Abstract

In this article, we present a straightforward in-situ approach for producing Ag NPs incorporated in graphene oxide (GO) blended with glutaraldehyde (GA) cross-linked polyvinyl alcohol (PVA) matrix. Samples are γ-irradiated by doses of 2, 5, and 10 kGy and in comparison with the pristine films, the thermal conductivity (‘k’) and effusivity are measured. ‘k’ decreases with irradiation doses up to 5 kGy and further increase in the dosage results increase in ‘k’. We performed FDTD modeling to verify the effect of polarization and periodicity on the absorptivity and emissivity spectra that are correlated to the ‘k’ and effusivity, empirically. Hence, we can confess that the structural properties of the prepared hybrid nanocomposite are manipulated by γ-irradiation. This attests that the PVA/GO-Ag/GA nanocomposite is radiation-sensitive and could be employed for thermal management systems. Moreover, their strong electrical insulation, as the measured dc conductivity of the γ-irradiated samples is found to be in the range of 2.66 × 10−8–4.319 × 10−7 Sm−1, which is below the percolation threshold of 1.0 × 10−6 Sm−1, demonstrates that they are excellent candidates for the use of thermal management materials. The low ‘k’ values allow us to use this promising material as thermal insulating substrates in microsensors and microsystems. They are also great choices for usage as wire and cable insulation in nuclear reactors due to their superior electrical insulation.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Thermal interface materials (TIMs) based on polymer dielectrics encounter low thermal conductivity (k) and can be modified by adding high k fillers [1]. Attaining high ‘k’ under a lower volume fraction while leveraging the thermal resistance at the interface between polymer matrix and filler [2] is a prodigious task. However, 2D nanosheets can be good fillers prevailing unique surficial properties, but result in dampened ‘k’ [3]. Phonon spectrum mismatch between polymer matrix and 2D nanosheets is responsible for this diminishment. Thus, regulating the ‘k’ path through filler-filler configuration can transcend the negative effect of interfacial thermal resistance [4] between filler and polymer matrix [5]. Thermal management materials (TMMs) with superior ‘k’ are very much necessary to exploit heat dissipation in modern applications for off-peak electricity storage, electronic circuits, energy-saving buildings, chemical reactors, data center industries, and thermal resonators [6,7,8,9]. Hence, blending 2D nanosheets with polymeric nanocomposites for designing a flexible, cost-effective, and lightweight filler-filler matrix of high ‘k’ can allow us to exploit the waste heat for stable and reliable energy harvesting devices [10,11,12].

Thermal effusivity or inertia delineates the thermal energy-transferring ability of a material, which is the direct square root product of ‘k’ and heat capacity [13, 14]. It is salient that the precise control of effusivity can directly manifest the ‘k’. Nano-enhanced phase change materials (NEPCMs) can drastically enhance the thermophysical properties by means of ‘k’, such as phase transition temperature, rheological effects, and chemical stability [15, 16]. Besides hybridization with nanoparticles (NPs) and hydrated salts can synergistically yield high thermal storage materials to achieve superior performance of devices [17, 18]. Among the numerous materials, silver (Ag NPs) possess exceptional thermal and electrical properties [16, 19,20,21,22] having the capability of augmenting static and transient thermal gradients [23, 24], which pre-eminently function with high ‘k’ fluctuations. The thermal gradients (∇T) have an intriguing influence on energy harvesting techniques such as photothermal (photovoltaic), mechanical (electromagnetic, electrostatic, piezoelectric), thermal (temperature gradient, temperature variation in pyroelectrics) [25, 26]. Photothermal responses based on Ag NPs demonstrate exceptional bonding and antibonding plasmonic resonance localization in optical frequencies, which can be meticulously tuned by manipulating the structural, morphological, and dispersion of NPs in these polymeric nanocomposites. Nonetheless, the periodicity (P) of NP dimers (having close proximity) driven plasmon hybridization will unveil resonances that govern the amount of photothermal heat generated owing to their plasmonic bonding modes. The localized surface plasmon resonance (LSPR) modes at resonant frequency (ωLSPR) result in scattering and absorption, which predominantly depend on the structural and chemical properties of the NPs, based polymer composites. Henceforth, conscientious and diligent maneuvering of these structural and chemical properties will fetch controllable absorptivity that can ultimately steer the thermal effusivity and ‘k’, accordingly.

That being the case, enhancing the structural and chemical properties of the 2D nanosheet blended polymer nanocomposites is a pioneering work in achieving enhanced photothermally induced heat energy production. Despite the biodegradable related disadvantages, their essential usage is accounted for their superior ‘k’ in radiation-sensitive and radiation-resistant applications [27, 28]. In this study, we prepared Ag NPs incorporated (in-situ) in graphene oxide (GO) blended with glutaraldehyde (GA) cross-linked polyvinyl alcohol (PVA) matrix in in-situ, simply referred to as “PVA/GO-Ag/GA”. Due to their numerous potential applications in the fields of energy storage and conversion, biosensors, catalysts, photocatalysts, surface-enhanced Raman scattering (SERS), diagnostics, imaging, drug delivery, and antibacterial agents, metal-decorated graphene oxide composites have attracted a lot of interest in the scientific community [29, 30]. Thanks to the thermal characteristics of graphene and its compounds [31, 32], the GO can act as a great filler facilitating heterogeneous nucleation sites to promote polymer crystallization and the heterogeneous nucleation effect is more effective at low filler concentrations [33]. γ-irradiation of these hybrid polymer nanocomposites is a proven non-destructive industrial technique that is widely employed to revamp their structural properties. Long polymer chains are either cross-linked and/or scissile when subjected to high-energy radiations like γ-rays [34]. Both scissile or cross-linking are typically favored by each other. In the pursuit of effective nanoscale device fabrication, harnessing substantial incident light becomes pivotal, leveraging the characteristics of NPs such as size, shape, orientation, and polarization, along with the properties of the surrounding medium. An overarching objective of our study is to fine-tune thermal conductivity by strategically manipulating the structural, morphological, and dispersion aspects of NPs in polymeric nanocomposites through gamma irradiation at relatively low doses. This deliberate control over structural and chemical properties opens avenues for achieving adjustable thermal conductivity, offering potential applications in thermal management systems. Subsequently, we can regulate the photothermal-driven effusivity and ‘k’, respectively, which have fundamental impacts on heat insulation efficiency.

On the other hand, the ‘k’ that is dependent on optical absorptivity owing to the presence of NPs surrounded by polymer matrix, holds a straightforward relation with emissivity [35]. Gustav Kirchhoff's law of thermal radiation states that given an object in thermal equilibrium with the surrounding radiation field consists of identical absorptivity and emissivity for every frequency, direction, and polarization [36]. It connotes, the more an object can absorb electromagnetic (EM) radiation, the more it can also emit the same kind of radiation ensuring less reflection and scattering. Compositional nanospheres like heteromolecular trimers (Au–Ag–Au) display twofold absorption and heat generation in a finite and isolated subwavelength structure [37]. To perceive this, we have carried out a finite difference time domain (FDTD) numerical investigation on the PVA/GO-Ag/GA matrix, evaluating the absorptivity and emissivity spectra under P-polarized (0°) and S-polarized (90°) radiation. It is evident that the polarization has negligible influence on the observed absorptivity and emissivity spectra for all periodicities at the nanoscale regime ascribing to the structural symmetry of NPs. This acquaints us with the validation of Kirchhoff's law; however, the light-matter interaction is unalike for both polarization states of the incident radiation. This is attested by the photothermal-induced power absorptivity profiles, which unveil the enhanced heat energy harvesting capability of PVA/GO-Ag/GA that can be correlated to thermal effusivity and ‘k’. Nevertheless, the thermal effusivity and ‘k’ plots are leveraging with the electrical characterization of γ-irradiated (of doses 0, 2, 5, 10 kGy) PVA/GO-Ag/GA matrix also authenticate the aforementioned results confessing that the proposed work can unveil heat conservation mechanism for fabricating the next generation TIMs.

2 Experimental section

2.1 Materials and methods

We purchased the silver nitrate (AgNO3), PVA (MW about 1, 15,000), sulphuric acid (H2SO4), and graphite powder (98% purity) from Loba Chemie Private Limited. The high-grade chemicals hydrogen peroxide (H2O2), sodium nitrate (NaNO3), potassium permanganate (KMNO4), and hydrochloric acid (HCl) were supplied by Merck Life Science Pvt. Ltd. glutaraldehyde was purchased from SD Fine Chem. Limited.

2.2 The synthesis of the GO

GO was prepared using Hummer's method [38]. Here, 50 ml of sulphuric acid and 3 g of graphite powder were combined and stirred constantly in an ice bath. The mixture was then mixed with 9 g of potassium permanganate and 3 g of sodium nitrate. The liquid was constantly kept stirring at room temperature after being removed from the ice bath. 5 ml of deionized water was added after stirring the mixture for 15 min at a steady temperature of 90 °C. To get rid of any potassium permanganate and manganese dioxide that might still be present, 150 ml of deionized water and 150 ml of hydrogen peroxide were added to the heated mixture. Then the pH was neutralized by washing after collecting the GO slurry.

2.3 Fabricating the PVA/GO-Ag/GA films

20 ml of deionized water with 0.5 weight percent of GO was sonicated for an hour. Later, 20 ml of H2O was added to PVA along with constant stirring and heating, until the mixture turned clear aqueous solution. Sonicated GO solution was then added to this and the mixture was stirred for an hour at 50 °C. The solution was constantly kept at a temperature of 50 °C for 1 more hour while being stirred and added 0.1 weight percent AgNO3 and 2 ml (1 vol%) of GA. Further, the pristine films (0 kGy) were γ-irradiated by 2 kGy, 5 kGy, and 10 kGy doses and the samples were denoted as shown in Table A1 (supplementary information).

2.4 Irradiation studies

The gamma irradiation process was conducted at the Centre for Application of Radioisotopes and Radiation Technology (CARRT), Mangalore University, Mangalagangotri, Konaje—574,199, Karnataka, India. The specifications of the gamma irradiation chamber 5000 include a Co60 source capacity (maximum) of 13,455 Ci (497.8 TBq at the time of irradiation). The dose rate at maximum capacity is 9.5 kGy/hr, with radial dose rate uniformity of + 25% or better.

The irradiation chamber has a sample chamber volume of 5 L and dimensions of 17.2 cm (diameter) × 20.5 cm (height). The chamber is constructed with lead and stainless steel for effective shielding. The overall unit size is 125 cm (length) × 106.5 cm (width) × 150 cm (height), and the irradiation time range starts from 6 s onwards.

2.5 Characterization

Infrared Fourier Transform (FTIR) spectra were collected using a Bruker OPUS 7.0 Alpha spectrometer, covering the range of 400–4000 cm−1. These spectra allowed us to investigate interfacial interactions involving PVA. UV–vis transmittance spectra of polymer nanocomposites were obtained utilizing a UV–vis spectrometer with a 200–800 nm wavelength range and was specifically a Shimadzu UV-1800 spectrophotometer. The X-ray diffractometer used for recording the XRD patterns of the samples was the Rigaku Ultima IV, Using Cu K radiation (wavelength: 0.1541 nm). The thermal conductivity measurements were conducted using the Modified Transient Plane Source (MTPS) method, incorporating C-Therm's single-sided sensor with guard ring technology. This sensor is adept at accommodating a wide array of sample types, ranging from solids and liquids to powders and pastes. Offering a measurement range of 0–500 W/mK and a temperature range of − 50 to 500 °C, the MTPS sensor ensures comprehensive thermal conductivity characterization. To guarantee accuracy, samples were meticulously prepared with a flat edge, ensuring a minimum diameter of 18 mm for optimal contact with the sensor. This methodology ensures the reliability and precision of the acquired thermal conductivity data.

3 Results and discussions

3.1 Morphological analysis

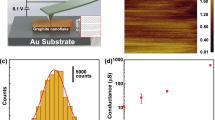

Figure 1 represents the surface morphology of PVA/GO-Ag/GA films with and without γ-irradiation. Figure 1a is 0 kGy film (S1) while Fig. 1b–d refers to the 2, 5, and 10 kGy γ-irradiated films (S2, S3, and, S4), respectively. We can see in Fig. 1a the distributed layers of GO in the PVA matrix after the addition of fillers to pristine PVA (Fig. A2) (supplementary information) as a result of GA crosslinking GO and the PVA matrix. Additionally, white bright spots that appear on the PVA crosslinked GO matrix show that Ag NPs have formed, and the size of the Ag NPs is shown in the supplementary Fig. A1a (supplementary information). As a result of γ-irradiation, the surface texture of the nanocomposite has sleeked. Nevertheless, the size of Ag NPs increases upon γ-irradiation as seen in Fig. A1a–c (supplementary information), but for the dose of 10 kGy, the size is decreased (Fig. A1d) (supplementary information). This is ascribed to the saturation of the influence of γ-irradiation occurring after 5 kGy, which caused the internal structural changes justified by the FTIR analysis described in Fig. A3a (supplementary information) in the supplementary information. This is elucidated by observing the γ-irradiated PVA/GO-Ag/GA nanocomposite film's spectra in comparison to the unirradiated film, which caused the polymer's crystalline structure to deteriorate as explained in Fig. A3b (supplementary information). The XRD patterns of unirradiated and γ-irradiated PVA and PVA/GO-Ag/GA are given in Fig. A3b (supplementary information) and crystallite data are summarized in Table A2 (supplementary information).

3.2 Photothermal studies

To discern the optothermal absorptivity and emissivity in the presence of Ag NPs surrounded by polymer matrix in relation to emissivity in a finite and isolated subwavelength structure (i.e. PVA/GO-Ag/GA), we performed an FDTD modeling at 300 K as illustrated in Fig. 2. With reference to Fig. A1 (supplementary information), the average diameter of Ag NPs is calculated as 48, 50, 82, and 72 nm for the γ-irradiation doses 0, 2, 5, and 10 kGy, respectively. Complementing the closely matching diameters of NPs of 0, 2 kGy, and 5, 10 kGy, accordingly, we considered the average diameter (d) of 48, 74 nm in the simulation to investigate the absorptivity and emissivity under the influence of polarization irrespective of the geometrical symmetry. This is to analyze the thermal absorptivity effect in terms of the structural changes resulting in terms of particle size and periodicity. Therefore, we illuminated the structure as shown in Fig. 2a with a Gaussian wave source (GWS) whose electric field vector is oscillating along the X-axis while propagating in the Z-direction. The Ag NPs [with optical constants of [39]] are submerged in the PVA/GO/GA polymer matrix where the ratio of optical constants of PVA: GO: GA is approximated based on the experimental molar ratios as 96:3:1 [40,41,42]. Figure 2b, c are the P-, S-polarization states of EM waves irradiating the structure under symmetry boundary conditions (BCs). The difference is that the electric field vector should always oscillate parallel to the anti-symmetric BCs owing to the laws of EM radiation. This is explicated with the top (XY) plane view of the structure above Fig. 2c as a reference. Perfectly matched layer BCs are chosen in the GWS direction to clear the dissipation of normally incident radiation at the boundaries in order to avoid reflections from walls.

FDTD simulation modeling of PVA/GO-Ag/ GA of a schematic representation of the structure illuminated by the Gaussian wave source in the Z-direction (here, P is the periodicity of Ag NPs, E-electric, M-magnetic field vectors, k-propagation vector, and R, T are transmission monitors to capture the power transmitted) b polarization 0° (or P-polarization), c polarization 90° (or S-polarization) under symmetry boundary conditions (BCs), correspondingly. The XY plane representation from the top view is shown for the E-, M-field vector orientation with reference to the BCs

Figure 3 explains the polarization-dependent absorptivity and emissivity spectra of Ag NPs dispersed in the PVA/GO/GA polymer matrix. Both curves are in good agreement with a slight discrepancy, as the power absorbed is a bit higher than emitted. This is because the material can never be a perfect blackbody to emit an equal amount of power absorbed when interaction with EM radiation takes place. The diameter of the Ag NPs is taken as 48 nm (corresponding to 0, 2 kGy) and 74 nm (corresponding to 5, 10 kGy) for this study with reference to Fig. A1 (supplementary information). The periodicity of NPs is intentionally varied as 60, 72, and 96 nm for 48 nm, and 90, 111, and 148 nm for 74 nm, to examine the influence of power absorptivity by NPs with respect to the close proximity to each other in response to the incoming radiation.

a–f P-Polarization and g–l S-polarization dependent absorptivity and emissivity spectra with LSPR resonance wavelength for the 0, 2, 5, and 10 kGy based NP sizes. a–c, g–i correspond to the periodicity 60, 72, 96 nm, and d–f, j–l correspond to the periodicity 90, 111, and 148 nm with respect to the polarization state of incident radiation, correspondingly

As we observe, the LSPR absorptivity peak of Ag is left shifted more or less around 400 nm except for the P = 90 nm for the d = 74 nm, in both polarization states of GWS. When the NPs are in close proximity, the LSPR wavelength tends to approach lower wavelengths below 400 nm (P = 60, 72, 96 nm) for both polarization states. The shift in absorptivity is accounted for by the opaque nature of metals below the plasmon frequency i.e. 420 nm for Ag NPs. However, for the higher diameters (74 nm) the left shift is observed but starting from 420 nm. In terms of absorption, the incident light, being normal, can couple into outgoing radiation modes (in transmission or reflection) that conserve the wave vector up to a reciprocal lattice vector in a direction of discrete periodicity.

To confess, the electric field intensity profiles are captured in Fig. 4a, b for both P-, 4(c, d) for S-polarization states at the respective wavelengths obtained for the corresponding ‘P’ and ‘d’ values referring to the 0, 2, 5, 10 kGy radiation doses in Fig. 3, accordingly. For better illustration, we have normalized the scale of the profiles to 0–10. Although there is no variation in the LSPR wavelength of absorption for respective periodicities in Fig. 3, we can witness that the structure is disparate in response to the incoming radiation. The electric field intensity distribution across the surfaces is shared among the surfaces of NPs when they are in close proximity and solely confining on the surfaces while they move distance from each other. Surface plasmons (SPs) are excitations that exist on the interface between a plane metal and a dielectric. They are confined to the surface but can propagate freely within that surface. This is similar for both P-, and S-polarization states irrespective of size and periodicity. However, for the S-polarization (90°) state it is trivial to evidence at lower periodicities with a 0–10 scale as given in Fig. 4c, d. To verify this, we have obtained the profiles at a lower scale, which are given in Fig. A3 (supplementary information). For the d = 48 nm (P = 60 nm; at 391 nm), we can see that the field is localized at the interface of the top surface of NP and dielectric-air interface when the NPs are in close proximity. Whereas, at 398 nm (P = 72 nm) the field is more dominant at the bottom surface while at 400 nm (P = 96 nm) it is concentrated only at the bottom, correspondingly. In the case of d = 74 nm, the LSPR wavelength 420 nm (P = 90 nm) shows the field is intending to localize at the bottom. But the 408 nm (P = 111 nm), both top and bottom surfaces try to confine the field while it is dominant at the bottom. For the 406 nm (P = 148 nm) it is only confined at the bottom of the NP. This can be interpreted as the fabricated structure being polarization sensitive and enabling it as an efficient and potential material for photothermovoltaic applications.

Electric field intensity profiles at the respective wavelengths referred to in Fig. 3 for both P-, and S-polarization states of normally illuminated PVA/GO-Ag/GA structure, respectively

To justify, we have captured the power absorption profiles and is summarized in Fig. 5 for the corresponding LSPR wavelengths mentioned for the d, P values in Fig. 3. Likewise, for the electric field intensity distribution for the polarization 90°, we have plotted the profiles at a lower scale to elucidate the power absorption spots within the NPs in Fig. A4 (supplementary information). This attests to our observation in Fig. 4 and also validates that the thermal absorptivity or emissivity is sensitive to the polarization and periodicity of NPs surrounded by the dielectric polymer matrix under thermal equilibrium.

Power absorbed in normally illuminated PVA/GO-Ag/GA structure at the respective wavelengths referred to in Fig. 3 for both P-, and S-polarization states, respectively

3.3 Thermal conductivity

Correlating the thermal absorptivity profiles obtained from the modeling we have investigated the thermal conductivity of the prepared PVA/GO-Ag/GA hybrid nanocomposite. The main heat carriers in metals are typically electrons, whereas the main heat carriers in polymers are phonons. In reality, it is conceivable that in the ordered structure of crystals, when an atom in the lattice vibrates, it transfers vibrational energy to the surrounding atoms, which in turn starts to oscillate and spread the energy further into the sample. Thermally, amorphous materials can be viewed as a collection of many imperfections that prevent heat transport. Although atoms can vibrate slightly close to the equilibrium position in the ordered molecular chains of crystalline regions of polymers, where heat transfers quickly, persistent random entanglement causes phonon scattering and affects phonon transport, leading to low k values [1, 43].

Using the following Eq. (1), the thermal conductivity (k) of nanocomposites was determined: ρ is the density of the nanocomposites, Cp is the specific heat, and σ is the thermal diffusivity, resulting in

Figure 6 depicts the thermal conductivity of nanocomposites irradiated for different gamma dosages. In the case of S1, the addition of nanocomposites boosts the thermal conductivity of PVA (Table 1), by effectively bridging the neighboring PVA-Ag-GA layers with GO, Ag NPs assist in maintaining the continuity of the thermal conductive network and create efficient thermally conductive routes, providing PVA composites with better thermal functionality. Reduced effective phonon scattering centers resulted in decreased interfacial thermal resistance due to the synergistic action of GO and Ag and improved heat conductivity [10].

As seen in Fig. 6, when the nanocomposite is subjected to radiation, the thermal conductivity drops because energy deposits may cause ionization, excitation, and the breaking of chemical bonds, which will lead to the formation of numerous free radical species. These radiation-induced free radicals instantaneously interact with the oxygen dissolved in the polymer nanocomposite to cause phonon scattering [31, 32]. Also according to a study by Lorenzo Mirizzi et al., amorphous materials have low thermal conductivity (k), due to the lack of crystalline structures. Defects (such as voids, entanglements, chain ends, and impurities) give rise to excess scattering events and reduce thermal conductivity [44] and Table A2 (supplementary information) shows that calculated values of crystallinity index decrease for S2 indicating the amorphous nature of the sample. As a result, the 2 kGy dose of radiation reduces the thermal conductivity of nanocomposites, k value decreases for S3. For sample S4, the k value increases. This is due to the fact that, as shown in Table A2 (supplementary information), an increase in irradiation dose causes the composites' crystallinity to increase, which raises the k value.

When comparing the thermal conductivity of nanocomposites with the pure matrix, thermal conductivity enhancement (TCE) was taken into account and given by [17]

where kp and kn stand for PVA’s and nanocomposites’ respective thermal conductivities. When compared to pure PVA, the TCE of the unirradiated sample was found to be 1.53 as noticed in Table 1, which is higher than irradiated nanocomposites.

3.4 Thermal effusivity

In addition to thermal conductivity, which is an important thermal property for heat conduction in solids, thermal effusivity (e) is a highly significant thermal parameter that controls the processes of heat transmission and heat exchange for solids and liquids. The relationship between these quantities is provided by [45]

where c is the specific heat capacity, ρ is the mass density and k is the thermal conductivity Ws1/2 m−2 K−1. The obtained thermal effusivity values for S1 show an improvement with the addition of filler content as seen in Fig. 6 and Table 1, demonstrating better heat exchange and transfer than S0. This is because when crystallinity rises, effective thermal pathways are created. For samples S2 and S3, irradiation causes a decrease in crystallinity, which leads to a decreasing phonon mean free path that causes excessive phonon scattering and hence lowers effusivity. Additionally, as the dose is increased, the crystallinity rises, favoring the improvement of effusivity [46].

3.5 Electrical conductivity

I-V (current–voltage) characteristics of the PVA/GO-Ag/GA have been carried out in the voltage range of -2 to 2 V in light of the fact that the electrical insulation of the filler likely had an impact on the use of nanocomposites in electronic devices. The plot of I-V characteristics of irradiated and unirradiated PVA/GO-Ag/GA nanocomposites is presented in Fig. 7. The measured values of electrical resistance and conductivity are depicted in Table 2. It is found that the dc (direct current) conductivity of S0 is 6.72 × 10−9 Sm−1, when nanofillers are added to GA cross-linked PVA, conductivity was found to have increased by one order (2.32 × 10−8 Sm−1). The rise in dc conductivity is caused by the creation of a charge transfer complex between the nanofillers and the cross-linked PVA matrix. Ag creates charge transfer complexes, lowering the barrier between the conducting channel and the trapping site, causing conduction at grain boundaries.

The secondary electrons produced during ionization undergo collision with other electrons in the nanocomposite, resulting in energy deposition and localized heating. This localized heating due above processes may introduce structural changes that adversely affect the electrical conductivity of the nanocomposite. When nanocomposites are exposed to γ-radiation dc conductivity increases and is found to be 4.319 × 10−7 Sm−1 for S2, this is because of the production of ions and free radicals, initially, some of them are trapped in the sample as the dose increases trapped charges are released and allows the easy movement of the charge carrier which increase the orderliness of dipole groups [47]. As the gamma dose increased to 5 kGy and 10 kGy conductivity decreased to 1.87 × 10−7 Sm−1 and 2.66 × 10−8 Sm−1 respectively, this is because charges are tightly packed in the matrix due to an increase in crystallinity. However, in comparison with the electrical conductivity of graphene-based polymer nanocomposite (1.0 × 10–6 Sm−1) at the percolation threshold [17], dc conductivity values of the PVA/GO-Ag/GA samples are far below. This indicates that the presence of insulating GO preventing the formation of electrical transfer pathways.

Generally, materials with enhanced electrical conductivity also exhibit higher thermal conductivity, especially if the conductive pathways for charge carriers coincide with paths for heat conduction. The relationship between electrical and thermal conductivity can be complex and is influenced by factors such as the type of fillers, their distribution, and the overall composite structure.

In our composite, after the sample is irradiated to 2 kGy electrical conductivity rises from 2.32 × 10−8 to 4.319 × 10−7 Sm−1. This might be due to the fact that as seen in Fig. A3a (supplementary information), the OH peak of S2 broadens after irradiation, indicating a decrease in the OH group due to bond breaking and chain scission. Additionally, a decline in the intensity of bands at 1421 and 1373 cm−1 suggests the decoupling of Ag–O and Ag-C bonds due to weak interactions between C-H and O–H vibrations. These structural changes, induced by irradiation, result in defects, the formation of free radicals, and a reduction in crystallinity, ultimately leading to increased electrical conductivity. Whereas thermal conductivity decreases from 0.40 ± 0.01 to 0.34 ± 0.01 Wm−1 K−1. The weak interaction between contacted fillers can contribute to high contact thermal resistance, leading to poor thermal coupling between the filler and matrix. This typically results in limited enhancement of thermal conductance in the composite due to a significant mismatch in the phonon spectra of the interface components.

Table 2 shows that electrical conductivity decreases with an increase in dose from 5 kGy onwards. This is because crystallinity reverts as PVA macromolecules crosslink, enhancing molecular mass. This crosslinking surrounds the nanoparticle, reducing nanoparticle mobility and, consequently, decreasing electrical conductivity. As the dose increases, the molecular mass around the nanoparticle further increases, leading to a continuous decrease in electrical conductivity. Contrastingly Table 1 reveals that thermal conductivity decreases up to 5 kGy and further increases for 10 kGy owing to an increase in crystallinity as evident from XRD. This divergence is because thermal properties exhibit marked differences from electrical properties in composites. The electrical properties of the organic matrix are negligible, with only the conductive fillers contributing to electrical conductivity. In contrast, for thermal transport, there is no absolute thermal insulator, and the contribution from thermal transport, through the organic matrix cannot be ignored. In summary, the observed changes in thermal and electrical properties at different irradiation doses are intricately linked to mechanisms such as secondary electron collisions, energy transfer to phonons, and radiolytic heating, highlighting the complex interplay between gamma radiation and the PVA/GO-Ag/Glutaraldehyde nanocomposite.

To the best of our knowledge, there have been very limited studies on the effect of gamma irradiation on the thermal conductivity of polymer nanocomposites. Table 3 shows that a recent study by Tarawneh MA et al. focused on the radiation effect on the thermal conductivity of TPE (thermoplastic elastomer) /CNT (carbon nanotube)/nanoclay, revealing an increase in conductivity with a dose increase from 0 to 150 kGy. However, with a further increase in the dose to 200 to 250 kGy, the thermal conductivity decreases to that of the unirradiated state.

In our work, the thermal conductivity value is found to be 0.4 Wm−1 K−1 for 0 kGy, and a decreasing trend is observed from 2 to 5 kGy doses. Interestingly, with an increase in the dose to 10 kGy, the thermal conductivity value shows an increase. This consistent change in thermal conductivity values indicates that the material can be tuned for the required thermal conductivity by gamma irradiation in thermal management systems. The merit of our work lies in tailoring the thermal conductivity at a relatively low gamma dose.

4 Conclusions

In this paper, we have prepared Ag NPs incorporated in graphene oxide (GO) blended with glutaraldehyde (GA) cross-linked polyvinyl alcohol (PVA) matrix by in-situ method, simply referred to as “PVA/GO-Ag/GA”. Upon γ-irradiating these films with the 0, 2, 5, and 10 kGy doses in order to structurally modify them for the enhancement of electrical and thermal properties. Using the FDTD modeling, we have studied the optothermal properties that are correlated with the thermal conductivity and effusivity of the hybrid nanocomposite. The prepared structure exhibits excellent thermal stability with respect to the polarization of incident radiation and makes it a very good candidate for photothermovoltaic applications. The results of the measurements show that at room temperature, thermal conductivity (k) initially falls with irradiation doses and increases as the dosage increases. With increasing dose, dc electrical conductivity first rises and then falls. An electrical conductivity of 4.319 × 10−7 Sm−1 was observed for the sample exposed to a 2 kGy dose, which is below the value of 1.0 × 10–6 Sm−1 observed at the percolation threshold. Studies on thermal and electrical performance show that these composite materials have outstanding suitability for the application of thermal management materials. These materials are found to be promising materials as thermal insulating substrates in microsensors and microsystems owing to the low thermal conductivity values. Along with that, their strong electrical insulation demonstrates that they are excellent candidates for use as wire and cable insulation in nuclear reactors.

4.1 Supplementary information: This information contains

-

1.

Comparison of particle size of pristine (a) 0 kGy and γ-irradiated PVA/GO-Ag/ GA (b) 2 kGy, (c) 5 kGy, and (d) 10 kGy, correspondingly.

-

2.

SEM image of pristine PVA

-

3.

a)FTIR spectra and (b) XRD patterns of pristine (0 kGy) and γ-irradiated PVA/GO-Ag/ GA nanocomposite films [48,49,50,51,52]

-

4.

Electric field intensity profiles at the respective wavelengths referred to in Fig. 3 for S-polarization states of normally illuminated PVA/GO-Ag/GA structure, respectively.

-

5.

Power absorbed in normally illuminated PVA/GO-Ag/GA structure at the respective wavelengths referred to in Fig. 3 for S-polarization states, respectively.

-

6.

Representation of samples with different irradiation doses.

-

7.

The crystallinity index and crystallite size values of PVA/GO-Ag/GA were obtained from XRD data.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and its supplementary information files.

References

Mirizzi L, Carnevale M, D’arienzo M, Milanese C, Di Credico B, Mostoni S, et al. Tailoring the thermal conductivity of rubber nanocomposites by inorganic systems: opportunities and challenges for their application in tires formulation. Molecules. 2021. https://doi.org/10.3390/molecules26123555.

Dang TML, Kim CY, Zhang Y, Yang JF, Masaki T, Yoon DH. Enhanced thermal conductivity of polymer composites via hybrid fillers of anisotropic aluminum nitride whiskers and isotropic spheres. Compos B Eng. 2017;114:237–46. https://doi.org/10.1016/j.compositesb.2017.02.008.

Sun M, Gao G, Dai B, Yang L, Liu K, Zhang S, et al. Enhancement in thermal conductivity of polymer composites through the construction of graphene/nanodiamond bi-network thermal transfer paths. Mater Lett. 2020. https://doi.org/10.1016/j.matlet.2020.127772.

Gao J, Yan Q, Lv L, Tan X, Ying J, Yang K, et al. Lightweight thermal interface materials based on hierarchically structured graphene paper with superior through-plane thermal conductivity. Chem Eng J. 2021. https://doi.org/10.1016/j.cej.2021.129609.

Hamidinejad SM, Chu RKM, Zhao B, Park CB, Filleter T. Enhanced thermal conductivity of graphene nanoplatelet-polymer nanocomposites fabricated via supercritical fluid-assisted in situ exfoliation. ACS Appl Mater Interfaces. 2018;10:1225–36. https://doi.org/10.1021/acsami.7b15170.

Kang JS, Wu H, Hu Y. Thermal properties and phonon spectral characterization of synthetic boron phosphide for high thermal conductivity applications. Nano Lett. 2017;17:7507–14. https://doi.org/10.1021/acs.nanolett.7b03437.

Liu Y, Wu K, Luo F, Lu M, Xiao F, Du X, et al. Significantly enhanced thermal conductivity in polyvinyl alcohol composites enabled by dopamine-modified graphene nanoplatelets. Compos Part A Appl Sci Manuf. 2019;117:134–43. https://doi.org/10.1016/j.compositesa.2018.11.015.

Garimella SV, Yeh LT, Persoons T. Thermal management challenges in telecommunication systems and data centers. IEEE Trans Compon Packaging Manuf Technol. 2012;2:1307–16. https://doi.org/10.1109/TCPMT.2012.2185797.

Zhang X, Zhang H, Li D, Xu H, Huang Y, Liu Y, et al. Highly thermally conductive and electrically insulating polydimethylsiloxane composites prepared by ultrasonic-assisted forced infiltration for thermal management applications. Compos B Eng. 2021. https://doi.org/10.1016/j.compositesb.2021.109207.

Yuan H, Li T, Wang Y, Wang X, Zhang X, Xia B, et al. Surface modification of BNNS bridged by graphene oxide and Ag nanoparticles: a strategy to get the balance between thermal conductivity and mechanical property. Compos Commun. 2021. https://doi.org/10.1016/j.coco.2021.100851.

Yang L, Zhang L, Li C. Bridging boron nitride nanosheets with oriented carbon nanotubes by electrospinning for the fabrication of thermal conductivity enhanced flexible nanocomposites. Compos Sci Technol. 2020. https://doi.org/10.1016/j.compscitech.2020.108429.

Agarwal S, Saxena NS, Kumar V. Temperature dependence thermal conductivity of ZnS/PMMA. Nanocomposite. 2014. https://doi.org/10.1007/978-3-319-03002-9_190.

Balderas-Lopeztt JA, Acosta-Avalost D, Alvaradot JJ, Sanchez-Sinenciot F, Falconyt C, Cruz-Oreas A, et al (1995) Photoacoustic measurements of transparent liquid samples: thermal effusivity Photoacoustic measurements of 1 transparent liquid samples: thermal 1 effusivity 5 Progiama Multidisciplinario en 6.

Wang J, Bras RL, Sivandran G, Knox RG. A simple method for the estimation of thermal inertia. Geophys Res Lett. 2010. https://doi.org/10.1029/2009GL041851.

Williams JD, Peterson GP. A review of thermal property enhancements of low-temperature nano-enhanced phase change materials. Nanomaterials. 2021;11:2578.

Guo Y, Ruan K, Shi X, Yang X, Gu J. Factors affecting thermal conductivities of the polymers and polymer composites: a review. Compos Sci Technol. 2020. https://doi.org/10.1016/j.compscitech.2020.108134.

Li X, Li Y, Alam MM, Miao J, Chen P, Xia R, et al. Enhanced through-plane thermal conductivity in Polymer nanocomposites by constructing graphene-supported BN nanotubes. J Mater Chem C Mater. 2020;8:9569–75. https://doi.org/10.1039/d0tc01871f.

Li X, Li Y, Alam MM, Chen P, Xia R, Wu B, et al. Enhanced thermal conductivity of nanocomposites with MOF-derived encapsulated magnetic oriented carbon nanotube-grafted graphene polyhedra. RSC Ad. 2020;10:3357–65. https://doi.org/10.1039/c9ra09199h.

Prof Dr. B, Gawad Mohammed Rabiea A, Ismaiel Ali Z, Abdel Aziz Meligi G, Mohammed Sayed H (2013) Radiation-induced synthesis of conducting polymer nanocomposite.

Yan Ma MZ, Wenjing Chen, Shikun Xiao (2022) Nano-Ag modified bio-based shape-stable phase change material for thermal energy storage. Int J Energy Res.

Yuan-kai Sun, Ya-fei Zhang, Li Xie (2022) Progress in the treatment of drug-induced liver injury with natural products. Pharmacol Res 183.

Darvin JR, Hossain MS, Nabil M, Uertz J, Mills G. Concentrated Ag nanoparticles in dodecane as phase change materials for thermal energy storage. ACS Appl Nano Mater. 2019;2:6187–96. https://doi.org/10.1021/acsanm.9b01027.

Joseph A Paradiso, Thad Starner (2005) Energy scavenging for mobile and wireless electronics. IEEE CS and IEEE ComSoc.

Quoilin S, Orosz M, Hemond H, Lemort V. Performance and design optimization of a low-cost solar organic Rankine cycle for remote power generation. Sol Energy. 2011;85:955–66. https://doi.org/10.1016/j.solener.2011.02.010.

Sebald G, Guyomar D, Agbossou A. On thermoelectric and pyroelectric energy harvesting. Smart Mater Struct. 2009. https://doi.org/10.1088/0964-1726/18/12/125006.

Ahmadivand A, Pala N. Analyzing photothermal heat generation efficiency in a molecular plasmonic silver nanomatryushka dimer. Plasmonics. 2016;11:493–501. https://doi.org/10.1007/s11468-015-0075-3/Published.

Tarawneh MA, Saraireh SA, Chen RS, Ahmad SH, Al-Tarawni MAM, Yu LJ. Gamma irradiation influence on mechanical, thermal, and conductivity properties of hybrid carbon nanotubes/montmorillonite nanocomposites. Radiat Phys Chem. 2021. https://doi.org/10.1016/j.radphyschem.2020.109168.

Tarafdar S, De SK, Manna S, De U, Nanda P (2010) Variation in viscosity and ion conductivity of a polymer-salt complex exposed to gamma irradiation 74.

Choi MS, Mirzaei A, Bang JH, Oum W, Kim SS, Kim HW. Improvement of NO2 sensing properties in Pd functionalized reduced graphene oxides by electron-beam irradiation. Front Mater. 2019. https://doi.org/10.3389/fmats.2019.00197.

Cobos M, De-La-Pinta I, Quindós G, Fernández MJ, Fernández MD. One-step eco-friendly synthesized silver-graphene oxide/poly(vinyl alcohol) antibacterial nanocomposites. Carbon N Y. 2019;150:101–16. https://doi.org/10.1016/j.carbon.2019.05.011.

Chen J, Li L. Effect of oxidation degree on the thermal properties of graphene oxide. J Market Res. 2020;9:13740–8. https://doi.org/10.1016/j.jmrt.2020.09.092.

Dreyer DR, Park S, Bielawski CW, Ruoff RS. The chemistry of graphene oxide. Chem Soc Rev. 2010;39:228–40. https://doi.org/10.1039/b917103g.

Mehra N, Mu L, Ji T, Yang X, Kong J, Gu J, et al. Thermal transport in polymeric materials and across composite interfaces. Appl Mater Today. 2018;12:92–130. https://doi.org/10.1016/j.apmt.2018.04.004.

Spadaro G, Alessi S, Dispenza C. Ionizing radiation-induced crosslinking and degradation of polymers. In: Sun Y, Chmielewski AG, editors. Applications of ionizing radiation in materials processing, 1. Poland: Institute of Nuclear Chemistry and Technology; 2017. p. 1–516.

Atallah S. A relationship between emissivity and thermal conductivity of metals. Brit J Appl Phys. 1966;17(4):573–4.

Luo C, Narayanaswamy A, Chen G, Joannopoulos JD. Thermal radiation from photonic crystals: a direct calculation. Phys Rev Lett. 2004. https://doi.org/10.1103/PhysRevLett.93.213905.

Toroghi S, Kik PG. Photothermal response enhancement in heterogeneous plasmon-resonant nanoparticle trimers. Phys Rev B Condens Matter Mater Phys. 2014. https://doi.org/10.1103/PhysRevB.90.205414.

Williams .Hummersjr ., Richarde . Offeman (1958) Preparation of graphitic oxide. J Am Soc 1339.

Edward DP, editor. Handbook of optical constants of solids. Academic Press; 1985.

Schnepf MJ, Mayer M, Kuttner C, Tebbe M, Wolf D, Dulle M, et al. Nanorattles with tailored electric field enhancement. Nanoscale. 2017;9:9376–85. https://doi.org/10.1039/c7nr02952g.

Politano GG, Vena C, Desiderio G, Versace C. Variable angle spectroscopic ellipsometry characterization of Reduced Graphene Oxide stabilized with poly(sodium 4-styrene sulfonate). Coatings. 2020. https://doi.org/10.3390/COATINGS10080743.

https://pubchem.ncbi.nlm.nih.gov/compound/Glutaraldehyde#section=Odor-Threshold

Gresil M, Wang Z, Poutrel QA, Soutis C. Thermal diffusivity mapping of graphene-based polymer nanocomposites. Sci Rep. 2017. https://doi.org/10.1038/s41598-017-05866-0.

Xu X, Chen J, Zhou J, Li B. Thermal conductivity of polymers and their nanocomposites. Adv Mater. 2018. https://doi.org/10.1002/adma.201705544.

El-Brolossy TA, Almutawa A. Thermal diffusivity and thermal effusivity enhancement of graphene-based polyvinyl chloride nanocomposites. IOP Conf Ser Mater Sci Eng. 2020. https://doi.org/10.1088/1757-899X/762/1/012006.

Faraji N, Mahmood Mat Yunus W, Kharazmi A, Saion E, Behzad K. Open photoacoustic cell configuration applied to the thermal characterization of liquid CdS nanocomposites. Int J Thermophys. 2014;35:53–61. https://doi.org/10.1007/s10765-013-1551-7.

Lotfy S, Atta A, Abdeltwab E. Comparative study of gamma and ion beam irradiation of polymeric nanocomposite on electrical conductivity. J Appl Polym Sci. 2018. https://doi.org/10.1002/app.46146.

Mruthyunjayappa KC, Paramashivaiah SA, Mallikarjunappa EK, Padre SM, Gurumurthy SC, Surabhi S, et al. A combined experimental and computational study of flexible polyvinyl alcohol (PVA)/graphene oxide (GO) nanocomposite films for superior UV shielding with improved mechanical properties. Mater Today Commun. 2023. https://doi.org/10.1016/j.mtcomm.105662.

Sunitha VR, Radhakrishnan S. Gamma irradiation effects on conductivity and dielectric behavior of PEO-based nano-composite polymer electrolyte systems. Polym Bull. 2020;77:655–70. https://doi.org/10.1007/s00289-019-02770-7.

Abdelaziz M, Abdelrazek EM. Effect of dopant mixture on structural, optical, and electron spin resonance properties of polyvinyl alcohol. Physica B Condens Matter. 2007;390:1–9. https://doi.org/10.1016/j.physb.2006.07.067.

Mahendia S, Tomar AK, Kumar S. Nano-Ag doping induced changes in optical and electrical behavior of PVA films. Mater Sci Eng B Solid State Mater Adv Technol. 2011;176:530–4. https://doi.org/10.1016/j.mseb.2011.01.008.

Abdelghany AM, Abdelrazek EM, Badr SI, Morsi MA. Effect of gamma-irradiation on (PEO/PVP)/Au nanocomposite: Materials for electrochemical and optical applications. Mater Des. 2016;97:532–43. https://doi.org/10.1016/j.matdes.2016.02.082.

Acknowledgements

The authors are thankful to the Director, of CARRT, Mangalore University, for extending the irradiation facility. All the authors are grateful to their respective organizations and ESSS (Engineering Simulation Scientific Software), Chile SPA for their invaluable technical support. Srivathsava Surabhi (FONDECYT Project No 3200832), D. V. Morales (FONDECYT Project No 3200467) are greatly indebted to the Programa Fondo Nacional de Desarrollo Científico y Tecnológico (FONDECYT) de la Agencia Nacional de Investigación y Desarrollo (ANID), Chile. Jong-Ryul Jeong (Project No 2020R1A2C1006136) is thankful to NRF-South Korea.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study's conception and design. Material preparation, data collection and analysis were performed by KCM, EKM*, SJS, GSC*, SS, NPT, J-RJ, DVMM. All authors read and approved the final manuscript. KCM: Carried out the experiment and analyse the data, Writing- Original draft preparation. EKM: Conceptualization and Methodology, Data Curation and Supervision. SJS: Involved in all stages of characterisation of samples. GSC: Data Curration, Validation and Manuscript preparation and co-supervision. SS: Carried out theoretical simulation, validation, and editing. NPT: Thermal conductivity measurement. J-RJ: Software and carried theoretical simulation. DVMM: Software and carried theoretical simulation. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Ethical approval

We all the authors declare that experiments carried out in this work not involve any human tissue.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kavitha, C.M., Eshwarappa, K.M., Shetty, S.J. et al. Modification of thermal and electrical characteristics of hybrid polymer nanocomposites through gamma irradiation for advanced applications. Discover Nano 19, 34 (2024). https://doi.org/10.1186/s11671-024-03972-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-024-03972-3