Abstract

Film bulk acoustic resonators (FBARs) have been evaluated for use as biosensors because of their high sensitivity and small size. This study fabricated a novel human IgE biosensor using shear-mode FBAR devices with c-axis 23°-tilted AlN thin films. Off-axis radio frequency (RF) magnetron sputtering method was used for deposition of c-axis 23°-tilted AlN thin films. The deposition parameters were adopted as working pressure of 5 mTorr, substrate temperature of 300°C, sputtering power of 250 W, and 50 mm distance between off-axis and on-axis. The characteristics of the AlN thin films were investigated by X-ray diffraction and scanning electron microscopy. The frequency response was measured with an HP8720 network analyzer with a CASCADE probe station. The X-ray diffraction revealed (002) preferred wurtzite structure, and the cross-sectional image showed columnar structure with 23°-tilted AlN thin films. In the biosensor, an Au/Cr layer in the FBAR backside cavity was used as the detection layer and the Au surface was modified using self-assembly monolayers (SAMs) method. Then, the antigen and antibody were coated on biosensor through their high specificity property. Finally, the shear-mode FBAR device with k t 2 of 3.18% was obtained, and the average sensitivity for human IgE detection of about 1.425 × 105 cm2/g was achieved.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Background

In recent years, piezoelectric materials have been used in surface acoustic wave (SAW) resonators [1-5] and film bulk acoustic wave resonators (FBARs) [6-10] because of their low cost, low weight, and good reproducibility. However, the SAW resonator has high insertion loss and poor power handling capability. Hence, this study evaluated the potential applications of FBARs for biosensors because of their advantages, including low insertion loss, good power handling, and small size. The FBAR devices were constructed by a piezoelectric layer sandwiched between two electrodes and attached to substrate with backside cavity. Piezoelectric materials such as zinc oxide (ZnO) and aluminum nitride (AlN) have been used in FBAR devices for various applications [11-13] owing to their high acoustic velocity, better quality factor, and high electromechanical coupling coefficient. Besides, the piezoelectric materials of ZnO and AlN can be combined with silicon technologies in semiconductor fabrication processes [14,15]. Moreover, the acoustic velocity of AlN is 10,400 m/s, and it suits application for FBAR devices.

The acoustic wave of a FBAR has two transmittance modes: longitudinal mode and shear mode. In shear mode, acoustic wave energy does not dissipate in a liquid environment [16]. The backside cavity of FBAR can be used as the detection area for adsorbent matter. Under a mass loading, a frequency shift would be resulted in the frequency response of a FBAR [17]. The analysis methods were used for biosensor in liquid and tiny mass detection in air through the shear mode and longitudinal mode, respectively. Thus, FBAR devices were fabricated and constructed to evaluate their potential use in biosensors.

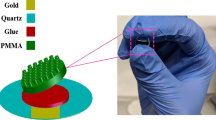

According to the medicine journal report, it is estimated that as many as 1.4 billion people of allergy [18]. Hence, the marketable merit of anti-allergic agent is calculated to be 20 billion USD dollars [19]. The conventional detecting allergy methods focus on testing the concentration of immunoglobulins E (IgE) in human serum. The IgE in human immune system was used to resist exterior germs and virus, but overreactions of the human immune system can cause allergies. Furthermore, the traditional detecting allergy methods have some disadvantages such as time-consuming detecting process and large size and expensive detecting instrument [20]. Therefore, this investigation focuses on micro allergic sensor devices, due to the advantages, such as small size, low-cost, fast detecting process, etc. Besides, the apparatus for evaluating the FBAR-based sensor devices is shown in Figure 1a,b.

Methods

Fabrication of FBAR devices

In this study, the FBAR devices for biosensors application were fabricated. Figure 2 showed the processes used to fabricate the shear-mode FBAR devices. The silicon nitride (Si3N4) was deposited on both sides of Si wafer by low-pressure chemical vapor deposition (LPCVD) as the supporting layer for the FBAR devices. The bottom electrodes, piezoelectric thin films, and top electrodes sandwiched structure is patterned by the photolithography process using four masking processes. The titanium (Ti) and platinum (Pt) layers were deposited on Si3N4/Si structure as bottom electrodes by a dual-gun DC sputtering system using 99.995% pure targets combined with first mask and lift-off method. The distance between target and substrate was fixed at 50 mm. As the base pressure was pumped down to 1 × 10−6 Torr, the film growth was carried out with working pressure of 3 and 1 mTorr for Ti and Pt, respectively. Then the high-quality AlN piezoelectric thin films were deposited on Pt/Ti layer using reactive radio frequency (RF) magnetron sputtering with off-axis deposition method. The Al target was 99.9995% pure, and the distance between target and substrate was fixed at 50 mm. As the base pressure was pumped down to 5 × 10−7 Torr, the sputtering conditions were set as working pressure of 5 mTorr, substrate temperature of 300°C, sputtering power of 250 W, and an off-axis to on-axis distance of 50 mm. To expose the bottom electrodes for electrical contact, AlN was wet-etched with 2.38% tetramethylammonium hydroxide (TMAH) using a second mask at room temperature. The top electrode can be obtained by the third patterning process after Pt/Ti was deposited on the AlN thin films. Finally, the backside of the structure was etched by combining the fourth mask and a 30% KOH solution to form the detection area. Therefore, the fabrication of the FBAR devices was then completed.

Characteristics measurement

The characteristics of AlN thin films, including crystalline properties, preferred orientation, and cross-sectional morphologies were examined. The crystalline properties and preferred orientation of the AlN thin films were determined by X-ray diffraction scanning between 20° and 60° using a Siemens D5000 (Munich, Germany) with CuKα radiation. The surface morphologies and cross sections of AlN thin films were observed by field-emission scanning electron microscope (FESEM, JEOL-6700; JEOL Ltd., Akishima-shi, Japan). Finally, the frequency responses of FBAR devices with the biosensors were measured by HP8720 network analyzer.

FBAR devices for biosensor applications

For biosensor applications of the FBAR, Au/Cr thin films were deposited in the backside cavity of FBAR devices as the detection layer using a dual-gun DC sputtering system as shown in Figure 3. In the self-assembly monolayers (SAMs) method, the Au surface was modified by adsorption of thiolate (CH3(CH2)nSH).

The SAMs method was performed as follows:

-

Step (1): Use oxygen plasma process for Au surface cleaning.

-

Step (2): Inject cysteine solution (R.T., 1 h).

-

Step (3): Inject deionized (DI) water and dry using N2 gas.

-

Step (4): Inject glutaraldehyde solution (2.5%, R. T., 1 h).

-

Step (5): Inject DI water and dry with N2 gas.

Then, the surface modification of FBAR devices were accomplished by the SMAs method. In the biosensors, human IgE was detected by using a coating process to detect antibody with antigen because of the high specificity between antigen and antibody. Hence, the coating process was performed as described in the literatures as follows [21-24]:

-

Step (1): Wash with 200 μl phosphate-buffered saline (PBS) solution three times.

-

Step (2): Dip 200 μl diluted mouse anti-human IgE antibody (37°C, 2 h).

-

Step (3): Inject 200 μl, Tween-20 wash buffer three times.

-

Step (4): Inject 200 μl, 10 wt.% bovine serum albumin (BSA) solution (37°C, 0.5 h).

-

Step (5): Inject 200 μl, Tween-20 wash buffer three times.

-

Step (6): Inject 200 μl, diluted human IgE antigen with 0.707 μg/ml concentration.

In the backend process of step (2) to step (6), the sample were cleaned using DI water to remove excess liquid and then dried with N2 gas. Figure 4 schematically depicts the IgE antigen/IgE antibody/glutaraldehyde/the integrated cystamine SAMs multilayer [20].

After the above SAMs and coating processes, the frequency response was measured before and after anti-human IgE antibody linked with the human IgE antigen. Finally, the sensitivity (S m ) of the biosensor was calculated using the following equation:

where δm is the loading mass (9.1875 ng/cm2) and δf is the variation of the resonate frequency. Finally, the sensitivities of FBAR devices for human IgE detection were investigated.

Results and discussion

Structural and morphological properties of AlN thin films

A highly c-axis orientation is the ideal piezoelectric property of a FBAR device. According to the literature, a 34.5° c-axis tilted piezoelectric thin film in FBAR device exits strongly shear-mode transmittance [25]. The optimized sputtering conditions for 23° c-axis tilted highly textured AlN thin films were obtained in our previous report [26], those were working pressure of 5 mTorr, substrate temperature of 300°C, sputtering power of 250 W, and the off-axis of 50 mm. Figure 5 shows the c-axis preferred orientation of AlN thin films with small full width at half maximum (FWHM). Besides, Figure 6 shows the cross-sectional images, which reveal columnar with 23°-tilted AlN thin films.

Frequency responses of shear-mode FBAR devices

Figure 7 shows the frequency responses of the FBAR devices with 23°-tilted AlN thin films, in which the longitudinal mode and shear-mode exist at 2.07 (f L) and 1.175 GHz (f S), respectively. The ratio of f L to f S can be determined from the following relationship:

where V L and V S are the acoustic velocity, C 33 and C 44 are an elastic constant, and ρ is density of the wurtzite AlN. In this study, the practical acoustic velocity of longitudinal mode is 1.76 times than that of the shear mode, which is still consistent with the literature [25,27]. The electromechanical coupling coefficient (k t 2) of shear mode is a numerical measurement of the conversion efficiency between electrical and acoustic energy in piezoelectric materials. The k t 2 of the shear mode of the FBAR was calculated to be about 3.18%.

Frequency responses of biosensors for human IgE detection

The Au/Cr thin films were adopted as detection layer using a dual-gun DC sputtering system, the oxygen plasma process was used to clean the surface of the Au layer in order to improve the hydrophilic properties of the contact area between the bio-drop and Au layer [28-32].

Besides, the analysis methods were used for biosensor in liquid and tiny mass detection in air through the shear mode and longitudinal mode, respectively. Figure 8 shows the frequency response of FBAR device in air and liquid environment. The longitudinal mode almost disappeared in liquid environment because of the decrease of quality factor (Q) which reduces the mass resolution substantially, whereas the shear mode maintains high readability. However, the literatures mentioned that the large reflection coefficient of longitudinal mode in solid and liquid interface which is the key factor result in the acoustic wave vanished. Therefore, the shear mode propagating in solid medium maintains its movement through a liquid environment [33-35]. The experimental and analytical results indicate that the longitudinal mode is the key indicator to identify the sensing environment, and the shear mode can be exploited in biosensor applications. Hence, FBAR devices with 23°-tilted AlN thin films are suitable for human IgE detection.

In this study, two devices of biosensors for human IgE detection were fabricated, and the frequency responses are shown in Figure 9. In Figure 9, f 0, f 1, f 2, f 3, and f 4 are the resonate frequencies of the shear-mode FBAR devices without loading, treated with the SAMs method, combined with the anti-human IgE antibody, linked with the human IgE antigen, and terminated with the anti-human IgE HRP, respectively. The properties of shear-mode FBAR device adopted for the coating mass detection are demonstrated in Figure 9. In some literatures, the resonant frequency were also used to confirm the coating mass adhered on FBAR devices [20,36].

Besides, after repeated testing, the variation of frequency response of the same device exhibited a tiny error of ±0.01%. In the bio-processes, the resonate frequency decreased the range of about 10 MHz which results from the bio-processes effect as SAMs, IgE antibody, IgE antigen, and HRP are added to the biosensor area. Figure 10 shows the variations of resonate frequency step by step from f 0 to f 4. It is confirmed that the matters have mutual bonding when coated on biosensor. However, the standard IgE reagent exist possible error value of ±0.5% in environment according to the official test reports and the enzyme-linked immunosorbent assay (ELISA).

To calculate the sensitivity (S m ) of the shear-mode FBAR devices for human IgE detection, the S m is calculated by \( {S}_m=\underset{\delta m\to 0}{ \lim}\left(\frac{\delta f}{f}\right)\left(\frac{1}{\delta m}\right) \). Table 1 shows the calculated sensitivities for human IgE detection of two biosensor devices. The average sensitivity calculated for the shear-mode FBAR devices for human IgE detection was about 1.425 × 105 cm2/g.

The results of this study demonstrate that the proposed shear-mode FBAR device is highly promising for use in human IgE detection because of its high sensitivity, small size, low-cost, and rapid reaction process than conventional quartz crystal micro-balance (QCM) [37-41].

Conclusions

This study fabricated shear-mode FBAR devices for biosensor applications. The AlN thin films and Pt/Ti were adopted as the piezoelectric and electrode layers, respectively, in FBAR devices. The AlN thin films were fabricated at a working pressure of 5 mTorr, substrate temperature of 300°C, sputtering power of 250 W, and off-axis of 50 mm. The resulted AlN thin films exhibited a strong c-axis orientation and 23°-tilted. The obtained shear-mode FBAR devices had a frequency response of 1.175 GHz and a k t 2 of about 3.18%. For biosensor applications, the Au/Cr thin films were deposited on backside cavity of FBAR as bio-detection layer. The SAMs method was used for surface modification of Au thin films. Human IgE was detected by using a coating process to detect antibody with antigen. The average sensitivity for the shear-mode FBAR devices for human IgE detection was about 1.425 × 105 cm2/g.

References

Jung JP, Lee JB, Kim JS, Park JS. Fabrication and characterization of high frequency SAW device with IDT/ZnO/AlN/Si configuration: role of AlN buffer. Thin Solid Films. 2004;447–448:605–9.

Legrani O, Elmazria O, Zhgoon S, Pigeat P, Bartasyte A. Packageless AlN/ZnO/Si structure for SAW devices applications. IEEE Sens J. 2013;13:487–91.

Meng X, Yang C, Chen Q, Gao Y, Yang J. Preparation of highly c-axis oriented AlN films on Si substrate with ZnO buffer layer by the DC magnetron sputtering. Mater Lett. 2013;90:49–52.

Kao KS, Cheng CC, Chung CJ, Chen YC. Surface acoustic wave properties of proton-exchanged LiNbO3 waveguides with SiO2 film. IEEE Trans Ultrason Ferroelectr Freq Control. 2005;52:503–6.

Wei CL, Chen YC, Cheng CC, Kao KS, Cheng DL, Cheng PS. Highly sensitive ultraviolet detector using a ZnO/Si layered SAW oscillator. Thin Solid Films. 2010;518:3059–62.

Clement M, Olivares J, Iborra E, González-Castilla S, Rimmer N, Rastogi A. AlN films sputtered on iridium electrodes for bulk acoustic wave resonators. Thin Solid Films. 2009;517:4673–8.

Lee JB, Jung JP, Lee MH, Park JS. Effects of bottom electrodes on the orientation of AlN films and the frequency responses of resonators in AlN-based FBARs. Thin Solid Films. 2004;447–448:610–4.

Yim M, Kim DH, Chai D, Yoon G. Effects of thermal annealing of W/SiO2 multilayer Bragg reflectors on resonance characteristics of film bulk acoustic resonator devices with cobalt electrodes. J Vac Sci Technol A. 2004;22:465–71.

Kirby PB, Potter MDG, Williams CP, Lim MY. Thin film piezoelectric property considerations for surface acoustic wave and thin film bulk acoustic resonators. J Eur Ceram Soc. 2003;23:2689–92.

Huang CL, Tay KW, Wu L. Fabrication and performance analysis of film bulk acoustic wave resonators. Mater Lett. 2005;59:1012–6.

Umar A, Rahman MM, Vaseem M, Hahn YB. Ultra-sensitive cholesterol biosensor based on low-temperature grown ZnO nanoparticles. Electrochem Commun. 2009;11:118–21.

Hong S, Yeo J, Manorotkul W, Kim G, Kwon J, An K, et al. Low-temperature rapid fabrication of ZnO nanowire UV sensor array by laser-induced local hydrothermal growth. J Nanomater. 2013;2013:246328.

Akiyama M, Morofuji Y, Kamohara T, Nishikubo K, Tsubai M, Fukuda O, et al. Flexible piezoelectric pressure sensors using oriented aluminum nitride thin films prepared on polyethylene terephthalate films. J Appl Phys. 2006;100:114318.

Iborra E, Clement M, Capilla J, Olivares J, Felmetsger V. Low-thickness high-quality aluminum nitride films for super high frequency solidly mounted resonators. J Appl Phys. 2012;520:3060–3.

Lin RC, Chen YC, Chang WT, Cheng CC, Kao KS. Highly sensitive mass sensor using film bulk acoustic resonator. Sensor Actuat A-Phys. 2008;147:425–9.

Zhang H, Kim ES. Micromachined acoustic resonant mass sensor. J Microelectromech S. 2005;14:699–706.

Chung CJ, Chen YC, Cheng CC, Kao KS. Synthesis and bulk acoustic wave properties on the dual mode frequency shift of solidly mounted resonators. IEEE Trans Ultrason Ferroelectr Freq Control. 2008;55:857–64.

Schwindt CD, Settipane R. Allergic rhinitis (AR) is now estimated to affect some 1.4 billion people globally and continues to be on the rise. Am J Rhinol. Allergy. 2012;26:S1–S1(1).

Rai M, Carpinella MC. Naturally occurring bioactive compounds. Baker & Taylor Books: Elsevier Science; 2006. pp. 271.

Chen YC, Chang WT, Cheng CC, Shen JY, Kao KS. Development of human IgE biosensor using Sezawa-mode SAW devices. Curr Appl Phys. 2014;14:608–13.

Huang IY, Lee MC. Development of a FPW allergy biosensor for human IgE detection by MEMS and cystamine-based SAM technologies. Sensor Actuat B-Chem. 2008;132:340–8.

Huang IY, Lee MC, Hsu CH, Wang CC. Development of a flexural plate-wave (FPW) immunoglobulin-E (IgE) allergy bio-sensing microsystem. Sensor Actuat B-Chem. 2012;162:184–93.

Huang IY, Lee MC, Chang YW. Development of a novel flexural plate wave biosensor for immunoglobulin-E detection by using SAM and MEMS technologies, 5th IEEE Conference on Sensors, October 2006. Daegu: IEEE; 2006. p. 70.

Huang IY, Lee MC, Chang YW, Huang RS. Development and characterization of FPW based allergy biosensor, ISIE 2007. IEEE International Symposium on Industrial Electronics, June 2007. Daegu: IEEE; 2007. p. 2736.

Qin L, Chen Q, Cheng H, Wang QM. Analytical study of dual-mode thin film bulk acoustic resonators (FBARs) based on ZnO and AlN films with tilted c-axis orientation. IEEE T Ultrason Ferr. 2010;57:840–1853.

Chen YC, Chang WT, Kao KS, Yang CH, Cheng CC. The liquid sensor using thin film bulk acoustic resonator with c-axis tilted AlN films. J Nanomater. 2013;2013:245095.

McNeil L, Grimsditch M, French RH. Vibrational spectroscopy of aluminum nitride. J Am Ceram Soc. 1993;76:1132–6.

Ostuni E, Chapman RG, Holmlin RE, Takayama S, Whitesides GM. A survey of structure–property relationships of surfaces that resist the adsorption of protein. Langmuir. 2001;17:5605–20.

Hook F, Rodahl M, Kasemo B, Brzezinski P. Structural changes in hemoglobin during adsorption to solid surfaces: effects of pH, ionic strength, and ligand binding. Proc Natl Acad Sci U S A. 1998;95:12271–6.

Kaufman ED, Belyea J, Johnson MC, Nicholson ZM, Ricks JL, Shah PK, et al. Probing protein adsorption onto mercaptoundecanoic acid stabilized gold nanoparticles and surfaces by quartz crystal microbalance and zeta-potential measurements. Langmuir. 2007;23:6053–62.

Tang Q, Xu CH, Shi SQ, Zhou LM. Formation and characterization of protein patterns on the surfaces with different properties. Synth Met. 2004;147:247–52.

Wang Y, Zhang Z, Jain V, Yi J, Mueller S, Sokolov J, et al. Potentiometric sensors based on surface molecular imprinting: detection of cancer biomarkers and viruses. Sensor Actuat B-Chem. 2010;146:381–7.

Chung CJ, Chen YC, Cheng CC, Wang CM, Kao KS. Superior dual mode resonances for 1/4 λ solidly mounted resonators, 2008 IEEE International Frequency Control Symposium, May 2008. Honolulu: IEEE; 2008. p. 250.

Beghi MG. Acoustic waves-from microdevices to helioseismology. INTECH. 2011;14:501.

Link M, Schreiter M, Weber J, Primig R, Pitzer D, Gabl R. Solidly mounted ZnO shear mode film bulk acoustic resonators for sensing applications in liquids. IEEE Trans Ultrason Ferroelectr Freq Control. 2006;53:492–6.

Yan Z, Zhou XY, Pang GKH, Zhang T, Liu WL, Cheng JG, et al. ZnO-based film bulk acoustic resonator for high sensitivity biosensor applications. Appl Phys Lett. 2007;90:143503-1–3.

Weber J, Albers WM, Jussipekka T, Mathias L, Reinhard G, Wersing W, et al. Shear mode FBARs as highly sensitive liquid biosensors. Sensor Actuat A-Phys. 2006;128:84–8.

Wingqvist G, Bjurström J, Liljeholm L, Yantchev V, Katardjiev I. Shear mode AlN thin film electro-acoustic resonant sensor operation in viscous media. Sensor Actuat B-Chem. 2007;123:466–73.

Mathias L, Weber J, Schreiter M, Wersing W, Elmazria O, Alnot P. Sensing characteristics of high-frequency shear mode resonators in glycerol solutions. Sensor Actuat B-Chem. 2007;121:372–8.

Wingqvist G, Anderson H, Lennartsson C, Weissbach T, Yantchev V, Spetz AL. On the applicability of high frequency acoustic shear mode biosensing in view of thickness limitations set by the film resonance. Biosens Bioelectron. 2009;24:3387–90.

Fua YQ, Luo JK, Du XY, Flewitt AJ, Li Y, Markx GH, et al. Recent developments on ZnO films for acoustic wave based bio-sensing and microfluidic applications: a review. Sensor Actuat B-Chem. 2010;143:606–9.

Acknowledgements

The authors gratefully acknowledge the financial support from the National Science Council, the Republic of China (NSC Grant Numbers: No. NSC 102-2221-E-366-002, and NSC102-2221-E-110-029) and from the National Sun Yat-sen University (The Aim for the Top University Project, NSYSU).

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors' contributions

WCS carried out the bulk acoustic resonators studies and drafted the manuscript. YCC, WTC and CHY participated in the design of the study. KSK and CCC conceived of the study and participated in its design and helped to draft the manuscript. All authors read and approved the final manuscript.

Authors' information

Ying-Chung Chen was born in Tainan, Taiwan, ROC, on November 4, 1956. He received the MS and PhD degrees in electrical engineering from the National Cheng Kung University, Tainan, Taiwan, in 1981 and 1985, respectively. Since 1983, he has been at the National Sun Yat-Sen University, Kaohsiung, Taiwan. He is a professor of electrical engineering at the National Sun Yat-sen University. His current research interests are in the areas of electronic devices, surface acoustic wave devices, thin-film technology, and electronic ceramics. He is a member of the Chinese Society for Materials Science and a registered electrical engineer at Taiwan.

Wei-Che Shih was born in Kaohsiung city, Taiwan, ROC, on December 17, 1986. He is currently a postgraduate student pursuing a PhD at the National Sun Yat-sen University, Taiwan. His current research interests are in the areas of piezoelectric material and film bulk acoustic wave devices.

Wei-Tsai Chang was born in Kaohsiung city, Taiwan, ROC, on October 13, 1982. He received the PhD degree in electrical engineering from the National Sun Yat-sen University, Kaohsiung, Taiwan in 2012. Currently, he is a postdoctoral researcher at the National Sun Yat-Sen University, Kaohsiung, Taiwan. His current research interests are in the field of piezoelectric material and film bulk acoustic wave devices.

Chun-Hung Yang was born in Kaohsiung city, Taiwan, ROC, on May 5, 1987. He received the MS degree in electrical engineering from the National Sun Yat-sen University, Kaohsiung, Taiwan in 2011.

Kuo-Sheng Kao was born in Chia-Yi City, Taiwan, ROC, on September 11, 1973. He received the MS and PhD degrees in electrical engineering from the National Sun Yat-sen University, Kaohsiung, Taiwan, in 1999 and 2004, respectively. Currently, he is an assistant professor of computer and communication at SHU-TE University, Kaohsiung, Taiwan. His current research interests are in the field of functional ceramic thin-film and acoustic wave devices.

Chien-Chuan Cheng was born in Keelung, Taiwan, ROC, on March 26, 1964. He received the MS and PhD degrees in electrical engineering from the National Sun Yat-sen University, Kaohsiung, Taiwan, in 1988 and 1995, respectively. Since 1990, he has been at De Lin Institute of Technology, Taipei, Taiwan. Currently, he is a professor of electronic engineering at De Lin Institute of Technology. His current research interests are in the areas of surface acoustic wave devices, electronic ceramics, and thin-film technology.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit https://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, YC., Shih, WC., Chang, WT. et al. Biosensor for human IgE detection using shear-mode FBAR devices. Nanoscale Res Lett 10, 69 (2015). https://doi.org/10.1186/s11671-015-0736-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-015-0736-3