Abstract

The nuclear facility TRIGA RC-1 is located at the ENEA Casaccia Research Center in Rome. It is a thermal spectrum research reactor with a thermal power of 1 MW and a Mark III containment. The failure of the fuel cladding of the General Atomic TRIGA is a well-known phenomenon in the literature and is normally expected during its lifetime. Depending on the severity of the cracking, this results in the transfer of radioactivity from inside the fuel rods to the demineralized moderation and cooling water of the primary circuit. This occurs especially when the fuel is heated, as the temperature rise leads to an increase in the internal pressure inside the rods, causing fission products, especially gaseous ones, to be released through the cracks. The sustained release of these fission products over time causes impurities with longer half-lives (e.g., Cs-137) to accumulate in the primary water purification system and, in particular, in the ion exchange resin tank. Therefore, the detection of Cs-137 in the ion exchange resins of the primary water purification system of the reactor is a sufficiently clear indication of the occurrence of such disturbances. Indeed, Cs-137 is not only a direct fission product of U-235, but is also produced by the decay of Xe-137 (one of the major fission noble gasses), which, because of its physical nature, readily escapes through the rod cladding. To ensure worker protection from ionizing radiation during the identification and replacement of defective fuel rods, a special program of physical, environmental, and personal radiation protection monitoring was conducted. In addition to a brief description of the work performed, this report presents the results of radiometric measurements and associated individual dose assessment performed before, during, and after the identification and replacement of the defected fuel elements.

Similar content being viewed by others

1 Introduction

1.1 TRIGA R.C.-1

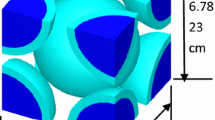

The TRIGA R.C.-1 (Training Research Isotopes General Atomics-Reattore Casaccia 1), located at the ENEA Casaccia Research Center in Rome, is a 1 MW research reactor of the Thermal Power Pool type with a Mark III containment system and a thermal neutron spectrum. The fuel currently loaded into the core consists of 111 cylindrical elements with varying burnup, made of a ternary alloy of zirconium (Zr), hydrogen (H) and uranium (U), enriched to 20% U-235 (about 4 kg U-235 in the core) [1]. The outer surface (cladding tubes) of the fuel assemblies is made of stainless steel with a uniform thickness of 0.5 mm. The reactor is controlled by three control rods loaded with neutron absorber material (\(B_4C\)). Inside the core are two instrumented fuel elements with thermocouples that measure the temperature of the element at a specific location in the core [1]. Inside the reactor, a controlled and gradual chain reaction is initiated by an americium/beryllium (Am/Be) source [1]. Neutron moderation is provided not only by the cooling water but also by the zirconium hydride in the fuel assemblies. Removal of the thermal energy generated by the core is provided by the natural circulation of the water [1]. The nuclear reactor TRIGA R.C.-1 is mainly used for basic research in nuclear physics and to produce radioisotopes for technical applications. It plays a fundamental role in neutron activation analysis in support of research in biology and chemistry carried out in the ENEA Casaccia Research Center laboratories [2] (Fig. 1).

The failure of the fuel cladding of the General Atomic TRIGA is a well-known phenomenon in the literature and is normally expected during its lifetime [3,4,5]. Depending on the severity of the cracking, this results in the transfer of radioactivity from inside the fuel rods to the demineralized moderation and cooling water of the primary circuit [3,4,5]. This occurs especially when the fuel is heated, as the temperature rise leads to an increase in the internal pressure inside the rods, causing fission products, especially gaseous ones, to be released through the cracks [3]. The sustained release of these fission products over time causes impurities with longer half-lives (e.g., Cs-137) to accumulate in the primary water purification system and, in particular, in the ion exchange resin tank [3]. The building housing the reactor TRIGA R.C.-1 extends over several floors (basement, first floor, mezzanine and second floor). The areas used for the research of damage fuel rods are [1]:

-

Reactor main building where the reactor is physically located. On top of the reactor pool, at the water surface, there is an area called TOP. It is accessible via a service stairway and consists of a corridor that can be used to control some of the equipment used to irradiate samples. The experimental system used for this activity was installed in this area.

-

Pump room, where all the equipment necessary for the functioning of the primary and secondary cooling circuits of the reactor is located.

-

Control room, where all the control and monitoring instruments for the reactor and all the controller of the experimental apparatus [6] are located.

-

Locker room, a room used for cloth change, for radiometric control and decontamination of personnel.

Table 1 shows the classification and radiological risk associated with each rooms [1].

To ensure worker protection from ionizing radiation during the identification and replacement of defective fuel rods, a special program of physical, environmental, and personal radiation protection monitoring was conducted [7]. In addition to a brief description of the work performed, this report presents the results of radiometric measurements and associated individual dose assessment performed before, during, and after the identification and replacement of the defected fuel elements.

1.2 Discovery of fission products

The first experimental evidence of a crack in one or more fuel rods was obtained during the routine replacement of the ion exchange resins of the reactor primary water treatment system [8]. During this operation, radiometric characterization of the resins was performed in accordance with the radioactive waste management procedure using gamma spectrometry [9]. Table 2 shows the results of radionuclide activities measured in the ion exchange resins of the primary cooling circuit of the reactor. The percentage value of measurement uncertainties (u) is given with a coverage factor \(k=2\). These measurements were made using an in situ gamma-ray spectrometry detector, ISOCS from Camberra. The detector was calibrated by Monte Carlo method (MC) using a software suite, Geometry Composer, of the recording program (Genie 2000).

Gamma spectroscopic measurement of ion exchange resins is expected to reveal the presence of Co-60, Mn-54, and Zn-65 [1]. These radionuclides are generated by the activation of the metallic components of the nuclear reactor and are transported by the water used in the primary cooling circuit. Such radionuclides tend to accumulate in the water purification system and can therefore be detected in the ion exchange resins during gamma spectroscopy measurements. Instead, the presence of Cs-137 in this characterization indicates the existence of a possible defect in one or more fuel rod coatings, although the presence of Cs-137 alone is not sufficient evidence. Certainty of a crack is obtained by focusing on the search for short-lived fission products in the water of the reactor’s primary circuit by gamma spectrometry [4, 5]. Since the fuel is the only source of production of fission products, it is obvious that identification of such radionuclides in the water of the primary circuit is means to demonstrating the lack of integrity of the fuel cladding itself. For this reason, an ignition of the reactor TRIGA R.C.-1 was programmed with a power of 100 kW for about 4 h. At the end of this ignition, a water sample was taken from the primary cooling system of the reactor and subsequently characterized by gamma spectrometry. The water sample was taken from the top of the water column (7 ms) in the core, called the reactor well, at a depth of about 50 cm from the surface. Three replicates of gamma spectrometry measurements (at different times) were performed on the same one-liter water sample collected in Marinelli geometry, with the sole objective of evaluating the presence of fission products in the water. These measurement were made using a low background spectrometry detector (Ortec HPGe), and the results are presented in Tables 3, 4 and 5. Several gamma peaks were observed in the recorded spectra, which were identified as fission and decay products with short half-lives. The observed radionuclides are consistent with defects of one or more reactor fuel assemblies [4, 5]. In the first measurement (Table 3), only Kr-85m, I-133, and Xe-135 are visible because the activation products of Ar-41 and Na-24 dominate the spectrum. In the subsequent measurements, I-131 was observed in addition to Cs-137. The three measurements at different times of the same water sample showed fission gas activities consistent with the half-lives of the observed species. All measured activities were referred to the time of water sampling (reference date: 18/05/2021-09:00). The percentage value of measurement uncertainties (u) is given with a coverage value of \(k=2\).

The objective of the activities was to detect cracks in the cladding of the reactor fuel TRIGA R.C.-1 by analyzing the presence of radionuclides produced by fission in the water of the reactor’s primary cooling circuit. In this way, it was possible to demonstrate the lack of integrity of the containment shell and to identify cracked fuel rods. In particular, the objective of the work was to set up a special physical surveillance program to search for fissured fuel assemblies [7].

2 Material and methods

The search for the fuel assemblies responsible for the release of fission products in the primary cooling water loop of the TRIGA R.C.-1 reactor was performed by gamma spectrometric measurements of water samples taken directly above each fuel rod during power operation of the reactor [10, 11]. The 100 kW power ensures that there is no water turbulence at the sampling position due to the temperature gradient inside the well. This sampling was performed using a suitable sampling circuit. Direct measurement of the primary water in which the fission gases are dissolved is not only the most direct and simplest method in terms of the sampling circuit to be implemented, but represents the fastest solution to obtain the desired response. Figure 2 shows the experimental measurement system.

When the primary circuit is not in operation, the fission gasses leaving the fuel element through the gap rise axially to the fuel rod into the water wetting the element. Using a suitably shaped pipe, flared at the end directly above the fuel element and connected at the upper end to an extraction pump, a predetermined flow of water was continuously extracted and directed to a coil surrounding the HPGe detector crystal. The discharged water can then be returned to the reactor well.

In particular, the experimental system consists of the following instruments:

-

Six-meter-long aluminum tube with an inner diameter of 21 mm and an outer diameter of 25 mm, which has a flare at one end for connection to each core element.

-

KNF FP 400 KPDCB-4 pump, polytetrafluoroethylene (PTFE) diaphragm, with ethylene-propylene-diene monomer (EPDM) seals, self-priming at a suction of up to 3 m of water, with a discharge of up to 10 m of water, flow rate adjustable from 0.3 to 4.6 ls per minute, for liquids up to 80 \(^{\circ }{\textrm{C}}\).

-

Dwyer RSF022V flow meter, from 0 to 8 ls per minute (water) for liquids up to 121 \(^{\circ }{\textrm{C}}\).

-

Fittings and tubes in brass, steel, PVC and silicone.

-

In situ detector for gamma spectrometry ISOCS from Canberra.

The element was identified by direct measurement of short-lived fission products such as Xe-138, Xe-137, Xe-135, Xe-135 m, Kr-89, Kr-88 and Kr-87 [4, 5, 10, 11].

Once a significantly responsible element was identified, it was necessary to:

-

Shut down the reactor.

-

Remove the potentially incriminated element and place it temporarily in one of the reactor pits.

-

Wait a certain period of time (to allow any released short-lived radionuclides contaminating the primary water to decay).

-

Replace, if necessary, the removed element with an intact element.

-

Repeat until no more leaks are detected.

To carry out this activity, in addition to the personnel required for normal operation of the reactor [1], four additional personnel units were deployed: one in the control room at the spectrometer control computer, two personnel units in the reactor room, on the TOP of the reactor room for handling the piping required for water removal and one radiation protection technician to perform radiation protection measurements. The fuel element search campaign lasted 5 working days of 4 h each (20 h in total) [7] (Fig. 3).

2.1 Identification of radiological risk

The extraordinary work to search for fissured fuel assemblies was associated with the risk of exposure to ionizing radiation resulting mainly from the normal operation of the reactor TRIGA R.C.-1 (during the work, the reactor operated at a power of 100 kW) and from the presence of fission products dissolved in the water of the reactor cooling system. The risk included both external exposure, mainly of the \(X-\gamma \) type and neutrons, and internal exposure resulting from the possible incorporation of radioactive substances (fission products dissolved in the water of the reactor cooling system and activation products from reactor operation). The activities were carried out in the following areas: the TOP of the reactor room, the pump room and the control room. The locker room was used at the beginning and end of each workday for personnel preparation and radiometric checks. In order to perform an accurate radiological risk assessment, the areas involved in the work were radiologically characterized by performing a test run with the reactor at a power of 100 kW for a full experimental working day (4 h) [7].

2.1.1 External exposure

During the reactor start-up, measurements of the ambient dose equivalent rate (\(H^*(10)\)) of the gamma and neutron radiation components of the radiation field were made under these conditions. Measurements of the gamma and neutron components were made at typical positions used for routine measurements of the radiological monitoring of the facility [2] (Fig. 4), as well as at the positions of operators engaged in the activities (in the area between the 3–5–6 positions of Fig. 4) [7], using appropriately calibrated stationary and portable measuring equipment. The results of these measurements are compatible with those found in the past in the plant at these performance levels. The average value of the measured \(H^* (10)\) due to the gamma component was 3 \(\upmu \)Sv/h, with peak values of 13 \(\upmu \)Sv/h (at the operator positions) and a background value of 0.1 \(\upmu \)Sv/h. Measurements of \(H^*(10)\) due to the neutron component yielded values comparable to the background ambient value (0.06 \(\upmu \)Sv/h). The maximum values determined during the radiological characterization of the working areas were used for the dose assessment [7].

2.1.2 Internal exposure

In order to assess the radiological risk of internal exposure, several measurements of radioactivity of atmospheric particles collected on cellulose and activated carbon filters (retention rate of 99%) were made. Sampling was performed at two locations: the first in the typical position of the plant operator during the described experimental activities (measurement position \({\textrm{n}}^{\circ }{\textrm{5}}\), Fig. 4) [7], the second on the surface of the reactor pool water, this position was chosen as the point of maximum concentration of release of gaseous fission products from the well water. Sampling was performed with a Nuvia NuRMS EGS suction system, and 3 \({\textrm{m}}^3\) were collected. Total alpha and beta concentration measurements, performed with a Thermo Scientific RadEyeHEC counter, yielded a total beta concentration value (based on Sr-90) of 4.0E–03 \({\mathrm{Bq/m}}^3\) and a total alpha concentration value (based on Am-241) of 6.0E–03 \({\mathrm{Bq/m}}^3\) with respect to the Detection Limit (DL) of the instruments used [7]. For comparison, according to Euratom recommendations, the reportable value for the beta concentration in air is 5.0E–03 \({\mathrm{Bq/m}}^3\) [12]. In addition, gamma spectrometric measurements of these samples gave no indication of activity in air attributable to any of the species or other fission products identified in the water sample (the Detection Limits (DL) value of Cs-137 was 4.2E–03 \({\mathrm{Bq/m}}^3\) and I-131 was 4.7E–03 \({\mathrm{Bq/m}}^3\)) [7].

2.2 Expected dose assessment

2.2.1 Effective dose from external exposure

Considering that the total exposure time for the procedure is 5 working days with a duration of 4 h each, an estimate of about 260 \(\upmu \)Sv for the effective dose of irradiation is obtained.

2.2.2 Committed effective dose

The assessment of the committed effective dose E(Sv) due to the incorporation of radionuclides was performed for the operators who handled the rod required for water sampling above the fuel assemblies, since they are the workers with the highest risk due to their tasks. For this assessment, I-131 was used as the reference radionuclide because it is the most representative radionuclide with respect to the evaluation of the committed effective dose and is present in the cooling water system [8]. It was conservatively assumed that all radioactivity measured in the air of the TOP of the reactor room (with respect to the DL of the equipment used) was due exclusively to I-131. All measurements of radioactivity in the air resulted in values below the DL. However, in this assessment it was assumed that the DL value is equal to the value actually measured.

An exposure time of 20 h results in the maximum inhaled activity given in Table 6. As mentioned, the radionuclide under consideration is I-131, and the value of the committed effective dose per unit intake corresponds to 1.1E–08 (AMAD 5 \(\upmu \)m, F absorption) in each case [13]. With these values, the committed effective dose value per inhalation \(E-ina\) (\(\upmu \)Sv) for the entire duration of the work (20 h) is around 1.0E+00 nSv. Since the operators wore full-face masks for the entire duration of the work, the component attributable to ingestion of the committed effective dose was considered negligible.

2.2.3 Total effective dose

The total expected effective dose E-tot [\(\upmu \)Sv], calculated as the sum of the effective dose due to external irradiation and the committed effective dose, was estimated to be about 260 \(\upmu \)Sv, since the contribution of the committed effective dose is negligible.

2.3 Emergency dose assessment

It should be noted that the above considerations do not take into account possible emergency events, even if they are highly unlikely, which should always be considered. As a reference event, the onset of positive reactivity and the rupture of the cladding of a fuel assembly are considered, with the plant operating for 605 days at a power of 1 MW. Assumptions for the assessments include the release of the following fission products in the reactor hall due to the rupture of the cladding of a fuel assembly:

-

Due to the rupture of the cladding of a fuel element, the following fission products are released into the reactor hall: 2.6E+11 Bq of Kr-85, 6.5E+12 Bq of Kr-85 m, 2.4E+13 Bq of Sr-89, 1.5E+12 Bq of Sr-90, 2.6E+13 Bq of Te-132, 1.6E+13 Bq of I-131, 2.3E+13 Bq of I-132, 3.5E+13 Bq of I-133, 3.2E+13 Bq of I-133, 3.5E+13 Bq of I-135, 3.5E+13 Bq of Xe-133, 8.3E+13 Bq of Xe-133 m, 1.1E+13 Bq of Xe-135, 9.5E+12 Bq Xe-135 m, 3.0E+13 Bq of Xe-138, 1.5E+12 Bq of Cs-134, 1.5E+12 Bq of Cs-137, 1.3E+09 Bq of Pu-239 [7].

-

Effective dose coefficient for adult external irradiation from ICRP 134 [11, 14].

-

Inhaled fraction: 1.0E–04 (efficiency of the full-face mask filter is 99.99%).

-

AMAD 5 \(\upmu \)m.

-

Pulmonary absorption of M-type compound for Cs-134, Cs-137, Te-132, Sr-89, Sr-90, and Pu-239.

-

Pulmonary absorption of F-type compound for I-131, I-132, I-133 and I-135.

-

Committed effective dose per unite of intake from ICRP 130 [15].

-

Operators wore full Personal Protective Equipment (PPE): full face mask (99.99 % filter efficiency), tyvek protective suit, gloves and overshoes.

-

As a precaution, it is assumed that the personnel will be on the site TOP of the reactor hall 1 h before the evacuation, which will be signaled by the fixed control instruments of the plant and by the extraordinary environmental monitoring set up for this operation.

Under these assumptions and using the dose assessment method used previously, the estimated effective dose for the operators in emergency case is evaluated to be 1.22 mSv (1.2 mSv due to external irradiation and 0.02 mSv due to internal irradiation).

2.4 Radiation protection and prevention measures

In order to ensure compliance with the safety measures, the necessary preventive and protective measures to be carried out were defined. To implement these measures, personnel were used who were classified as Category A radiation-exposed workers, were specially trained, and had years of experience working in nuclear facility. Operating personnel were provided with Personal Protective Equipment (PPE) to minimize inhalation of radioactive dust: Full face mask with combined filter for dust, gas and vapors (MSA 93Reactor B/St) with 99.99% efficiency, Tyvek protective suit with hood (elastic at wrists and ankles) to be worn over the work suit, double vinyl/latex disposable gloves, and Tyvek and latex overshoes [7]. Considering the emergency dose assessment, it was decided to use full-face masks and Tyvek suits to protect the individuals involved in the experiments. This decision was justified by the need to prevent emergency events, such as the possible release of fission products from the reactor pool water, especially during the movement of fuel rods. Since this possibility cannot be excluded with certainty, it was considered appropriate to take additional protective measures to ensure the safety of operators (Fig. 5).

2.5 Personal monitoring

Individual external exposure monitoring was performed using passive thermoluminescent dosimeters for whole-body and extremity (ring) \(X-\gamma \) rays and whole-body thermal and fast neutron components. During activities at the reactor’s TOP site, personnel were also provided with direct-reading dosimeters sensitive to \(X-\gamma \) rays and neutron radiation to provide an immediate estimate of personal dose in terms of Hp(10). Individual internal exposure monitoring was performed at the beginning and end of activities using in vivo whole-body counts (WBC) and thyroid counts (TC) for high-energy gamma radiation and radiotoxicological analyzes (total alpha-beta count and gamma spectrometry of daily urine and mass spectrometry of mucus at the end of each working day) aimed at detecting fission products dissolved in water (e.g., Cs-137 and I-131) [7].

2.6 Environmental surveillance

In conjunction with the special activities, environmental monitoring of working areas was conducted using appropriate stationary and portable instruments that were properly calibrated [7]. Specifically, the following instruments were used:

-

An Automess 6150AD-t and a Berthold LB-6411 radiometer to record the \(H^*(10)\) (gamma and neutron components) during all phases of the rod’s motion required to search for the broken fuel assembly.

-

An i-CAM system for direct monitoring of airborne particle activity of total alpha/beta in \({\mathrm{Bqh/m}}^3\) of the reactor room.

-

Five gamma measurement systems equipped with alarms (Geiger–Muller compensated for dose rate measurement) to control exposure intensity. These detectors are located at key points in the facility, with particular use of the device on the TOP flange of the reactor room.

-

A monitor that continuously detects the gaseous activity in the air of the reactor room and the activity emitted through the stack. The measurement complex consists of a NaI(Tl) spectrometer.

-

Two sampling stations on cellulose and activated carbon filters for collection of atmospheric particles from TOP the reactor room (suction pump flow rate of 3 \({\textrm{m}}^3/{\textrm{h}}\)).

-

A low background Ortec HPGe spectrometer to measure the gamma activity of atmospheric particles deposited on cellulose and Activated carbon filters (search for I-131 as an indicator of the dispersion of gaseous fission products in the reactor room).

-

A Berthold LB 124 contamination meter for direct measurement of surface contamination in \({\mathrm{Bq/cm}}^2\).

-

A Berthold LB 147 stationary hand/foot contamination meter for assessing surface contamination on personnel clothing in \({\mathrm{Bq/cm}}^2\).

-

A Thermo Scientific RadEyeHEC counter for indirect measurement of surface contamination on surfaces (wipe test) in \({\mathrm{Bq/cm}}^2\).

2.7 Dose constrains and alarm thresholds

In order to optimize radiation protection, dose constrains and alarm thresholds were established, above which certain decisions or actions would have been required (mandatory personnel rotation, suspension of activity, evacuation) [16]. The following dose limits were established:

-

2 mSv (1/10 of the annual limit [17]) as the individual dose limit for external exposure.

-

1 mSv/h the limit value for the rate of equivalent environmental dose in the room TOP of the reactor hall.

The following alarm thresholds were also established:

-

10 \({\mathrm{Bqh/m}}^3\) as the alarm threshold for direct measurement of aerosol concentration of total alpha radioactivity in the reactor room.

-

550 \({\mathrm{Bqh/m}}^3\) the alarm threshold for direct measurement of the total aerosol concentration of beta radioactivity in the reactor room.

-

0.8 \({\mathrm{mSv/h}}\) the alarm threshold for the direct measurement of the ambient dose equivalent of the gamma monitor located on the flange (reactor well head) of the reactor compartment.

These alarm thresholds were evaluated based on the following considerations:

-

Intervention threshold for total alpha equal to 1 \({\mathrm{Bq/m}}^3\) (defined based on the annual effective dose limit for U-234 and assuming 2000 working hours at the monitoring point).

-

Intervention level for total beta equal to 55 \({\mathrm{Bq/m}}^3\) (defined on the basis of the annual effective dose limit for Sr-90 and assuming a stay of 2000 working hours at the measurement point);

-

Filter efficiency of the full-face mask of 99.99%;

-

Type S absorption for particles with an AMAD value of 1 \(\upmu \)m;

-

100 \(\upmu \)Sv of committed effective dose.

3 Results

3.1 Personal physical surveillance

3.1.1 Effective dose from external exposure

Direct-reading dosimeters worn by operators have eliminated accidental or emergency exposures. Table 7 lists the dose assessment of external exposures of personnel involved in the activities that were derived from the readings of the passive thermoluminescent dosimeters. From this, it can be seen that these are negligible compared to the individual dose constraint from external exposure given earlier (assessed at 2 mSv, which is 1/10 of the annual limit [17])

3.1.2 Committed effective dose

The analyses of nasal mucus, samples of which were taken at the end of each of the 5 working days, gave a negative result (values below the DL of the method used – 0.5 Bq for alpha emitters and 1 Bq for beta emitters). Internal contamination studies with WBC and TC excluded the presence of any anthropogenic radionuclides (values below DL values: 30 Bq for Cs-137 and 10 Bq for I-131) and gamma spectrometry measurement of urine excluded the presence of anthropogenic radionuclides. Therefore, the effective dose to the exposed personnel involved in the activities is considered to be zero.

3.2 Environmental monitoring

Ambient dose equivalent rate measurements made throughout the work period resulted in exposures comparable to those occurring during normal operation of the 100 kW power reactor (13 \(\upmu \)Sv/h at the operator’s position and typical values at fixed measurement points). In addition, no levels above the dose constraints of the \(H^*(10)\) (2 mSv/h) rate were detected in the vicinity of the operator’s workplace throughout the duration of the work. Direct measurement of the integrated radioactive aerosol concentration in the reactor room showed a total alpha concentration of zero (the alert threshold was set at 10 \({\mathrm{Bqh/m}}^3\)) and a value of 40 \({\mathrm{Bqh/m}}^3\) for the total beta concentration (the alert threshold was set at 550 \({\mathrm{Bqh/m}}^3\)). Gamma spectrometric measurements of atmospheric particles in the reactor room deposited on cellulose and activated carbon filters excluded the presence of anthropogenic radionuclides (for Cs-137 values below the value of the DL - 4.2E–03 \({\mathrm{Bq/m}}^3\) and for I-131 values below the value of the DL - 4.7E–03 \({\mathrm{Bq/m}}^3\)). In accordance with the described framework, it was shown that during operation all measured values allowed to consider the radiation protection situation as optimal.

3.3 Identification of defected fuel rod

The experimental activity was performed within the expected time. It successfully identified a cracked fuel element responsible for the main contribution to the presence of gaseous fission products in the water of the reactor’s primary cooling loop [7]. The identified fuel element (Fig. 6) is one of the two instrumented elements located in the inner ring of the core (position B03). This element was removed from the core and placed in the reactor pit racks to cool before being moved to the interim storage facility in accordance with plant procedures. After re-configuring the core, the reactor was powered up at 100 kW to check for the presence of additional cracked elements. Direct measurements with the reactor on showed that no dissolved gaseous fission products were present in the water. To confirm this result, a second series of gamma spectroscopy measurements of the reactor coolant circuit water was performed using the same methods as previously described to look for gaseous fission products. For this purpose, a water sample was taken from the top of the reactor hall (50 cm depth) after the reactor had been shut down. The measurement results confirmed the absence of gaseous fission products in the water at a reactor power of 100 kW also in this case. Since the operating power of the reactor is 1 MW and in order to confirm the obtained results, another start-up of the reactor was performed at a higher power (500 kW) for about 4 h. Again, direct measurements with the reactor on did not detect any dissolved gaseous fission products in the water. After commissioning was completed, one liter of water was again sampled using the same methods as previously described and the same gamma spectroscopy measurements were repeated. However, the measured activity concentrations in this case are not directly comparable to those of the research campaign because the two water samples were taken at different powers after reactor startup. The measurement performed 10 min after the water sampling did not show any gaseous fission products. In this case, the acquired spectrum was dominated by the structures of Na-24 and Ar-41 peaks. The results of the measurements performed 12 h and 3 days after the reactor shutdown are shown in Tables 8 and 9. The observation of fission products in these measurements is evidence of the presence of another defected element. The activity levels of these radionuclides in the water indicate that the extent of this identified rupture is significantly less than that of the previous one (element B03). The activities in Tables 8 and 9 are given at the time of water sampling (cutoff date: 15/02/2022 at 09:00). The percentage value of measurement uncertainty (u) is given with a coverage value of \(k = 2\) (Fig. 7).

4 Conclusion

The methodology used to prepare the special program for monitoring the radiation protection of individuals and the environment has been shown to be adequate to ensure the protection of workers and the public from ionizing radiation during all phases of the research and replacement of the fissile fuel assembly. According to the described framework, it can be stated that during the operation all values of the performed measurements allowed to exclude exceeding of the dose limits for the personnel and increase in the external and internal radiation dose for the population.

The experimental method used allowed the identification of the fuel element most responsible for the presence of gaseous fission products in the water. However, subsequent measurements have shown the presence of at least one other element that is not intact and whose damage is less severe than the one already identified. Therefore, a new research campaign is currently being organized to identify the remaining fissured elements.

Data Availability Statement

This manuscript has associated data in a data repository. [Authors’ comment: The data used and analyzed in this article are taken from the documentation of the TRIGA R.C.-1 facility. Due to the confidential nature of the information, the dissemination of the data is restricted. However, in the case of a specific request, the authors are happy to share the data or part of it directly with the interested party, after verifying the legitimacy of the request and the authorization to access the confidential data.]

References

L. Di Paolo, Progetto Definitivo e Rapporto di Sicurezza Reattore RC-1 Ad 1 MW (ENEA, Rome, Italy, 1966)

L. Sperandio, Programma della Sorveglianza Fisica ed Ambientale Dell’impianto Triga RC-1 - Anno 2022. ENEA, Rome, Italy (2002)

E.A. Tigliole, Identification of a leaking TRIGA fuel element at the reactor facility of Pavia. Paper presented at the world TRIGA users conference; Vienna (Austria) (2004)

G.D. Bouchey, Detection and location of leaking triga reactor fuel elements. Nucl. Technol. 10(2), 211–214 (2017)

J.S. Bennion, Identification of Leaking Triga Fuel Elements (University of Utah Nuclear Engineering Laboratory, Salt Lake City, 1987)

E.A.L. Lepore, Valutazione di Una Procedura di Individuazione i Eventuali Fessurazioni Negli Elementi di Combustibile del Nocciolo del Reattore Triga RC-1. ENEA, Rome, Italy (2021)

L. Sperandio, Relazione Riguardante Le Misure di Prevenzione e Protezione Dai Rischi da Radiazioni Ionizzanti da Attuare Nelle Operazioni di Ricerca e Sostituzione degli Elementi di Combustibile Fessurati Dell’impianto Triga RC-1 del C.R. Casaccia dell’ENEA. ENEA, Rome, Italy (2022)

Impianto Triga RC-1 - C.R. CASACCIA. Presupposti Tecnici per Il Piano di Emergenza Esterna. ENEA, Rome, Italy (1999)

G. Chiesa, Regolamento di Esercizio per L’impianto Nucleare TRIGA RC-1 (ENEA, Rome, Italy, 2002)

R.R. Rodrigues, Designing a system to detect leaking in fuel elements in Brazilian Triga research reactor. Int. J. Nucl. Energy Sci. Technol. 12(3), 239–251 (2018)

E. A.Z. Mesquita, System to detect leaking in fuel elements in triga nuclear research reactor, in Proceedings of the 1st Iberic Conference on Theoretical and Experimental Mechanics and Materials, 11th National Congress on Experimental Mechanics, Porto/Portugal 4–7 November 2018 (2018)

E. Union, Laying down Basic Safety Standards for Protection Against the Dangers Arising from Exposure to Ionising Radiation, and Repealing Directives 89/618/Euratom, 90/641/Euratom, 96/29/Euratom, 97/43/Euratom and 2003/122/Euratom. EURATOM, COUNCIL DIRECTIVE 2013/59/EURATOM (2013)

ISO-16638-1: Radiological Protection , Monitoring and Internal Dosimetry for Specific Materials—Part 1: Inhalation of Uranium Compounds (2015)

E.A.F. Paquet, Occupational intakes of radionuclides: Part 2. ICRP Pubblication 134 45(3), 1–352 (2016)

E.A.K. Eckerman, Compendium of dose coefficients based on icrp pubblication 60. ICRP Pubblication 119, 41 (2012)

L. Falconi, Stato di Conservazione Dell’impianto Nucleare TRIGA RC-1 e Revisione Periodica della Sicurezza Nucleare (PSR) (ENEA, Rome, Italy, 2020)

D.L. Governo, Attuazione delle Direttive 2013/59/Euratom, Norme Fondamentali Relative Alla Protezione Contro i Pericoli Derivanti Dall’esposizione Alle Radiazioni Ionizzanti in Materia di Radiazioni Ionizzanti. Governo Italiano, Rome, Italy (2022)

Funding

Open access funding provided by Ente per le Nuove Tecnologie, l'Energia e l'Ambiente within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sperandio, L., Lepore, L., Borra, E.M. et al. Identification of a defected fuel rod in the TRIGA R.C.-1 facility of the ENEA Casaccia Research Center: radiation protection aspects. Eur. Phys. J. Plus 138, 1023 (2023). https://doi.org/10.1140/epjp/s13360-023-04457-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-023-04457-5