Abstract

Background

The required pretreatment of CAD/CAM ceramic materials before resin composite cement application varies among studies. The aim of the present study was to evaluate the effect of hydrofluoric acid concentration and etching time on the shear bond strength (SBS) of two adhesive and two self-adhesive resin composite cements to different CAD/CAM ceramic materials.

Methods

SBS of two adhesive (Panavia V5, Kuraray, [PV5]; Vita Adiva F-Cem, Vita Zahnfabrik, [VAF]) and two self-adhesive (RelyX Unicem 2 Automix, 3 M Espe, [RUN]; Vita Adiva S-Cem, Vita, [VAS]) cements to four different CAD/CAM materials (Vitablocs Mark II, Vita, [VM]; Vita Enamic, Vita, [VE]; e.max CAD, Ivoclar Vivadent, [EC]; Vita Suprinity PC, Vita, [VS]) was measured. The effect of the surface pretreatment by using two different hydrofluoric acid products (HF5% Vita Ceramics Etch, Vita and HF9% buffered, Ultradent Porcelain Etch, Ultradent Products) were assessed at etching times of 0 s, 5 s, 15 s, 30s and 60s for each cement and restorative material combination (n = 10 per group, total n = 1440).

Results

Significant effects were found for the etching time and cement for all materials with highest shear bond strength for etching times of 60s = 30s = 15 s ≥ 5 s > 0 s and for RUN>PV5 = VAF > VAS (p < 0.05). Etching with HF5% for 5 s to 15 s resulted in higher SBS values, while no differences were observed between HF5% and HF9% buffered when the substrates were etched for 30s to 60s (p < 0.05).

Conclusions

Within the limitations of this study the recommended surface pretreatment of silicate ceramics is HF etching with concentrations of 5% or 9% for 15 s to 60s to achieve highest shear bond strength while the glassy matrix is sufficiently dissolved. The tested resin composite cements can be applied with all tested materials and suggested for clinical application.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Background

Digital technology in dentistry was introduced in the late 80s and ever since was constantly developed [1,2,3]. Together with progressive changes in the equipment industry, new developments of different restorative materials resulted in major breakthroughs of computer-aided-design/computer-aided-manufacturing (CAD/CAM) technologies. Nowadays, computerized manufacturing is often routinely involved in restorative dentistry and is associated with high accuracy, accelerated production speed and reduced manual application [4]. Tooth-colored CAD/CAM restorative materials have been successfully documented over the last two decades with promising performance [5,6,7,8].

Feldspar ceramic has been considered a gold standard due to its tooth-like appearance, based on light transmission and natural effect [9, 10]. However, the low mechanical properties, as for instance fracture strength [11,12,13] was a limiting factor for its application and stimulated further advancements of glass ceramics reinforced with different fillers [14, 15]. Hence, lithium disilicate (LiS2) ceramic (as a high-strength and highly esthetic material) [16] and polymer-infiltrated ceramic (due to similar hardness and elastic modulus to dental structures; higher fracture toughness and reduced brittleness) [17, 18] were developed [9]. The reported survival rate of CAD/CAM-fabricated polymer-infiltrated ceramic inlays is 97.4 and 95.6% for partial coverage restorations after three years [19]. In comparison, the mean survival rate of CAD/CAM LiS2 veneers reaches 99% with 96.4% success after 5 years [20]. However, the high clinical survival and success rates of CAD/CAM single restorations is based not only on the novel materials, but is strongly determined by the strength and durability of the bond formed between the restorative material, luting cement and substrate [9, 21]. Based on current evidence, adhesive bonding of ceramic restorations provides high retention, improves marginal adaptation, prevents micro-leakage and increases fracture resistance of restored teeth and the respective restorations [22,23,24,25]. Moreover, resin composite cements are available in tooth-colored shades, which is crucial for luting minimally invasive ceramic restorations [26].

To achieve micromechanical interlocking with the resin composite cement, the surface of silicate ceramics has to be roughened [27,28,29,30]. The recommended procedure comprises etching with 5% hydrofluoric acid (HF) and application of silane coupling agent to additionally achieve a chemical bond [31,32,33,34,35,36]. The application of HF acid reacts with silicate, which leads to the removal of the glass phase and results in an increased ceramic surface area [37,38,39]. Despite the fact that HF acid is the undisputed ceramic surface etchant, the concentration and etching time are highly controversial, i.e. varying from 5 to 10% and from 15 s to 90s [39,40,41,42,43,44,45,46]. Nevertheless, after the acid etching procedure, the application of silane as a coupling agent linking the hydrophilic restoration surface with hydrophobic resin composite cement is generally recommended [43, 47,48,49].

In order to simplify the technique-sensitive surface pretreatment for an application of adhesive resin composite cement, self-adhesive cements were introduced [50]. It has been demonstrated that self-adhesive cements are suitable for bonding to dentin, while bonding to enamel substrate is considered inferior in comparison with the etch-and-rinse or self-etch adhesive techniques, in which the applied primer allows further micromechanical interlocking [5, 51,52,53,54]. Nonetheless, data on bonding behavior between CAD/CAM ceramic materials, different adhesive cements and surface pretreatment is controversial [32, 34, 49]. Resin composite cements are brittle materials and therefore susceptible to tensile loading rather than to compressive stress [55,56,57]. Since adhesion of cements to ceramics is commonly tested using a shear bond strength test design, it would be of interest to analyze the effect of the cement’s diametral tensile strength on shear bond strength.

The aim of the present study was to evaluate the effect of hydrofluoric acid concentration and etching time on the shear bond strength (SBS) of adhesive and self-adhesive resin composite cements to different CAD/CAM ceramic materials and to determine the diametral tensile strengths of four different resin composite cements. The hypotheses of the present study were that i) different HF acid concentrations affect the surface morphology of CAD/CAM ceramic materials and shear bond strength, ii) varying HF acid etching times affect the surface morphology of CAD/CAM ceramic materials and shear bond strength.

Methods

Shear bond strength (SBS) [30, 33, 50, 58, 59] of two adhesive (Panavia V5 [PV5], Kuraray Noritake; Vita Adiva F-Cem [VAF], Vita) and two self-adhesive (RelyX Unicem 2 Automix [RUN], 3 M Espe; Vita Adiva S-Cem [VAS], Vita) cements to four different CAD/CAM materials (Vitablocs Mark II [VM], Vita; Vita Enamic [VE], Vita; e.max CAD [EC], Ivoclar Vivadent; Vita Suprinity PC [VS], Vita) was measured (Table 1). The effect of the surface pretreatment using two different hydrofluoric acid products (HF5% Vita Ceramics Etch [HF5], Vita and HF9% buffered [HF9], Ultradent Porcelain Etch, Ultradent Products) were assessed at etching times of 0 s, 5 s, 15 s, 30s and 60s for each cement and restorative material combination (Fig. 1, n = 10 per group, total n = 1440).

Groups for shear bond strength test. The CAD/CAM materials VM, VE, EC and VS served as substrates for the shear bond strength test. Their surfaces were pre-treated with hydrofluoric acid (HF) of different concentrations and etching times. Afterwards, the respective system primer (RXCP, VACP, CCPP, VACP) and cement (RUN, VAS, PV5, VAF) was applied and shear bond strength was measured after 24 h water storage at 37 °C (n = 10 per group)

CAD/CAM blocks of each material were cut in slices with a thickness of 3.5 mm using a diamond band saw (Exakt 30–700, Exakt; Norderstedt, Germany) under permanent water-cooling. The substrate slices were then grinded (SiC paper grit P180, Struers, Baltrup, Denmark) to attain a similar roughness as it is given by a CAD/CAM milling machine (Ra = 1.88 μm for VM and VE, 2.71 μm for EC, 2.52 μm for VS after crystallization) [60]. Specimens of EC and VS were additionally crystallized (Vacumat 4000, Vita) according to the recommendation of the manufacturers. For EC temperature increase was 30 °C/min for 15 min up to the crystallizing temperature of 850 °C which was held for 10 min. Cooling temperature was 680 °C. For VS temperature increase was 55 °C/min to 840 °C for 8 min with cooling at 680 °C.

Substrates were cleaned in 70% ethanol prior to crystallizing and before pre-treatment for SBS in an ultrasonic bath (TPC-15, Telsonic, Bronschhofen, Switzerland) for 4 min. Roughness of the specimens was measured with a tactile stylus (Hommeltester T1000, cantilever Type TKK 50, Zug, Switzerland): VM (1.9 ± 0.5 μm), VE (1.8 ± 0.8 μm), EC (0.5 ± 0.1 μm) and VS (0.8 ± 0.1 μm). Hydrofluoric acid etching was performed for either 0 s, 5 s, 15 s, 30s or 60s with HF5 or HF9 and then rinsed thoroughly with water for 20s. After etching, the substrate surfaces were dried with oil-free air and pre-treated with the appropriate ceramic primer recommended by the manufacturer of the respective cement (Table 1, Fig. 1). The primer used in combination with PV5 was Clearfil Ceramic Primer plus [CCPP] (Kuraray Noritake). For both VAF and VAS Vita Adiva Ceramic Primer [VACP] (Vita) was used and to RUN RelyX Ceramic Primer [RXCP] (3 M Espe) was assigned. The respective primers were applied on the substrate surfaces with a microbrush for 20s and dried with oil-free air.

An acrylic cylinder with an inner diameter of 2.9 mm, outer diameter of 4.1 mm, and height of 4 mm was tightened in a custom made device onto the substrate surface to avoid leaking of the cement. The respective cement was filled into the cylinder opening. A steel screw (BN 617, Bossard; Zug, Switzerland) with a diameter matching the inner diameter of the acrylic cylinder was inserted parallel to the axis of the cylinder and loaded with 10 N. The cement was light cured from three different directions for 20s per side (Elipar DeepCure S, 3 M Espe, Neuss, Germany). All specimens were stored in distilled water at 37 °C for 24 h. SBS was measured in a universal testing machine (Z020 Zwick/Roell, Ulm, Germany). The specimens were positioned in the sample holder with the bonding surface parallel to the loading piston. The loading piston had a chisel configuration and was positioned with a distance of 2 mm to the specimen surface. The distance of 2 mm was chosen to prevent extensive cohesive failures by increasing the leverage effect [30, 33]. The load was applied to the outer surface of the cylinder with a crosshead speed of 1 mm/min. Load at failure was recorded, and SBS (σ) was calculated with the following formula: σ = F/πr2, in which F is the load in N at fracture and r is the radius of the bonded area of the cylinder in mm (1.45 mm). SBS of specimens that de-bonded during water storage was recorded as 0.0 MPa and included in the statistical analysis. Failure patterns were classified visually as either cohesive failure in the substrate, adhesive failure, mixed or cohesive failure in the cement. Images of those typical failure patterns were obtained with scanning electron microscopy (ESEM XL30, Philips, Eindhoven, the Netherlands). Additionally, SEM images were obtained of etched substrates of the respective groups.

Diametral tensile strength of all 4 resin composite cements was measured [55, 57, 61, 62]. Cylindrical test specimens 3 mm in height and diameter (n = 10) were produced using a customized Teflon mold. The cement was filled into the respective cavities of the mold and kept in place with a plastic foil and a glass plate on each side. Specimens were light cured for 20s from both sides (Elipar DeepCureS, 3 M Espe). All specimens were then stored in 37 °C water for 24 h. Specimens were loaded until fracture after 24 h of water storage using a universal testing machine (Z020, Zwick/Roell). Cross-head speed was set to 1 mm/min. Prior to the measurements, the specimens were sized in diameter and height using a digital caliper (Cal IP 67, Tesa, Ingersheim, Germany). Diametral tensile strength values were calculated using the following equations:

F is the fracture load; d the specimen diameter and h the specimen height.

All data was tested for normal distribution using Shapiro-Wilk test (StatPlus Pro, v6.1.25, AnalystSoft; Walnut, CA, USA) (p < 0.05). To analyze diametral tensile strength one-way ANOVA was applied followed by Fisher LSD test to investigate differences between resin composite cements (p < 0.05). For SBS data one-way ANOVA was performed for each cement to test the influence of etching time. Three-way ANOVA was applied for each etching time to test for effects of the factors substrate, HF concentration, and cement. Post-hoc Fisher LSD test was performed to determine differences within the subgroups (p < 0.05).

Results

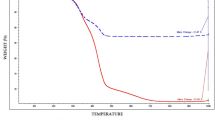

Shear Bond strength means and standard deviations of all groups with statistics are given in Table 2. Overall, significantly highest values were observed for etching time of 60s = 30s = 15 s ≥ 5 s > 0 s (p < 0.001). For the cements, statistically significantly highest SBS values were recorded for RUN>PV5 = VAF > VAS (p < 0.001). Etching with HF5% for 5 s to 15 s resulted in higher SBS values (p < 0.005) while no differences were observed between HF5% and HF9% buffered when the substrates were etched for 30s to 60s (p > 0.05). The correlation between SBS values and etching time of the pooled data for all materials and HF concentrations is displayed in Fig. 2.

No etching of the surfaces resulted in adhesive fractures on all substrates. For VAS, fractures were adhesive or within the resin composite cement irrespective of the surface pretreatment on all substrates. For the other cements, fractures of etched surfaces of VM and VE were mainly cohesive in the restorative material or mixed failures and for EC and VS mainly cohesive within the resin composite cement or mixed failures. SEM images of typical failures modes are presented in Fig. 3.

SEM analysis revealed no differences in etching morphology of the substrates between HF5 and HF9, and images are displayed for HF5 (Fig. 4). Prolonged etching up to 60s, increased the irregularities, undercuts and removal of ceramic particles. HF etching for 5 s or 15 s on EC with either of the concentrations did not suffice to dissolve the glassy matrix completely creating a different pattern than those of 30s to 60s.

SEM images of substrate surfaces feldspar ceramic (VM), polymer-infiltrated ceramic (VE), lithium disilicate (EC) and zirconia reinforced lithium silicate (VS) pre-treated with 5% hydrofluoric acid for the respective times 0 s, 5 s, 15 s, 30s and 60s. No differences were observed with SEM between HF5 and HF9. Magnification for VM and VE is 2′000x, for EC and VS 10′000x

Diametral tensile strength of the resin composite cement was significantly higher for PV5 (p < 0.005) than for VAF (p = 0.005) and RUN (p = 0.009) that did not differ significantly (p = 0.823) (Table 3). VAS presented significantly lower diametral tensile strength values than all other cements (p < 0.001).

Discussion

The purpose of the present study was to determine the effect of surface pretreatment with 5 and 9% hydrofluoric acid of four different CAD/CAM ceramic materials on shear bond strength of different resin composite cements. Additionally, diametral tensile strengths of four resin composite cements were investigated. It was demonstrated that irrespective of the ceramic material, a minimal etching time of 15 s with 5% or 9% HF is required to achieve the highest shear bond strength. When performing SBS testing with a cement with a low diametral strength, cohesive fractures within the cement and consequently lower SBS values can be expected.

The present study partially rejected the first hypothesis that different HF acid concentrations affect the surface morphology of different CAD/CAM ceramic materials and shear bond strength using four different resin composite cements. The investigated HF acid concentrations of 5 and 9% buffered revealed only differences for etching times of 5 s and 15 s where HF5% displayed higher SBS values. This might be due to a prolonged reaction time of HF9% due to its buffered composition. However, no differences were observed in SEM images. Other findings report significant difference in SBS mean values between HF acid concentrations of 5, 7.5 and 10% for lithium disilicate ceramic [32, 39] and no significance between 5 and 10% HF acid for feldspar and lithium disilicate ceramics were found [34].

The second hypothesis that HF acid etching time affects the substrate’s surface morphology and SBS was confirmed. The highest SBS values for all tested CAD/CAM ceramic materials were observed after etching times of 15 s to 60s, which were accompanied by increased structural irregularities and undercuts due to removal of ceramic particles that are responsible for sufficient micromechanical retention [36, 63]. In the present study differing etching patterns were observed for EC between 15 s and 30s that did not affect SBS values. For practical reasons and to ensure complete etching of the substrate with sufficient dissolution of the glassy matrix the authors recommend an etching time with HF for longer than 15 s and up to 60s as the manufacturer also recommends an etching time of 20s.

Most studies reported the importance of ceramic surface pretreatment with HF acid of 4.8 to 10% and application for 15 s to 60s which agrees with the present findings [40,41,42,43,44,45,46, 64]. Recent scientific data determined no significant differences in SBS values regarding prolonged etching time from 20s to 120 s for feldspar and LiS2 ceramic [32, 34]. It is recommended to etch a polymer-infiltrated ceramic for 30s to 60s in order to achieve the highest bond strength [30, 33].

Substrate surface pretreatment without HF etching in the present study served as a control group to assess bonding capacity to machined surface limited in mechanical interlocking. Thus, mainly the chemical bond may have been measured, which resulted in lowest SBS values for all materials and induced mostly adhesive fractures. Even though the machined surfaces were silanized, the fractures for all materials occurred basically on the bonding interface between ceramic surface and cement. These findings are in agreement with previous reports for glass-based ceramics and polymer-infiltrated ceramic [30, 35, 50]. The surface roughness Ra of VM (1.9 ± 0.5 μm), VE (1.8 ± 0.8 μm), EC (0.5 ± 0.1 μm) and VS (0.8 ± 0.1 μm) of the unetched substrates differed, which can be explained by the crystallization process of EC and VS. Therefore SBS values of unetched specimens were also significantly higher of the rougher substrates VM and VE. Reported surface roughness values Ra for VM and VE after CAD/CAM proceeding were found to be Ra = 1.9 μm [60] and it was similar to the values of the present study (VM: 1.9 μm, VE: 1.8 μm). However, EC and VS had lower roughness in the present study (EC: 0.5 μm, VS: 0.8 μm) compared with other reports (EC:2.7 μm, VS:2.5 μm) [60]. It can be explained by the hardness of EC and VS, which might be less susceptible to the treatment with 180 grit silica paper than to the grinding instruments of a CAD/CAM unit.

In the present study, silane application for different cements was strongly followed by manufacturer instructions to avoid chemical interferences. Hence, the primer consisting MDP monomer (10-Methacryloyloxydecyl dihydrogen phosphate) was only applied for PV5, but no superior effect was observed when compared to other primers containing only silane as a bonding agent. Applied on the etched surface, the silane coupling agent creates a chemical bond between Si-O-Si groups in silicate ceramic and methacrylate groups in resin composite cement, and strengthens the adhesion between both materials [30]. Scientific data demonstrated that a silane coupling agent improves the SBS between resin composite cement and silicate ceramic as well as polymer-infiltrated ceramic [33, 49]. A previous study reported slightly higher SBS values sheared with a 2 mm distance for RUN on VE after etching for 15 s to 60s followed by the application of a silane ranging from 9.0 ± 2.9 MPa to 10.1 ± 1.5 MPa, that may be explained by the use of a different silane [30, 33].

The present study revealed mainly cohesive fractures within etched restorative materials of VM and VE with all luting cements except VAS. This indicates that the formed bond between resin composite cement, silane and substrate was stronger than the intrinsic strength of the substrate material itself. EC and VS groups experienced also mainly cohesive fractures, however, within the cement and not the substrate. This observation has been reported previously [25], and is most likely related to the variation in the materials’ flexural strength: VM 105 MPa [14] and VE 137 MPa [14] < EC 348 MPa [15] and VS 443 MPa [15]. The high strength of EC and VS resulted in fractures within the cements. For VM and VE with its increased roughness as shown in SEM images, a strong interlocking between cement and substrates led to cohesive fractures within the restorative material.

In the current study, the specimens were sheared with a 2 mm distance between loading piston and bonding area. Fractures of specimens in a SBS test set-up occur when either the maximal normal stress or shear stress levels are overstepped. When the distance between force application point and fracture area is increased, normal stress is also increased at the same force level. Consequently, fractures occur at lower force levels than when specimens are sheared without distance. SBS values of the present study are therefore lower and cannot be compared to previous studies using the same test set-up [33, 50]. The distance of 2 mm was selected in the present protocol because less crucial cohesive material fractures were observed when specimens were sheared with 2 mm distance due to the increased leverage effect leading to fractures at lower forces [30, 33]. The applied shear bond strength design can be considered a comparable method to the ISO 29022 shear test, although the SBS values obtained with the present design were generally lower than those generated with the ISO test [50]. SBS testing is a valuable method to asses bonding performance between interfaces as long as failures occur at the interface with no fractures of the substrate. As soon as cohesive fractures are involved, the test method has been criticized as unreliable [50, 65, 66].

Further, the low SBS values of VAS led to either adhesive or cohesive fractures within the cement. The diametral tensile strength of 17.6 ± 1.7 MPa was significantly lower than the values of RUN, PV5 and VAF. This could explain the nature of the fractures found with VAS.

The samples in the recent study were evaluated after 24 h water storage at 37 °C without considering the effect of aging. Further investigations regarding bond strength between novel CAD/CAM materials and composite resin cements, as well as regarding surface pretreatment of both tooth and restorative material have to be investigated under clinical conditions.

Conclusions

Within the limitations of this study the recommended surface pretreatment of VM, VE, EC and VS is HF etching with concentrations of 5% or 9% for 15 s to 60s. Furthermore, the tested resin composite cements can be applied with all tested materials and suggested for clinical application as follow: RUN>PV5 = VAF > VAS.

Availability of data and materials

Data are available on request from the authors.

Abbreviations

- CAD/CAM:

-

Computer-aided-design/computer-aided-manufacturing

- EC:

-

e.max CAD

- HF:

-

Hydrofluoric acid

- LiS2:

-

Lithium disilicate

- PV5:

-

Panavia V5

- RUN:

-

RelyX Unicem 2 Automix

- SBS:

-

Shear bond strength

- VAF:

-

Vita Adiva F-Cem

- VAS:

-

Vita Adiva S-Cem

- VE:

-

Vita Enamic

- VM:

-

Vita Mark II

- VS:

-

Vita Suprinity

References

Lutz F, Krejci I, Mormann W. Tooth-colored posterior restoration. Phillip J Restaur Zahnmed. 1987;4:127–37.

Mormann WH, Brandestini M. Cerec-system: computerized inlays, onlays and shell veneers. Zahnarztl Mitt. 1987;77:2400–5.

Mormann WH, Brandestini M, Lutz F. The Cerec system: computer-assisted preparation of direct ceramic inlays in 1 setting. Quintessenz. 1987;38:457–70.

Joda T, Zarone F, Ferrari M. The complete digital workflow in fixed prosthodontics: a systematic review. BMC Oral Health. 2017;17:124.

Frankenberger R, Taschner M, Garcia-Godoy F, Petschelt A, Kramer N. Leucite-reinforced glass ceramic inlays and onlays after 12 years. J Adhes Dent. 2008;10:393–8.

Otto T, De Nisco S. Computer-aided direct ceramic restorations: a 10-year prospective clinical study of Cerec CAD/CAM inlays and onlays. Int J Prosthodont. 2002;15:122–8.

Reiss B. Clinical results of Cerec inlays in a dental practice over a period of 18 years. Int J Comput Dent. 2006;9:11–22.

Sjogren G, Molin M, van Dijken JW. A 10-year prospective evaluation of CAD/CAM-manufactured (Cerec) ceramic inlays cemented with a chemically cured or dual-cured resin composite. Int J Prosthodont. 2004;17:241–6.

Peumans M, Valjakova EB, De Munck J, Mishevska CB, Van Meerbeek B. Bonding effectiveness of luting composites to different CAD/CAM materials. J Adhes Dent. 2016;18:289–302.

Vichi A, Carrabba M, Paravina R, Ferrari M. Translucency of ceramic materials for CEREC CAD/CAM system. J Esthet Restor Dent. 2014;26:224–31.

Belli R, Wendler M, de Ligny D, Cicconi MR, Petschelt A, Peterlik H, et al. Chairside CAD/CAM materials. Part 1: measurement of elastic constants and microstructural characterization. Dent Mater. 2017;33:84–98.

Wendler M, Belli R, Petschelt A, Mevec D, Harrer W, Lube T, et al. Chairside CAD/CAM materials. Part 2: flexural strength testing. Dent Mater. 2017;33:99–109.

Belli R, Wendler M, Zorzin JI, Lohbauer U. Practical and theoretical considerations on the fracture toughness testing of dental restorative materials. Dent Mater. 2018;34:97–119.

Awada A, Nathanson D. Mechanical properties of resin-ceramic CAD/CAM restorative materials. J Prosthet Dent. 2015;114:587–93.

Elsaka SE, Elnaghy AM. Mechanical properties of zirconia reinforced lithium silicate glass-ceramic. Dent Mater. 2016;32:908–14.

Tysowsky GW. The science behind lithium disilicate: a metal-free alternative. Dent Today. 2009;28:112–3.

He LH, Swain M. A novel polymer infiltrated ceramic dental material. Dent Mater. 2011;27:527–34.

Coldea A, Swain MV, Thiel N. Mechanical properties of polymer-infiltrated-ceramic-network materials. Dent Mater. 2013;29:419–26.

Spitznagel FA, Scholz KJ, Strub JR, Vach K, Gierthmuehlen PC. Polymer-infiltrated ceramic CAD/CAM inlays and partial coverage restorations: 3-year results of a prospective clinical study over 5 years. Clin Oral Investig. 2018;22:1973–83.

Nejatidanesh F, Savabi G, Amjadi M, Abbasi M, Savabi O. Five year clinical outcomes and survival of chairside CAD/CAM ceramic laminate veneers - a retrospective study. J Prosthodont Res. 2018.

Fischer H, De Souza RA, Watjen AM, Richter S, Edelhoff D, Mayer J, et al. Chemical strengthening of a dental lithium disilicate glass-ceramic material. J Biomed Mater Res A. 2008;87:582–7.

Blatz MB, Sadan A, Kern M. Resin-ceramic bonding: a review of the literature. J Prosthet Dent. 2003;89:268–74.

Addison O, Marquis PM, Fleming GJ. Quantifying the strength of a resin-coated dental ceramic. J Dent Res. 2008;87:542–7.

Groten M, Probster L. The influence of different cementation modes on the fracture resistance of feldspathic ceramic crowns. Int J Prosthodont. 1997;10:169–77.

Yao C, Zhou L, Yang H, Wang Y, Sun H, Guo J, et al. Effect of silane pretreatment on the immediate bonding of universal adhesives to computer-aided design/computer-aided manufacturing lithium disilicate glass ceramics. Eur J Oral Sci. 2017;125:173–80.

Holderegger C, Sailer I, Schuhmacher C, Schlapfer R, Hammerle C, Fischer J. Shear bond strength of resin cements to human dentin. Dent Mater. 2008;24:944–50.

Sorensen JA, Engelman MJ, Torres TJ, Avera SP. Shear bond strength of composite resin to porcelain. Int J Prosthodont. 1991;4:17–23.

Chen JH, Matsumura H, Atsuta M. Effect of etchant, etching period, and silane priming on bond strength to porcelain of composite resin. Oper Dent. 1998;23:250–7.

Chen JH, Matsumura H, Atsuta M. Effect of different etching periods on the bond strength of a composite resin to a machinable porcelain. J Dent. 1998;26:53–8.

Rohr N, Flury A, Fischer J. Efficacy of a universal adhesive in the bond strength of composite cements to polymer-infiltrated ceramic. J Adhes Dent. 2017;19:417–24.

Stewart GP, Jain P, Hodges J. Shear bond strength of resin cements to both ceramic and dentin. J Prosthet Dent. 2002;88:277–84.

Puppin-Rontani J, Sundfeld D, Costa AR, Correr AB, Puppin-Rontani RM, Borges GA, et al. Effect of hydrofluoric acid concentration and etching time on bond strength to Lithium Disilicate glass ceramic. Oper Dent. 2017;42:606–15.

Schwenter J, Schmidli F, Weiger R, Fischer J. Adhesive bonding to polymer infiltrated ceramic. Dent Mater J. 2016;35:796–802.

Mokhtarpour F, Alaghehmand H, Khafri S. Effect of hydrofluoric acid surface treatments on micro-shear bond strength of CAD/CAM ceramics. Electron Physician. 2017;9:5487–93.

Lise DP, Perdigao J, Van Ende A, Zidan O, Lopes GC. Microshear bond strength of resin cements to Lithium Disilicate substrates as a function of surface preparation. Oper Dent. 2015;40:524–32.

Tian T, Tsoi JK, Matinlinna JP, Burrow MF. Aspects of bonding between resin luting cements and glass ceramic materials. Dent Mater. 2014;30:e147–62.

Della Bona A, van Noort R. Ceramic surface preparations for resin bonding. Am J Dent. 1998;11:276–80.

Venturini AB, Prochnow C, Rambo D, Gundel A, Valandro LF. Effect of hydrofluoric acid concentration on resin adhesion to a feldspathic ceramic. J Adhes Dent. 2015;17:313–20.

Sundfeld Neto D, Naves LZ, Costa AR, Correr AB, Consani S, Borges GA, et al. The effect of hydrofluoric acid concentration on the bond strength and morphology of the surface and Interface of glass ceramics to a resin cement. Oper Dent. 2015;40:470–9.

Guarda GB, Correr AB, Goncalves LS, Costa AR, Borges GA, Sinhoreti MA, et al. Effects of surface treatments, thermocycling, and cyclic loading on the bond strength of a resin cement bonded to a lithium disilicate glass ceramic. Oper Dent. 2013;38:208–17.

Makishi P, Andre CB, Silva JL, Bacelar-Sa R, Correr-Sobrinho L, Giannini M. Effect of storage time on bond strength performance of multimode adhesives to indirect resin composite and Lithium Disilicate glass ceramic. Oper Dent. 2016;41:541–51.

Aboushelib MN, Elmahy WA, Ghazy MH. Internal adaptation, marginal accuracy and microleakage of a pressable versus a machinable ceramic laminate veneers. J Dent. 2012;40:670–7.

Kalavacharla VK, Lawson NC, Ramp LC, Burgess JO. Influence of etching protocol and Silane treatment with a universal adhesive on Lithium Disilicate bond strength. Oper Dent. 2015;40:372–8.

Yoshida F, Tsujimoto A, Ishii R, Nojiri K, Takamizawa T, Miyazaki M, et al. Influence of surface treatment of contaminated lithium disilicate and leucite glass ceramics on surface free energy and bond strength of universal adhesives. Dent Mater J. 2015;34:855–62.

Ozturk E, Bolay S, Hickel R, Ilie N. Shear bond strength of porcelain laminate veneers to enamel, dentine and enamel-dentine complex bonded with different adhesive luting systems. J Dent. 2013;41:97–105.

Carvalho AO, Bruzi G, Anderson RE, Maia HP, Giannini M, Magne P. Influence of adhesive Core buildup designs on the resistance of Endodontically treated molars restored with Lithium Disilicate CAD/CAM crowns. Oper Dent. 2016;41:76–82.

Matinlinna JP, Lassila LV, Ozcan M, Yli-Urpo A, Vallittu PK. An introduction to silanes and their clinical applications in dentistry. Int J Prosthodont. 2004;17:155–64.

Nagai T, Kawamoto Y, Kakehashi Y, Matsumura H. Adhesive bonding of a lithium disilicate ceramic material with resin-based luting agents. J Oral Rehabil. 2005;32:598–605.

Lee Y, Kim JH, Woo JS, Yi YA, Hwang JY, Seo DG. Analysis of self-adhesive resin cement microshear bond strength on leucite-reinforced glass-ceramic with/without pure Silane primer or universal adhesive surface treatment. Biomed Res Int. 2015;2015:361893.

Hu M, Weiger R, Fischer J. Comparison of two test designs for evaluating the shear bond strength of resin composite cements. Dent Mater. 2016;32:223–32.

Van Meerbeek B, Yoshihara K. Clinical recipe for durable dental bonding: why and how? J Adhes Dent. 2014;16:94.

Peumans M, De Munck J, Van Landuyt K, Van Meerbeek B. Thirteen-year randomized controlled clinical trial of a two-step self-etch adhesive in non-carious cervical lesions. Dent Mater. 2015;31:308–14.

Frankenberger R, Hartmann VE, Krech M, Kramer N, Reich S, Braun A, et al. Adhesive luting of new CAD/CAM materials. Int J Comput Dent. 2015;18:9–20.

Rohr N, Fischer J. Tooth surface treatment strategies for adhesive cementation. J Adv Prosthodont. 2017;9:85–92.

Blumer L, Schmidli F, Weiger R, Fischer J. A systematic approach to standardize artificial aging of resin composite cements. Dent Mater. 2015;31:855–63.

Fonseca RG, Artusi TP, dos Santos JG, Adabo GL. Diametral tensile strength of dual-curing resin cements submitted exclusively to autopolymerization. Quintessence Int. 2007;38:e527–31.

Rohr N, Fischer J. Effect of aging and curing mode on the compressive and indirect tensile strength of resin composite cements. Head Face Med. 2017;13:22.

Stawarczyk B, Hartmann R, Hartmann L, Roos M, Ozcan M, Sailer I, et al. The effect of dentin desensitizer on shear bond strength of conventional and self-adhesive resin luting cements after aging. Oper Dent. 2011;36:492–501.

Bahr N, Keul C, Edelhoff D, Eichberger M, Roos M, Gernet W, et al. Effect of different adhesives combined with two resin composite cements on shear bond strength to polymeric CAD/CAM materials. Dent Mater J. 2013;32:492–501.

Mota EG, Smidt LN, Fracasso LM, Burnett LH Jr, Spohr AM. The effect of milling and postmilling procedures on the surface roughness of CAD/CAM materials. J Esthet Restor Dent. 2017;29:450–8.

Cassina G, Fischer J, Rohr N. Correlation between flexural and indirect tensile strength of resin composite cements. Head Face Med. 2016;12:29.

Burgin S, Rohr N, Fischer J. Assessing degradation of composite resin cements during artificial aging by martens hardness. Head Face Med. 2017;13:9.

Ataol AS, Ergun G. Effects of surface treatments on repair bond strength of a new CAD/CAM ZLS glass ceramic and two different types of CAD/CAM ceramics. J Oral Sci. 2018;60:201–11.

Prochnow C, Venturini AB, Grasel R, Gundel A, Bottino MC, Valandro LF. Adhesion to a Lithium Disilicate glass ceramic etched with hydrofluoric acid at distinct concentrations. Braz Dent J. 2018;29:492–9.

Van Noort R, Noroozi S, Howard IC, Cardew G. A critique of bond strength measurements. J Dent. 1989;17:61–7.

Versluis A, Tantbirojn D, Douglas WH. Why do shear bond tests pull out dentin? J Dent Res. 1997;76:1298–307.

Acknowledgements

The authors are grateful to 3 M Espe, Ivoclar Vivadent, Kuraray and Vita Zahnfabrik for providing this study with materials and to Fredy Schmidli for the lab support.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

AS: data collector, given final approval of the version to be published, agreed to be accountable for all aspects of the work LR: data collector, given final approval of the version to be published, agreed to be accountable for all aspects of the work AG: manuscript draft, given final approval of the version to be published, agreed to be accountable for all aspects of the work JF: analysis and interpretation of data, critical revising, given final approval of the version to be published, agreed to be accountable for all aspects of the work NUZ: critical revising, given final approval of the version to be published, agreed to be accountable for all aspects of the work NR: analysis and interpretation of data, statistics, manuscript draft and critical revising, given final approval of the version to be published, agreed to be accountable for all aspects of the work.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

All authors declare they have no competing interests. However, JF is beside his function as Head of the Division of Dental Materials and Engineering at University of Basel - also Head of Research & Development at VITA Zahnfabrik. The materials were kindly provided by 3 M Espe, Ivoclar Vivadent, Kuraray and Vita Zahnfabrik without rights on the outcome of the study.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

About this article

Cite this article

Straface, A., Rupp, L., Gintaute, A. et al. HF etching of CAD/CAM materials: influence of HF concentration and etching time on shear bond strength. Head Face Med 15, 21 (2019). https://doi.org/10.1186/s13005-019-0206-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13005-019-0206-8