Abstract

A new, sizable family of 2D transition metal carbonitrides, carbides, and nitrides known as MXenes has attracted a lot of attention in recent years. This is because MXenes exhibit a variety of intriguing physical, chemical, mechanical, and electrochemical characteristics that are closely linked to the wide variety of their surface terminations and elemental compositions. Particularly, MXenes are readily converted into composites with materials including oxides, polymers, and CNTs, which makes it possible to modify their characteristics for a variety of uses. MXenes and MXene-based composites have demonstrated tremendous promise in environmental applications due to their excellent reducibility, conductivity, and biocompatibility, in addition to their well-known rise to prominence as electrode materials in the energy storage sector. The remarkable characteristics of 2D MXene, including high conductivity, high specific surface area, and enhanced hydrophilicity, account for the increasing prominence of its use in storage devices. In this review, we highlight the most recent developments in the use of MXenes and MXene-based composites for electrochemical energy storage while summarizing their synthesis and characteristics. Key attention is paid to applications in supercapacitors, batteries, and their flexible components. Future research challenges and perspectives are also described.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

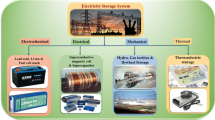

The two most important issues to be dealt with as quickly as possible to stop global climate change are energy and the environment. It should be accorded the highest priority because these are interconnected. Since fossil fuel burning accounts for the greater portion of air pollution and subsequent global warming in today's globe, clean energy sources are still being sought after [1,2,3]. One of the acknowledged causes for the search for clean energy technologies is the current shift in consumer desire for electric automobiles, smart devices, monitors, the Internet of things (IoT), etc. [4, 5]. Some of the clean energy sources are solar, wind, biomass, geothermal, etc. Among them, solar energy has been widely utilized for electricity supply. The output of the energy varies greatly depending on factors like the hour of the day and the season due to the intermittency of renewable energy. To use the energy that is produced, especially during peak hours, it must be stored. A predicted power generation and consumption curve for renewable energy for a particular season is shown in Fig. 1. From the figure, the amount of electricity generated in a given time (green region) is greater than what the load needs. In this case, the excess energy needs to be stored with the intervention of a storage device [6]. Both for mobile and stationary applications, the selection criteria for renewable energy storage options are still up for debate.

Adapted from reference [6], Copyright (2017) by the authors. Licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license

Average electricity generation and consumption from renewable energy.

Although conventional capacitors are attractive options for the said applications, there are still concerns about the resources' availability, durability, scalability, and ability to be recycled after decomposition. Some potential electrochemical energy storage (EES) technologies are the supercapacitor (SC) and batteries, which can address or support these problems when used in conjunction with other sustainable energy sources. While SCs can produce high power densities, good cycle rates, low self-discharge, and a wide temperature range, they suffer in the area of low energy density, as shown in Fig. 2. Batteries, on the other hand, are one of the main sources of available electrochemical conversion and storage devices with high energy densities but lacking in terms of self-discharge, charging time, life cycle, temperature tolerance, and various risks in transport applications [7, 8].

Ragone plot for the various energy storage and conversion devices. Adapted with permission [8], Copyright (2015), John Wiley and Sons

One of the most essential components of these EES devices is the electrode. The effectiveness of the electrodes affects the device's performance. Any device's effectiveness in real-time applications depends on the stability and building blocks of its material qualities, which can be customized for each application. It is well established that tailoring nanoscale properties have a much greater impact than tailoring bulk size qualities. Depending on their quantum confinement, nanoscale materials can be categorized as zero-dimension (0D) [9, 10], one-dimension (1D) [11], two-dimension (2D) [12, 13], and three-dimension (3D) [14]. 2D materials have received substantial study due to their intriguing features for a variety of applications. The study of 2D materials is a particularly interesting field in the development of new materials, from graphene and its derivatives to dichalcogenides. 2D materials like graphene have developed their own aesthetic and are advancing toward commercialization. Due to their structural characteristics and other benefits, carbon and its derivatives, including carbon nanofibers, carbon nanotubes, and carbon nanospheres, have been used as EES electrodes.

MXene has also attracted a lot of research interest as one of the most recent 2D materials. Generally speaking, MXenes were being researched for usage as electrode materials in SCs and lithium-ion batteries (LIBs) because of their remarkable characteristics, including high conductivity, high specific surface area, and enhanced hydrophilicity [15]. The primary method of producing MXenes is by etching the A layers from various MAX phases, comprising ternary nitrides or carbides with the chemical formula Mn+1AXn (M denotes an early transition metal, A denotes a group IVA or IIIA element, X denotes C, and/or N, and n = 1, 2, 3, 4). MAX phases have layered hexagonal structures; the Mn+1Xn units and the A layers are stacked alternately. Since M-X bonds are substantially stronger than M-A bonds, it is possible to selectively chemically etch the A layers without damaging the M-X bonds, leaving behind weakly bonded Mn+1Xn layers that are easily separable by sonication [16, 17]. There are two types of MXenes: (i) double transition metal (DTM) MXenes, where D stands for two separate transition metals represented by M' and M", and (ii) mono-TM MXenes, where TM stands for only a single type of TM, as in Ti2CTx, V2CTx, Ti3C2Tx, and Nb4C3Tx. DTM MXene is identical to mono-TM MXene, except that two TMs of the DTM occupy metal sites instead of just one TM [18]. Based on its structure, DTM MXene may be categorized as (i) ordered (Fig. 3a, b) or (ii) solid solution MXene (Fig. 3c). For the first category, M and M" occupy either in-plane (like Mo4/3Y2/3CTx) or out-of-plane (OOP) sites, respectively (like Mo2TiC2Tx and Mo2Ti2C3Tx). According to Fig. 3a, in-plane ordered MXene has the formula M4/3M2/3XTx, where M and X are the numbers of M layers, and the TMs are arranged in alternating sites in each M layer. Ordered TM in a different atomic plane and an inner layer of M" metal sandwiched by an exterior layer of M characterize MXenes with the formula M2M"X2Tx or M2/M"X3Tx [19]. MXene, a solid solution with two TMs, has the formula (M, M)n+1CnTx (Fig. 3c) [20], similar to (TiV)2CTx, (TiNb)3C2Tx, and (Nb, Zn)4C3Tx. All experimentally and theoretically created DTM MXenes up to this point have been carbides. Meanwhile, no reports of DTM MXene (TMCNs or TMCs in particular) have been made. DTM MXene's layered structure is created from its parent MAX phases; therefore, it is fascinating that the composition of DTM MXene can be regulated by the composition of MAX phases. There are more than 20 DTM MXenes made from MAX at the moment (Fig. 3, solid gradient backdrop); however, many of them have not been etched to their matching DTM MXenes (Fig. 3, horizontal lines). Similarly, theoretically predicted DTM MXene (Fig. 3, background diagonal striped line) [21] has not been supported by experimentally produced DTM MXene or their DTM MAX phase precursors. As a new member of the MXene family, M2XTx, the thinnest MXene, has an in-plane-ordered structure where M and M" occupy each M layer (Fig. 3a), where M represents V, Nb, Cr, Mo, W, Mn, and M is Sc, Y, or Zr. Similar to other MXenes, the unique atomic ordering in this form of MXene arises from an in-plane-ordered MAX phase precursor. This is because of four factors: (i) the 2:1 stoichiometric ratio of M and M", (ii) the remarkable difference in atomic radii of M and M", where M" is bigger, (iii) the significant difference in electronegativity of M" and A-layer atoms, and (iv) the selective etching of the Al layer to form an in-plane-ordered DTM MXene. In addition, introducing vacancies causes differences in electrochemical active sites or changes the surface termination quantity and distribution along with M. As an illustration, divacancies cause Mo4X3CTx to have more -F terminations than Mo2CTx. In Mo4/3CTx, the electron shortage for surface termination due to the reduced Mo concentration improves -F termination over = O termination. Electrochemical reactions are set in motion by the more electrically conductive Mo4/3CTx.

Representation of experimentally as well as theoretically designed DTMs, including a in-plane order, and b out-of-plane order MXenes. c Solid-solution disordered MXenes. Adapted with permission [21], Copyright (2020), Cambridge University Press

Due to the lack of information on the photo/electrocatalytic activity of in-plane-ordered DTM and divacancy MXene, further research into the change-transport kinetics in DTM, as well as the impacts of vacancies and surface termination composition, is warranted. In contrast, MXenes formed using out-of-plane ordered DTM [22] have M metal layers at their core (shown in purple in Fig. 3b), which are sandwiched between layers of M' (shown in green) at their surface. Only Mo2ScAlC2, Cr2VAlC2, MoTiAlC2, and MoTi2AlC3 have been produced experimentally as out-of-plane ordered DTM MAX phases. When strictly etched, ordered MAX phases retain the structural ordering that makes them unique, and this is demonstrated in the derivative material MXene. Some out-of-plane ordered DTM MXenes may exhibit semi-conductor or semi-metallic conductivity, while Momo-M, M3X2Tx, and M4X3Tx commonly exhibit polar conductivity (metallic) [22,23,24,25,26].

MXenes have a wide range of interesting electrical, mechanical, magnetic, and electrochemical features thanks to their adaptable chemistries. It is particularly easy for MXenes to build composites with different materials due to their high flexibility, 2D morphologies, and layered architectures. This opens up the possibility of combining the exceptional qualities of several materials in a complementary manner [27]. As a result, not only MXenes but also MXene-based composites have generated a lot of research interest and show tremendous promise for a variety of applications. Due to their good electrochemical activity and high conductivity, MXenes-based materials have been used as high-performance electrode materials for supercapacitors, sodium-ion batteries, and lithium–sulfur batteries [28].

Amazingly, they have recently become even more well known in disciplines relating to the environment. In particular, they have been applied to gas sensors and biosensors that exhibit superb performances [29]. They can remove/reduce contaminants such as organic dyes, heavy metal ions, and eutrophic substances from water [30]. They have also been employed as effective catalysts/co-catalysts for the applications of electro/photocatalytic water splitting and photocatalytic CO2 reduction [31]. While the uses of MXenes in environmental applications have been recognized and thoroughly covered in some reviews, the most hopeful developments in MXenes' energy storage applications have not been comprehensively outlined. Although there have been a few reported reviews on MXenes, this work focuses primarily on MXenes and MXene-based composites for electrochemical energy storage applications. In this review, we highlight the most recent developments in the use of MXenes and MXene-based composites for electrochemical energy storage while summarizing their synthesis and characteristics. The most common synthesis techniques, such as the top-down (HF, fluorine-based salt, anhydrous, Lewis etching, etc.) and bottom-up (chemical and physical vapor deposition) approaches, for MXene have been discussed. Also, physical and chemical methods for synthesizing MXene nanocomposite materials have been carefully presented. In addition, the various properties (electronic, mechanical, and electrochemical) and how they can be modified for enhanced storage abilities have been highlighted. Key attention is paid to applications in supercapacitors, batteries, and their flexible components. Future research challenges and perspectives are also described.

Synthesis of MXenes and their nanocomposites

More than 150 MAX phases, including ordered double intermediate metal structures and solid solutions, have been described in the literature; more than 30 MXenes out of that total have been produced from these phases [32, 33]. Top-down and bottom-up methods are the two primary strategies used for the synthesis of 2D MXenes. In contrast to the bottom-up strategy, which focuses on the development of MXenes from atoms and molecules, the top-down method corresponds to the exfoliation of huge crystal amounts into single-layered MXene sheets [27, 34]. MXene-based nanocomposites have been developed in recent times to overcome the limitations of pure MXene materials. Synthesis strategies for MXenes and their nanocomposites can be categorized as shown in Fig. 4.

Top-down approach

Selective etching of the A layer in the MAX phases is the standard top-down method for producing MXenes from MAX phases. Before etching, the MAX phase has a three-dimensional (3D) structure, and the etching process can change the MAX phase into MXene, which has a two-dimensional (2D) layered structure [35]. The A elements are etched off once the chemical link between the M and A elements in the MAX phase is broken during the etching process. While the MA bond is metallic in origin, the strong MX bond is a combination of covalent, metal, and ionic bonding [36]. The MX and MA bonds can both be broken at high temperatures, creating a structure that resembles a rock [37]. Additionally, both M and A elements are removed during etching with extremely corrosive chlorine, which results in the formation of carbide derivatives. Therefore, the two etching techniques should be wisely chosen, and a suitable technique should be used to specifically etch out the A element [38]. HF etching, fluorine-based salt etching, anhydrous etching, Lewis acid etching, alkali etching/hydrothermal treatment, and electrochemical etching are some of the etching procedures and agents used in various studies.

HF etching

In the first 2D MXene synthesis described by Naguib et al. [39], the Al was dissolved to generate Ti3C2Tx, and the etching was carried out at room temperature on a Ti3AlC2 MAX phase. HF is thought to be a very selective etching agent. The etching period, HF concentration, MAX phase morphology, particle size, and interatomic interaction strength are all factors that impact the nature of the MXene [16]. Selective HF etching of MXene surfaces results in a variety of potential terminations (OH, F, O, and H). Consequently, the formula Mn+1XnTx is frequently used for MXenes (where T symbolizes the possible surface terminations, e.g., –OH, –F, –O, –H, etc.). Equation (1) describes the reaction pathway for selectively etching A from Mn+1AXn phases while the resulting Mn+1Xn reacts with H2O as shown in Eq. (2) and later with HF as indicated in Eq. (3), resulting in the surface -OH or -F functional groups in the resulting MXenes.

By raising the etching temperature, the etching time, which is influenced by the strength of the metallic M-A bonding in the MAX phase, can be shortened. Usually, strong HF or a lengthy etching time are required to synthesize MXenes (Mn+1Xn) with a high n. For instance, at similar etching conditions, Mo2Ti2AlC3 [40] has a twofold longer etching duration of about 96 h than Mo2TiAlC2, which was 48 h [22]. MXenes have been discovered to be accessible in non-MAX phases as well. For instance, Meshkian et al. [41] obtained Mo2C by selectively etching the gallium (Ga) layer from the Mo2-Go2C MAX phase. Although Mo2Go2C has a distinct structure from MAX phases, it does have layers of Ga-atoms sandwiched between layers of Mo2C. Furthermore, Zr3Al3C5 in the non-MAX phase was reacted with HF, AlF3, CH4, and Zr3C2 to selectively remove the Al3C3 layers, resulting in Zr3C2. As it is, Zr3C2 will react with water and HF to produce various surface terminations (–OH, –F, –O, and –H) [42]. Unlike the MAX phase, which has Al layers separating the metal carbide, nitride, or carbon nitride layers, non-MAX phases frequently feature Al-C intercalating layers or units, which result in either M2C or M3C2 MXenes upon etching by the removal of either Al or Al–C. Therefore, non-MAX phases have enormous potential for the synthesis of novel MXene types [43]. Because it is simple to synthesize, and manage in the laboratory, and is inexpensive to prepare, the selective HF-etching approach is the most preferred among researchers. The use of dangerous chemicals, however, is the main disadvantage of this etching technique, which somewhat diminishes its appeal.

Fluorine-based salt etching

Mono-fluoride salts

To create MAX phases by etching the A-layer, HF-etching uses a mainly hydrated solution with fluoride ions, such as LiF + HCl or HF mixes, as opposed to using straight HF due to its corrosive nature and environmental considerations. The A-atoms are etched as a result of the HCl and LiF interaction, which creates HF in situ [17]. The etching concept of the fluoride salt and strong acid approach is comparable to that of HF etching; however, in the former, metal cations like Li+ and Na+ as well as water intercalation are present. Since these cations have positive charges while the surface of MXene has a negative charge, they can be injected into the interlayer of MXene to increase the interlayer distance, weakening the contact between MXene nanosheets and minimizing the self-stacking phenomenon of MXene [38]. Additionally, the MXenes do not require any additional delamination procedures to produce single-layer or single-layer flakes. Ghidiu et al. [17] etched Ti3AlC2 with lithium fluoride (LiF) and HCl to produce single-phase Ti3C2Tx in high purity. Wang et al. [44], who used an ammonium fluoride solution, later disclosed a simpler and safer hydrothermal technique for selectively etching Ti3AlC2 (NH4F). The two instances are depicted in Eqs. (4, 5):

As opposed to the accordion-like lamellae morphology of MXenes obtained through HF etching, these approaches produce MXene flakes as shown in Fig. 5a. Again, utilizing LiF/Ti3AlC2 at a concentration ratio of 5:1, followed by sonication, produced small MXene nanosheets, but handshaking for 5 min and increasing the LiF/Ti3AlC2 concentration ratio to 7.5:1 produced big MXene flakes [45]. Few-layer MXenes or individual-layer MXenes can be produced by adjusting the concentration ratio of LiF/Ti3AlC2 without the need for additional processing steps like mechanical vibration or ultrasonication [45]. An (NH4)3AlF6 salt was created using NH4F and AlF3. Single MXene sheets delaminate as a result of the Li+ and NH4+ ions intercalating the layers between the sheets [44]. The use of fluoride-based synthetic processes, however, prevents this promising class of materials from being used in real-world applications.

a A summary of the schematic preparation of Ti3AlC2 and Ti3C2Tx. Adapted with permission [45], Copyright (2016), John Wiley and Sons. b A schematic fabrication process and results obtained. Adapted with permission [46], Copyright (2017), Elsevier. c Synthesis routes for a deep red solution by the halogen etching of MAX phases. Adapted with permission [50], Copyright (2021), American Chemical Society. d A schematic reaction between NaOH water solution and Ti3AlC2 under various circumstances. Adapted with permission [55], Copyright (2018) John Wiley and Sons. e X-ray diffraction patterns, SEM pictures, and cross-sectional HR-TEM images of Ti3AlC2, Ti3C2Tx, and Ti3C2Tx film from anodic etching of bulk Ti3AlC2 in a binary aqueous electrolyte. Adapted with permission [56], Copyright (2018), John Wiley and Sons

Bi-fluoride salts

To create Ti3C2 MXenes more safely, the volatile and perilous HF can also be swapped out with the relatively mild bi-fluoride salts: NH4HF2, NaHF2, and KHF2 (Fig. 5b) [46]. The overall description of the etching mechanism is shown in Eqs. 6–8:

The process produces Ti3C2 with many surface termination groups known as Ti3C2Fy (OH)zYm. By extending the interlayer gap, the intercalated Y cations (NH4+, Na+, or K+) produce MXenes with a 2D flake morphology [47]. Similar to other etching techniques, the resultant MXene product is impacted by variables such as etching time, bi-fluoride concentration, and temperature [48]. However, water is the primary solvent used in the majority of etching techniques, and hydrophilic surface tail groups (Tx) such as -O, -OH, -F, and -Cl are used to functionalize the exposed M-layer faces of etched MAX nanosheets. This restricts the use of MXene in systems with water sensitivity [38].

Anhydrous etching

Due to the absence of water, water-free etching has the potential to improve MXenes' electrocatalytic performance. For instance, lithium-ion batteries and sodium-ion batteries with organic electrolytes can be harmed by even small amounts of water [49]. Vaia et al. [50] described a productive room-temperature etching technique that produces MXenes from Ti3AlC2 using halogens (Br2, I2, ICl, and IBr) in anhydrous conditions (Fig. 5c). The molar ratio of the halogen to the MAX phase, the absolute halogen concentration, the solvent, and the temperature all have a significant role in a radical-mediated reaction. With the help of this etching technique, MXene characteristics can be modified by carefully chosen surface chemistries. Additionally, Natu and co-workers [51] demonstrated that MAX can be etched and delaminated in the absence of water by utilizing organic polar solvents in the presence of ammonium dihydrogen fluoride. They also demonstrated that Ti3C2Tz flakes with a lot of fluorine terminations can be made using this etching technique. Further, they showed that Ti3C2Tz electrodes etched in propylene carbonate produced Na-ion battery anodes with twice the capacity of electrodes etched in water.

Lewis acid etching

Fluorine-based acids and salts can have negative environmental effects when used for etching. Furthermore, extra -F groups on the surface of MXene might negatively impact how well they perform in environmental applications. Recently, Lewis acid etching has been acknowledged as a practical method for creating fluorine-free MXenes. Li et al. [52] achieved the creation of Ti3C2Cl2 and Ti2CCl2 MXene further by reducing Ti3ZnC2 and Ti2ZnC in the molten salt of ZnCl2 after successfully preparing a series of MAX phases with Zn by elemental replacement method. Lewis acid, like ZnCl2, has a significant acidity when it is molten, and this acidic environment assisted to remove Al from the MAX phase. The main force behind the outward dissemination of Al was the volatility of AlCl3. Additionally, diffusion was encouraged by the liquid environment, which helped the replacement reaction to succeed. First, the raw material was prepared using a combination of Ti3AlC2:ZnCl2 = 1:1.5. A simplification of the reaction (Eq. 9) could be used to generalize the development of the Zn-containing MAX phase [52]:

An alumina crucible holding the Zn-containing MAX phase was fed into a tube furnace at 550 °C for 5 h while being ventilated with Ar. After the reaction, the product was obtained and dried at 40 °C after being washed with deionized water. This method of etching mechanism was comparable to HF etching, where Zn2+ and Cl− in the ZnCl2 played roles that were equivalent to H+ and F−, respectively. Several conventional (aluminum-containing) and unconventional (silicon-, zinc-, and gallium-containing) MAX phases were transformed into comparable MXenes using a new Lewis acid etching technique developed by Li et al. [28]. The standard approach used titanium silicon carbide (Ti3SiC2) as a precursor and copper (II) chloride (CuCl2) molten salt as an etchant. The as-prepared Cu particles were later removed from the product by treating it with (NH4)2S2O8 (ammonium persulfate) solution. The concluding Ti3C2Tx MXene mostly contained O-terminated groups as well as Cl-terminated groups since O-containing groups were introduced during this process. The authors also showed that MXenes produced by this method have the potential to develop into high-rate negative electrode materials [53]

Alkali etching or hydrothermal treatment

Although synthesis methods based on HF etching and fluoride salts could successfully remove the "A" layer from the MAX phases, using HF solution (even at low concentrations) is not environmentally friendly. Therefore, the creation of HF-free etching procedures is crucial for both environmental and safety reasons. Recently, high-quality MXene has been produced by investigating alkaline etching of the MAX phases. It is essential to remove dissolved oxygen from DI water by bubbling with Ar gas since MXenes are sensitive to dissolved oxygen. Equations (10) and (11) demonstrate how the MAX phase may be successfully etched by the hydrothermal treatment followed by repeated washing processes while using concentrated NaOH in deaerated water [54]

As presented in Fig. 5d, Li et al. [55] published a method in 2018 for producing Ti3C2Tx MXene using NaOH. Hydroxide anions (OH) target the layers of aluminum in this process, which causes the oxidation of aluminum atoms. Alkali is then added to the produced aluminum hydroxides (Al(OH)3), and the exposed Titanium atoms are completed by either OH or O. The process also results in the creation of fresher Al hydroxides, which are prevented from interacting with the OH again because they are contained within the titanium layers' lattice. The problem was resolved by employing a range of hydrothermal temperatures as well as sodium hydroxide water solution concentrations in an Ar atmosphere. The MXenes made using this hydrothermal process have higher OH and O terminations than their HF-etched equivalents, which significantly boosts their supercapacitor efficiency.

Further, using the DFT calculations, Wang et al. [57] proposed a strategy (i) to model the practicability of different MAX materials with Al and Ga interlayer elements, (ii) to predict the deciding etching conditions of temperature and pressure (T&P), and (iii) to solve the mystery of selective etching of MAX phases using HCl (Fig. 6a, b). After that, they proposed an experimental method for etching a variety of MAX materials, such as Mo2Ga2C and Cr2AlC, using the HCl-hydrothermal etching method, which is both straightforward and highly tunable (Fig. 6c, d). Compared to Mo2CTx MXenes, which are synthesized by the HF-etching approach, the as-prepared fluoride-free Mo2CTx of high quality only exhibits Cl- and O-containing terminations and has a distinct capacitive behavior. Similarly, using hydrothermal etching with HCl, Guo et al. [58] effectively synthesized very pure Mo2CTx MXene from Mo2Ga2C. Pure Mo2CTx MXene was obtained in an NH4F + HCl solution at a temperature of 140 °C, which is significantly lower than the temperatures required by other etching solutions. The atomic force microscopic (AFM) technique confirmed that the thickness of the as-prepared monolayer Mo2CTx nanosheet was 1.5–0.3 nm. The Mo2CTx MXene was shown to be stable in an Ar environment at temperatures up to 500 °C. The Mo2CTx MXene underwent a series of changes as the temperature rose, culminating in the formation of Mo2C/MoC/Mo3C2 at 700 °C, where it was shown to be stable alongside Mo2CTx MXene. Further, to check the effect of fluoride on HCl-based hydrothermal etching of V2AlC, Wang et al. [59], prepared a high-purity V2CTx MXene. Because of its reduced potential for harm and increased efficiency, this strategy is preferable. It was found through characterization that the produced V2CTx was of greater purity and had superior electrochemical characteristics as an anode for lithium-ion batteries. By adjusting the reactive conditions of the system, high yields and high purities of V2CTx produced with various etching systems are possible. However, V2CTx MXene produced at various etching systems demonstrates widely varying electrochemical performance. The superior performance of V2CTx produced in a solution of NH4F and HCl is attributed to the fact that the interlayer distance between the two atoms has been widened, making active sites for ions more easily accessible, and the resulting lower impedance.

Representation of temperature- and pressure-dependent map of the chemical potential of a Al in AlCl3 (Al(AlCl3)), and b Ga in GaCl3 (μGa(GaCl3)). c Preparation strategy for the fluoride-free Mo2CTx, and d SEM picture of Mo2CTx MXene. Adapted with permission [57], Copyright (2021), Wiley–VCH GmbH

Electrochemical etching

An etchant is used in the majority of etching techniques, but it can have some influence on the etching outcomes. When no etchant is utilized, electrochemical etching minimizes the negative consequences of etchant. Exfoliation can also be accomplished electrochemically by increasing the interlayer gap. In contrast to MX binding, which includes a mass transfer from the target material to another material, electrochemical etching involves electron transfer as a component of the surface reaction and is primarily dependent on the chemical activity of the MA bond [60]. By reducing the Van der Waals interactions between layers through ion intercalation, electrochemical methods also create 2D materials such as monolayer 2D flakes [56]. A working electrode for the MAX phase and a counter electrode are submerged in an electrolyte in a typical experiment. Ions are created when a potential is applied, which causes the MAX phase to inflate and create 2D nanosheets [28, 61]. The MAX layers can inflate, separate, and exfoliate when exposed to cathodic or anodic potentials [62]. Two-dimensional materials can undergo cathodic exfoliation in a non-aqueous environment to avoid oxidation and provide high-quality non-oxidized nanoplates. For instance, exfoliation of black phosphorus (BP) via cathodic intercalation of tetra-alkylammonium cation frequently resulted in different layers between 2 and 11 [63, 64]. Anodic etching was used by Yang et al. [56] to show an effective fluorine-free etching technique based on Ti3AlC2 in an aqueous electrolyte (Fig. 5e).

The anode was made of Ti3AlC2, and the Cl− in the electrolyte quickly corroded the Al and destroyed the Ti–Al bond in the anode. The anode Ti3C2Tx (Tx = OH, O) is an alkaline solution made up of NH4Cl and tetramethylammonium hydroxide (TMA-OH). The anode was made of Ti3AlC2, and the Cl− in the electrolyte quickly corroded the Al and destroyed the Ti–Al bond in the anode. The anode Ti3AlC2 was quickly totally etched after subsequent embedding of NH4OH into the nanosheets and stimulated more etching beneath the surface. As a response, the etching procedure is suggested in Eq. (12):

MXene was synthesized swiftly using electrochemical etching at room temperature. The investigations also proved that MXene-based all-solid-state SCs had higher capacitance following electrochemical etching than MXene which had been etched using LiF/HCl. As a result, electrochemical exfoliation may be a useful technique for producing MXene nanosheets with the precise size and thickness needed. The low yield of MXene monolayer and the need for harsh reaction conditions for exfoliation, as well as the difficulties in removing electrolytic ions, solvents, and ionic liquids from the finished products, all demand improvement [16]. Other cutting-edge top-down techniques include mechanical, electromagnetic, thermal reduction, ammoniation, algal extraction, and etching [65].

Bottom-up approaches

In addition to top-down synthetic techniques, bottom-up methods such as chemical vapor deposition (CVD) and physical vapor deposition (PVD) can be used to create bare MXenes. The bottom-up method is a controllable means to generate epitaxial films of MXenes with few layers, in contrast to top-down procedures, which utilized etchant materials to obtain multilayered MXenes.

Chemical vapor deposition

The CVD approach offers a suitable alternative to the previously stated ways for producing MXene quickly and with a respectable yield. Ultra-thin MXene materials can be prepared via CVD. By using CVD on a Cu/Mo alloy surface in a CH4 environment at 1085 °C, Gogotsi et al. [66] created ultra-thin 2D a-Mo2C. Mo2C crystals' thickness and size were adjusted by changing the experimental circumstances, with growth time and deposition temperature controlling the lateral size and nucleation density of Mo2C. This technique can be used to create crystals with a variety of shapes, including triangular, rectangular, hexagonal, octagonal, nonagonal, and dodecagonal ones, which have Mo atoms packaged hexagonally [67, 68]. Furthermore, Jia et al. [69] enhanced this technique and published the synthesis of ultra-thin n-Mo2C nanosheets utilizing MoO2 as a template and source of Mo. By heating a tantalum-copper bi-layer with the proper precursor, Wang et al. [70] reported the synthesis of MXenes nanosheets using the CVD technique to produce incredibly thin tantalum carbide, nitride, and boride layers (C2H2, B powder, and NH3). The scratch and oxidation resistance of copper was improved by the strong interface adhesion of these ultrathin materials.

The 2D materials created by etching feature surface-ending functional groups, whereas the MXenes created by CVD do not. However, they have unique properties and a stable atomic structure, enabling the investigation of their interior characteristics and their impact on domain boundaries. The intrinsic electrical and optical properties of MXenes may be studied thanks to such bottom-up techniques, which highlights the critical significance of comprehending the MXene function [71]. Using in situ aberration and corrected scanning transmission electron microscopy, Sang et al. [72] revealed the homoepitaxial Frank-van der Merwe atomic layer development mechanism of TiC single adlayers formed on surfaces of Ti3C2 MXene substrates with the substrate serving as the source material as shown in Fig. 7a. At temperatures above 500 °C, hexagonal TiC single adlayers grew on defunctionalized surfaces of Ti3C2 MXene, activated by thermal exposure and electron-beam irradiation, creating novel 2D materials Ti4C3 and Ti5C4 (Fig. 7b–e). Additionally, to increase the cost savings and scalability of MXenes via the CVD approach, high-temperature conditions and pricey sacrificial growth substrates remain barriers.

Adapted from reference [72], Copyright (2018), The Author(s). Published by Springer Nature. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license

a MXene homoepitaxial development. b Atomic resolution STEM image from a monolayer Ti3C2Tx along the [001] zone axis at ambient temperature. c Crystal structure of monolayer Ti3C2Tx as seen from [100] and [001] zone axes. d A STEM image of a heated monolayer Ti3C2 flake. e A STEM photograph of heated MXene flakes.

Physical vapor deposition

To create MAX phases, PVD is thought to be a popular technique. Generally speaking, PVD syntheses are performed between 700 and 1000 °C [73]. For example, Cr2AlC, Cr2GeC, and V2GeC may typically couple MAX phases with M-elements of the 5th/6th group at a reasonably low substrate temperature (500 °C), whereas Ti-based MAX phases need a higher temperature [74, 75]. In addition to material selection, efforts to lower the temperature for the substrate include the use of ionized deposition techniques, such as high-power impulse magnetron sputtering and sequential deposition at an appropriate temperature (~ 650 °C for Ti3–SiC2), which can detach elements and develop MAX phase at a lower temperature. It is typically preferable to repeat sputter deposition under industrial circumstances by controlling particular elements, composites, or compounds from the target composites or compounds. Reactive sputtering with N2-gas is typically used to create MAX nitrides [76]. The reactive sputtering method for MAX carbide is somewhat constrained while the process window for producing pure MAX phases is often constricted. However, several studies are showing that the technology has the potential for wider deployment. For the phase MAX synthesis, cathodic arc deposition has a more limited utility than sputtering, for example, Ti2AlC creation through a cathodic pulsed arc system from Ti-, Al-, and C- components. The fundamental difference between arc deposition and sputtering is the higher flux ionization degree (almost 100%), which suggests a means to lower temperature [77, 78]. On a sapphire (0001) substrate, Mo2C thin films were created by Zhang et al. [79] using the plasma-enhanced pulsed laser deposition technique (PLD). The synthesized crystal's structure was discovered to be face-centered cubic with a favored orientation of the < 111 > direction at 700 °C. At a lower temperature, in contrast, the crystal developed an orthorhombic shape. In contrast to CVD, this approach relies heavily on the methane plasma to create Mo2C thin films at a very low growth temperature. Pyrolysis and the template method are two further contemporary bottom-up strategies [65].

The top-down synthetic method may produce a variety of MXenes compounds with novel compositions. Additionally, even in the same MXenes and MAX phases, there are numerous probabilities for selectively etching the layer, leading to a variety of surface functional groups, traits, and intended uses. Many bottom-up techniques, including pyrolysis, template method, CVD, and PVD, have been devised in recent years for the production of 2D MXenes. When using this method, superior crystal structure materials are created, as opposed to the MXenes produced using top-down methods. These techniques also enable the synthesis of high-quality 2D MXenes, such as heterostructures, tantalum nitride, tantalum carbide, tungsten carbide, and tantalum nitride. These samples have enormous promise for a wide range of uses, including SCs, batteries, and fuel cells [54]. Although there are still many drawbacks to be solved, such as high temperatures, pricey substrate, harsh environments, less-than-ideal structures and morphologies, and restricted quantities. Therefore, more work is needed to improve the capacity and simplify the preparation processes and growing environments.

Designing strategies for MXene nanocomposites

Strong van der Waals interactions and hydrogen bonds between neighboring layers during the production process have made it difficult to adopt MXenes for practical use. To address these issues, combining 2D MXenes with other nanomaterials, such as 0D, 1D, 2D, and 3D materials, double-layered hydroxides, conducting polymers, and metal oxide will be a successful strategy [80,81,82,83,84]. Physical or chemical methods could be used to develop design strategies for these nanocomposites.

Physical strategy

The physical approach is a straightforward way to create nanocomposites since it allows for the formation of novel products while also avoiding difficult phases in the synthesis process. Ex situ mixing and in situ growth are the two subcategories of the physical synthesis technique [85].

In situ growth

In terms of size and form, in situ growth or self-assembly is now the most advanced method for creating nanomaterials. Firm hybrids are produced without the creation of new chemical bonds thanks to the electrostatic attraction between electrolytes with various charges [86]. This method has been successfully used to create a variety of hybrid materials [86,87,88]. Structures and electrochemical properties are frequently significantly influenced by changing the weight ratio of MXene and its equivalents. To produce single-to-few layer dispersions of Ti3C2Tx flakes from 1 to 5 wt.%, Wyatt et al. [89] established a self-assembly technique of Ti3C2Tx to aluminum that can be adjusted. They also demonstrate how, at concentrations over 5 wt%, the same procedure can be used to incorporate multilayers of Ti3C2Tx that have already been pre-stacked or to re-stack multilayers of Ti3C2Tx that have been single- to few-flaked (Fig. 8a). The creation of a network of Ti3C2Tx in the Al matrix using near-full coverage of Al by Ti3C2Tx can be exploited to produce multifunctional structural and/or conductive metal composites. Future additive manufacturing of bulk Ti3C2Tx–Al metal composites benefited from the ability of this self-assembly technique to produce huge batches of Ti3C2Tx–Al powder. In the attempt to generate 3D-hydrogel hybrids of MXene and graphene (MGH), Sikdar et al. [90] described a wholly room-temperature casting-based method that avoided the potential of oxidation by inducing spontaneous gelation with metallic zinc particles. The MGH was utilized as an SC electrode because of its high mass-specific capacitance (357 F/g at 10 mV/s) and outstanding capacity retention (95.6% after 10,000 charge/discharge cycles). These simple and affordable MXene-graphene hydrogels are a desirable alternative for a variety of applications that call for 3D porous structures.

a Fabrication and characterization of Ti3C2Tx and Al for electrostatic self-assembly. Adapted with permission [89], Copyright (2022), Elsevier. b An illustration of how porous rGO/Ti3C2Tx films are made, as well as XRD patterns of GO, GO/Ti3C2Tx, rGO/Ti3C2Tx films, rGO, and Ti3C2Tx powders. Adapted with permission [93]. Copyright (2017), Royal Society of Chemistry. c Schematics of the production of MXene-rGO composite aerogels, along with flake size distributions and pressure–strain curves for the final materials. Adapted with permission [99], Copyright (2018), American Chemical Society. d Schematic diagram of the synthesis of the M/CoS2/CCS composite. e XRD patterns of the CoS2/CCS-1, CoS2/CCS-2, and CoS2/CCS-3 and the FESEM images. Adapted with permission [96], Copyright (2022), Elsevier

Ex situ mixing

This is a well-known procedure where solutions of dispersed MXene and other nanomaterials are mixed and swirled to enable the interlayers to create a conventional sandwich or hybrid shape. The interlayer gap is increased by these structures, which speeds up ion transport and improves the performance of the nanohybrid. This procedure also involves combining the solutions before alternate layers are deposited [91, 92]. Xu et al. [93] discussed the idea of making flexible all-solid-state SCs out of reduced graphene oxide (rGO)/Ti3C2Tx film by employing rGO as a binder to link electrochemically active conducting particles. The co-cathode approach was used to combine these SCs with flexible thin-film solar cells to create energy conversion and storage devices ECSDs (Fig. 8b). The reduction at 300 °C while under vacuum was followed by vacuum-assisted filtration of the GO/Ti3C2Tx dispersion to create the porous rGO/Ti3C2Tx films. By using this method, MXenes were not required to be delaminated, and thick electrodes with adequate electrolyte accessibility could be produced. The composite material, as synthesized, showed a greater specific capacitance than GO, RGO, or MXene.

Chemical strategy

Comparatively to MXene nanocomposites made using the physical synthesis approach, chemical strategy is crucial for enhancing their physicochemical and thermomechanical properties. The processes for chemical synthesis include direct thermal treatment, hydrothermal–solvothermal synthesis, and reagent reduction [85].

Direct thermal treatment

Without the use of reducing chemicals, thermal or heat treatment techniques can successfully remove active surface functional groups [85]. A MAX (Ti3AlC2) precursor was used to create a 2D transition metal carbide, MXene (MX–TixCxTx), and MX@Pt nanocomposites. The efficient (MXene/Pt) nanocomposite photocatalysts were made using simple water bath sonication and CVD tubular furnace direct thermal annealing. The structural conformation of MX@Pt nanocomposites was also compared to the successfully synthesized MAX into MXene (MX) flakes using XRD data, which showed good crystalline diffracted peaks. MXene nanocomposites with few-layer sheets coated with "Pt" were investigated using surface FESEM morphology [94]. Vacuum freeze-drying (65 °C) under 25 Pa, followed by annealing (300 °C) for 1 h under Ar gas, produced a lightweight GO-based MXene hybrid foam (MX-RGO) [95]. To ascertain the precise physicochemical properties and prospective uses, various foam compositions were created.

Hydrothermal–solvothermal synthesis

A common method for creating MXene nanocomposites is hydrothermal–solvothermal synthesis, which is similar to thermal or heat treatment techniques. This process involves placing the reactants in a closed container with a solvent present at a high temperature and pressure for a predetermined amount of time, followed by washing and drying. The reaction must be carried out at medium or low temperatures because extremely high temperatures can damage MXene's structural integrity [85]. The most utilized process of producing nanomaterials or composites is the hydrothermal technique. The nanocrystals formed under conditions of high pressure and temperature have good crystallinity, controlled nanoparticle size, and exceptional dispersibility. Ion or molecule activity is significantly increased in the subcritical state, compared to solid-state reactions, to produce a variety of chemicals [85]. For the design of supercapacitor devices in both symmetric and asymmetric modes, a unique, one-pot hydrothermal synthesis of Ti3C2Tx (MXene)/CoS2/CuCo2S4 nanohybrid with various reactive equivalents was demonstrated (Fig. 8d). A morphological investigation demonstrated the successful coating of CuCo2S4 particle- and sheetlike CoS2 on Ti3C2Tx nanosheets (Fig. 8e). The electrochemical efficiency was improved by varying the MXene to CoS2/CuCo2S4 ratio. This suggested MXene-based hybrid nanocomposite electrode has tremendous potential for use in future energy technologies, thanks to its exceptional cycle life and high electrochemical energy storage efficiency [96]. MXene/SnTe nanocomposites were produced in situ by Jiang et al. [97] using a simple solvothermal technique. Comprehensive characterization results showed that the addition of 2D MXene to the SnTe matrix can suppress Sn vacancies to produce a lower carrier concentration and induce abundant MXene/SnTe interfaces, which simultaneously enhanced the electrical and thermal transport properties. Their work investigated a novel approach to integrate 2D MXene into SnTe-based materials with enhanced thermoelectric properties, which can open up new avenues for developing and producing high-performance thermoelectric materials.

Reagent reduction

During the production of MXene nanocomposite, a reagent or chemical is given to the reaction medium to react with a precursor by a procedure known as chemical reduction [85]. Ti–O–C covalent connections were formed to create rGO/MXene sheets, which are extremely strong MGO sheets (MXene and GO). The created rGO/MXene sheets were cross-linked by 1-aminopyrene-disuccinimidyl to minimize the voids within the GO layers and improve the symmetry of the arrangement of GO platelets, which gave the material super-toughness [98]. To create GO/MXene sheets, the dispersed GO and MXene media were sonicated for 10 min.

After that, the mixture was mixed for 6 h, vacuum-assisted filtered, and dried at 60 °C for 12 h. After multiple washes with dimethylformamide (DMF) and ethanol, the GO/MXene sheets were reduced with HI and then added with 1-aminopyrine-disuccinimidyl to produce the desired product. By freeze-drying and using reducing agents, a highly self-healable 3D rGO/MXene (Ti3C2Tx) composite aerogel was created [99]. The performance of the composite was first optimized using several GO/MXene solutions. The aerogel was created by freeze-drying the solutions. The aerogels were then added to a solution of acetic acid and hydrogen iodide at 60 °C for 3 h, after which washing and freeze-drying were performed. The rGO/MXene (Ti3C2Tx) electrode was then made utilizing a laser cutting technique as described in Fig. 8c. A 3D self-healable rGO/MXene (Ti3C2Tx) was made from this material, which was once treated with a carboxylated polyurethane shell. The finished product was used in a supercapacitor.

Properties of MXenes

MXenes exhibit a unique blend of traits, including excellent electrical and mechanical performance. MXenes stand out from other 2D materials, such as graphene, due to their hydrophilic nature combined with improved thermal conductivities [100]. Through linkages between morphology and geometric structure, surface functioning, and composition, the associated features and expulsive performances can be changed [101, 102].

Structure of MXenes

In the precursor material MAX phase, group A elements (Fig. 9) are selectively etched to produce MXenes. The more chemically reactive Group A elements can be removed by etching because the MX bonds are stronger than the MA bonds, while the layered structure of Mn+1Xn is retained [103, 104]. MXenes have the generic formula Mn+1XnTx (n = 1, 2, 3), where M represents transition metals like Ti, Mo, Cr, Nb, and V, X is carbon or nitrogen, and Tx stands for different surface functional groups like –OH, –O, and –F [105]. MXenes are made up of many layers of hexagonal crystal cells. Wherever the X atoms fill the octahedral interstitial locations, the M atoms are packed hexagonally [106].

A representation of the location of a MAX phase's constituent elements in the periodic table. Adapted with permission [107], Copyright (2021), Elsevier

With a change in the amount of n in the general formula, the arrangement pattern of MXene atoms will alter. The hexagonal dense packing of M2X MXenes contrasts with the cubic dense packing of M3X2 and M4X3 MXenes. The M layer atoms in MXenes form a total of 6 chemical connections with the chemical groups linked to the surface and the adjacent X layer atoms since the coordination number of transition metal ions is typically 6, which gives MXenes their surface group Tx. The applications of MXene-based flexible sensors and supercapacitors are greatly impacted by these highly adaptable surface groups, which are one of the qualities that set MXenes apart from 2D materials like graphene and transition metal sulfides. Surface groups, for instance, may impact on MXene's capability for material fusion [108] as well as the adsorption potential of particular detection molecules [109].

Electronic properties

The electronic property of MXene is a significant aspect that is of primary importance. The surface groups (–OH, –F, –O) on MXenes can be changed by adjusting their functional groups, material balance, or creation of solid solutions, as well as by manipulating the reaction circumstances [110]. For instance, the conductivity and mobility of single-layer Ti3C2Tx MXene that was chemically modified using 4-nitrobenzene-diazonium tetrafluoroborate salts decreased as the concentration of the 4-nitrophenyl group was grafted onto the surface of MXene (Fig. 10a–c) [111]. The electrical characteristics of MXenes, including work function, conductivity, and mobility, can also be altered by manipulating surface groups of MXenes by substitution and elimination processes in the molten inorganic salt [112]. The procedure used to create MXenes also has some influence on electrical characteristics in addition to the influencing elements mentioned above. Better conductivity for the same type of MXene is frequently obtained by synthesizing it under softer etching conditions. This is because only a little etching can effectively preserve MXene's structure, and the produced nanosheets are both big and relatively free of flaws.

a A schematic showing the synthesis of Ti3C2Tx and its subsequent diazonium functionalization. b Transfer curves for 10 mM, 0.01 mM, and 0.5 mM and pristine Ti3C2Tx. c The Ion/Ioff of f-Ti3C2Tx and field mobility μFET. Adapted with permission [111], Copyright (2021), American Chemical Society

The high electron density of MXenes around the Fermi level caused by the d-orbital electrons of the transition metal layer elements and the interior metal carbide layer's ability to effectively transport electrons are what cause their high conductivity [113, 114]. Additionally, alterations in the surface groups and transition metal layer components have a significant impact on the electrical characteristics of MXenes. For instance, Ti can be switched out for Mo in the outer transition metal-M layer of M3C2 and M4C3 MXenes to vary the material's behavior in terms of how electrons are transported from a metal to a semiconductor. Figure 10a demonstrates that at any temperature, the replacement of Mo-containing MXene has a higher resistivity than the corresponding Ti-containing MXene. However, the Mo-containing MXene with the surface group –O exhibited the metal electron transport behavior, unlike the Mo-containing MXenes with the surface groups –OH or –F [115]. Furthermore, the electrical conductivities connected to the pressed films of MXenes coincided with those of multilayer graphene and were greater than those in nanocarbon tubes. It was evident that functional molecules might hinder resistivity growth by increasing it with different layers. As a result, the conductivities of simulated functions have maximal values compared to observations from experiments [116]. The electrical conductivities of Ti3C2Tx varied from 850 to 9870 S/m because of differences in the following factors: surface functionality; defect concentration; d-spacing between MXenes particles; delamination yield; and lateral dimensions brought about by the etching procedure [117]. Generally, increased lateral expansion and shorter etching times combined produce MXenes with fewer flaws and greater levels of electrical conductivity [118]. Furthermore, environmental wetness may affect their electrical conductivities, which would encourage them to be used in sensing applications [119].

Mechanical properties

Surface terminations have a significant impact on the mechanical properties of MXenes. The O-end MXenes are anticipated to be quite rigid, but MXenes ended by other groups (F and OH) display lesser elastic stiffness and toughness in comparison with their O-end counterparts [120]. Its distinctive lattice coefficients, which include many terminations, can be likened to those of MXenes: the lattice limits of O-ended MXenes are often greater than those of F or OH-removed MXenes [121]. Particularly, when compared to straightforward MXenes, surface-functionalized MXenes offer greater flexibility and adaptability. By creating a sandwich structure, Li et al. [122] for the first time added a-Fe2O3/MnO2 (FM) to MP. The MXene surface's numerous active sites and favorable hydrophilic characteristics allowed FM to interact with the MP (Fig. 11a). The accumulation and loss of FM were minimized by complexing with MP. Additionally, the impact of increased loading on MP was superior mechanical qualities and enhanced flexibility. To show that it can be utilized as a flexible energy device, they tested its flexibility. Flexibility tests were performed on the final product between 0 and 180 degrees [122]. The results, as presented in Fig. 11b, made it abundantly evident that even at a 180° bending angle the single capacitor's capacitance retention can reach 98.2% and that its CV curve virtually overlaps that without bending. As shown in Fig. 11c, the electronic meter was powered by three capacitors. In another study, Qingsen et al. [123] used Ti3C2Tx MXene nanosheets that had been pretreated with polyethylene glycol to create a new nanocomposite by melting them together with thermoplastic polyurethane (TPU). Tensile strength and elongation at break were observed to rise by 41.2% and 15.4%, respectively, at MXene loading values of 0.5 wt.% (Fig. 11d, e). TPU's crystalline speed is increased slightly by MXene, and the movement of tiny gas molecules is effectively slowed down when temperatures are high. Low-frequency properties of TPU nanocomposites as storage modulus, loss modulus, and complicated viscosity improve as MXene concentration rises. The findings show that TPU nanocomposites can benefit from MXene nanoparticles in mechanical, thermal, and rheological aspects. Within this framework, to enjoy the mechanical features of MXenes, the concerned scientific community is focusing on using the conducting polymers with the MXenes to improve their performance in multifunctional applications. Table 1 summarizes the main parameters in the mechanical properties of MXene-based materials.

a An illustration showing how to make MP/FM/MP and MXene films on carbon cloth. b Capacitance retention at various bending angles. c Electronic meter driven by three supercapacitors. Adapted with permission [122], Copyright (2022), Elsevier. Mechanical features of pure TPU and MXene/TPU hybrid with various loading of Ti3C2Tx MXene; d stress–strain curves, and e tensile strength, tensile modulus, and elongation at break. Adapted with permission [123]. Copyright (2022), Wiley and Sons

Electrochemical properties

Based on Bader charge analysis, the M element in the MXene is in a substantially lower oxidation state than its corresponding oxides (the most stable thermodynamic class). MXene can consequently oxidize as a result. Additionally, termination groups have a significant impact on the oxidation state of the MXene's M element, and this state can be controlled via moderate redox oxidization, in which MXene acts as a reducing agent and noble metal ions act as oxidants [129]. In contrast to total oxidation into oxides, moderate oxidation also preserves structural integrity and allows for the production of noble metal nanoparticles. The equally distributed noble metal nanoparticles in MXene and the appealing enhanced Raman scattering at the surface are striking [130]. Due to the abundance of redox sites, MXenes and Ti3C2Tx MXenes in particular, have strong electrochemical properties. Due to the hydronation of the terminal group containing oxygen, the Ti oxidation state continually changes. In other words, the relationship between the change in potential and the change in the Ti oxidation state is almost linear. The Ti3C2Tx has various capacitance characteristics that depend on the size of the electrolyte's cations, surface terminations, morphology, interlayer spacing, etc. The electrostatic pull between opposing charges is produced when electrolytic cations intercalate between the Ti3C2Tx interlayers. Therefore, if the size of the cations is smaller than the interlayer spacing, they will intercalate through the interlayers. Due to the rapid redox reaction, this will result in pseudocapacitance behavior. Large cations, on the other hand, will not fit through the interlayers and will repel one another electrostatically, preserving excellent cycle stability. In order to produce the electric double-layer capacitance, the cations will adsorb at the surface [131]. Due to this, MXene has a remarkable capacity for storage in acidic solutions. The following (Eq. 13) is a representation of the electrochemical reaction [132]:

As determined by nuclear magnetic resonance NMR analysis, \({\text{Ti}}_{3} {\text{C}}_{2} {\text{O}}_{x - \delta } \left( {{\text{OH}}} \right)_{y + \delta } {\text{F}}_{z}\) was the predicted surface chemistry for MXene produced using the in situ HF technique, giving it a maximum theoretical capacity of 615 C/g. Though MXenes have only been reported to have an experimental capability of about 135 C/g. Gogotsi et al. [132] performed numerous tests on a 90 nm thick MXene film to investigate this discrepancy between theoretical and actual results. They concluded that glassy carbon, as opposed to platinum or gold, might significantly increase the capacity of the MXenes. The limited usage of active sites and incomplete redox reactions constrained by the narrow potential window were potential causes. Additionally, the Pt or Au could restrict the process by catalyzing water splitting, whereas glassy carbon has outstanding overpotential for oxygen evolution reaction (OER) with a wide potential window (> 1.0 V), allowing the inherent capacity of different materials towards OER, making glassy carbon as the foremost current collectors in energy storage as well as water splitting applications. Thus, a 90 nm thick MXene sheet with a high capacitance of 450 F/g and outstanding electrochemical performance was reported by Gogotsi and colleagues. Surface modification or heteroatom doping is another method for increasing the capacitance of MXenes. As an illustration, by combining solvothermal and ex situ nitrogen doping using urea as a nitrogen source, Que et al. [133] were able to manufacture nitrogen-doped MXene (NTi3C2). The highest value of ultrahigh capacitance ever recorded up to this point was found in the synthesized N-Ti3C2 electrode, which measured 927 F/g. Another illustration is the electrochemical efficiency of the Ti3C2Tx anode material for LIBs, which Li et al. [134] described. For the Ti3C2Tx anode at 0.1C, capacity values of 450 and 250 mAh/g, respectively, were obtained during the initial discharge and charge. Additionally, the produced Ti3C2Tx demonstrated good cycling stability; after 1600 cycles at 5C, a capacity number of 119 mAh/g was attained. It has been discovered that the preparation variables, functional groups, thermal treatments, and chemical oxidation are the primary parameters impacting the electrochemical characteristics of MXene anodes, many of them strongly interconnected. El-Ghazaly et al. [135] examined the electrochemical behavior of i-MXene (Mo1.33CTz), a vacancy-containing material (Fig. 12a), in sulfate-based aqueous electrolytes with univalent (Li+, Na+, or K+) or divalent (Mg2+, Mn2+, or Zn2+) cations. The findings demonstrate that the Mo1.33CTz MXene electrodes were not degraded in these sulfate electrolytes when operated in a potential window greater than 1 V. The volumetric capacitance of the Mo1.33CTz MXene electrodes, as measured in 1.0 M MnSO4 solution reached up to 677 F/cm3. After 5000 cycles of charging and discharging, the asymmetric devices still held 97% of their initial capacitance. The results of the analysis are displayed in Fig. 12b–g. This suggests that using intercalating cations can improve Mo1.33CTz MXene’s electrochemical performance.

a A schematic representation of the Mo1.33CTz MXene. b Operating potential window; SSCC stands for the stainless-steel current collector; c and d CV profiles at a scan rate of 2 mV/s. e and f Volumetric capacitance variation with scan rate. g The capacitance retention at a current density of 10 A/g in electrolytes with 1 M NaSO4, 1 M ZnSO4, 1 M MgSO4, and 0.5 M K2SO4. Adapted with permission [135], Copyright (2022) by the authors. Published by Elsevier B.V. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license

Using Zn as the anode and Ti3C2Tx as the cathode, Li et al. [136] investigated the charge storage mechanism of the Ti3C2Tx-based-Zn-ion hybrid micro-SC. To create the highly effective electrochemical SC, the researchers discovered that during the discharge process, Zn changed to Zn2+ and transported from the anode to the Ti3C2Tx MXene cathode, intercalating the layers of MXene. The Zn2+ ion intercalation into MXene layers was revealed by the SEM examination, which also revealed the dispersion of Ti, C, and Zn components in the cathode [136]. Generally speaking, the electrochemical performance of MXene-based supercapacitors varies depending on the synthesis techniques, MXene precursors, dimension and architecture of MXene, electrolyte, electrode architecture, and their dispersion as fillers in different composites.

MXenes for electrochemical energy storage devices

Types of electrochemical energy devices

The development of clean, effective, and sustainable energy conversion and storage technologies has become one of the imperative strategies for the global science and technology community as a result of the rise in energy demand. Electrochemical technologies, including fuel cells, batteries, and supercapacitors, have been acknowledged as being among the most significant energy conversion and storage techniques. Due to their many benefits, including quick charging, long charge/discharge cycles, and wide working temperature ranges, supercapacitors have several uses in electronic devices, airplanes, smart grids, hybrid/electric vehicles, and other industries. Batteries have also been employed in several applications including stationary and mobile systems [6]. However, there are still several issues with electrochemical energy systems, including a low energy density for SCs and high costs of manufacturing, and low power density for batteries. Supercapacitors and batteries are the two main EES technologies that will be discussed; in particular, their basic principles, mode of operations, and applications based on MXene materials will be emphasized.

Supercapacitors

Electrochemical devices also known as supercapacitors (SCs) are used to store energy by collecting charge or through faradic reactions at the interface of the electrode and electrolyte. Due to the quick adsorption–desorption of charged ions, ultrahigh power densities are produced during charge storage in an SC. Additionally, SCs have a longer lifespan than batteries and are linked to relatively low specific energies. Based on the electrode materials employed in electrode manufacturing, SCs may be divided into three types: pseudocapacitor, electrochemical double-layer capacitor (EDLC), and hybrid capacitor.

The arrangement of charges/ions at the electrode/electrolyte interfaces causes a double layer to develop on its own when a conducting electrode is put into a solution of an ion-conductive electrolyte. This is the basic operation of the EDLC. The EDLC, in which charges/ions are physically held via electrostatic charge adsorption at the electrode/electrolyte interface, is the most extensively used SC. The fact that there is no charge transfer at the electrode and electrolyte interfaces is one of the most distinctive features of EDLCs. EDLCs are mostly carbon-based materials.

The specific capacitance and performance of the EDLC device are significantly influenced by the accessible surface area of the various electroactive materials and the surface properties of the carbonaceous materials. Upon the application of a voltage, a double layer is created between the electrode/electrolyte interface as shown in Fig. 13a. Figure 13b compares the energy and power density of various types of capacitors and devices. This causes the adsorption and desorption of the ions. Pseudocapacitors, in contrast to EDLCs, store charge by Faradaic processes, which involve fast and reversible redox reactions at/near the surface of the electroactive materials. This mechanism is connected to the valence state of the electrode material changing primarily as a result of electron/ionic transfer. The first electrode material to display pseudocapacitive properties was RuO2. Despite undergoing a Faradaic reaction, the charge storage that results from a charge transfer reaction on a thin RuO2 film typically has a rectangular shape, which is a property of various capacitive materials. Electrode materials with capacitive electrochemical properties that store charge by charge transfer of Faradaic processes across the double layer of the device are known as pseudocapacitors.

Adapted from reference [137], Copyright (2021) by the authors. Licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license

a Schematic representation of EDLC operation. Adapted with permission [8], Copyright (2015), John Wiley and Sons. b Comparison of energy and power density of various types of capacitors and devices.

EDLCs have lower energy densities but long durability, very high specific power, and function well in both aqueous and non-aqueous electrolytes. On the other hand, pseudocapacitors have higher specific energies and specific capacitance, but due to their irreversible redox processes, they have a narrow operating potential window and poor cycling stability. To take advantage of both the EDLC and pseudocapacitive materials, a hybrid capacitor—a single capacitor cell that uses both material features—has been developed. Both capacitive and redox electroactive materials are impregnated in a thin film of polymeric electrolyte where charge storage happens via reversible redox mechanisms. The performance of the hybrid cell as a whole is influenced by both electrochemical and electrostatic causes. The hybrid supercapacitor's capacity for charge storage is proven over a wide range of potentials, providing more specific power and energy without compromising cycle stability.

Batteries

The primary research goals in energy storage systems continue to be the creation of positive and negative electrode materials with high capacity, great cycle stability, low cost, and high efficiency. Several materials have been employed as electrode materials for various battery systems because of their outstanding qualities such as high conductivity, solid structural stability, and changeable shape. For a variety of uses, batteries including lead–acid, Ag–Zn, Ni–Cd, Na–S, etc., have been created. Battery cycle lifetimes are typically around 1200 cycles. Because they are robust even in small quantities and have high energy densities, various battery systems have attracted attention. In some works, electroactive organic compounds are included in electrodes made for Li-ion batteries [138]. When added, they offer substitute ions, such as Na+, Mg2+, and Ca2+. Some metal ions, enhance the functionality of battery systems. For instance, prior studies have shown that organic batteries with potassium ions introduced function better [139]. Batteries have also been made with graphene and other carbon-based materials. Through electrochemical species intercalation, interconnected networks, wide surfaces, and large pore sizes, energy is stored in batteries [140].

According to the contact of electrons on the metallic electrodes, oxidation and reduction reactions take place in the electrodes when two dissimilar electrodes are combined with a dilute electrolyte. One electrode, known as the cathode, acquires a negative charge as a result of the oxidation reaction. Due to the reduction reaction, an additional electrode is given a positive charge and is referred to as the anode. A battery's negative terminal is created by the cathode, whereas the positive terminal is created by the anode. Energy can be stored in a chemical form in rechargeable storage systems, which are practical energy storage devices. There are numerous battery types available today, each with unique concepts that fit a particular need. These developments frequently include a variety of features, such as different sizes and chemical components built into them. Battery technology has advanced significantly in recent years, particularly with regard to Li-ion batteries (LIBs) [141, 142]. LIBs are now widely utilized in small electronic devices, renewable energy sources, and microgrid systems. Depending on the electrolytic system, LIBs have a high energy storage efficiency and attractive characteristics such as low maintenance requirements, extended cycle lives, and high design flexibility. A schematic representation of the interior structure of LIB is shown in Fig. 14. The most adaptable electrolytes are aqueous ones, but they have many disadvantages, such as low heat stability and a propensity to quickly degrade into hazardous chemicals [143]. The demand for batteries in electric vehicles and smart grid applications is a key factor in the commercialization of batteries. Apart from price variances, each battery type differs from the others in terms of operating performance and attributes. As a result, one type of battery can be especially suitable for a certain storage function. Therefore, the energy storage business will greatly benefit from a range of battery technologies.

Adapted from reference [142], Copyright (2020) by the authors. Licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license

Schematic structure of the interior of a Li-ion battery.

MXenes for supercapacitors

MXene inks can be converted into 2D films of MXene (Ti3C2Tx) for improved electron transport when making electrodes for supercapacitors. The breakdown of MXene components and oxidative instability when in contact with water are the key issues preventing its practical implementation. The MXene composite can have tartaric acid added to it to prevent oxidation and firmly keep the assembly components together [144]. By using the laser crystallization process to create sandwiched electrodes (for example, MXene/Fe3O4/MXene), the device's areal capacitance and cycle stability will be improved [145]. The structural and electrochemical features of 2D MXene can be changed by annealing treatment [146]. Due to architectural and chemical changes on the surface of the MXene, direct annealing processes aid in improving the strength of the structures, electrochemical performances, and cycle stability. This also promotes ion movement and enhances electrolyte accessibility for high-performance supercapacitors [147].

There is currently significant research into finding new and high-capacitance MXene-based SC electrode materials. 2D MXenes such as Ti3C2, Mo2C, Ti2C, and Mo1.33C have demonstrated enhanced electrochemical features as SC electrodes. By selectively etching Al from vanadium aluminum carbide (V4AlC3), a multilayered 2D vanadium carbide (V4C3) MXene was synthesized for SC electrode material [148]. The synthesized material exhibited strong rate performance, high capacitance (209 F/g at 2 mV/s), and stable extended cyclic performance. The large pore volumes and specific surface areas, strong hydrophilicity, and the numerous valence states of the vanadium contributed to the excellent capacitance of the V4C3 MXene. The good electronic conductivity of the synthesized 2D electrodes is primarily responsible for their superior cycle stability and enhanced rate performance. Another work also presented a thorough examination of the characteristics and the electrochemical performance of a synthesized V4C3 MXene as a potential supercapacitor electrode [149]. By utilizing Hydrofluoric acid etching to remove the intermediary "A-Aluminum" layer from the MAX phase, the 2D MXene was created. The synthesized samples demonstrated a layered structure, good electrochemical performance, and device stability for SC applications. This performance can be attributed to the inherent features of the vanadium atom.

The investigation of sustainable energy storage systems, such as Zn-ion hybrid SCs (HSCs), is motivated by the rising demand for quickly rechargeable batteries and SCs as well as the scarcity of their active components (such as Li and Co). Etman et al. [150] reported how Zn-ion HSCs were used as freestanding Mo1.33CTz–Ti3C2Tz coupled MXene films (Fig. 15a). One-step vacuum filtration was employed to create the mixed MXene films from pure MXene suspensions. The mixed MXene produced capacities of around 159 mAh/g at 0.5 mV/s scan rate. Additionally, after 8000 cycles, the electrodes showed a promising 90% capacity retention as shown in Fig. 15d. The mixed MXene also recorded energy densities of around 103 Wh/kg at power densities of 0.143 kW/kg. The above performance can be attributed to in-plane ionic transport which resulted in an increased number of the available electrochemically active sites as displayed by the SEM images in Fig. 15b,c. 2D Mo1.33C MXene is mostly researched in the H2SO4 electrolyte medium and exhibits tremendous promise for energy storage applications. The electrode potential is nevertheless restricted by H2SO4 to about 0.9 V and 1.3 V for symmetric and asymmetric devices, respectively. Ghazaly and co-researchers [151] investigated Mo1.33C MXene's electrochemical performance in a LiCl electrolyte, which is less hazardous compared to H2SO4. According to the research, the operational potential window for the device (vs. Ag/AgCl) was a wide − 1.2 to + 0.3 V, with a volumetric capacitance of 815 F/cm3 at 2 mV/s. This was subsequently utilized to create MXene-based asymmetric SCs (Mo1.33C/MnxOn) (Fig. 15e), and the performance of the electrochemical system was assessed in a 5 M LiCl electrolyte. Figure 15f shows CV curves of the positive and negative electrodes at 10 mV/s. A volumetric energy density of 58 mWh/cm3 and a maximum power density of 31 W/cm3 were attained, thanks to the broad voltage widow of the Mo1.33C/MnxOn devices. Figure 15g shows the gravimetric capacitance of MXene//MnxOn device at different scan rates. 2D V2CTx MXene was also created by selectively etching layers of Al from the V2AlC MAX phase using a NaF + HCl etching solution at 90 °C for 72 h. The performance of the resulting material as an SC electrode was then evaluated using an electrolyte that mimicked seawater. An excellent capacitance (181.1 F/g) was displayed by synthesized electrodes with 89.1% of the initial capacitance retained even after 5000 cycles [152].

Adapted from reference [150], Copyright (2021) by the authors. Published by Elsevier Ltd. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license. e Schematic illustration of Mo1.33C/MnxOn design f Capacitance of MXene//MnxOn device using different scan rates. g Ragone plot of Mo1.33C/MnxOn compared with some MXene-based devices. Adapted with permission [151], Copyright (2021) by the authors. Published by Elsevier B.V. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license