloroform, ethyl acetate, and toluene (5:4:3, by volume), but still we search for a green system, hence another system composed of acetone: ethyl acetate (3:7, v/v) was tried and also, a satisfactory separation was obtained. Eventually in order to extend our search for terms of greenness, different ratios of methanol: ethyl acetate were attempted, and we concluded that ethyl acetate: methanol (9:1, v/v) was the best ratio, also we found that the pH of the system affects the resolution of the two bands of LDC and MIC, so formic acid is added. In conclusion [ethyl acetate: methanol: 0.1% formic acid (9:1:0.1, by volume] was the ideal developing system for the optimum separation with the maximum greenness.

Scanning wavelength

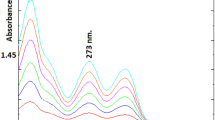

For attaining good sensitivity of LDC, MIC, MTP and SAC with minimal noise, three different wavelengths were tried (210.0, 220.0, and 230.0 nm). Satisfactory results were obtained by using the wavelength 220.0 nm which gave sharp and symmetrical peaks for the four drugs with high sensitivity and minimum noise as shown in, Fig. 2.

TLC Chromatogram of laboratory prepared mixture containing 0.50 µg/band SAC (Rf = 0.12 ± 0.01), 1.20 µg/band LDC (Rf = 0.30 ± 0.01), 1.00 µg/band MIC (Rf = 0.42 ± 0.01) and 0.50 µg/band MTP(Rf = 0.54 ± 0.01) using a mobile phase consisting of ethyl acetate: methanol: formic acid (9:1:0.1, v/v/v) and detection was performed at 220.0 nm

Optimization of the RP-HPLC method

There were several attempts for the simultaneous separation of the five components. By trying methanol and phosphate buffer with isocratic elution in different ratios 90: 10, v/v and 85: 15, v/v, resolution was less than the accepted limit. Also, in case of isocratic elution, by trying 80: 20 methanol and phosphate buffer ratio, longer time of analysis was obtained, so gradient elution was employed. Different flow rates were tried, 1.0 mL/min and 1.2 mL/min, longer run time was obtained. The optimal flow rate was 1.5 mL/min, which yielded lower retention time for all analytes while maintaining acceptable peak resolution. Finally, a good separation was accomplished by the above-mentioned optimum conditions. The suggested system allows good baseline separation with optimal resolution. A chromatogram of SAC, MTP, DMA, LDC and MIC is shown in Fig. 3, retention times were 1.61 min, 2.19 min, 2.52 min, 3.25 min and 7.38 min, respectively.

Composition of the mobile phase and elution mode

One of the goals of this work was to develop an approach that was environmentally beneficial. As a result, we consider two factors: solvent safety and waste minimization. If a solvent-free method is not viable, the green option is solvent reduction or the replacement of organic solvents with ‘‘green solvents’’ [46]. Environment-friendly solvents include methanol, ethanol, ethyl acetate, heptane, and hexane. Acetonitrile, on the other hand, is not environmentally friendly [47]. The findings also revealed that ethanol/water and methanol/water mixes are less harmful to the environment than pure alcohol. Solvents are ranked in descending order of greenness depending on a variety of factors. Water, for example, ranks first, followed by ethanol and acetone, whereas carbon tetrachloride and benzene rank last [48]. Because ethanol/water mixtures have a higher viscosity than methanol/water mixtures, they are more viscous at ambient temperature and high backpressures result from such high viscosity, methanol is the substance of choice in RP-HPLC and TLC methods, since the prior published LC technique [30] employed acetonitrile as the mobile phase, also buffer was used instead of water to attain shorter analysis time without sacrificing the greenness of the mobile phase. Additionally, in TLC method ethyl acetate is chosen instead of chloroform and toluene which are not environmentally friendly.

Method validation

The method's system suitability parameters were determined [49] showing acceptable resolution, peak symmetry, and selectivity (Table 1). The suggested methods were validated in compliance with ICH Q2 (R1) guideline [50].

Range and linearity

Under optimal conditions, five concentrations in the range of (0.3–3.0 µg/band) for LDC, and MIC were analyzed in triplicate for TLC method. Seven concentrations were determined in triplicates in the range of 1.00–100.00 µg/mL for MIC and 2.00–100.00 µg /mL for LDC, five and six concentrations (1.00–20.00 µg/mL) for MTP and DMA respectively for RP-HPLC method were analyzed under the specified chromatographic conditions for each method. Linear correlations were observed between the average peak areas and corresponding concentrations (Table 2).

Accuracy

Three pure samples (1.20, 1.40 and 1.50 µg/band) for LDC, and (0.90, 1.20 and 1.50 µg/band) for MIC were determined in triplicates for TLC method and five pure samples (7.00, 20.00, 40.00, 60.00 and 80.00 µg/mL) for MIC and LDC, and (3.00, 6.00, 12.00, 14.00 and 17.00 µg/mL) for MTP and DMA were analyzed in triplicates for RP-HPLC method to ensure the accuracy of the suggested techniques. The % recoveries were calculated using the concentrations obtained from the relevant regression equations. The percentage recoveries obtained indicated that the suggested methods were accurate (Table 2).

Precision

Repeatability (intra-day precision), three different concentrations of LDC (0.50, 0.70 and 2.00 µg/band), and (0.70, 1.00 and 3.00 µg/band) for MIC were determined in triplicates on three successive times within the same day for TLC method and three different concentrations of MIC and LDC (30.00, 50.00 and 70.00 µg/mL) and (5.00, 10.00, 15.00 µg/mL) for MTP and DMA for RP-HPLC method and the results are displayed in (Table 2) indicating good precision with small values of percentage relative standard deviation (% RSD).

Intermediate precision (inter-day precision), on three consecutive days, replication of the same three concentrations of the examined drugs was carried out. The % RSD values were shown to be minimal, indicating that the data was reasonably repeatable (Table 2).

Specificity

Mixtures containing LDC, and MIC for TLC method, in addition, the two drugs, MTP and DMA for RP-HPLC method in various ratios were used to determine specificity under the previous conditions mentioned. Specificity was monitored by the changes of peak areas and then calculating the %RSD. Table 2 shows that the proposed methods have satisfactory results.

Robustness

Robustness refers to a system's ability to remain unaffected by slight changes in method parameters. For TLC method, changing the wavelength by 1 nm and saturation time ± 5 min (Table 2). For RP-HPLC method, changing in the ratio of pH by 0.05, flow rate ± 0.05 mL/min and the change in wavelength (210.0 ± 1 nm). Response was monitored by the changes of peak areas and then calculating the %RSD which showed that small deliberate changes in the tested parameters had no effect on the methods' stability Table 2.

Application to pharmaceutical formulation

The suggested methods were used to determine MIC and LDC in their gel dosage form (Micoban® oral gel). Applicability of the proposed procedures for determining these chemicals in their formulations on a regular basis is confirmed by the percentage of recoveries being within the specified range with the application of the standard addition technique for the RP-HPLC method, the accuracy of the proposed techniques is further evaluated (Table 3).

Statistical analysis

The results of the suggested RP-HPLC method for the analysis of pure samples of MIC and LDC and those obtained by the analysis of MIC and LDC in their dosage form by the TLC method were compared statistically to the results obtained by the reported HPLC–DAD method [30]. The calculated t and F values were lower than the tabulated ones indicating that there is no significant difference between the suggested methods and the reported one (Table 4).

Assessment of the proposed method’s greenness

The suggested methods' greenness profile was assessed and graded in contrast to the published technique using the following three assessment tools:

National environmental method index (NEMI)

NEMI is a tool used to assess the analytical procedures' environmental sustainability. Using a symbol divided into four quadrants, despite the fact that it is the least accurate tool for assessing the method's greenness [38]. The profile requirements are described by four keywords: PBT, hazardous, corrosive, and waste are all represented by the four quadrants, 1-PBT is persistent, bio-accumulative, and toxic. If the Environmental Protection Agency's Toxic Release Inventory (EPA-TRI) does not classify the chemicals as PBT, the appropriate quadrant is colored green [51]. 2-The chemicals utilized aren't dangerous, thus they're not included on the TRI list [52]. 3-the medium's pH ranges from 2 to 12; 4- the waste produced is less than 50 g. For the suggested methods and the published one, we designed the NEMI pictograms (Table 5). The reagents and solvents utilized aren't PBT. The methanol used is classified as hazardous by the TRI list. Because the pH is 6.0, the method is regarded as non-corrosive. The amount of waste produced is less than 50 g for RP-HPLC and TLC methods. The published methodology also had one non-shaded quadrant that related to hazardous quadrant.

Green analytical procedure index (GAPI)

The GAPI assessment that has been developed could be a useful semi quantitative tool for lab research and education [39]. It is used to evaluate the overall greenness of an analytical procedure [53]. It covers 15 different aspects of sample preparation and collection, as well as the safety and health implications of the chemicals and substances employed, waste management, and equipment [54]. For each step, GAPI utilizes a three-color scale: ranging from green to yellow to red just like traffic lights, where green denotes a safe technique and red denotes operations that are not environmentally friendly. The suggested RP-HPLC and TLC methods' green assessment profile, as well as the other technique utilizing the GAPI tool, are shown in Table 5.

Analytical GREEnness metric (AGREE)

Pena-Pereira has developed AGREE in June 2020, a downloadable greenness assessment software [40]. AGREE is based on the twelve fundamentals of GAC, SIGNIFICANCE. The final score in AGREE, is a fraction of a unit, going from zero to one. The generated pictogram is separated into twelve portions, with the ability to adjust the width of each component based on its significance. Each segment has a unique color scheme that ranges from dark green (= 1) to dark red (= 0). The circular pictogram's center contains the final score. The AGREE tool was made with basic principles in mind, such as inclusivity, input flexibility, simplicity, and yield clarity [55]. The tool was accessed through a link mentioned in AGREE publications [40, 56].

The proposed RP-HPLC and TLC approaches are greener than the previous reported method, according to GAPI, and AGREE assessment tools, the proposed methods produced greener GAPI quadrants. Additionally, the AGREE score (0.61) for RP-HPLC and (0.6) for TLC are greater than previously reported (0.46). While the proposed methods and the published one are equal in NEMI scoring, the methods have one non-shaded quadrant that related to hazardous quadrant and three quadrants were colored green, satisfying three NEMI criteria. The results indicated that the suggested techniques have a minimal impact on the environment (Table 5).

The suggested TLC approach was successfully applied in determining MIC and LDC in their synthetic mixtures and in their gel dosage form. While RP-HPLC method was successful to determine MIC, LDC and MTP in their gel dosage form beside DMA in presence of SAC without interfering with one another. The LOD of DMA by the proposed RP-HPLC method is 0.084 µg/mL and the MTP was revealed to be within acceptable limits (0.13%). The system suitability parameters were found to be satisfactory (Table 1). The developed methods were validated in accordance with ICH guidelines, to evaluate sufficient validation characteristics (Table 2). The specificity of the proposed chromatographic approaches was confirmed by laboratory mixtures analysis (Table 2). Furthermore, the methods' robustness was assessed by deliberate changes in some experimental circumstances and then calculating the %RSD (Table 2). The RP-HPLC method validity was confirmed using the standard addition technique (Table 3).

Conclusion

Environmentally friendly, accurate, and sensitive TLC and RP-HPLC methods are presented. GAPI, NEMI and AGREE tools were used to evaluate the greenness of the methods. Additionally, we used the three tools to compare the suggested methods to the published one. The results demonstrate that the proposed methods have a decreased ecological impact. In general, evaluating the analytical methodologies' greenness should be included in method validation parameters. Additionally, prior to conducting practical trials in a lab, the sustainability of analytical techniques should be established to minimize the risk of chemicals being released into the environment. Furthermore, critical separation conditions in TLC, such as developing system and scanning wavelength all have been studied, in addition, flow rate, composition of mobile phase and the type of elution for RP-HPLC have also been examined.

Overall, our results indicate that the proposed TLC technique can be utilized to determine MIC and LDC. Consequently, it became necessary to shift to the RP-HPLC approach to analyze the toxic impurity; DMA, which was not separated by the TLC approach, along with the primary active ingredients MIC and LDC, and the excipient; MTP in bulk powder, mixtures, and a pharmaceutical formulation. The described methods could be employed for routine analysis in quality control labs.

Availability of data and materials

All data analyzed during this study are included in this published article and raw data are available from the corresponding author upon reasonable request.

Abbreviations

- GAC:

-

Green analytical chemistry

- LDC:

-

Lidocaine hydrochloride

- MIC:

-

Miconazole nitrate

- MTP:

-

Methyl paraben

- SAC:

-

Saccharin sodium

- DMA:

-

Dimethyl aniline

- TLC:

-

Thin layer chromatography

- HPLC:

-

High performance liquid chromatography

- ICH:

-

International council for harmonisation

- WHO:

-

World health organization

- BP:

-

British pharmacopoeia

- DAD:

-

Diode array detector

- NEMI:

-

National environmental methods index

- GAPI:

-

Green analytical procedure index

- AGREE:

-

Analytical greenness metric

- % RSD:

-

Percentage relative standard deviation

- EPA-TRI:

-

Environmental protection agency's toxic release inventory

- LOD:

-

Limit of detection

- LOQ:

-

Limit of quantification

References

Her Majesty’s Stationery Office; London: 2020 British Pharmacopoeia Commission. Her Majesty’s Stationery Office; London: 2020 British Pharmacopoeia Commission—British Pharmacopoeia. British Pharmacopoeia.

Columb MO, MacLennan K. Local anaesthetic agents. Anaesth Intensive Care Med. 2007;8(4):159–62.

World Health Organization. World Health Organization. World Health Organization model list of essential medicines: 22nd list (2021). World Health Org. 2021;2021:62–62.

Fothergill AW. Miconazole: a historical perspective. Expert Rev Anti Infect Ther. 2006. https://doi.org/10.1586/14787210.4.2.171.

Martindale SS. the complete drug reference. London: The pharmaceutical Press; 2014.

Li W, Gao L, Shi Y, Wang Y, Liu J, Cai Y. Spatial distribution, temporal variation and risks of parabens and their chlorinated derivatives in urban surface water in Beijing. China Sci Total Environ. 2016;539:262–70.

Lin Y, Ferronato C, Deng N, Wu F, Chovelon JM. Photocatalytic degradation of methylparaben by TiO2: multivariable experimental design and mechanism. Appl Catal B. 2009;88:32–41.

Xiao X, Lu M, Nan J, Zuo X, Zhang W, Liu S, et al. Rapid microwave synthesis of I-doped Bi4O5Br 2 with significantly enhanced visible-light photocatalysis for degradation of multiple parabens. Appl Catal B. 2017;218:398–408.

Lincho J, Martins RC, Gomes J. Paraben compounds—part i: An overview of their characteristics, detection, and impacts. Appl Sci. 2021. https://doi.org/10.3390/app11052307.

Frontistis Z, Antonopoulou M, Petala A, Venieri D, Konstantinou I, Kondarides DI, et al. Photodegradation of ethyl paraben using simulated solar radiation and Ag 3 PO 4 photocatalyst. J Hazard Mater. 2017;323:478–88.

Bebawy LI, Elghobashy MR, Abbas SS, Shokry RF. Chromatographic determination of aminoacridine hydrochloride, lidocaine hydrochloride and lidocaine toxic impurity in oral gel. J Chromatogr Sci. 2016;54:492–9.

Al Nebaihi HM, Primrose M, Green JS, Brocks DR. A High-Performance liquid chromatography assay method for the determination of lidocaine in human serum. Pharmaceutics. 2017;9:52.

Shaukat A, Hussain K, Bukhari NI, Shehzadi N. Simultaneous determination of paracetamol and lidocaine hydrochloride in detamol injection using RP-HPLC. J Res Pharm. 2022;26:609–16.

Junger AS, Jesus FFS, Fracassi da Silva JA, Daniel D, Jesus DP. A simple and fast method for determination of benzocaine and lidocaine in pharmaceutical formulations by capillary electrophoresis with spectrophotometric detection. Sep Sci Plus. 2019;2:422–7.

Lotfy HM, Tawakkol SM, Fahmy NM, Shehata MA. Validated stability indicating spectrophotometric methods for the determination of lidocaine hydrochloride, calcium dobesilate, and dexamethasone acetate in their dosage forms. Ana Chem Lett. 2013;3:208–25.

Omer LS, Ali RJ. Extraction-spectrophotometric determination of lidocaine hydrochloride in pharmaceuticals. Int J Chem. 2017;9:49–61.

Merey HA, Ramadan NK, Diab SS, Moustafa AA. Green spectrophotometric methods for the determination of a binary mixture of lidocaine hydrochloride and cetylpyridinium chloride in the presence of dimethylaniline. Spectrochim Acta A Mol Biomol Spectrosc. 2020;242:118743.

Saad AS, Al-Alamein AMA, Galal MM, Zaazaa HE. Voltammetric determination of lidocaine and its toxic metabolite in pharmaceutical formulation and milk using carbon paste electrode modified with C18 silica. J Electrochem Soc. 2019;166:B103–9.

Saad AS, Alamein AMA, al, Galal MM, Zaazaa HE. Novel green potentiometric method for the determination of lidocaine hydrochloride and its metabolite 2, 6-dimethylaniline; application to pharmaceutical dosage form and milk. Electroanalysis. 2018;30:1681–7.

Eticha T, Kahsay G, Hailu T, Gebretsadikan T, Asefa F, Gebretsadik H, et al. Development and validation of an extractive spectrophotometric method for miconazole nitrate assay in pharmaceutical formulations. J Anal Methods Chem. 2018. https://doi.org/10.1155/2018/2191072.

Patel KG, Shah PM, Shah PA, Gandhi TR. validated high-performance thin-layer chromatographic (HPTLC) method for simultaneous determination of nadifloxacin, mometasone furoate, and miconazole nitrate cream using fractional factorial design. J Food Drug Anal. 2016;24:610–9.

Heneedak HM, Salama I, Mostafa S, El-Sadek M. HPLC and chemometric methods for the simultaneous determination of miconazole nitrate and nystatin. J Chromatogr Sci. 2012;50:855–61.

El-Bagary RI, Elkady EF, Tammam MH, Elmaaty AA. Simultaneous determination of miconazole and hydrocortisone or mometasone using reversed phase liquid chromatography. Eur J Chem. 2012;3:421–5.

Pereira FC, Stradiotto NR, Zanoni MV. Voltammetric characteristics of miconazole and its cathodic stripping voltammetric determination. An Acad Bras Cienc. 2002;74:425–32.

Patil PM, Wankhede SB, Chaudhari PD. Stability-indicating HPTLC method for simultaneous determination of Ketoprofen, Methyl Paraben and Propyl Paraben in gel formulation. J Pharm Res. 2013;6:945–53.

Naik KM, Nandibewoor ST. Electroanalytical method for the determination of methylparaben. Sens Actuators A Phys. 2014;212:127–32.

Esteki M, Nouroozi S, Shahsavari Z. A fast and direct spectrophotometric method for the simultaneous determination of methyl paraben and hydroquinone in cosmetic products using successive projections algorithm. Int J Cosmet Sci. 2016;38:25–34.

Cheng Z, Ran Q, Liu J, Deng X, Qiu H, Jia Z, et al. Rapid determination for benzoic acid, sorbic acid, phenyllactic acid, phenylalanine, and saccharin sodium in vinegar by high-performance liquid chromatography-UV. Food Anal Methods. 2020;13:1673–80. https://doi.org/10.1007/s12161-020-01784-6.

Grembecka M, Baran P, Błażewicz A, Fijałek Z, Szefer P. Simultaneous determination of aspartame, acesulfame-K, saccharin, citric acid and sodium benzoate in various food products using HPLC-CAD-UV/DAD. Eur Food Res Technol. 2014;238:357–65.

Belal TS, Haggag RS. Gradient HPLC-DAD stability indicating determination of miconazole nitrate and lidocaine hydrochloride in their combined oral gel dosage form. J Chromatogr Sci. 2012;50:401–9.

Gałuszka A, Migaszewski Z, Namieśnik J. The 12 principles of green analytical chemistry and the SIGNIFICANCE mnemonic of green analytical practices. TrAC, Trends Anal Chem. 2013;50:78–84.

Anastas PT, Kirchhoff MM. Origins, current status, and future challenges of green chemistry. Acc Chem Res. 2002;35:686–94.

Martínez J, Cortés JF, Miranda R. Green chemistry metrics a review. Processes. 2022;10(7):1274.

Prajapati P, Shah H, Shah SA. Implementation of QRM and DoE-based quality by design approach to VEER chromatography method for simultaneous estimation of multiple combined dosage forms of paracetamol. J Pharm Innov. 2022;17:2–18.

Ostovan A, Ghaedi M, Arabi M, Yang Q, Li J, Chen L. Hydrophilic multitemplate molecularly imprinted biopolymers based on a green synthesis strategy for determination of B-family vitamins. ACS Appl Mater Interfaces. 2018;10:4140–50.

Prajapati PB, Radadiya K, Shah SA. Quality risk management based: analytical quality by design approach to eco-friendly and versatile chromatography method for simultaneous estimation of multiple fixed-dose-combination products of anti-diabetic drugs. J Pharm Innov. 2020. https://doi.org/10.1007/s12247-020-09506-5.

Płotka-Wasylka J, Kurowska-Susdorf A, Sajid M, de la Guardia M, Namieśnik J, Tobiszewski M. Green chemistry in higher education: state of the art, challenges, and future trends. ChemSusChem. 2018. https://doi.org/10.1002/cssc.201801109.

Keith LH, Gron LU, Young JL. Green analytical methodologies. Chem Rev. 2007;107:2695–708.

Płotka-Wasylka J. A new tool for the evaluation of the analytical procedure: green analytical procedure index. Talanta. 2018;181:204–9.

Pena-Pereira F, Wojnowski W, Tobiszewski M. AGREE—analytical GREEnness metric approach and software. Anal Chem. 2020;92:10076–82.

Wojnowski W, Tobiszewski M, Pena-Pereira F, Psillakis E. AGREEprep—Analytical greenness metric for sample preparation. TrAC Trends Anal Chem. 2022. https://doi.org/10.1016/j.trac.2022.116553.

El-Kafrawy DS, Abo-Gharam AH, Abdel-Khalek MM, Belal TS. Comparative study of two versatile multi-analyte chromatographic methods for determination of diacerein together with four non-steroidal anti-inflammatory drugs: greenness appraisal using Analytical Eco-Scale and AGREE metrics. Sustain Chem Pharm. 2022;28:100709.

Prajapati PB, Thakor MA, Bodiwala KB, Shah SA. Quality Risk Management-Based AQbD approach to development of VEER chromatography method for the estimation of multiple combined formulations of anti-hypertensive drugs. J AOAC Int. 2021;104:605–19.

Prajapati PB, Jayswal KV, Shah SA. DoE and risk-based DMAIC principle for implementation of enhanced analytical quality by design approach to multipurpose-chromatography method for simultaneous estimation of multiple fixed-dose combination products of aspirin. J AOAC Int. 2021;104:1430–41.

Prajapati PB, Bodiwala KB, Shah SA. Analytical quality-by-design approach for the stability study of thiocolchicoside by eco-friendly chromatographic method. J Planar Chromatogr - Mod TLC. 2018;31:477–87.

Armenta S, Esteve-Turrillas FA, Garrigues S, de la Guardia M. Alternative green solvents in sample preparation. Green Anal Chem. 2022. https://doi.org/10.1016/j.greeac.2022.100007.

Capello C, Fischer U, Hungerbühler K. What is a green solvent? A comprehensive framework for the environmental assessment of solvents. Green Chem. 2007;9:927.

Alfonsi K, Colberg J, Dunn PJ, Fevig T, Jennings S, Johnson TA, et al. Green chemistry tools to influence a medicinal chemistry and research chemistry based organisation. Green Chem. 2008;10:31–6.

United States Pharmacopeial Convention. The United States Pharmacopoeia 30, the National Formulary 25; The US Pharmacopoeial Convention: Rockville, MD, 2007. Electronic version.

International Conference on Harmonization of Technical Requirements for Registration of Pharmaceuticals for Human Use ICH Harmonised Tripartite Guideline Validation of Analytical Procedures : Text and Methodology Q2(R1). 2005.

Emergency planning and community right-to-know act-section 313: Guidance for Reporting Toxic Chemicals: Pesticides and Other Persistent Bioaccumulative Toxic (PBT) Chemicals. 2001.

Epa U, of Resource Conservation O. Hazardous Waste Listings a User-Friendly Reference Document. 2012. http://www.epa.gov/epawaste/wyl/stateprograms.htm

Roshdy A, Salam RA, Hadad G, Belal F, Elmansi H. Green quality by design HPLC approach for the simultaneous determination of Bilastine and Montelukast. BMC Chem. 2023. https://doi.org/10.1186/s13065-023-00953-y.

Abdallah NA, El-Brashy AM, Ibrahim FA, El-Awady MI. Micellar eco-friendly HPLC method for simultaneous analysis of ternary combination of aspirin, atorvastatin and ramipril: application to content uniformity testing. BMC Chem. 2023. https://doi.org/10.1186/s13065-023-00929-y.

Marzouk HM, El-Hanboushy S, Obaydo RH, Fayez YM, Abdelkawy M, Lotfy HM. Sustainable chromatographic quantitation of multi-antihypertensive medications: application on diverse combinations containing hydrochlorothiazide along with LC–MS/MS profiling of potential impurities: greenness and whiteness evaluation. BMC Chem. 2023. https://doi.org/10.1186/s13065-023-01015-z.

Gamal M, Naguib IA, Panda DS, Abdallah FF. Comparative study of four greenness assessment tools for selection of greenest analytical method for assay of hyoscine: N -butyl bromide. Anal Methods. 2021;13:369–80.

Acknowledgements

Not applicable.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

EA: Methodology, Software, Validation, Resources, Writing original draft. M.H and A.A: Writing review & editing, Visualization, Supervision. G.E and N.G: Methodology, Writing review & editing, Software, Supervision. All authors read and approved the manuscript for publication.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Ashour, E.S., Hegazy, M.A., Al-Alamein, A.M.A. et al. Green chromatographic methods for determination of co-formulated lidocaine hydrochloride and miconazole nitrate along with an endocrine disruptor preservative and potential impurity. BMC Chemistry 17, 151 (2023). https://doi.org/10.1186/s13065-023-01065-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13065-023-01065-3