Abstract

Purpose

This study aimed to investigate the effects of new and used burs on CAD-CAM PMMA resin color changes following thermocycling.

Materials and methods

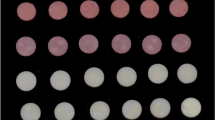

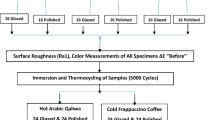

Twenty disk-shaped specimens (10 × 2 mm) were made using a single brand of CAD-CAM polymethyl methacrylate resin (Polident) for the color test. Group N consisted of half of the specimens that were machined using the new tungsten carbide bur set, and Group U consisted of the specimens that were milled using the used bur set (500 machining time). A color test was performed on the specimens both before and after thermocycling. For the statistical analysis, the Kruskal-Wallis and Dunn Pairwise Comparison tests were employed.

Results

The ∆E* value of specimens (2.057) milled with the used bur was higher than those of specimens milled with the new bur (0.340), but this value is within clinically acceptable limits. After thermocycling, specimens milled with the utilized burs had the greatest L* (93.850) and b* (5.000) values. After thermocycling, statistically significant differences were discovered between Group N and Group U as well as between specimens milled with the utilized bur before and after thermocycling.

Conclusion

Thermocycling process have an effect on the mean ∆E values of specimens milled with the used carbide bur, but these ∆E* values were not statistically significant.

Clinical significance

The color and clinical performance of CAD-CAM restorations may be affected by variations in CAD-CAM milling bur properties, particularly those related to their frequent use.

Similar content being viewed by others

Background

Preliminary restorations have long been made with polymethyl methacrylate (PMMA). While this material has been able to produce adequate temporary functional restorations, it has come with disadvantages such shrinkage, excess monomer, and color changes [1, 2]. Dentists now have access to long-term temporary restorations made of polymer materials manufactured with CAD/CAM technology, as an alternative to traditionally polymerized materials. These so-called high-density polymers are polymerized in an industrial setting with optimum pressure and temperature parameters, under regulated and standardized conditions. Because of this, temporary restorations made using CAD/CAM technology from industrially produced resin blocks have a higher mechanical stability than restorations made using conventional methods [3, 4]. Since the prosthesis may be subjected to functional stress during implantation therapies like full occlusal reconstruction, periodontal surgeries, and maxillofacial rehabilitations, these restorations have the potential to be used for longer clinical periods [5,6,7]. The importance of aesthetic appeal of temporary polymer restorations increases with the length of time they are utilized in clinical settings. In order for dental restorations to be aesthetically pleasing, they need to closely mimic natural teeth [8]. In addition, one of the key components in fulfilling expectations of patients is the aesthetic appearance of the prosthesis [9,10,11]. and attaining outcomes in aesthetically demanding areas that are physiologically acceptable.

Denture materials must be enhanced to better resist temperature variations in the oral cavity in order to extend the life of dental restorations. Like all materials, long-term interim restorations are exposed to the oral environment and intraoral temperature changes [12].

After prolonged use, a variety of factors can influence the color change of denture materials. These factors has been widely studied [13,14,15,16,17,18,19,20], however the effects of tungsten carbide bur quality on the color changes of CAD-CAM PMMA resins have not been investigated. For this reason, the aim of the current study was to assess the impact of new and used burs on the color changes of CAD-CAM PMMA resin after and before thermocycling. The hypotheses were that color changes of CAD-CAM PMMA resin materials would affected by the use of new and used burs.

Materials and methods

A single brand of CAD-CAM PMMA resin (PMMA CAD-CAM disc, multilayer; Polident d.o.o, Slovenija) was used to create a total of 20 disk-shaped specimens (10 × 2 mm) (n = 10/group). A CAD-CAM milling system (inlab MC X5, Sirona Dental System, GmbH, Germany) was used to mill the specimens. A total of ten disk-shaped specimens were machined using the new tungsten carbide bur sets (Dentsply, Slot 4, Bur 0.5 PMMA; Slot 5, Bur 1.0 PMMA; Slot 6, Bur 2.5 PMMA, Sirona), while the remaining ten were milled using the used burs, which had milled 500 PMMA crowns during 500 machining cycles.

CIE L*, a*, and b* [21] color values of all specimens were measured using a colorimeter EasyShade Advance (Vita Zahnfabrik, Bad Säckingen, Germany). L* a* b* values were measured at 3 different points on each specimen. Following that, these specimens were subjected to thermocycling (TC) (Thermocycler 1100/1200; SD Mechatronik, Germany) at 5000 cycles, 5 °C to 55 °C, 10 s transfer time, 30 s dwell time, and then color values of specimens were measured once more. Differences between the two color measurements (ΔE*) were calculated as a reference using the equation ΔE* (L, a,b)= [(L1 − L2)2+(a1 − a2)2+(b1 − b2)2]½ [21] where L1, a1 and b1 represent the values for the before thermal cycling and L2, a2 and b2 represent the values for the after thermal cycling. Clinically acceptable limits of the ΔE*value of specimens were evaluated as a reference using clinical color matching tolerance (Table 1) [22].

The Kruskal-Wallis and Dunn Pairwise comparison tests were used to assess the color difference values, with p-values of less than.05 being deemed statistically significant.

Results

Tables 2 and 3 displayed the mean values of L*, a*, and b*. Specimens milled with the used bur had a greater ΔE*value (2.057) than those milled with the new bur (0.340), although this difference is still within limits that are considered good/clinically acceptable (Table 4). After thermocycling, specimens milled with the utilized burs had the greatest L* (93.850) and b* (5.000) values. After thermocycling, statistically significant differences were discovered between Group N and Group U as well as between specimens milled with the utilized bur before and after thermocycling. There were no statistically significant variations in the a* values (Tables 2 and 3).

Discussion

Any color changes are among the most important clinical features of all dental materials. High color stability and resistance to color changes are desirable qualities for interim materials. High-pressure and temperature-polymerized PMMA resin blocks for CAD-CAM systems enhance optical characteristics and stability of color [23,24,25]. The current study investigated the effect of new and used burs on color changes of a CAD-CAM PMMA resin. Based on the findings, the hypothesis of the current study that new and used burs have an effect on color values of CAD-CAM PMMA specimens was partially rejected. In the current study L*, a* and b*values were increased in all specimens milled with the new tungsten carbide burs after thermocycling, but these were not statistically significant. However, statistically significant differences in L* and b* values were found in specimens milled with the used tungsten carbide burs. The color differences of specimens milled with the new tungsten carbide burs after thermocycling were clinically acceptable limits (ΔE*: 0.340). However, in specimens milled with the used tungsten carbide burs (ΔE*: 2.057), these values increased and, were within good/clinically acceptable (ΔE*<3.5) [22].

The Commission Internationale de l’Eclairage (CIE) L*a*b color system is a continuous color scale that encompasses all colors that are visible to the human eye. Therefore, it is suitable for research on how people perceive color variations in dental materials [23]. Worldwide, color research in dentistry is nearly solely conducted using the CIELAB color system. The CIE L*a*b* color scale is a roughly uniform color scale, meaning that variations in points displayed in the color space correlate to variations in colors as perceived visually. The CIE L*a*b* color space is arranged like a cube, with L* represented by the vertical axis. L* has values between 0 and 100, which indicate black and perfect reflecting diffuser, respectively [27]. The horizontal axes denoted as a* and b* correspond to the red-green and yellow-blue continuums, respectively. These continuums might have positive or negative values, and their numerical bounds are not specified [24].

The surface quality of interim restoration materials may be reduced and new surface defects may result from milling procedures [27]. Temperature changes and decreased resin surface quality can cause gradually color change of materials [30,31,32]. In the current study, particles of the milled CAD-CAM PMMA material may have gathered between the grooves of the bur with each use. Depending on how long and how often it was used, the surface of the bur may have worn. The surface of the bur may become worn from repeated use, which would reduce its ability to cut the surface of CAD-CAM PMMA material. This would also cause the milling quality of the bur to deteriorate and have an impact on the surface characteristics of material like surface roughness. The variation in the surface characteristics of CAD-CAM PMMA materials may have had an impact on the color qualities of materials. For this reason, in the current study, the specimens milled with the used bur may have exhibited the color changes after thermocycling.

For implant-supported prostheses, long-term interim restorations are needed following the immediate loading operation. These temporary restorations must tolerate prolonged occlusal loading and other oral environment factors, like as temperature variations, during the osseointegration process [31,32,33,34]. Long-term interim restorations should therefore have superior mechanical qualities and be able to endure the four to six month osseointegration and healing processes. As a result in the current study, the specimens were subjected to 5000 thermocycles, which corresponded to 6 months of physiological aging [35]. The samples milled using the used bur had a ΔE* value that was around six times higher than the ones milled with the new bur. The results of the current study suggested that, throughout the six months of use, the CAD-CAM PMMA temporary bridges milled with a used bur might potentially change color if they are subjected to acidic meals such as vinegar and colored beverages such as tea, coffee, and cola. This issue needs to be investigated with further studies.

Since this is one of the first research to look at how milling bur quality affects CAD-CAM PMMA resin color changes, the findings of current study cannot be compared to those of other studies. There has been a lot of study done on the properties of CAD-CAM resin materials, but not much has been done on the CAD-CAM systems themselves [12, 33, 36]. Whether the operators employed the burs in accordance with the manufacturer instructions or for a longer period of time was suspected to affect some properties of the CAD-CAM PMMA resin material. The results of this study should serve as a reminder that regular milling bur replacement is necessary to obtain satisfactory, consistent color outcomes for CAD-CAM PMMA resin. From an economic perspective, it is also critical to ascertain the duration during which CAD-CAM milling burs retain their cutting efficiency during the milling of different restorations.

The main purpose of this study was to investigate whether the bur quality affects the color change of the material. Therefore, we examined whether the use of used bur affects the color change of the PMMA. In our next study, we aim to see whether drinks with a coloring effect such as tea and coffee will cause color change in the PMMA material milled with the used bur. The current in vitro study had limitations in that it only evaluated one brand of CAD-CAM PMMA resin, only color changes of materials, and only one extent of milling using tungsten carbide burs (500 machining times). Future research should compare different resin materials, CAD-CAM systems, and milling procedures to better understand the effects of these variables and, ultimately, to improve the properties of CAD-CAM PMMA resin materials produced by CAD-CAM system.

Conclusions

Within the limitations of the current study, the following results were drawn.

-

1.

The L* values which indicate black and perfect reflecting diffuser and b*values which indicate yellow-blue continuums, of the tested interim materials with the used bur significantly increased after thermocycling.

-

2.

The ∆E* value (2.057 ) which indicate color difference of specimens milled with the used bur was higher than those of specimens milled with the new bur (0.340), but this value is within clinically acceptable limits.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper.

References

Tasın S, Ismatullaev A, Usumez A. Comparison of surface roughness and color stainability of 3-dimensionally printed interim prosthodontic material with conventionally fabricated and CAD-CAM milled materials. J Prosthet Dent. 2022;128:1094–101.

Al-Qahtani S, Tulbah HI, Binhasan M, Abbasi MS, Ahmed N, Shabib S, Farooq I, Aldahian N, Nisar SS, Tanveer SA, Vohra F, Abduljabbar T. Surface properties of polymer resins fabricated with subtractive and additive manufacturing techniques. Polym (Basel) 2021;24;13:4077.

Ellakany P, Fouda SM, Mahrous AA, AlGhamdi MA, Aly NM. Influence of CAD/CAM milling and 3D-printing fabrication methods on the mechanical properties of 3-unit interim fixed dental prosthesis after thermo-mechanical aging process. Polym (Basel) 2022:144103.

Wang C, Shi YF, Xie PJ, Wu JH. Accuracy of digital complete dentures: a systematic review of in vitro studies. J Prosthet Dent. 2021;125:249–56.

Song SY, Shin YH, Lee JY, Shin SW. Color stability of provisional restorative materials with different fabrication methods. J Adv Prosthodont. 2020;12:259–64.

Angwarawong T, Reeponmaha T, Angwaravong O. Influence of thermomechanical aging on marginal gap of CAD–CAM and conventional interim restorations. J Prosthet Dent. 2020;124:566.

Marwa I, Elagra MI, Rayyan MR, Alhomaidhi MM, Alanazi AA, Alnefaie MO. Color stability and marginal integrity of interim crowns: an in vitro study. Eur J Dent. 2017;11:330–4.

Güth JF, Zuch T, Zwinge S, Engels J, Stimmelmayr M, Edelhoff D. Optical properties of manually and CAD/CAM-fabricated polymers. Dent Mater J. 2013;32:865–71.

Heydecke G, Locker D, Awad MA, Lund JP, Feine JS. Oral and general health-related quality of life with conventional and implant dentures. Community Dent Oral Epidemiol. 2003;31:161–8.

- Sahin O, Koroglu A, Dede DÖ, Yilmaz B. Effect of surface sealant agents on the surface roughness and color stability of denture base materials. J Prosthet Dent. 2016;116:610–16.

Hong G, Murata H, Li Y, Sadamori S, Hamada T. Influence of denture cleansers on the color stability of three types of denture base acrylic resin. J Prosthet Dent. 2009;101:205–13.

Al-Dwairi ZN, Tahboub KY, Baba NZ, Goodacre CJ, Özcan M. A comparison of the surface properties of CAD/CAM and conventional polymethylmethacrylate (PMMA). J Prosthodont. 2019;28:452–7.

Shin JW, Kim JE, Choi YJ, Shin SH, Nam NE, Shim J-S, et al. Evaluation of the Color Stability of 3D-Printed Crown and Bridge materials against various sources of discoloration: an in Vitro Study. Mater. 2020;13:5359.

Kim JE, Choi WH, Lee D, Shin Y, Park SH, Roh BD, Kim D. Color and translucency stability of three-dimensional printable dental materials for crown and bridge restorations. Mater. 2021;14:650.

Gruber S, Kamnoedboon P, Özcan M, Srinivasan M. CAD/CAM complete denture resins: an in vitro evaluation of color stability. J Prosthodont. 2021;30:430–9.

Song SY, Shin YH, Lee JY, Shin SW. Color stability of provisional restorative materials with different fabrication methods. J Adv Prosthodont. 2020;12:259.

Ellakany P, Fouda SM, AlGhamdi MA, Aly NM. Comparison of the color stability and surface roughness of 3-unit provisional fixed partial dentures fabricated by milling, conventional and different 3D printing fabrication techniques. J Dent. 2023;131:104458.

Yao Q, Morton D, Eckert GJ, Lin WS. The effect of surface treatments on the color stability of CAD-CAM interim fixed dental prostheses. J Prosthet Dent. 2021;126:248–53.

Takhtdar M, Azizimoghadam N, Kalantari MH, Mohaghegh M. Effect of denture cleansers on color stability and surface roughness of denture bases fabricated from three different techniques: conventional heat-polymerizing, CAD/CAM additive, and CAD/CAM subtractive manufacturing. Clin Exp Dent Res. 2023;9:840–50.

Sayegh MS, Daou M, Najjar G, Zebouni E. In vitro comparison of the color degradation of two computer–aided design/computer–aided manufacturing provisional materials: a 12–month simulation. J Indian Prosthodont Soc. 2023;23:38–44.

Imamura S, Takahashi H, Hayakawa I, Loyaga-Rendon PG, Minakuchi S. Effect of filler type and polishing on the discoloration of composite resin artificial teeth. Dent Mater J. 2008;27:802–8.

Chu FC, Chow TW, Chai J. Contrast ratios and masking ability of three types of ceramic veneers. J Prosthet Dent. 2007;98:359–64.

Liebermann T, Wimmer PR, Schmidlin H, Scherer P, Loffler ¨M, Roos B, Stawarczyk. Physicomechanical characterization of polyetheretherketone andcurrent esthetic dental CAD/CAM polymers after aging in different storage media,J. Prosthet Dent. 2016;115:321–e3282.

Goiato MC, Santos DM, Haddad MF, Pesqueira AA. Effect of accelerated aging on the microhardness and color stability of flexible resins for dentures. Braz Oral Res. 2010;24:114–9.

Edelhoff D, Beuer F, Schweiger J, Stimmelmayr M, Güth JF. CAD/CAM-generated high-density polymer restorations for the pre-treatment of complex cases: a case report. Quint Int. 2012;43:457–67.

Pervin Imirzalioglu, Ozgul Karacaer, Burak Yilmaz, Ilknur Ozmen Msc. Color stability of denture acrylic resins and a soft lining material against tea, coffee, and nicotine. J Prosthodont. 2010;19:118–24.

Xu BT, Zhang B, Kang Y, Wang YN, Li Q. Applicability of CIELAB/CIEDE2000 formula in visual color assessments of metal ceramic restorations. J Dent. 2012;40(Suppl 1):e39.

Huan H. Machining characteristics and surface integrity of yttria stabilized tetragonal zirconia in high speed deep grinding. Mater Sci Eng A 2003;345: 155-63.

Bitencourt SB, Kanda RY, Jorge CF, Barão VAR, Sukotjo C, Wee AG, et al. Long-term stainability of interim prosthetic materials in acidic/staining solutions . J Esthet Restor Dent. 2020;32:73–80.

Shinawi LA. Effect of denture cleaning on abrasion resistance and surface topography of polymerized CAD CAM acrylic resin denture base. Electron Physician. 2017;9:4281–88.

Proussaefs P. Immediate provisionalization with a CAD/CAM interim abutment and crown: a guided soft tissue healing technique. J Prosthet Dent. 2015;113:91–5.

Scotti CK, Velo MMAC, Rizzante FAP, de Lima Nascimento TR, Mondelli RFL, Bombonatti JFF. Physical and surface properties of a 3Dprinted composite resin for a digital workflow. J Prosthet Dent. 2020;124:e6141–5.

Della Bona A, Cantelli V, Britto VT, Collares KF, Stansbury JW. 3D printing restorative materials using a stereolithographic technique: a systematic review. Dent Mater. 2021;37(2):336–50.

Schepke U, Meijer HJ, Kerdijk W, Cune MS. Digital versus analog complete-arch impressions for single-unit premolar implant crowns: operating time and patient preference. J Prosthet Dent. 2015;114(3):403–6. e1.

Gale MS, Darvell BW. Thermal cycling procedures for laboratory testing of dental restorations. J Dent. 1999;27:89–99.

Sagsoz NP, Yanıkoglu N, Ulu H, Bayındır F. Color changes of polyamid and polymetyhl methacrylate denture base materials. Open J Stomatol. 2014;4:489–96.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

P.O; Investigation, Methodology, Writting-Original draf preparation, Supervision, Writing-Reviewing and Editing., M.U; Investigation, Methodology.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Oyar, P., Ulusoy, M. Effect of milling procedures in CAD-CAM systems on the color changes of CAD-CAM polymethyl methacrylate resin material as interim material. BMC Oral Health 24, 618 (2024). https://doi.org/10.1186/s12903-024-04350-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12903-024-04350-2