Abstract

Background

In this study, the antimicrobial activity of three different cleanser tablets on S. mutans and C. albicans adhesion to PMMA, polyamide and 3D printed resin was investigated.

Methods

40 samples were prepared for PMMA (SR Triplex Hot), polyamide (Deflex) and 3D printed resin (PowerResins Denture) materials and divided into four subgroups for cleansers (Aktident™, Protefix™, Corega™ tablets and distilled water) (n = 5). After the surface preparations were completed, the samples were immersed separately in tubes containing the prepared microorganism suspension and incubated at 37˚C for 24 h. After the incubation, the samples were kept in the cleanser solutions. The samples were then transferred to sterile saline tubes. All the tubes were vortexed and 10 µl was taken from each of them. Sheep blood agar was inoculated for colony counting. The inoculated plates were incubated for 48 h for S. mutans and 24 h for C. albicans. After incubation, colonies observed on all plates were counted. Statistical analyses were done with three-way ANOVA and Tukey’s multiple comparison test.

Results

Polyamide material registered the highest colony count of S. mutans, whereas PMMA registered the lowest. Significant differences in S. mutans adherence (p = 0.002) were found between the three denture base materials, but no such difference in C. albicans adherence (p = 0.221) was identified between the specimens. All three cleanser tablets eliminated 98% of S. mutans from all the material groups. In all these groups, as well, the antifungal effect of Corega™ on C. albicans was significantly higher than those of the other two cleanser tablets.

Conclusions

According to the study’s results, it may be better to pay attention to surface smoothness when using polyamide material to prevent microorganism retention. Cleanser tablets are clinically recommended to help maintain hygiene in removable denture users, especially Corega tablets that are more effective on C. albicans.

Similar content being viewed by others

Background

Many different base materials have been used to fabricate denture bases. The most commonly used material is polymethylmethacrylate (PMMA), but polyamides, acrylic resin derivatives, and metal alloys are also favored alternatives. PMMA remains superior to these because of its ease of manipulation, biocompatibility, dimensional stability, and economic properties [1, 2].

Despite the advantages of PMMA, however, it also suffers from certain disadvantages, such as a porous surface. Interdental spaces, the metal retainers for removable prostheses, and the indentations and protrusions created during the modeling of prostheses are conducive to microorganism retention. The scratches and microporosities that may occur during the polymerization and polishing of prostheses cause plaque to accumulate and bacterial and fungal colonies to proliferate [3, 4]. In addition to the disadvantages of PMMA, allergic reactions and the increasing aesthetic expectations of patients have prompted a search for alternative base materials. Examples include polyamides, which are thermoplastic polymers formed by the condensation reaction of a diamine and dibasic acid. These materials have high elasticity, sufficient strength, low amount of residual monomer, and superior aesthetic properties [5, 6]. The widespread use of acrylic resins and advances in material technology allow the use of different production techniques, such as subtractive and additive manufacturing [7]. Additive manufacturing, also known as three-dimensional (3D) printing, is a rapidly developing technique for creating objects by layering, used in many fields for dentistry, such as surgical guides, temporary restorations, and resin models. This technology can also contribute to the reduction of technical errors and the production of complex designs. Among its limitations are the insufficient resolution of current printers and shortcomings related to repetitive production [8,9,10].

Among oral flora, Streptococcus mutans is the microorganism that initially attaches to the surfaces of prostheses. The attachment of S. mutans to flat surfaces is explained by electrostatic forces [11, 12]. When S. mutans colonize in the oral flora, they provide not only an adhesion surface but also lactate, which can supply a carbon source on which Candida albicans cells can grow [13]. C. albicans is the most important etiologic cause for denture stomatitis. The literature reported that C. albicans is the most commonly proliferating microorganism in removable dentures (65%), while S. mutans and S. aureus are found in 53.3% and 34.4% of such prostheses, respectively [14,15,16].

Effective cleaning of dentures is necessary to prevent oral infection and systemic spread [17, 18]. Cleaning can be achieved through mechanical or chemical approaches or a combination of these, but the most preferred and economical method is brushing. The problem is that elderly patients cannot carry out effective brushing because of their poor manipulation skills and diminished vision [19, 20]. Therefore, the use of cleaning solutions that contribute to prosthetic hygiene by sanitizing hard-to-clean pores and spaces has become widespread. The most popular chemical cleaners are alkaline peroxides (sodium perborate, potassium monopersulfate), alkaline hypochlorites (sodium hypochlorite, trisodium phosphate), disinfectants (chlorhexidine, glutaraldehyde), diluted acids (hydrochloric acid, phosphoric acid), and enzymes [21,22,23]. Alkaline peroxide agents are available in powder form or as effervescent tablets. When alkaline peroxide is dissolved in water, the perborate produced reacts with the water, and a peroxide solution is formed, thereby releasing oxygen. This oxygen release plays a role in the micromechanical removal of attachments on prostheses. If used regularly, these cleaners can effectively remove residues [22, 24].

Studies have examined the effects of cleaning agents on the microbial uptake of acrylic base materials [19, 25,26,27], but the data is limited on which agent reduce the uptake of C. albicans and S. mutans in PMMA, polyamide, and 3D printing resins. The current research investigated how different cleanser tablets affect microorganism retention in PMMA, polyamide, and 3D-printed acrylic resin base materials. The investigation was guided by the following null hypotheses:

-

(1)

Differences in materials do not change the uptake of microorganisms.

-

(2)

There is no difference between the cleaning efficacy of various cleanser tablets.

Methods

Preparation of samples

Three base materials were used in the study: PMMA, polyamide, and 3D printed acrylic resin (Table 1). The minimum sample size to be included in the study was calculated as 4.85 ~ 5 for each group with a large effect size (f = 0.40), a type 1 error value of 0.05 and a power value of 0.90, for a total of 120 samples. In order to calculate the sample size, G-Power ver. 3.1.9.4 program was used [35, 36]. For each group of materials, 40 disc-shaped specimens (Ø10 × 3 mm ) were prepared (Fig. 1). PMMA samples were produced by using conventional heat polymerization technique whereas polyamide fabricated by injection-moulding. 3D printed samples were designed as a virtual Ø10 × 3 mm round disk and saved as a standard tessellation language file using a software program (Mashmixer, Autodesk). The design was crafted onto a biocompatible acrylic resin (PowerResins Denture™, Istanbul, Turkey) at a structural orientation of 90° using a digital light processing-based 3D printer (Dentafab Sega, 3Bfab Technology Company, Istanbul, Turkey). The specimens were soaked in isopropyl alcohol for one minute, then air-dried and postpolymerized in an ultraviolet device (Medifive, Twin Cure, Korea) at 405 nm for 10 min. To ensure standardization, the surfaces of all the samples were ground with 800-, 1000-, and 1200-grit silicon carbide abrasives (Gripo 2 V, Metkon, Bursa, Turkey) at 100 rpm under water cooling. The roughness of the standardized surfaces was checked using a contact profilometer (Surtronic 25, Taylor Hobson, Leicester, UK) with a measuring length of 4 mm and a speed of 1 mm/sec. Surface roughness values are shown in Table 2. For each material type, samples were randomly selected and divided into two subgroups to be tested using S. mutans and C. albicans.

Preparation of cleanser tablet solutions

To examine antimicrobial efficacy, four groups were formed: three that were cleaned using alkaline peroxide cleanser tablets and a control group cleaned by immersion in distilled water (n = 5). The tablets were reprepared daily with distilled water according to the manufacturers’ instructions. The manufacturers and usage details of the tablets are presented in Table 3.

Microorganism experiments

Surface preparations were completed, and the samples were sterilized with ethylene oxide. Bacterial suspensions containing S. mutans (obtained from the National Culture Collection of the Public Health Institution of Turkey) and C. albicans (patient isolate) strains were adjusted to a turbidity of 0.5 McFarland (10 for colony forming units (CFUs)/ml) using tryptic soy broth (1 ml) and brain–heart infusion broth (1 ml), respectively. All specimens whose surfaces were to be tested were immersed in tubes containing the prepared microorganism suspensions and incubated at 37 °C for 24 h. After incubation, all the samples were transferred into sterile tubes. Sterile saline (1 ml) was added to the tubes containing the control specimens, whereas the solutions (1 ml) prepared according to the manufacturers’ instructions were added to the tubes where the three other groups of specimens were kept (Table 3). The temperature at the surfaces of the prepared tubes was kept at 37 °C using cleaners. The samples were then transferred to tubes containing 500 µl of sterile saline. Each tube was vortexed for 30 s to allow the remaining microorganisms to flow into the saline. After vortexing, 10 µl of the solution in each tube was spread onto the surface of sheep blood agar (Oxoid™ Blood Agar Base, CM0055, Thermofisher Scientific, Denmark) plates for inoculation and colony counting. The plates inoculated with S. mutans were incubated for 48 h under a 5% CO atmosphere, whereas those inoculated with C. albicans were incubated for 24 h under normal atmospheric conditions. After incubation, the colonies observed on all the plates were counted using a Quebec Colony Counter (American Optical Corp., Buffalo, NY, USA) and on the basis of the classical formula for CFUs. The values obtained were multiplied by 100 to calculate CFU/ml.

Statistical analyzes

Data analyses were performed using JAMOVI (v. 2.0.0.0) and IBM SPSS (v. 23.0). Descriptive statistics are presented as mean ± standard deviation (mean ± SD). The normality of the data was assessed using the Kolmogorov-Smirnov test. As the data were normally distributed, they were analysed using three-way factorial ANOVA. In cases wherein differences were detected in the analysis, Tukey’s multiple comparison test was conducted to investigate the groups that caused such dissimilarities. A p < 0.05 was considered indicative of statistical significance.

Results

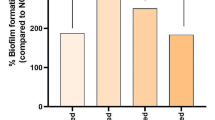

The average counts of S. mutans and C. albicans colonies in the control group are shown in Fig. 2. Polyamide material registered the highest colony count of S. mutans, whereas PMMA registered the lowest. Significant differences in S. mutans adherence (p = 0.002) were found between the three denture base materials, but no such difference in C. albicans adherence (p = 0.221) was identified between the specimens.

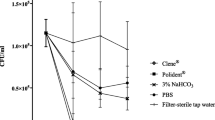

The descriptive statistics of the efficiency with which different microorganisms were cleaned and the efficiency of cleanser tablets across different acrylic resins are provided in Table 4. The three-way ANOVA uncovered significant differences in microbial adhesion between material types (< 0.0001), tablet types (< 0.0001), microorganism types (< 0.0001), interactions between microorganism–tablet factors (< 0.0001), and interactions between microorganism–material factors (0.006). No significant difference was found between the interactions of material, tablet, and microorganism types (p = 0.087) (Table 5). The control group (distilled water immersion) exhibited higher S. mutans and C. albicans adhesion than the tablet-treated groups, and this difference was significant. However, the C. albicans specimens cleaned with Corega™ showed significantly lower colony counts than those treated using Aktident™ and Protefix™, as determined by Tukey’s HSD test (Table 6). No significant difference in S. mutans colony count was found between the tablet-treated PMMA, polyamide, and 3D-printed specimens. Lower C. albicans adherence was found on the PMMA resin specimens, and this significantly differed from adherence in both the polyamide and 3D-printed samples after treatment with the cleanser tablets (Table 7).

The results on the cleaning efficiency (in percentage) of the tablets for the acrylic resins are listed in Table 8. All three cleanser tablets eliminated 98% of S. mutans from all the material groups. In all these groups, as well, the antifungal effect of Corega™ on C. albicans was significantly higher than those of the other two cleanser tablets (Aktident™ and Protefix™).

Discussion

Different production techniques affect the surface structures of materials and the attachment of microorganisms [28,29,30,31]. This study examined C. albicans and S. mutans adhesion on removable prosthetic materials fabricated through varying techniques and determined the effectiveness of denture cleanser tablets in removing these microorganisms from material surfaces. The null hypotheses were partially rejected. The results showed that C. albicans viability was influenced by the brand of cleanser tablet and the type of resin used.

In this study, C. albicans showed more adhesion to the base materials than S. mutans. This may be due to the differences in the adhesion mechanism between the two microorganisms. While S. mutans adheres to flat surfaces using electrostatic forces [12], C. albicans adheres in two stages. In the first stage, the microorganism reversibly adheres to the surface and in the second stage, colonisation and tighter attachment occurs [32]. In agreement with our results, Ozel et al. [33] investigated the retention of S. mutans and C. albicans on temporary crown materials and reported that Candida albicans was more prevalent in all material groups.

Polyamide resins generally exhibit a rougher structure than PMMA surfaces [25, 34]. To prevent effects from these differences, all the sample groups in this study were standardized through typical surface modification procedures, and their initial surfaces were measured using a profilometer (PMMA: 0.30 ± 0.05 μm, Polyamide:0.34 ± 0.02 μm, 3D: 0.28 ± 0.03 μm). Nevertheless, the highest S. mutans uptake in the control group was observed in the polyamide resins, followed by the 3D-printed specimens.

It was observed that the lowest retention of both microorganisms was in the PMMA group. A previous study on this topic also found that the retention of C. albicans was lower in PMMA than in polyamide, and this difference was explained by the fact that the residual monomer in PMMA inhibits adhesion by reducing the surface energy [35]. Meirowitz et al. [36] also reported in their study that 3D printed resins may play a predisposing role in denture stomatitis due to a higher colonisation of C. albicans compared to heat cured resins. The chemical composition of the 3D printed and conventional PMMA resins are almost similar, but the fabrication techniques reveals different. Several studies have reported inconsistent results with regarding the adhesion of C. albicans to 3D-printed dentures. The surface properties of the 3D resin can be influenced by factors such as the type of printer, layer thickness and structure angle, and printing orientation [37,38,39]. Koujan et al. [40] explored the adhesion of C. albicans to acrylic resins produced by different techniques (heat polymerization, CAD/CAM milling, and 3D printing) and found that microorganism adhesion is highest in 3D-printed acrylic resin. Another study inquired into the effects of acrylic production methods on C. albicans uptake and biofilm formation. The authors reported that the surface topography of 3D-printed resins increased microorganism uptake and that patients using prostheses made with this material should be closely monitored for oral hygiene [41]. In the present research, no statistical difference was found between the amount of colonization of C. albicans on different base materials, but the numerical data showed that these microorganisms were most prevalent in the 3D-printed resins. This result may be due to the surface properties of the layers in resins fabricated via 3D printing. Many authors have also reported that the dimpled surfaces formed by the connection between such layers irreversibly stimulate the settlement of microorganisms [42, 43].

Alkaline peroxide effervescent tablets usually contain sodium perborate and sodium bicarbonate. The sodium perborate dissociates from the alkaline peroxide solution formed when the tablets are dissolved in water. The peroxide solution releases oxygen and mechanically removes the debris; also produces oxygen free radicals with antimicrobial activity and enzymes that degrade biofilm proteins [44]. The actident cleanser tablets used in this study contained sodium bicarbonate, while Protefix and Corega tablets contained both sodium bicarbonate and sodium perborate and were used at different immersion times.

Most studies have been conducted on C. albicans, and no research has been found on the effects of cleanser tablets on S. mutans uptake on polyamide resins [25, 45]. In this study, results indicated that all the effervescent tablets showed strong antimicrobial activity against S. mutans colonization because of their superficial location on biofilm in the three acrylic resin groups, but they, except for Corega™, achieved insufficient effects against C. albicans. These results are compatible with the literature. For example, Souza et al.’s [46] study on the cleaning efficacy of propolis solution as well as saline and alkaline peroxide solutions on PMMA acrylic resins showed that Corega™ tablets containing alkaline peroxide are significantly effective against S. mutans and C. albicans. Another in vitro study on the efficacy of different alkaline peroxide tablets on some biofilms showed that Corega™ tablets effectively reduce the viability of both S. mutans and C. albicans biofilms [47]. Meanwhile, Andrade et al. [44] used Corega™ tablets and set the immersion time to 5 min to delve into the efficacy of effervescent tablets and ultrasonic cleaners against C. albicans and S. mutans in prosthesis biofilms. The authors found that the tablets significantly reduce S. mutans colonization but are inadequate against C. albicans. In our study, the holding times recommended by the manufacturers of the cleanser tablets (Corega™ = 15 min, Aktident™ = 15 min, and Protefix™ = 10 min) were used. The difference between this study and that of Andrade et al. in terms of the functioning of Corega™ may be related to the immersion time of the tablets. Similarly, the results derived by Volchkova et al. [48] differ from those of our research. The authors evaluated the effectiveness of cleansing soap and Protefix™ tablets on microorganisms in removable prostheses and noted that the latter satisfactorily reduces the amount of C. albicans on the materials under an immersion time of 15 min. Drake et al. [49] examined the effectiveness of antibacterial alkaline peroxide tablets on C. albicans and S. mutans. The authors similarly showed that whereas S. mutans colonization is largely eliminated, no significant reduction in colony occurs with respect to C. albicans.

The study by Hayran et al. [50] reported that the polarity of the resins may influence the anticandidal activity of denture cleanser tablets and that Corega tablets can be applied to all resin types. Although the polarities of the different base resins were not evaluated in our study, there are similarities with the relevant study in terms of the study groups (heat-cured PMMA, thermoplastic resin).

This in vitro study has some limitations. Under in vivo conditions, the antimicrobial properties of saliva may help to wash dentures and reduce microbial adhesion. Also, mechanical cleaning procedures and unpolished areas in contact with oral tissues can increase the retention of microorganisms. The parameters tested should be evaluated in an in vivo model to clearly understand the behavior of these materials and denture cleansers. Further studies are needed to investigate the activity and synergistic behavior of microorganisms in the complex biofilm environment.

Conclusions

These findings suggest that polyamide materials should have a smooth surface to avoid microbial retention. Cleanser tablets, especially Corega™ which are more effective against C. albicans, are clinically recommended to maintain hygiene in users of removable dentures. Further studies should focus on material parameters related to microbial growth.

Data availability

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- PMMA:

-

Poly Methyl Methacrylate

- CAD-CAM:

-

Computer aided design-Computer aided manufacturing

- 3D:

-

Three dimensional

References

İnan H, Tamam E, Bağış B. In vitro investigation of different base materials used in complete dentures in terms of surface roughness. Selcuk Univ Dişhek Fak Derg. 2008;17:171–6.

Machado C, Sanchez E, Azer SS, Uribe JM. Comparative study of the transverse strength of three denture base materials. J Dent. 2007;35(12):930–3.

Machmud E. Effectiveness of Roselle Effervescent Tablets as traditional Medicinal plants in preventing growth of Candida albicans colonies and Streptococcus mutans. J Contemp Dent Pract. 2018;19(8):925–8.

Dikbaş Ş, Köksal T. Substances and methods used in cleaning and disinfection of removable dentures. Hacettepe Dişhek Fak Derg. 2005;29:16–27.

Stafford GD, Huggett R, MacGregor AR, Graham J. The use of nylon as a denture-base material. J Dent. 1986;14:18–22.

Singh JP, et al. Flexible denture base material: a viable alternative to conventional acrylic denture base material. Contemp Clin Dent. 2011;2(4):313.

Anadioti E, Musharbash L, Blatz MB, Papavasiliou G, Kamposiora P. 3D printed complete removable dental prostheses: a narrative review. BMC Oral Health. 2020;20(1):1–9.

Anadioti E, Kane B, Soulas E. Current and emerging applications of 3D printing in restorative dentistry. Curr Oral Health Rep. 2018;5:133–9.

Bhargav A, Sanjairaj V, Rosa V, Feng LW, Yh JF. Applications of additive manufacturing in dentistry: a review. J Biomed Mater Res B Appl Biomater. 2018;106(5):2058–64.

Barazanchi A, Li KC, Al-Amleh B, Lyons K, Waddell JN. Additive technology: update on current materials and applications in dentistry. J Prosthodont. 2017;26(2):156–63.

Akca AE, Akca G, Gökce S, Sultan N, Özdemir A. Investigation of bacterial attachment in different fixed prosthetic restoration materials. Gülhane Tıp Derg. 2005;47(4):251–5.

Satou J, Fukunaga A, Satou N, Shintani H, Okuda K. Streptococcal adherence on various restorative materials. J Dent Res. 1988;67:588–91.

Metwalli KH, Khan SA, Krom BP, Jabra-Rizk MA. (2013). Streptococcus mutans, Candida albicans, and the human mouth: a sticky situation. PLoS Pathog, 9(10), e1003616].

Minagi S, Miyake Y, Inagaki K, Tsuru H, Suginaka H. Hydrophobic interaction in Candida albicans and Candida tropicalis adherence to various denture base resin materials. Infect Immun. 1985;47(1):11–4.

Ribeiro DG, Pavarina AC, Dovigo LN, Machado AL, Giampaolo ET, Verdant CE. Prevalence of Candida spp. associated with bacteria species on complete dentures. Gerodontology. 2012;29(3):203–8.

McIntyre GT. Oral candidosis. Dent Update. 2001;28:132–9.

Compagnoni MA, et al. Relationship between Candida and nocturnal denture wear: quantitative study. J Oral Rehabil. 2007;34:600–5.

Işeri U, Uludamar A, Ozkan YK. Effectiveness of different cleaning agents on the adherence of Candida albicans to acrylic denture base resin. Gerodontology. 2011;28(4):271–6.

Lucena-Ferreira SC, Ricomini-Filho AP, Silva WJ, Cury JA, Cury AA. Influence of daily immersion in denture cleanser on multispecies biofilm. Clin Oral Investig. 2014;18(9):2179–85.

Razak PA, Richard KM, Thankachan RP, Hafiz KA, Kumar KN, Sameer KM. Geriatric oral health: a review article. J Int Oral Health. 2014 Nov-Dec;6(6):110–6. PMID: 25628498; PMCID: PMC4295446.

Ausburger RH, Elahi JM. Evaluation of seven proprietary denture cleansers. J Prosthet Dent. 1982;47:356–8.

Budtz-Jorgensen E. Materials and methods for cleaning dentures. J Prosthet Dent. 1979;42:619–23.

Cakan U, Yilmaz T, Kara HB. Matrix of denture cleaning solutions in precision bonded dentures evaluation of its effect on retention. Selcuk Dent J. 2015;2(1):1–6.

Abelson DC. Denture plaque and denture cleansers. J Prosthet Dent. 1981;45(4):376–9.

Freitas-Fernandes FS, Cavalcanti YW, Ricomini AP, Filho, Silva WJ, Cury AADB, Bertolini MM. Effect of daily use of an enzymatic denture cleanser on Candida albicans biofilms formed on polyamide and poly (methyl methacrylate) resins: an in vitro study. J Prosthet Dent. 2014;112(6):1349–55.

Alfouzan AF, Tuwaym M, Aldaghri EN, et al. Efficacy of denture cleansers on Microbial Adherence and Surface Topography of Conventional and CAD/CAM-Processed denture base resins. Polym (Basel). 2023;15(2):460.

Silva FC, Kimpara ET, Mancini MN, Balducci I, Jorge AO, Koga-Ito CY. Effectiveness of six different disinfectants on removing five microbial species and effects on the topographic characteristics of acrylic resin. J Prosthodont. 2008;17(8):627–33.

Revilla-León M, Morillo JA, Att W, Ozcan M. Chemical composition, knoop hardness, surface roughness, and adhesion aspects of additively manufactured dental interim materials. J Prosthodont. 2021;30:698–705.

Aykent F, Yondem I, Ozyesil AG, Gunal SK, Avunduk MC, Ozkan S. Effect of different finishing techniques for restorative materials on the surface roughness and bacterial adhesion. J Prosthet Dent. 2010;103:221–7.

Bollen CML, Lambrechts P, Quirynen M. Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: a review of the literature. Dent Mater. 1997;13:258–69.

Kawai K, Urano M, Ebisu S. Effect of surface roughness of porcelain on adhesion of bacteria and their synthesizing glucans. J Prosthet Dent. 2000;83(6):664–7.

Waters MG, Williams DW, Jagger RG, Lewis MA. Adherence of Candida albicans to experimental denture soft lining materials. J Prosthet Dent. 1997;77(3):306–12. https://doi.org/10.1016/s0022-3913(97)70188-4.

Ozel GS, Guneser MB, Inan O, Eldeniz AU. Evaluation of C. Albicans and S. Mutans adherence on different provisional crown materials. J Adv Prosthodont. 2017;9(5):335–40. https://doi.org/10.4047/jap.2017.9.5.335. Epub 2017 Oct 16. PMID: 29142640; PMCID: PMC5673609.

Kawara M, Iwata Y, Iwasaki M, Komoda Y, Iida T, Asano T et al. Scratch test of thermoplastic denture base resins for non-metal clasp dentures. J Prosthodont Res. 2014;58(1):35–40.) 2014;112(6):1349-55.

de Freitas Fernandes FS, Pereira-Cenci T, da Silva WJ, Filho AP, Straioto FG, Del Bel Cury AA. Efficacy of denture cleansers on Candida spp. biofilm formed on polyamide and polymethyl methacrylate resins. J Prosthet Dent. 2011;105(1):51–8. https://doi.org/10.1016/S0022-3913(10)60192-8.

Meirowitz A, Rahmanov A, Shlomo E, Zelikman H, Dolev E, Sterer N. Effect of denture base fabrication technique on Candida albicans Adhesion in Vitro. Mater (Basel). 2021;14(1):221.

Goodacre BJ, Goodacre CJ. Additive manufacturing for complete denture fabrication: a narrative review. J Prosthodont. 2022;31(S1):47–51.

Li P, Fernandez PK, Spintzyk S, Schmidt F, Beuer F, Unkovskiy A. Effect of additive manufacturing method and build angle on surface characteristics and Candida albicans adhesion to 3D printed denture base polymers. J Dent. 2022;116:103889.

Alhajj MN, Halboub E, Yacob N, et al. Adhesion of Candida Albicans to digital versus conventional acrylic resins: a systematic review and meta-analysis. BMC Oral Health. 2024;24:303. https://doi.org/10.1186/s12903-024-04083-2.

Koujan A, Aggarwal H, Chen PH, Li Z, Givan DA, Zhang P, Fu CC. Evaluation of Candida albicans Adherence to CAD-CAM Milled, 3D-Printed, and heat-cured PMMA Resin and Efficacy of different disinfection techniques: an in Vitro Study. J Prosthodont. 2023;32(6):512–8.

Osman RB, Khoder G, Fayed B, Kedia RA, Elkareimi Y, Alharbi N. Influence of fabrication technique on adhesion and biofilm formation of Candida albicans to Conventional, Milled, and 3D-Printed denture base Resin materials: a comparative in Vitro Study. Polymers. 2023;15:1836.

Pereira-Cenci T, Cury AA, Cenci MS. In Vitro candida colonization on acrylic resins and denture liners: influence of surface free energy, roughness, saliva, and adhering bacteria. Int J Prosthodont. 2007;20:308–10.

Quirynen M, Marechal M, Busscher HJ. The influence of surface free energy and surface roughness on early plaque formation. An in vivo study in man. J Clin Periodontol. 1990;17:138–44.

de Andrade IM, Cruz PC, da Silva CH, de Souza RF, Paranhos Hde F, Candido RC, Marin JM, de Souza-Gugelmin MC. Effervescent tablets and ultrasonic devices against Candida and mutans Streptococci in denture biofilm. Gerodontology. 2011;28(4):264–70.

Ferreira MA, Pereira-Cenci T, Rodrigues de Vasconcelos LM, et al. Efficacy of denture cleansers on denture liners contaminated with Candida species. Clin Oral Investig. 2009;13:237–42.

De Souza RF, Silva-Lovato CH, De Arruda CNF, Regis RR, Zanini AP, Longo DL, De Paranhos HFO. Efficacy of a propolis solution for cleaning complete dentures. Am J Dent. 2019;32(6):306–10.

Paranhos HD, Coimbra FC, Salles MM, Oliveira VC, Macedo AP, Pagnano VD, Silva-Lovato CH. In vitro evaluation of the effectiveness of alkaline peroxide solutions in reducing the viability of specific biofilms. Am J Dent. 2019;32(4):201–7.

Volchkova IR, Yumashev AV, Borisov VV, Doroshina VI, Kristal EA, Repina SI. (2020). Influence of removable denture cleaning agents on adhesion of oral pathogenic Microflora A Randomized Controlled Trial. Open Dentistry J, 14(1).

Drake D, Wells J, Ettinger R. Efficacy of denture cleansing agents in an in vitro bacteria-yeast colonization model. Int J Prosthodont. 1992 May-Jun;5(3):214–20.

Hayran Y, Sarikaya I, Aydin A, Tekin YH. (2018). Determination of the effective anticandidal concentration of denture cleanser tablets on some denture base resins. J Appl oral Sci, 26, e20170077.

Acknowledgements

Not applicable.

Funding

The research does not have financial support.

Author information

Authors and Affiliations

Contributions

ŞEG prepared the samples, wrote the content of the article and assisted in microbial experiments. GS contributed to the editing of the article content, contributed to the preparation of samples, and assisted in microbial experiments.FC performed the microbial experiments.GG carried out the preparation of the samples, interpretation of the statistical analysis, and English translation of the article.All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Geduk, Ş.E., Sağlam, G., Cömert, F. et al. Antimicrobial activity of cleanser tablets against S. mutans and C. albicans on different denture base materials. BMC Oral Health 24, 633 (2024). https://doi.org/10.1186/s12903-024-04403-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12903-024-04403-6