Abstract

A novel method for estimating the wood moisture content above the fiber saturation point (FSP) is proposed, and the method performance is confirmed. Previous studies have highlighted that there is a negative linear correlation between the specific dynamic Young’s modulus (log (E/ρ)) and tangent loss (log (tanδ)) of clear small wood specimens. We confirm that this correlation can be obtained for air-dried commercial lumber from Japanese cedar, or sugi (Cryptomeria japonica), via experimental analysis. The best-fit linear regression line of this correlation only changes by the apparent density above the FSP (i.e., only by the moisture content of the specimen) when E and tanδ are kept constant in this high moisture content range. Here, we derive an equation to calculate the moisture content using log (E/ρ) and log (tanδ) based on the regression line of sugi wood at the FSP. A 45-day drying test was conducted on 23 green lumber specimens, with the E/ρ and tanδ values calculated from the natural resonance frequency fr, the logarithmic decrement λ and dimensions at various drying stages. The estimated moisture contents are in good agreement with the measured values, confirming the performance of proposed moisture content method.

Similar content being viewed by others

Introduction

Non-destructive and practical methods for estimating the moisture content of green wood and wood during the drying process are important. However, there are currently no methods that satisfy all of these demands, particularly when acquiring moisture content estimations in regions above the fiber saturation point (FSP). Popular methods involve moisture meters that employ electric capacitance or electrical resistance, but these instruments are not good at measuring the moisture content above the FSP. Furthermore, they can only evaluate the moisture content near the wood surface, obtaining measurements within several centimeters of the surface at most, such that it is difficult to obtain the average moisture content of lumber with a larger cross section. Moisture meters that employ microwave transmission are sometimes equipped on-site for deeper measurements; however, these instruments are expensive, and their measured values are strongly influenced by densities above the FSP [1, 2]. Near-infrared ray [3, 4] and X-ray [5] methods have also been employed to estimate the moisture content, even above the FSP. However, the near-infrared ray method can only evaluate the moisture content near the wood surface, and it is influenced by the wood quality, such as the grain angle, juvenile wood, and knots. The X-ray method is impractical in that it requires a large equipment for radiation shielding.

Previous studies [6,7,8,9,10] have reported that the apparent dynamic modulus of elasticity calculated from the propagation speed of the sound or stress wave increased as the moisture content increased above the FSP. Guan et al. [11] tried to estimate the moisture content of lumber using these characteristics, but a correction that used values before the drying process was necessary to eliminate the influence of inherent variations in the mechanical properties of the wood specimens. Toyoshima et al. [12] estimated the moisture content using the stress wave velocity by classifying the specimens into groups based on their apparent density. The vibrational properties of wood can also be an indicator of moisture content. For example, the resonance frequencies and calculated dynamic moduli of elasticity both vary as a function of the weight as it increases above the FSP. Some basic studies and advances have been conducted based on these characteristics. Guan et al. [13, 14] estimated the moisture content gradient in lumber using the ratio of the natural frequencies for several vibration modes. Aratake et al. [15] estimated the moisture content using the ratio of the natural frequencies for higher vibration modes to those at the initial stage of drying to avoid influences from the inherent variations in the mechanical properties of the wood specimens. Kamaguchi et al. [16, 17] and Iki et al. [18] applied the lateral impact vibration method to sugi (Cryptomeria japonica) and todomatsu (Abies sachalinensis) tree stems, and successfully obtained rough estimates of the heartwood moisture content. Tsutsumi et al. [19] predicted the average moisture content precisely using statistical models based on the vibrational spectra.

Wood is a viscoelastic material, with a dynamic modulus that accounts for both the storage modulus (elasticity) and loss modulus (energy loss). The ratio between the loss and storage moduli of a viscoelastic material is generally defined as tanδ. tanδ can be calculated simultaneously and relatively easily via the free–free vibration method, which is often used to measure the elasticity modulus of wood. Previous studies have investigated the relationship between the specific elasticity modulus and tanδ to better understand wood properties. The relationship between the specific elasticity modulus and tanδ has been widely investigated to improve the properties of wood specimens used for musical instruments [20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36]. Norimoto et al. [25] reported that the relationship between log (E/ρ) and log (tanδ) for small clear specimens exhibited a strong negative correlation [20,21,22,23,24,25,26,27,28], with this correlation attributed to the microfibril angle (MFA). Ono and Norimoto [22,23,24] noted that this correlation could be found in all wood species. Several reports [29,30,31,32,33] have since evaluated the changes in the mechanical properties of chemically modified wood using this correlation. For example, Akitsu et al. [30] reported that the regression line of this correlation shifted when the cell walls were modified by substituents or molecules via chemical treatment. Other reports [33,34,35,36] have investigated the influence of heartwood extract on this correlation. For example, Yano [33] reported that the heartwood extract of western red cedar largely contributed to the decrease in tanδ. However, few researchers have investigated the dependency of this correlation on the moisture content. Sasaki et al. [26] and Akitsu et al. [32] concluded that the regression line increased as the moisture content increased up to the FSP, but no reports have investigated the response of this correlation above the FSP. Furthermore, an exhaustive literature search indicates that this correlation has only been investigated using small clear specimens, with no reports using lumber or logs that possess defects, such as knots or grain slope.

Here, we propose a new method for estimating the moisture content above the FSP using the vibrational properties of wood, while avoiding the inherent effects of the density or mechanical properties variation of wood. We first conducted experiments to identify the correlation between log (E/ρ) and log (tanδ) for air-dried commercial sugi lumber. The best-fit linear regression line of the correlation shifted as a function of the apparent density above the FSP when E and tanδ were kept constant. We then derived an equation from this observation to calculate the moisture content using log (E/ρ), log (tanδ), and the best-fit regression line of the correlation that was applicable for sugi wood. We finally verified the efficacy of our proposed estimation method by conducting drying tests for 45 days using 23 green lumber specimens, by calculating the E/ρ and tanδ values from the natural resonance frequency fr, the logarithmic decrement λ and dimensions at various stages during the drying process.

Theoretical background

Previous studies have used small clear specimens to demonstrate that the relationship between log (E/ρ) and log (tanδ) exhibits a strong negative correlation [20,21,22,23,24,25,26,27,28]. These studies have concluded that each species should only have one correlation between the specific dynamic Young’s modulus (log (E/ρ)) and tangent loss (log (tanδ)) for any moisture content below the FSP. This correlation can be expressed as:

where ρ30 denotes the density for 30% moisture content (FSP), and the tanδ and E values are for the FSP.

The change in this correlation for moisture contents above the FSP is then discussed. The E and tanδ values are constant for moisture contents above the FSP [37, 38], whereas the apparent density ρ changes with the moisture content. The density ratio above the FSP (mu) is defined as:

where u represents the moisture content (%) and is above the FSP. Equation (2) can be rewritten as:

Substituting Eq. (3) into Eq. (1) yields:

Equation (4) highlights that a, which is the slope of the regression line of the correlation between log (E/ρ) and log (tanδ), should be constant for any moisture constant above the FSP, whereas the value of the segment varies as a function of mu. The regression line will therefore shift horizontally due to changes in the moisture content, as shown in Fig. 1.

Equation (4) can be rewritten to yield:

Equation (6) is then derived as:

where \(p = \frac{1}{a}\) and \(q = - \frac{b}{a}\). Substituting \(\rho_{u} = \left( {1 + 0.01u} \right)\rho_{0}\) and \(\rho_{30} = 1.3\rho_{0}\) into Eq. (2) yields:

Substituting Eq. (7) into Eq. (6) then yields:

The moisture content u can be obtained via Eq. (8) using E/ρu and tanδ for a wood specimen of a given species when the a and b values for the wood species are known (e.g., calculated in advance). Here E/ρu represents the specific dynamic Young’s modulus when the moisture content of the specimen is u.

In order to calculate both E/ρ and tanδ, only the natural resonance frequency fr, the logarithmic decrement λ and dimensions are needed. First two can be measured from free–free flexural vibration tests. Note that there is no need to measure density separately because fr is not the function of E, but the function of E/ρ.

The natural resonance frequency fr of the free–free flexural vibration of square timber can be written as:

where h and l denote the thickness and length of the wood specimen, respectively. Log (E/ρ) can be derived from Eq. (9) as:

Equation (10) shows that log (E/ρ) can be obtained from the dimensions and resonance frequency of the wood specimen.

The logarithmic decrement λ can be calculated from the damped vibration waveform, such that tanδ can be expressed as:

Materials and experimental methods

Specimens

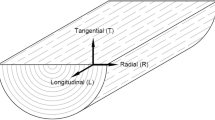

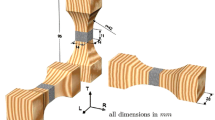

Three specimen groups of sugi (Cryptomeria japonica) were analyzed.

Group A: air-dried specimens

Ten specimens, each approximately 45 mm × 50 mm in cross section and 1000 mm in length, were cut from four pieces of lumber from the Kyoto University experimental forest and conditioned in a room at 23 °C and 50% relative humidity on average. The moisture content of the specimens, which was estimated via the oven-dry method, was 12–14%. The specimens were designated A1-1–A4-3, and were either boxed heart or without core in cross section. The specimens possessed different defects, such as knots and grain slope. Table 1 shows the specifications of the Group A specimens.

Group B: green specimens from the boxed heart cross section

Nine green specimens were prepared. They were cut from logs that were cut, pruned, and conditioned in the forest for a month. The nominal dimensions of each specimen were 44.5 mm in square cross section and 1000 mm in length, and each specimen was almost entirely heartwood. Both end surfaces were sealed to avoid a moisture content gradient in the longitudinal direction.

Group C: green specimens without a core cross section

Fourteen green specimens were prepared following the same procedure employed for the Group B specimens. The nominal dimensions of each specimen were 51.1 mm × 55.4 mm in cross section and 1060–1070 mm in length, with most taken from the boundary between heartwood and sapwood. Both end surfaces were sealed to avoid a moisture content gradient in the longitudinal direction.

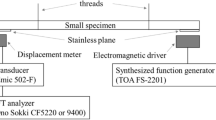

Method to measure the vibrational characteristics

Each specimen was supported horizontally and hung with two ropes at the node positions for the primary mode of flexural vibration. The center of the specimen was then struck with a hammer to excite a flexural vibration. A piezoelectric acceleration sensor (TEAC 701, frequency range is 3–30,000 Hz, machine weight is 3.04 g) was attached 20 mm from the hammer strike position. The signal from the sensor was amplified 100-fold using an amplifier (TEAC SA-611), high-pass filtered at 10 Hz, and processed using a FFT analyzer (Ono Sokki, CF5220). The logarithmic decrement λ was obtained from the time-domain signal during the 1.0-s period after the each hammer strike. The natural resonance frequency fr was obtained from frequency-domain signal. The signal from the sensor was sampled at either 1024 or 2560 Hz, providing a frequency resolution of either 0.5 or 1.25 Hz, and processed using an exponential window in the FFT transform. The vibration test was repeated four times and the average fr and λ were calculated in order to increase the accuracy of the measurement values. The resonance frequency range was 100–200 Hz in this experiment. Previous reports [39, 40] suggested that tanδ could be evaluated independently in this frequency range.

Experimental methods and conditions

The Group B specimens were dried for 43 days under a roof in open-air conditions. The Group C specimens were dried for 47 days in an air-conditioned room at 23 °C and 50% relative humidity. Vibration tests were conducted 16 times at 1–4-day intervals on each specimen during the drying process. The weight and dimensions of each specimen were also measured prior to each vibration test. The dimensions were measured using a caliper (0.05-mm resolution), and were represented by the average of three measurements along the clear surface. Moisture measurements were acquired for some of the specimens via the oven-dry method during each vibration test.

Results and discussion

Influence of defects on the correlation between the specific dynamic Young’s modulus and tangent loss

Figure 2 shows the correlation between log (E/ρ) and log (tanδ) for the Group A specimens, which exhibits a linear regression with a correlation coefficient of 0.96. The best-fit regression line for the Group A specimens (solid line) approximately coincides with the best-fit regression line for small clear specimens of hinoki (Chamaecyparis obtusa) (dashed line), which were measured in a previous study [25]. The correlation of the small clear specimens was reported to be derived from the MFA [28]. According to this study, when the MFA is small mechanical property of specimens depend largely on the microfibril of S2 layer in cell walls, which is elastic component, however, when the MFA become larger, this depend also on the matrix in S2 layer, which is viscoelastic component. Therefore, dynamic Young’s modulus of specimen should become smaller and tangent loss become larger in accordance with the increase of MFA. Our experiment suggests that the correlation is not heavily influenced by knots or juvenile wood in the heartwood since all of the Group A specimens satisfied the correlation, even though they possess knots and grain slope, and are either boxed heart or without core in cross section.

Correlation between log (E/ρ) and log (tanδ) for the Group A specimens. The solid line is the best-fit regression line for the Group A specimens. The dashed line is the best-fit regression line of hinoki small clear specimens from a previous report [25]

We address this observed correlation by associating the knots, grain slope, and juvenile wood in the heartwood with MFA. Previous research [21, 22, 27] has suggested that small clear specimens with various grain slopes satisfied the same correlation as that derived from MFA. McDonald and Bendtsen [41] measured the grain slope angle near knots using an electrostatic capacitance device, and suggested that knots could be regarded as the local grain slope. These studies suggest that the grain slope and local grain slope around knots can be regarded as MFA in a broad sense. Defects that cannot be regarded as MFA, such as cracks derived from dead knots, are thought to have little influence on the correlation at our specimen size. Hirakawa and Fujisawa [42] and Hirakawa et al. [43] suggested that the dynamic Young’s modulus of small clear sugi specimens could be easily predicted from the MFA of S2 layers of latewood tracheids and their air-dried densities via multiple regression analysis, which was applied to sugi logs [43]. It was clear that the heartwood of these sugi logs contained juvenile wood. Therefore, this juvenile wood could also be regarded as MFA in a broad sense.

We conclude that the correlation can be applied not only to small clear specimens, but to specimens with defects, such as knots and grain slope, and juvenile wood. This result acquired by using air-dried specimens is considered to be applied to the correlation of specimens at other higher moisture contents.

Influence of moisture content on the correlation

Figure 3 shows the relationship between log (E/ρ) and log (tanδ) for the Group C specimens during the drying process. The measured moisture contents, which were calculated via the oven-dry method, are provided next to the samples. The samples of the each plot symbol in Fig. 3 belong to the same group of moisture contents at every 20% interval. The ellipses are added in Fig. 3 to show that each plot group approximately aligned along a straight line with a certain slope. These results are as expected from the theoretical background, as shown in Fig. 1. Although tanδ and E theoretically should not change above the FSP, the tanδ values decrease and E values increase for most of the specimens at the initial stage of drying process even when the average moisture contents of specimens are above FSP. This may be because the surface moisture contents of the specimens got to be below the FSP due to the moisture content gradients in cross sections. However, we did not consider the influence of the moisture content gradient on the moisture content estimations during this experiment.

Relationship between log (E/ρ) and log (tanδ) for the Group C specimens during the drying process. The moisture contents, which were calculated via the oven-dry method, are provided next to each sample. The ellipses are drawn to show each plot group approximately aligned along a straight line with a certain slope

Correlation between the specific dynamic Young’s modulus and tangent loss at the FSP

In order to estimate the moisture content of the specimens, it is necessary to acquire the regression line at the 30% moisture content (FSP), as shown in Eq. (1). However, it is difficult to get enough number of specimens precisely at 30% moisture content. Therefore, to acquire the regression line, we used the E and tanδ values of specimens group B and C when their drying process commenced as representative values of the vibrational characteristics above the FSP, and the density values at 30% moisture content ρ30 of specimens group B and C calculated from their oven-dried densities and Eq. (12). Figure 4 shows the correlation between log (E/ρ30) and log (tanδ) for the Group B and C specimens, which exhibit a high degree of correlation. The best-fit regression line in Fig. 4 was calculated as Eq. (13), where a = − 1.126 and b = 12.76. All sugi lumbers at 30% moisture content should satisfy this regression line.

Estimation of the moisture content using measured coefficients and the theoretical estimation method

Moisture contents of specimens group B and C during drying were estimated using Eq. (8). Here a and b coefficients were calculated in the previous section, and the E/ρ and tanδ values were calculated from the fr, λ and dimensions measured at the moisture content we aim to achieve. The estimated moisture contents were defined as uE. The measured moisture contents, which were calculated via the oven-dry method, were defined as uM. Figure 5 shows the relationship between uE and uM for the case where uM is larger than 30%. The moisture content could be estimated with high accuracy using our proposed method. The width of the 95% prediction intervals of the measured moisture contents was approximately 35% (broken lines in Fig. 5), assuming a normal distribution of the errors. This error could be attributed to as follows: the error in measurement of vibrational properties, the moisture content gradient in cross section and the variation of mechanical properties from the regression line of Eq. (13). First error could be less when specimens are larger in size. Further studies are needed in order to clarify the influence of moisture content gradient and variation of mechanical properties from the regression line on the accuracy of our proposed method.

Conclusion

The correlation between log (E/ρ) and log (tanδ) for small clear specimens was also confirmed for lumber with defects. This was investigated because lumber defects, such as knots and grain slope, can be regarded as MFA variations in a broad sense. We proposed a novel method for estimating the moisture content of sugi wood above the FSP based on the correlation between log (E/ρ) and log (tanδ) for sugi at the FSP by measuring the wood specimen dimensions and two vibrational properties of the natural resonance frequency fr, the logarithmic decrement λ, which can be measured from their flexural vibration. We conducted a series of experiments to confirm the efficacy of our method in estimating the moisture content. The moisture content could be estimated with high accuracy using our proposed method. Further investigations about moisture content gradient and variation of mechanical properties from the regression line are needed for more accurate estimation. Moreover, this method can be applied to any wood species where the regression line of the correlation between log (E/ρ) and log (tanδ) at the FSP is already known.

References

Aichholzer A, Schuberth C, Mayer H, Arthaber H (2018) Microwave testing of moist and oven-dry wood to evaluate grain angle, density, moisture content and the dielectric constant of spruce from 8 GHz to 12 GHz. Eur J Wood Prod 76:89–103

Lundgren N, Hagman O, Johansson J (2006) Predicting moisture content and density distribution of Scots pine by microwave scanning of sawn timber II: evaluation of models generated on a pixel level. J Wood Sci 52:39–43

Leblon B, Haddadi A, Tsuchikawa S, Burger J, Stirling R, Pirouz Z, Grove K, Nader J, Larocque A (2013) A review of near-infrared spectroscopy for monitoring moisture content and density of solid wood. Forestry Chronicle 89:595–606

Tham VTH, Inagaki T, Tsuchikawa S (2018) A novel combined application of capacitive method and near-infrared spectroscopy for predicting the density and moisture content of solid wood. Wood Sci Technol 52:115–129

Watanabe K, Saito Y, Avramidis S, Shida S (2008) Non-destructive measurement of moisture distribution in wood during drying using digital X-ray microscopy. Drying Technol 26:590–595

Gerhards CC (1975) Stress wave speed and MOE of sweetgum ranging from 150 to 15 percent MC. For Prod J 25:51–57

James WL, Boone RS, Galligan WL (1982) Using speed of sound in wood to monitor drying in a kiln. For Prod J 32:27–34

Kodama Y (1992) Velocity and damping of ultrasonic waves in wood with various moisture content. J Soc Mater Sci, Jpn 41:144–147 (in Japanese)

Sobue N (1993) Simulation study on stress wave velocity in wood above fiber saturation point. Mokuzai Gakkaishi 39:271–276 (in Japanese)

Guan H, Nishino Y, Tanaka C (2002) Sound velocity in the fiber direction of douglas fir wood in the moisture content region above the fiber saturation point. Mokuzai Gakkaishi 48:1–6 (in Japanese)

Guan H, Nishino Y, Tanaka C (2002) Estimation of moisture content in sugi wood with sound velocity during the natural drying process. Mokuzai Gakkaishi 48:225–232 (in Japanese)

Toyoshima I, Yamasaki M, Sasaki Y (2016) Estimating the moisture content of lumber above the fiber saturation point using stress wave velocity during the natural drying process. For Prod J 66:453–460

Guan H, Nishino Y, Tanaka C (2000) Longitudinal natural frequency of wood bar with the free water distribution in the length direction. Mokuzai Gakkaishi 46:275–281 (in Japanese)

Guan H, Nishino Y, Tanaka C (2001) Longitudinal natural frequencies of softwood logs in the natural drying process. Mokuzai Gakkaishi 47:405–411 (in Japanese)

Aratake S, Arima T, Sakoda T (1994) Estimation of moisture content of lumber and logs using higher natural frequency of longitudinal vibrations. Mokuzai Gakkaishi 49:474–480 (in Japanese)

Kamaguchi A, Nakao T, Kodama Y (2000) Non-destructive measurement of heartwood moisture content in sugi (Cryptomeria Japonica D. Don) standing tree by lateral impact vibration method. Mokuzai Gakkaishi 46:13–19 (in Japanese)

Kamaguchi A, Nakao T, Nakai T, Tamura A (2001) Measurement of heartwood moisture content of sugi by lateral impact vibration method. Mokuzai Gakkaishi 47:235–241 (in Japanese)

Iki T, Tamura A, Iizuka K (2010) The non-destructive evaluation of green moisture content in todomatsu (Abies sachalinensis) using a lateral vibration method. Mokuzai Gakkaishi 56:33–40 (in Japanese)

Tsutsumi H, Oribe S, Haga H, Fujimoto T (2017) Nondestructive evaluation of wood properties in standing trees using vibration spectra. Mokuzai Gakkaishi 63:291–296 (in Japanese)

Norimoto M (1982) Structure and properties of wood used for musical instruments I. on the selection of wood used for piano soundboards. Mokuzai Gakkaishi 28:407–413 (in Japanese)

Ono T (1983) Effect of grain angle on dynamic mechanical properties of wood. J Soc Mater Sci 32:108–113 (in Japanese)

Ono T, Norimoto M (1983) Study on Young’s modulus and internal friction of wood in relation to the evaluation of wood for musical instruments. Jpn J Appl Phys 22:611–614

Ono T, Norimoto M (1984) On physical criteria for the selection of wood for soundboards of musical instruments. Rheol Acta 23:652–656

Ono T, Norimoto M (1985) Anisotropy of dynamic Young’s modulus and internal friction in wood. Jpn J Appl Phys 24:960–964

Norimoto M, Tanaka F, Ohogama T, Ikimune R (1986) Specific dynamic Young’s modulus and internal friction of wood in the longitudinal direction. Wood Res Technol 22:53–65 (in Japanese)

Sasaki T, Norimoto M, Yamada T, Rowell RM (1988) Effect of moisture on the acoustical properties of wood. Mokuzai Gakkaishi 34:794–803 (in Japanese)

Yano H, Oonishi K, Mukudai J (1990) Acoustic properties of wood for top plate of guitar. J Soc Mater Sci 39:23–28 (in Japanese)

Yano H, Matsuoka I, Mukudai J (1992) Acoustic properties of wood for violins. Mokuzai Gakkaishi 38:122–127 (in Japanese)

Yano H, Yamada T, Minato K (1986) Changes in acoustical properties of sitka spruce due to reaction with formaldehyde. Mokuzai Gakkaishi 32:984–989 (in Japanese)

Akitsu H, Norimoto M, Morooka T (1991) Vibrational properties of chemically modified wood. Mokuzai Gakkaishi 37:590–597 (in Japanese)

Yano H, Minato K (1992) Improvement of the acoustic and hygroscopic properties of wood by a chemical treatment and application to the violin parts. J Acoust Soc Am 92:1222–1227

Akitsu H, Norimoto M, Morooka T, Rowell RM (1993) Effect of humidity on vibrational properties of chemically modified wood. Wood Fiber Sci 25:250–260

Yano H (1994) The changes in the acoustic properties of western red cedar due to methanol extraction. Holzforschung 48:491–495

Sugiyama M, Matsunaga M, Minato K, Norimoto M (1994) Physical and mechanical properties of pernambuco (Guilandina echinata Spreng) used for violin bows. Mokuzai Gakkaishi 40:905–910 (in Japanese)

Ahang T, Bai S, Bardet S, Almeras T, Thibaut B, Beuchene J (2011) Radial variations of vibrational properties of three tropical woods. J Wood Sci 57:377–386

Bremaud I, Amusant N, Minato K, Grill J, Thibaut B (2011) Effect of extractives on vibrational properties of African padauk (Pterocarpus soyauxii Thab.). Wood Sci Technol 45:461–472

Kollmann F, Krech H (1960) Dynamic measurement of damping capacity and elastic properties of wood. Holz Roh Werk 18:41–54

Suzuki S (1980) Relationship between specific gravity and decrement of dynamic Young’s modulus with water. Mokuzai Gakkaishi 26:299–304 (in Japanese)

Ono T, Kataoka A (1979) The frequency dependence of the dynamic Young’s modulus and internal friction of wood used for the soundboards of musical instruments II. the dependence of the Young’s modulus and internal friction on frequency, and the mechanical frequency dispersion. Mokuzai Gakkaishi 25:535–542 (in Japanese)

Tonosaki M, Okano T, Asao I (1983) Vibrational properties of sitka spruce with longitudinal vibration and flexural vibration. Mokuzai Gakkaishi 29:547–552 (in Japanese)

McDonald KA, Bendtsen BA (1986) Measuring localized slope of grain by electrical capacitance. For Prod J 36:75–78

Hirakawa Y, Fujisawa Y (1995) The relationships between microfibril angles of the S2 layer and latewood tracheid lengths in elite sugi tree (cryptomeria japonica) clones. Mokuzai Gakkaishi 41:123–131 (in Japanese)

Hirakawa Y, Yamashita K, Nakada R, Fujisawa Y (1997) The effects of S2 microfibril angles of latewood tracheids and densities on modulus of elasticity variations of sugi tree (Cryptomeria japonica) logs. Mokuzai Gakkaishi 43:717–724 (in Japanese)

Declarations

The datasets used and/or analyzed during the current study are available upon request from the corresponding author.

Funding

This work was performed as part of a research project funded by Kyoto University.

Author information

Authors and Affiliations

Contributions

TF contributed to the conceptualization, investigation, methodology, visualization, and original draft of the manuscript. YY and YS contributed to the data curation, formal analysis, investigation, methodology, and review and editing of the manuscript. YF contributed to the conceptualization, data curation, funding acquisition, investigation, methodology, project administration, supervision, validation, visualization, and review and editing of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Fukui, T., Yanase, Y., Sawada, Y. et al. Estimations of the moisture content above the fiber saturation point in sugi wood using the correlation between the specific dynamic Young’s modulus and tangent loss. J Wood Sci 66, 35 (2020). https://doi.org/10.1186/s10086-020-01879-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s10086-020-01879-y