Abstract

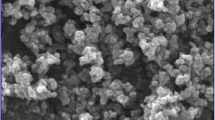

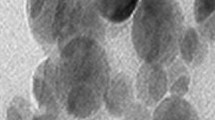

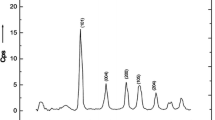

This study represents the performance of Fe2O3/water nanofluid (20 nm) in a double-pipe heat exchanger equipped with twisted-tape inserts for enhancing heat transfer. Fe2O3/water nanofluid is used because it has a higher thermal conductivity. Considered parameters include mass flow rate, twist ratio of tape, temperature and the volumetric portion of nanoparticles to water. The nanoparticles volume concentrations are 0.08% and 0.1% (v/v), and different twisted tapes with twist ratios of 2.5 ≤ y/w ≤ 5.2 are used. The Reynolds number variation is within the turbulent flow regime of 5000 < Re < 28,500. The obtained results show that adding nanoparticles as well as twisted-tape inserts increases heat transfer and Nusselt number. However, the effects of nanoparticles are more pronounced in high Reynolds number flows. Combining the positive effects of nanofluid and twisted tape, Nusselt number is significantly improved up to 103.45% in the test case. Moreover, there is no major change in friction factor. A multilayer perceptron (MLP) artificial neural network (ANN) with Levenberg–Marquardt (LM) learning algorithm and tangent sigmoid nonlinear transfer function is implemented for the aim of modeling the Nusselt number.

Similar content being viewed by others

Abbreviations

- A :

-

Heat transfer area (m2)

- C p :

-

Specific heat (kJ kg−1 °C−1)

- D :

-

Tube diameter (m)

- d :

-

Nanoparticle diameter (m)

- f :

-

Friction factor

- h :

-

Convective heat transfer coefficient (W m−2 °C−1)

- \( h_{\text{E}} \) :

-

Enhanced convective heat transfer coefficient

- \( h_{\text{NE}} \) :

-

Non-enhanced convective heat transfer coefficient

- k :

-

Thermal conductivity (W m−1 °C−1)

- L :

-

Tube length (m)

- ṁ :

-

Mass flow rate (kg s−1)

- Nu:

-

Nusselt number (dimensionless)

- Pe:

-

Peclet number (dimensionless)

- Pr:

-

Prandtl number (dimensionless)

- Q :

-

Heat transfer rate (W)

- Re:

-

Reynolds number (dimensionless)

- T :

-

Temperature (°C)

- U :

-

Overall heat transfer coefficient (W m−2 °C−1)

- V :

-

Velocity (m2 s−1)

- n :

-

Flow behavior index

- ∆Tlm :

-

Logarithmic mean temperature difference (°C)

- ∆pnf :

-

Pressure drop

- α :

-

Thermal diffusivity (m2/s)

- ρ :

-

Density (kg m−3)

- ϑ :

-

Kinematic viscosity (m2/s)

- φ v :

-

Nanoparticle volume concentration (dimensionless)

- \( \eta \) :

-

Performance evaluation analysis

- f:

-

Fluid

- i:

-

Inside

- in:

-

Inlet

- m:

-

Mean

- ave:

-

Average

- nf:

-

Nanofluid

- o:

-

Outside

- out:

-

Outlet

- p:

-

Particles

- w:

-

Wall

- ANN:

-

Artificial neural network

- MLP:

-

Multilayer perceptron

- LM:

-

Levenberg–Marquardt

- SEM:

-

Scanning electron microscopy

- TEM:

-

Transmission electron microscopy

- XRD:

-

X-ray powder diffraction

References

R. Barzegarian, A. Aloueyan, T. Yousefi, Thermal performance augmentation using water based Al2O3-gamma Nanofluid in a horizontal shell and tube heat exchanger under forced circulation. Int. Commun. Heat Mass Transf. 86, 52–59 (2017). https://doi.org/10.1016/j.icheatmasstransfer.2017.05.021

A. El Maakoul, A. Laknizi, S. Saadeddine, A.B. Abdellah, M. Meziane, M. El Metoui, Numerical design and investigation of heat transfer enhancement and performance for an annulus with continuous helical baffles in a double-pipe heat exchanger. Energy Convers. Manag. 133, 76–86 (2017). https://doi.org/10.1016/j.enconman.2016.12.002

M. Omidi, M. Farhadi, M. Jafari, A comprehensive review on double pipe heat exchangers. Appl. Therm. Eng. 110, 1075–1090 (2017). https://doi.org/10.1016/j.applthermaleng.2016.09.027

A.R.S. Suri, A. Kumar, R. Maithani, Heat transfer enhancement of heat exchanger tube with multiple square perforated twisted tape inserts: experimental investigation and correlation development. Chem. Eng. Process. 116, 76–96 (2017). https://doi.org/10.1016/j.cep.2017.02.014

Y. He, L. Liu, P. Li, L. Ma, Experimental study on heat transfer enhancement characteristics of tube with cross hollow twisted tape inserts. Appl. Therm. Eng. 131, 743–749 (2018). https://doi.org/10.1016/j.applthermaleng.2017.12.029

A. Shahsavar, Z. Rahimi, M. Bahiraei, Optimization of irreversibility and thermal characteristics of a mini heat exchanger operated with a new hybrid Nanofluid containing carbon nanotubes decorated with magnetic nanoparticles. Energy Convers. Manag. 150, 37–47 (2017). https://doi.org/10.1016/j.enconman.2017.08.007

S. Yang, Y. Chen, J. Wu, H. Gu, Performance simulation on unilateral ladder type helical baffle heat exchanger in half cylindrical space. Energy Convers. Manag. 150, 134–147 (2017). https://doi.org/10.1016/j.enconman.2017.07.062

B. Sun, A. Yang, D. Yang, Experimental study on the heat transfer and flow characteristics of nanofluids in the built-in twisted belt external thread tubes. Int. J. Heat Mass Transf. 107, 712–722 (2017). https://doi.org/10.1016/j.ijheatmasstransfer.2016.11.084

A. Saysroy, S. Eiamsa-ard, Periodically fully-developed heat and fluid flow behaviors in a turbulent tube flow with square-cut twisted tape inserts. Appl. Therm. Eng. 112, 895–910 (2017). https://doi.org/10.1016/j.applthermaleng.2016.10.154

U. Arunachalam, M. Edwin, Experimental studies on laminar flow heat transfer in nanofluids flowing through a straight circular tube with and without V-cut twisted tape insert. Heat Mass Transf. 54(3), 673–683 (2018). https://doi.org/10.1007/s00231-017-2162-9

N.R. Kumar, P. Bhramara, B.M. Addis, L.S. Sundar, M.K. Singh, A.C. Sousa, Heat transfer, friction factor and effectiveness analysis of Fe3O4/water Nanofluid flow in a double pipe heat exchanger with return bend. Int. Commun. Heat Mass Transf. 81, 155–163 (2017). https://doi.org/10.1016/j.icheatmasstransfer.2016.12.019

O. Mahian, L. Kolsi, M. Amani, P. Estellé, G. Ahmadi, C. Kleinstreuer, S. Wongwises, Recent advances in modeling and simulation of nanofluid flows-Part I: fundamental and theory. Phys. Rep. 790, 1–48 (2019). https://doi.org/10.1016/j.physrep.2018.11.004

O. Mahian, L. Kolsi, M. Amani, P. Estellé, G. Ahmadi, C. Kleinstreuer, H. Niazmand, Recent advances in modeling and simulation of nanofluid flows-part II: applications. Phys. Rep. 791, 1–59 (2018). https://doi.org/10.1016/j.physrep.2018.11.003

S. Rashidi, M.H. Kashefi, F. Hormozi, Potential applications of inserts in solar thermal energy systems–a review to identify the gaps and frontier challenges. Sol. Energy 171, 929–952 (2018)

S. Rashidi, N. Karimi, O. Mahian, J.A. Esfahani, A concise review on the role of nanoparticles upon the productivity of solar desalination systems. J. Therm. Anal. Calorim. 135(2), 1145–1159 (2019)

S. Rashidi, O. Mahian, E.M. Languri, Applications of nanofluids in condensing and evaporating systems. J. Therm. Anal. Calorim. 131(3), 2027–2039 (2018)

S. Rashidi, P. Javadi, J.A. Esfahani, Second law of thermodynamics analysis for nanofluid turbulent flow inside a solar heater with the ribbed absorber plate. J. Therm. Anal. Calorim. 135(1), 551–563 (2019)

S. Rashidi, M. Akbarzadeh, N. Karimi, R. Masoodi, Combined effects of nanofluid and transverse twisted-baffles on the flow structures, heat transfer and irreversibilities inside a square duct–a numerical study. Appl. Therm. Eng. 130, 135–148 (2018)

S. Akar, S. Rashidi, J.A. Esfahani, Second law of thermodynamic analysis for nanofluid turbulent flow around a rotating cylinder. J. Therm. Anal. Calorim. 132(2), 1189–1200 (2018)

H. Shamsabadi, S. Rashidi, J.A. Esfahani, Entropy generation analysis for nanofluid flow inside a duct equipped with porous baffles. J. Therm. Anal. Calorim. 135(2), 1009–1019 (2019)

M. Akbarzadeh, S. Rashidi, R. Masoodi, O. Samimi-Abianeh, Effect of Transverse twisted baffles on performance and irreversibilities in a duct. J. Thermophys. Heat Transf. 33(1), 49–62 (2018)

N.M. Zade, S. Akar, S. Rashidi, J.A. Esfahani, Thermo-hydraulic analysis for a novel eccentric helical screw tape insert in a three dimensional tube. Appl. Therm. Eng. 124, 413–421 (2017)

S.A. Farshad, M. Sheikholeslami, Turbulent nanofluid flow through a solar collector influenced by multi-channel twisted tape considering entropy generation. Eur. Phys. J. Plus 134(4), 149 (2019)

S.M. Seyyedi, A.S. Dogonchi, R. Nuraei, D.D. Ganji, M. Hashemi-Tilehnoee, Numerical analysis of entropy generation of a nanofluid in a semi-annulus porous enclosure with different nanoparticle shapes in the presence of a magnetic field. Eur. Phys. J. Plus 134(6), 268 (2019)

A. Aghaei, H. Khorasanizadeh, G.A. Sheikhzadeh, A numerical study of the effect of the magnetic field on turbulent fluid flow, heat transfer and entropy generation of hybrid nanofluid in a trapezoidal enclosure. Eur. Phys. J. Plus 134(6), 310 (2019)

M. Jamiatia, Numerical investigation in comparing the influence of water-silver-magnesium oxide hybrid nanofluid and water-silver normal nanofluid on fluid flow, heat transfer and entropy generation in an enclosure with rotating heat sources. Eur. Phys. J. Plus 134(8), 405 (2019)

N. Fallahnezhad, H.R. Nazif, Heat convection and hydrodynamic analysis of laminar developing nanofluid channel flow with variable properties under constant magnetic field and heat flux. Eur. Phys. J. Plus 134(8), 409 (2019)

H. Ahmadi, O. Shafiee, Experimental comparative study on the performance of nano-SiO2 and microsilica in stabilization of clay. Eur. Phys. J. Plus 134(9), 459 (2019)

M. Alegria-Zamudio, R.F. Escobar-Jiménez, J.F. Gómez-Aguilar, J. García-Morales, J.A. Hernández-Pérez, Double pipe heat exchanger temperatures estimation using fractional observers. Eur. Phys. J. Plus 134(10), 496 (2019)

R. Kumar, G.S. Seth, A. Bhattacharyya, Entropy generation of von Karman’s radiative flow with Al2O3 and Cu nanoparticles between two coaxial rotating disks: a finite-element analysis. Eur. Phys. J. Plus 134(12), 597 (2019)

H. Aslani, M. Moghiman, Experimental models to estimate supercooling behavior of ZrO2 nanofluid phase change materials. Eur. Phys. J. Plus 134(12), 602 (2019)

J. Mackolil, B. Mahanthesh, Sensitivity analysis of radiative heat transfer in Casson and nano fluids under diffusion-thermo and heat absorption effects. Eur. Phys. J. Plus 134(12), 619 (2019)

F. Nasirzadehroshenin, M. Sadeghzadeh, A. Khadang, H. Maddah, M.H. Ahmadi, H. Sakhaeinia, L.G. Chen, Modeling of heat transfer performance of carbon nanotube nanofluid in a tube with fixed wall temperature by using ANN-GA. Eur. Phys. J. Plus 135(2), 217 (2020)

M. Ramezanizadeh, M.H. Ahmadi, M.A. Nazari, M. Sadeghzadeh, L.G. Chen, A review on the utilized machine learning approaches for modeling the dynamic viscosity of nanofluids. Renew. Sustain. Energy Rev. 114, 109345 (2019)

G. Pathipakka, P. Sivashanmugam, Heat transfer behaviour of nanofluids in a uniformly heated circular tube fitted with helical inserts in laminar flow. Superlatt. Microstruct. 47(2), 349–360 (2010)

K. Wongcharee, S. Eiamsa-ard, Enhancement of heat transfer using CuO/water nanofluid and twisted tape with alternate axis. Int. Commun. Heat Mass Transf. 38, 742–748 (2011)

L. Syam Sundar, N.T. Ravi Kumar, M.T. Naik, K.V. Sharma, Effect of full length twisted tape inserts on heat transfer and friction factor enhancement with Fe3O4 magnetic Nanofluid inside a plain tube: an experimental study. Int. J. Heat Mass Transf. 55, 2761–2768 (2012)

R. Aghayari, H. Maddah, M. Farokhi, S.H. Jahanizadeh, K.H. Ashtary, Effect of twisted-tape turbulators and nanofluid on heat transfer in a double pipe heat exchanger. J. Eng. 2014, 1–9 (2014)

H. Maddah, M. Alizadeh, N. Ghasemi, S.R. Wan Alwi, Experimental study of Al2O3/water Nanofluid turbulent heat transfer enhancement in the horizontal double pipes fitted with modified twisted tapes. Int. J. Heat Mass Transf. 78, 1042–1054 (2014)

K. Wongcharee, S. Eiamsa-ard, Friction and heat transfer characteristics of laminar swirl flow through the round tubes inserted with alternate clockwise and counter-clockwise twisted-tapes. Int. Commun. Heat Mass Transf. 38, 348–352 (2011)

R.M. Manglik, A.E. Bergles, Heat transfer and pressure drop correlations for twisted tape inserts in isothermal tubes: part I-laminar flows. Trans. ASME J Heat Transf 115, 881–889 (1993)

R.M. Manglik, A.E. Bergles, Heat transfer and pressure drop correlations for twisted-tape inserts in isothermal tubes, part II: transition and turbulent flows. Trans ASME J. Heat Transf. 115, 890–896 (1993)

P.K. Sarma, T. Subrahmanyam, P.S. Kishore, V. Dharma Rao, S. Kakac, A new method to predict convective heat transfer in a tube with twisted tape inserts for turbulent flow. Int. J. Therm. Sci. 41, 955–960 (2002)

P.K. Sarma, P.S. Kishore, V. DharmaRao, T. Subrahmanyam, A combined approach to predict friction coefficients and convective heat transfer characteristics in a tube with twisted tape inserts for a wide range of Re and Pr. Int. J. Therm. Sci. 44, 393–398 (2005)

P. Naphon, Heat transfer and pressure drop in the horizontal double pipes with and without twisted tape insert. Int. Commun. Heat Mass Transf. 33, 166–175 (2006)

S. Eiamsa-ard, C. Thianpong, P. Eiamsa-ard, P. Promvonge, Thermal characteristics in a heat exchanger tube fitted with dual twisted tape elements in tandem. Int. Commun. Heat Mass Transf. 37, 39–46 (2010)

S. Eiamsa-ard, C. Thianpong, P. Eiamsa-ard, Turbulent heat transfer enhancement by counter/co-swirling flow in a tube fitted with twin twisted tapes. Exp. Therm. Fluid Sci. 34, 53–62 (2010)

S. Eiamsa-ard, P. Seemawute, K. Wongcharee, Influences of peripherally-cut twisted tape insert on heat transfer and thermal performance characteristics in laminar and turbulent tube flows. Exp. Therm. Fluid Sci. 34, 711–719 (2010)

S. Eiamsa-ard, P. Promvonge, Performance assessment in a heat exchanger tube with alternate clockwise and counter-clockwise twisted-tape inserts. Int. J. Heat Mass Transf. 53, 1364–1372 (2010)

J. Guo, A. Fan, X. Zhang, W. Liu, A numerical study on heat transfer and friction factor characteristics of laminar flow in a circular tube fitted with center-cleared twisted tape. Int. J. Therm. Sci. 50, 1263–1270 (2011)

Y. Xuan, Q. Li, Investigation on convective heat transfer and flow features of nanofluids. ASME J. Heat Transf. 125, 151–155 (2003)

L. Syam Sundar, K.V. Sharma, Turbulent heat transfer and friction factor of Al2O3 Nanofluid in circular tube with twisted tape inserts. Int. J. Heat Mass Transf. 53, 1409–1416 (2010)

K. Wongcharee, S. Eiamsa-ard, Heat transfer enhancement by using CuO/water Nanofluid in corrugated tube equipped with twisted tape. Int. Commun. Heat Mass Transf. 39, 251–257 (2012)

M. Fakoor-Pakdaman, M.A. Akhavan-Behabadi, P. Razi, An empirical study on the pressure drop characteristics of Nanofluid flow inside helically coiled tubes. Int. J. Therm. Sci. 65, 206–213 (2013)

M. Fakoor-Pakdaman, M.A. Akhavan-Behabadi, P. Razi, An experimental investigation on thermo-physical properties and overall performance of MWCNT/heat transfer oil Nanofluid flow inside vertical helically coiled tubes. Exp. Therm. Fluid Sci. 40, 103–111 (2012)

H. Maddah, R. Aghayari, M.H. Ahmadi, M. Rahimzadeh, N. Ghasemi, Prediction and modeling of MWCNT/Carbon (60/40)/SAE 10 W 40/SAE 85 W 90 (50/50) nanofluid viscosity using artificial neural network (ANN) and self-organizing map (SOM). J. Therm. Anal. Calorim. 134(3), 2275–2286 (2018)

W. Duangthongsuk, S. Wongwises, An experimental study on the heat transfer performance and pressure drop of TiO2-water nanofluids flowing under a turbulent flow regime. Int. Commun. Heat Mass Transf. 53, 334–344 (2010)

S. Eiamsa-ard, K. Kiatkittipong, Heat transfer enhancement by multiple twisted tape inserts and TiO2/water nanofluid. Appl. Therm. Eng. 70(1), 896–924 (2014)

H. Mohammadiun, M. Mohammadiun, M. Hazbehian, H. Maddah, Experimental study of ethylene glycol-based Al2O3 nanofluid turbulent heat transfer enhancement in the corrugated tube with twisted tapes. Heat Mass Transf. 52(1), 141–151 (2016)

S. Eiamsa-ard, C. Thianpong, P. Eiamsa-ard, P. Promvonge, Thermal characteristics in a heat exchanger tube fitted with dual twisted tape elements in tandem. Int. Commun. Heat Mass Transf. 37(9), 39–46 (2010)

N. Ghasemi, R. Aghayari, H. Maddah, Designing an artificial neural network using radial basis function to model exergetic efficiency of nanofluids in mini double pipe heat exchanger. Heat Mass Transf. 53(1), 1–13 (2017). https://doi.org/10.1007/s00231-017-2261-7

H. Maddah, N. Ghasemi, Experimental evaluation of heat transfer efficiency of Nanofluid in a double pipe heat exchanger and prediction of experimental results using artificial neural networks. Heat Mass Transf. 53(12), 3459–3472 (2017). https://doi.org/10.1007/s00231-017-2068-6

B. Alireza, M. Kahani, M.A. Nazari, M.A. Ahmadi, W.M. Yan, Sensitivity analysis and application of machine learning methods to predict the heat transfer performance of CNT/water nanofluid flows through coils. Int. J. Heat Mass Transf. 128, 825–835 (2019)

M.H. Ahmadi, A. Tatar, M.A. Nazari, R. Ghasempour, A.J. Chamkha, W.M. Wei-Mon Yan, Applicability of connectionist methods to predict thermal resistance of pulsating heat pipes with ethanol by using neural networks. Int. J. Heat Mass Transf. 126, 1079–1086 (2018)

M. Kahani, M.H. Ahmadi, A. Tatar, M. Sadeghzadeh, Development of multilayer perceptron artificial neural network (MLP-ANN) and least square support vector machine (LSSVM) models to predict Nusselt number and pressure drop of TiO2/water nanofluid flows through non-straight pathways. Numer. Heat Transf. Part A Appl. 74(4), 1190–1206 (2018)

R. Loni, A. Kasaeian, K. Shahverdi, E.A. Asli-Ardeh, B. Ghobadian, M.H. Ahmadi, ANN model to predict the performance of parabolic dish collector with tubular cavity receiver. Mech. Ind. 18(4), 408 (2017)

H. Maddah, M. Ghazvini, M.H. Ahmadi, Predicting the efficiency of CuO/water nanofluid in heat pipe heat exchanger using neural network. Int. Commun. Heat Mass Transf. 104, 33–40 (2019)

M.H. Ahmadi, B. Mohseni-Gharyehsafa, M. Farzaneh-Gord, R.D. Jilte, R. Kumar, K.W. Chau, Applicability of connectionist methods to predict dynamic viscosity of silver/water nanofluid by using ANN-MLP, MARS and MPR algorithms. Eng. Appl. Comput. Fluid Mech. 13(1), 220–228 (2019)

R. Aghayari, H. Maddah, M.H. Ahmadi, W.M. Yan, N. Ghasemi, Measurement and artificial neural network modeling of electrical conductivity of CuO/glycerol nanofluids at various thermal and concentration conditions. Energies 11(5), 1190 (2018)

R.B. Blasius, W.E. Stewai, E.N. Lightfoot, Transport Phenomena, 2nd edn. (Wiley, New York, 2002)

J.L. Zhou, L.G. Chen, Z.M. Ding, F.R. Sun, Exploring the optimal performance of irreversible single resonance energy selective electron refrigerator. Eur. Phys. J. Plus 131(5), 149 (2016)

S.J. Xia, L.G. Chen, F.R. Sun, Maximum cycle work output optimization for generalized radiative law Otto cycle engines. Eur. Phys. J. Plus 131(11), 394 (2016)

Y. Yin, L.G. Chen, F. Wu, Optimal power and efficiency of quantum Stirling heat engines. Eur. Phys. J. Plus 132(1), 45 (2017)

S.J. Xia, L.G. Chen, Capital dissipation minimization for a class of complex irreversible resource exchange processes. Eur. Phys. J. Plus 132(5), 201 (2017)

Z.X. Wu, L.G. Chen, Y.L. Ge, F.R. Sun, Power, efficiency, ecological function and ecological coefficient of performance of an irreversible Dual-Miller cycle (DMC) with nonlinear variable specific heat ratio of working fluid. Eur. Phys. J. Plus 132(5), 203 (2017)

Y.L. Ge, L.G. Chen, X.Y. Qin, Z.H. Xie, Exergy-based ecological performance of an irreversible Otto cycle with temperature-linear-relation variable specific heats of working fluid. Eur. Phys. J. Plus 132(5), 209 (2017)

S.J. Xia, L.G. Chen, Theoretical and experimental investigation of optimal capacitor charging process in RC circuit. Eur. Phys. J. Plus 132(5), 235 (2017)

L.G. Chen, Z.M. Ding, J.L. Zhou, W.H. Wang, F.R. Sun, Thermodynamic performance optimization for an irreversible vacuum thermionic generator. Eur. Phys. J. Plus 132(7), 293 (2017)

S. Çakmak, D. Türkpençe, F. Altintas, Special coupled quantum Otto and Carnot cycles. Eur. Phys. J. Plus 132(12), 554 (2017)

W.L. Peng, Y.C. Zhang, Z.M. Yang, J.C. Chen, Performance evaluation and comparison of three-terminal energy selective electron devices with different connective ways and filter configurations. Eur. Phys. J. Plus 133(2), 38 (2018)

F.R. Tang, R. Zhang, H.C. Li, L. Bai, Understanding performance properties of chemical engines under a trade-off optimization: low-dissipation versus endoreversible model. Eur. Phys. J. Plus 133(5), 176 (2018)

A. Ocampo-Garcia, M.A. Barranco-Jimenez, A.F. Angulo-Brown, Thermodynamic and thermoeconomic optimization of coupled thermal and chemical engines by means of an equivalent array of uncoupled endoreversible engines. Eur. Phys. J. Plus 133(8), 342 (2018)

L.G. Chen, S.J. Xia, Progresses in generalized thermodynamic dynamic-optimization of irreversible processes. Sci. Sin Technol. 49(9), 981–1022 (2019)

L.G. Chen, S.J. Xia, H.J. Feng, Progress in generalized thermodynamic dynamic-optimization of irreversible cycles. Sci. Sin Technol. 49(11), 1223–1267 (2019)

L.G. Chen, Y.L. Ge, X.Y. Qin, Z.H. Xie, Exergy-based ecological optimization for a four-temperature-level absorption heat pump with heat resistance, heat leakage and internal irreversibility. Int. J. Heat Mass Transf. 129, 855–861 (2019)

Z.M. Ding, L.G. Chen, Y.L. Ge, Z.H. Xie, Optimal performance regions of an irreversible energy selective electron heat engine with double resonance. Sci. China Technol. Sci. 62(3), 337–405 (2019)

L. Zhang, S.J. Xia, L.G. Chen, Y.L. Ge, C. Wang, H.J. Feng, Entropy generation rate minimization for hydrocarbon synthesis reactor from carbon dioxide and hydrogen. Int. J. Heat Mass Transf. 137, 1112–1123 (2019)

J. You, H.J. Feng, L.J. Chen, Z.H. Xie, Constructal design of nonuniform heat generating area based on triangular elements: a case of entropy generation minimization. Int. J. Therm. Sci. 139, 403–412 (2019)

H.J. Feng, G.S. Tao, C.Q. Tang, Y.L. Ge, L.G. Chen, S.J. Xia, Exergoeconomic performance optimization for a regenerative gas turbine closed-cycle heat and power cogeneration plant. Energy Rep. 5, 1525–1531 (2019)

S.S. Qiu, Z.M. Ding, L.G. Chen, F.K. Meng, F.R. Sun, Optimal performance regions of energy selective electron cooling devices consisting of three reservoirs. Eur. Phys. J. Plus 134(6), 273 (2019)

J.F. Shen, L.G. Chen, Y.L. Ge, F.L. Zhu, Z.X. Wu, Optimum ecological performance of irreversible reciprocating Maisotsenko-Brayton cycle. Eur. Phys. J. Plus 134(6), 293 (2019)

S. Levario-Medina, G. Valencia-Ortega, L.A. Arias-Hernandez, Thermal optimization of Curzon–Ahlborn heat engines operating under some generalized efficient power regimes. Eur. Phys. J. Plus 134(7), 348 (2019)

L. Zhang, L.G. Chen, S.J. Xia, Y.L. Ge, C. Wang, H.J. Feng, Multi-objective optimization for helium-heated reverse water gas shift reactor by using NSGA-II. Int. J. Heat Mass Transf. 148, 119025 (2020)

L.G. Chen, F.K. Meng, Z.M. Ding, S.J. Xia, H.J. Feng, Thermodynamic modeling and analysis of an air-cooled small space thermoelectric cooler. Eur. Phys. J. Plus 135(1), 80 (2020)

H.J. Feng, W.X. Qin, L.G. Chen, C.G. Cai, Y.L. Ge, S.J. Xia, Power output, thermal efficiency and exergy-based ecological performance optimizations of an irreversible KCS-34 coupled to variable temperature heat reservoirs. Energy Convers. Manag. 205, 112424 (2020)

Z.X. Wu, H.J. Feng, L,G. Chen, W. Tang, J.Z. Shi, Y.L. Ge, Constructal thermodynamic optimization for ocean thermal energy conversion system with dual-pressure organic Rankine cycle. Energy Convers. Manag. (2020) (in press)

H.J. Feng, J. You, L.G. Chen, Y.L. Ge, S.J. Xia, Constructal design of a non-uniform heat generating disc based on entropy generation minimization. Eur. Phys. J. Plus 135, 2113–2130 (2020)

L.G. Chen, F.K. Meng, Y.L. Ge, H.J. Feng, S.J. Xia, Performance optimization of a class of combined thermoelectric heating devices. Sci. China Technol. Sci. 63 (2020) (in press)

M.I. Khan, S. Javed, M. Waqas, T. Hayat, A. Alsaedi, Entropy optimization in Ag–H2O and Cu–H2O nanomaterial flow with cubic autocatalysis chemical reaction. Eur. Phys. J. Plus 134(10), 500 (2019)

A. Anjum, N.A. Mir, M. Farooq, S. Ahmad, N. Rafiq, Optimization of entropy generation in thermally stratified polystyrene-water/kerosene nanofluid flow with convective boundary condition. Eur. Phys. J. Plus 134(4), 176 (2019)

N. Ghasemi, R. Aghayari, H. Maddah, Optimizing the parameters of heat transmission in a small heat exchanger with spiral tapes cut as triangles and Aluminum oxide nanofluid using central composite design method. Heat Mass Transf. 54(7), 2113–2130 (2018). https://doi.org/10.1007/s00231-018-2292-8

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant No. 51779262). The authors wish to thank the reviewers for their careful, unbiased and constructive suggestions, which led to this revised manuscript.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Aghayari, R., Maddah, H., Pourkiaei, S.M. et al. Theoretical and experimental studies of heat transfer in a double-pipe heat exchanger equipped with twisted tape and nanofluid. Eur. Phys. J. Plus 135, 252 (2020). https://doi.org/10.1140/epjp/s13360-020-00252-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-020-00252-8