Abstract

Bent crystals are a compact and versatile tool to manipulate ultra-relativistic particle beams in accelerators. Indeed, the unrivaled steering power achievable exploiting channeling of particles between the atomic planes is comparable to that of a \(10^{2-3}\) Tesla magnetic dipole. Since the first experiments in the 1980s, extensive research has been delivering important results for new physics experiments and applications in accelerators. The substantial technological development, accompanied by reliable Monte Carlo simulations, has increased the steering efficiency from a few % to the intrinsic maximum efficiency of \(\sim 80\%\), limited by scattering of the particles with nuclei inside the crystal. The recently started two-year (2022–2023) project GALORE of INFN aims to assess experimentally the possibility to overcome this hard limit by developing a new generation of bent crystals, featuring an innovative geometry characterized by a crystalline microstructure which influences particle dynamic in the crystal lattice to boost efficiency close to 100%. The manufacturing process will exploit well-established techniques developed for silicon microelectronics, and experimental testing will be carried out at the extracted beamlines of CERN North Area with high-energy hadron beams. The success of this project could strongly impact the employment of bent crystal in frontier energy accelerators, boosting performance of already proposed schemes as well as enabling completely inedited use of bent crystal in particle physics experiment in accelerators.

Graphic Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

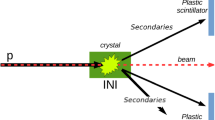

In a crystalline lattice, atoms occupy well-defined positions and appear organized along planes and rows, resulting in regularly spaced distributions of electron and nuclei densities. If a charged particle impinges on such atomic planes or axes at a sufficiently small angle, it is captured under a channeling regime [1]. The crystal atomic planes become a pathway for propagation of the particles inside the crystal. If the crystal is bent, this causes the deflection of the particle beam [2]. The large steering power achievable in such compact objects is equivalent to hundreds of Tesla magnetic dipoles of the same size, at multi-TeV beam energy like the ones at the Large Hadron Collider (LHC). This stimulated the application in accelerators as elements useful for beam steering. Compared to magnetic optical elements used in accelerators, crystals operate without need of either a power source or a cryogenic environment and are extremely compact and lightweight, making them appealing for integration in particle accelerators. The first experiments conducted in the 1980s recorded deflection efficiencies in the order of few percent or less, which was raised to few tens of percent in the 1990s [3] mainly thanks to a proper design of the crystal geometry [4]. In more recent years, considerable improvements in crystal manufacturing techniques [5] allowed the efficient deflection (tens of %) of particle beams in ultra-high-energy accelerators such as the SPS [6,7,8] and the LHC [9, 10]. Moreover, under optimized conditions the physically maximum achievable efficiency of \(\sim 80\%\) was recorded [11]. After a long R &D mainly carried in the frame of the UA9 collaboration and in which the INFN-Ferrara played a key role, the use of bent crystals has been recently added as a part of the baseline upgrade of the LHC ion collimation system in the framework of the High Luminosity LHC (HL-LHC) project. Bent crystals could be also used to extract the halo of the LHC beam toward fixed-target experiments using existing detectors [12, 13] or even toward an extracted line enabling a groundbreaking physics program accessible within fixed-target experiments with the multi-TeV proton and ion beams [14, 15]. Crystal-based solutions [16] are also under consideration for the extraction of SPS beams [17] or at synchrotron facilities [18]. Current techniques for bent crystal manufacturing are unable to overcome the limit of \(\sim 80\%\) for the steering efficiency. Indeed, the intrinsic limitation is caused by the interaction of the beam particle with the atoms of the lattice: Particles impinging on the crystal too close to atomic planes are rapidly “dechanneled” and are not deflected (nuclear dechanneling). A solution to circumvent this limitation was proposed in [19] through the suggestion of an innovative crystal geometry (Fig. 1). The concept exploits the feature of channeled particles trajectories, which is characterized by oscillation in the planar potential well. The dynamics of this behavior has been thoroughly investigated and is well understood, so much that simulation could predict related fine phenomena that were shortly afterward confirmed in experiments, such as quasichanneling oscillation [20, 21] and antichanneling [22]. At the very beginning of the crystal, before dechanneling can occur, the oscillation motion starts to point most of the particle trajectories toward the center of the interplanar potential. At this point, if the particle were to exit the crystal lattice, they would progress in straight line and would result focused after a short distance. Thus, if a crystal were to be machined to obtain a first layer separated by a precise distance from the rest of the bulk, this geometry could act as a sort of “channeling lens” by forcing the channeled particle to reenter the crystal far from the nuclei in the lattice planes, hence suppressing nuclear dechanneling. This method is theoretically capable of permitting steering efficiency close to 100%; we strongly believe that the bent crystal fabrication technology is ready to achieve this potential. Availability of lightweight and inexpensive elements capable of particle steering with efficiency close to 100% might open innovative scenarios for manipulation of particle beams at the energy and intensity frontiers, with elective application in beam collimation and fixed-target experiments at the LHC.

2 Goals and expected results

The project aims to implement a novel bent crystal geometry, exploitable for ultra-relativistic particles steering. Such a scheme has the feature to boost channeling efficiency close to 100%, thanks to the suppression of the spoiling contribution of dechanneling caused by the scattering of channeled particles with the lattice nuclei.

The GALORE project will face the technological challenges needed to realize the first prototype of this novel crystal deflector, such as:

-

a new and innovative bending approach, based on the use of thin tensile films, to deform crystals to be used in setups for particle beam steering.

-

manufacturing of a microstructure at the beam entry face of the crystal, which will act as a lens for the channeled particles. Figure 1 shows a sketch of the crystal which we aim to manufacture.

The upper figure shows trajectories of hadrons (180 GeV pions) channeled between (110) planes of a silicon crystal. Thick gray trajectories correspond to particles which entered the crystal with a small impact parameter with respect to atomic planes and are rapidly dechanneled. The lower figure shows trajectories for particles entering the crystal with the same impact parameter as in the previous simulation. (Highlighted area between Z1 and Z2 indicates the region with crystal interruption.) Thick gray lines indicate the trajectories corresponding to particles which in the case of a “classical” crystal would be dechanneled. In both figures, the dashed lines represent atomic planes

The crystal manufactured for this project will be optimized for experiments with hadron of energy 180GeV, available at the extracted beamline of SPS at CERN. (Thanks to their low divergence and high energy, such beam has already been used to investigate interactions with bent crystals eligible for installation in SPS and LHC rings.) A slight adaptation of the geometry manufactured for operations at 180 GeV will lead to crystals suitable for operations at higher energies; for example, a properly manufactured crystal might enhance performance for crystal-assisted SPS slow extraction, improve LHC beam halo collimation and deliver new possibilities for extraction for fixed-target experiments. Moreover, these results would strongly support new proposals of crystal-based beam manipulation in existing or future accelerators (HL-LHC, FCC, \(\mu \)-collider).

3 Methodology

The idea of the project is based on the predictions of Monte Carlo simulations, in particular using the CRYSTALRAD code [23] which calculates the trajectories of charged particles in the planar and axial electric field of either a straight, bent or periodically bent crystal. The code takes into account multiple and single Coulomb scattering on nuclei and electrons, nuclear scattering and ionization energy losses and successfully simulated several channeling experiments [24, 25]. Figure 2a shows the calculated trajectories for 180 GeV pions channeled between (110) planes of a silicon crystal: Their motion is characterized by oscillations between atomic planes, but particles with an initially too low impact parameter are rapidly dechanneled (red trajectories). Such particles do not contribute to the steering efficiency and might generate nuclear interactions with the crystal, a harmful aspect for crystals aiming to operate as elements to collimate or extract a particle beam in an accelerator. Figure 2b shows trajectories for particles channeled in a crystal equipped with the “crystalline lens” proposed in GALORE. Between the entry face of the crystal and the coordinate \(Z_1\), particles are channeled in a thin silicon lens and start to oscillate, with trajectories pointing to the middle of the channel. At \(Z_1\), the crystalline structure is interrupted through a trench (red area): Particles move in rectilinear motion until the crystal restarts at \(Z_2\). The net result is that particles which would have normally suffered dechanneling are now recovered (green trajectories). This leads to an increase in steering efficiency and lowering of the rate of nuclear interactions occurring in the crystal–beam interaction, especially for alignment within a quarter of critic angle.

The crystalline lens must be realized avoiding misalignment of the atomic planes at the two sides of the trench (red area in Fig. 2b). With this aim, the crystal will be manufactured starting from a single silicon crystal, to be shaped through techniques typically used for silicon micromachining. The main dimensions and bending radius of the crystal will be optimized assuming as an elective application the case of HL-LHC beam collimation, i.e., the radius will be 80 m, and the thickness along the beam be 4.1 mm, of which the first 0.1 mm will be a straight section containing the crystalline lens, and the remaining 4 mm will be bent. Optimal dimensions of the lens scale as the square root of the beam energy. In order to validate the predictions, we plan to carry out experimental observation of the crystal modified channeling efficiency at the energy of 180 GeV available in CERN facilities. The optimal dimensions will be optimized through well-validated Monte Carlo approaches, in order to achieve best result with beam available at CERN North Area. The depth of the trench will be about \(150~\upmu \hbox {m}\), and its height about 10 mm, values sufficiently large to intersect a reasonable section of beam to allow usable statistics. To assure a perfect alignment of the atomic planes across the trench, we plan to maintain flat the initial 0.1 mm of the crystal and impose bending only on the remaining 4 mm. We plan to control the deformation state of the crystal with high accuracy developing an innovative bending approach based on thin tensile films deposited on the surface of the crystal. In more details, crystal deformation will be based on the action of a thin silicon nitride film (\(\text {Si}_3\text {N}_4\)) deposited via Low Pressure Chemical Vapor Deposition (LPCVD) techniques. Deposition of this material and its properties are well established from silicon micromachining: The deposition occurs from gas precursors at a temperature of \(920\,^{\circ }\text {C}\) in ultra-high vacuum. A tensile stress between film and substrate is generated during cooling as a consequence of the mismatch between the coefficients of thermal expansion of the two materials, and the stress reachable with this technique can reach up to \(\approx 1\) GPa, depending on film thickness and environment during deposition process. Besides the tensile film features, the achievable radius of curvature depends on the square of the crystal thickness (in good approximation with Stoney’s law) [26]. Thus, a wide range of radii of curvature from units to hundreds of meters can be obtained by carefully tailoring film and crystal geometry to suit each case requirement.

This material is chosen because:

-

it is ultra-high vacuum compatible

-

guarantees a strong adhesion to silicon

-

is radiation resistant

-

can be deposited controlling its thickness to sub-nm level over 4–6-inch-diameter areas

-

imparts to silicon sufficiently high stress needed for this application (\(\sim 800\) MPa)

The deposition occurs on all the wafer surfaces: Removal of the film from one of the faces through chemical methods leads to deformation of the wafer. In this project, deposition of a \(\text {Si}_3\text {N}_4\) layer 172 nm on a \(500-\upmu \text {m}\)-thick silicon substrate is selected to obtain a radius of curvature of 80 m, which is the value required for the collimation of the LHC. Manufacturing of the crystal will start from (110) oriented silicon wafer (orientation delivering the highest channeling efficiency) nominally \(500~\mu \text {m}\) thick.(see Fig 3)

Crystal-assisted particle beam steering at high energy requires crystals free of dislocations: The purchased wafers will be certified by the supplier as dislocations-free through chemical etching techniques [27, 28], and the wafers will be recertified through X-ray topography techniques [29] at the European Synchrotron Radiation Facility (ESRF). Subsequently, wafer topology and thickness will be characterized with nm-accuracy at INFN-Ferrara through a laser interferometer (Zygo Verifire HDX) and an infrared interferometer (Fogale TMAP-4). These measurements will be used to tune the exact thickness of \(\text {Si}_3\text {N}_4\) to be deposited. The bending procedure will be completed by removal via chemical wet etching of \(\text {Si}_3\text {N}_4\) from one of the surfaces of the wafer. The micro-trench will be realized through a Deep Reactive Ion Etching (DRIE) process. This technology, routinely adopted at plenty of worldwide facilities, allows the realization of structures with high aspect ratio. As the entire process is based solely on chemical reactions, it leaves surfaces free from subsurface lattice damage.

The morphology of the crystal will be characterized through scanning electron microscopy (SEM) and infrared interferometry at INFN-Ferrara to verify the dimensions of the lens with submicron accuracy. White light interferometry (Veeco NT1100, at INFN-Ferrara) and laser interferometry (Zygo Verifire HDX at INFN-Ferrara) will provide the status of the crystal deformation state with nm-accuracy. Such characterizations will be complemented with precise measurement of the bending angle and torsion of the crystal via X-rays with High-Resolution X-rays Diffractometer (HR-XRD, Panalytical X-Pert PRO-XL, at INFN-Ferrara). Alignment of the atomic planes across the trench will be verified through HR-XRD using a solid-state detector of high spatial resolution. The setup will be prepared through an upgrade of the existing HR-XRD to achieve misalignment between atomic planes across the trench with sub-Å resolution. Further characterization of the initial “crystal lens” will be carried out exploiting Rutherford backscattering. Indeed, the experimental setup available at INFN-Legnaro National Laboratory permits to study channeling of MeV proton in the sample to probe crystal lattice down to 10 microns depth with nanometric resolution.

In synergy with INFN CSN5 STORM experiment, a dedicated beamtime at CERN H8 beamline with 180 GeV positive pions (\(\pi ^+\)) will be requested. Through the use of a tracking telescope [30], it will be possible to probe the steering efficiency of the crystal while separating particles impacting in or out of the crystal lens structure, to calculate the steering efficiency boost achieved by the new geometry.

In synergy with MSCA Global Fellowship TRILLION (GA. 101032975), Monte Carlo simulation will be used to optimize geometry of the setup and to reach a deeper understanding of the experimental results, as well as investigate cases of interest for applications at high-energy particle accelerators.

4 Impact and repercussions

The use of bent crystals to steer high-energy particles features a long history of worldwide successes leading to new physics experiments and schemes for beam manipulation. Despite that, the use of this technology has been limited to cases where the limitation on the efficiency in beam steering was acceptable. Availability of a new generation of crystals capable of steering particle beams with efficiency close to 100% would be a turning point in the usage of bent crystal in high-energy accelerators, boosting established setup and enabling new groundbreaking schemes. For example, after a long-lasting experimental campaign driven by UA9 experiment at the extracted beamlines of the SPS and within the SPS ring, crystals have been tested as primary collimators of the LHC beam and became baseline elements for operations of HL-LHC. The research team at INFN-Ferrara built one of the crystals presently installed in the LHC and is currently engaged in the production of new bent crystals for such purpose. In future, crystals equipped with a crystalline lens could be supplied to the CERN following the success of the GALORE program. The Physics Beyond Colliders (PBC) initiative at CERN aims to investigate potential uses of the CERN accelerator complex beyond the scopes of the LHC collider physics. Crystal-assisted solutions for SPS beam extraction in the context of the Beam Dump Facility are currently being studied. Another important subject of investigation, carried out by the LHC Fixed-Target initiative in the PBC, is the possibility to extract part of the halo of the LHC beams and use it for fixed-target experiments: High-performance bent crystals have a key role for the investigated setups in several experiments, as they could operate with lower impact on circulating beams. Indeed, the possibility to deploy such setups would unlock a rich variety of fixed-target opportunities at a record energy [16]. The feasibility of such proposals strongly depends on the availability of crystal kickers to integrate in the accelerators main ring. The main goal of the GALORE program, which is to obtain higher-performance crystals with reliable fabrication technology, could strongly support future commissioning. Future accelerators at the high-energy frontier such as FCC, ILC and \(\mu \)-collider require progressively more powerful and reliable solutions for manipulating the beam, and the technology developed by GALORE would be fundamental for assisting the design of such ambitious projects. Indeed, the ultimate potential of crystal deflectors is well expressed by the concept of the circular crystal collider: a circular accelerator exploiting exclusively bent crystals to steer the beam [31]. If crystal with perfect efficiency were available, this type of accelerator could operate at energy orders of magnitude larger than the FCC-hh.

5 Conclusion

The possibility to suppress hard scattering with nuclei via fabrication of a microstructure at the beginning of a crystal has the potential to achieve the complete potential of channeling phenomenon for manipulation of particle beams. The project GALORE has defined a scientific program in order to manufacture and characterize the first prototypes of a new generation crystalline particle beam deflector by influencing standard channeled particle dynamic in the crystal. The technology from semiconductor electronics and MEMS fields have been selected in order to produce the required microstructure. A set of measures to obtain a complete characterization of the crystal sample were outlined. The most suited experimental setup was defined with the goal of confirming the successful particle dynamic modification via the enhancement of channeling efficiency.

Data Availability Statement

This manuscript has no associated data, or the data will not be deposited. [Authors’ comment: The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request].

References

J. Lindhard, Influence of crystal lattice on motion of energetic charged particles. Danske Vid. Selsk. Mat. Fys. Medd. 34, 14 (1965)

E.N. Tsyganov, Some Aspects of the Mechanism of a Charge Particle Penetration Through a Monocrystal. Technical Reports on Fermilab (1976). Preprint TM-682

R.A. Carrigan, D. Chen, G. Jackson, N. Mokhov, C.T. Murphy, S. Baker, A. Bogacz, D. Cline, S. Ramachandran, J. Rhoades, J. Rosenzweig, A. Asseev, V. Biryukov, A. Taratin, J.A. Ellison, A. Khanzadeev, T. Prokofieva, V. Samsonov, G. Solodov, B. Newberger, E. Tsyganov, H.J. Shih, W. Gabella, B. Cox, V. Golovatyuk, A. McManus, Beam extraction studies at 900 GeV using a channeling crystal. Phys. Rev. ST Accel. Beams 5, 043501 (2002). https://doi.org/10.1103/PhysRevSTAB.5.043501

A. Afonin et al., High-efficiency multipass extraction of 70-GeV protons from an accelerator with a short bent crystal. Phys. Lett. B 435(1), 240–244 (1998). https://doi.org/10.1016/S0370-2693(98)00940-X

S. Baricordi, V. Guidi, A. Mazzolari, D. Vincenzi, M. Ferroni, Shaping of silicon crystals for channelling experiments through anisotropic chemical etching. J. Phys. D: Appl. Phys. 41(24), 245501 (2008)

W. Scandale, G. Arduini, R. Assmann, C. Bracco, S. Gilardoni, V. Ippolito, E. Laface, R. Losito, A. Masi, E. Metral et al., First results on the SPS beam collimation with bent crystals. Phys. Lett. B 692(2), 78–82 (2010)

W. Scandale, G. Arduini, R. Assmann, C. Bracco, F. Cerutti, J. Christiansen, S. Gilardoni, E. Laface, R. Losito, A. Masi, E. Metral, D. Mirarchi, S. Montesano, V. Previtali, S. Redaelli, G. Valentino, P. Schoofs, G. Smirnov, L. Tlustos, E. Bagli, S. Baricordi, P. Dalpiaz, V. Guidi, A. Mazzolari, D. Vincenzi, S. Dabagov, F. Murtas, A. Carnera, G. Della Mea, D. De Salvador, A. Lombardi, O. Lytovchenko, M. Tonezzer, G. Cavoto, L. Ludovici, R. Santacesaria, P. Valente, F. Galluccio, A. Afonin, M. Bulgakov, Y. Chesnokov, V. Maisheev, I. Yazynin, A. Kovalenko, A. Taratin, V. Uzhinskiy, Y. Gavrikov, Y. Ivanov, L. Lapina, V. Skorobogatov, W. Ferguson, J. Fulcher, G. Hall, M. Pesaresi, M. Raymond, A. Rose, M. Ryan, O. Zorba, G. Robert-Demolaize, T. Markiewicz, M. Oriunno, U. Wienands, Comparative results on collimation of the SPS beam of protons and PB ions with bent crystals. Phys. Lett. B 703(5), 547–551 (2011). https://doi.org/10.1016/j.physletb.2011.08.023

W. Scandale, G. Arduini, M. Butcher, F. Cerutti, M. Garattini, S. Gilardoni, A. Lechner, R. Losito, A. Masi, A. Mereghetti, E. Metral, D. Mirarchi, S. Montesano, S. Redaelli, R. Rossi, P. Schoofs, G. Smirnov, E. Bagli, L. Bandiera, S. Baricordi, P. Dalpiaz, G. Germogli, V. Guidi, A. Mazzolari, D. Vincenzi, G. Claps, S. Dabagov, D. Hampai, F. Murtas, G. Cavoto, F. Iacoangeli, L. Ludovici, R. Santacesaria, P. Valente, F. Galluccio, A. Afonin, Y. Chesnokov, A. Durum, V. Maisheev, Y. Sandomirskiy, A. Yanovich, A. Kovalenko, A. Taratin, Y. Gavrikov, Y. Ivanov, L. Lapina, J. Fulcher, G. Hall, M. Pesaresi, M. Raymond, Observation of strong leakage reduction in crystal assisted collimation of the SPS beam. Phys. Lett. B 748, 451–454 (2015). https://doi.org/10.1016/j.physletb.2015.07.040

W. Scandale, G. Arduini, M. Butcher, F. Cerutti, M. Garattini, S. Gilardoni, A. Lechner, R. Losito, A. Masi, D. Mirarchi, S. Montesano, S. Redaelli, R. Rossi, P. Schoofs, G. Smirnov, G. Valentino, D. Breton, L. Burmistrov, V. Chaumat, S. Dubos, J. Maalmi, V. Puill, A. Stocchi, E. Bagli, L. Bandiera, G. Germogli, V. Guidi, A. Mazzolari, S. Dabagov, F. Murtas, F. Addesa, G. Cavoto, F. Iacoangeli, L. Ludovici, R. Santacesaria, P. Valente, F. Galluccio, A. Afonin, Y. Chesnokov, A. Durum, V. Maisheev, Y. Sandomirskiy, A. Yanovich, A. Kovalenko, A. Taratin, A. Denisov, Y. Gavrikov, Y. Ivanov, L. Lapina, L. Malyarenko, V. Skorobogatov, T. James, G. Hall, M. Pesaresi, M. Raymond, Observation of channeling for 6500 GeV/c protons in the crystal assisted collimation setup for LHC. Phys. Lett. B 758, 129–133 (2016). https://doi.org/10.1016/j.physletb.2016.05.004

S. Redaelli, M. Butcher, C. Barreto, R. Losito, A. Masi, D. Mirarchi, S. Montesano, R. Rossi, W. Scandale, P. Serrano-Galvez et al., First observation of ion beam channeling in bent crystals at multi-TeV energies. Eur. Phys. J. C 81(2), 1–7 (2021)

W. Scandale et al., Observation of nuclear dechanneling for high-energy protons in crystals. Phys. Lett. B 680(2), 129–132 (2009). https://doi.org/10.1016/j.physletb.2009.08.046

C. Barschel, et al. Report from the LHC fixed target working group of the CERN physics beyond colliders forum (2019)

D. Mirarchi, A. Fomin, S. Redaelli, W. Scandale, Layouts for fixed-target experiments and dipole moment measurements of short-lived baryons using bent crystals at the LHC. Eur. Phys. J. C 80(10), 1–16 (2020)

E. Uggerhoj, U. Uggerhoj, Strong crystalline fields-a possibility for extraction from the LHC. Nucl. Instrum. Methods Phys. Res. Sect. B 234(1), 31–39 (2005)

D. Kikoła, S. Brodsky, G. Cavoto, C. Da Silva, F. Donato, M. Echevarria, E. Ferreiro, C. Hadjidakis, I. Hřivnáčová, A. Klein et al., A fixed-target programme at the LHC for heavy-ion, hadron, spin and astroparticle physics: After@ LHC. Nucl. Phys. A 982, 971–974 (2019)

A. Mazzolari, M. Romagnoni, R. Camattari, E. Bagli, L. Bandiera, G. Germogli, V. Guidi, G. Cavoto, Bent crystals for efficient beam steering of multi TeV-particle beams. Eur. Phys. J. C 78(9), 720 (2018). https://doi.org/10.1140/epjc/s10052-018-6196-z

F.M. Velotti, L.S. Esposito, M.A. Fraser, V. Kain, S. Gilardoni, B. Goddard, M. Pari, J. Prieto, R. Rossi, W. Scandale et al., Septum shadowing by means of a bent crystal to reduce slow extraction beam loss. Phys. Rev. Accel. Beams 22(9), 093502 (2019)

M. Garattini, D. Annucci, O. Blanco-García, P. Gianotti, S. Guiducci, A. Liedl, M. Raggi, P. Valente, Crystal slow extraction of positrons from the Frascati DA\(\phi \)NE collider. Phys. Rev. Accel. Beams 25(3), 033501 (2022)

V. Tikhomirov, A technique to improve crystal channeling efficiency of charged particles. J. Instrum. 2(08), P08006 (2007)

A. Sytov, V. Guidi, V. Tikhomirov, E. Bagli, L. Bandiera, G. Germogli, A. Mazzolari, Planar channeling and quasichanneling oscillations in a bent crystal. Eur. Phys. J. C 76(2), 1–15 (2016)

T. Wistisen, R. Mikkelsen, U. Uggerhøj, U. Wienands, T. Markiewicz, S. Gessner, M. Hogan, R. Noble, R. Holtzapple, S. Tucker et al., Observation of quasichanneling oscillations. Phys. Rev. Lett. 119(2), 024801 (2017)

E. Bagli, D. De Salvador, L. Bacci, F. Sgarbossa, L. Bandiera, R. Camattari, G. Germogli, A. Mazzolari, A. Sytov, G. Guidi, Enhancement of the inelastic nuclear interaction rate in crystals via antichanneling. Phys. Rev. Lett. 123(4), 044801 (2019)

A. Sytov, V. Tikhomirov, L. Bandiera, Simulation code for modeling of coherent effects of radiation generation in oriented crystals. Phys. Rev. Accel. Beams 22(6), 064601 (2019)

S. Aiola, L. Bandiera, G. Cavoto, F. De Benedetti, J. Fu, V. Guidi, L. Henry, D. Marangotto, F.M. Vidal, V. Mascagna et al., Progress towards the first measurement of charm baryon dipole moments. Phys. Rev. D 103(7), 072003 (2021)

L. Bandiera, A. Sytov, D. De Salvador, A. Mazzolari, E. Bagli, R. Camattari, S. Carturan, C. Durighello, G. Germogli, V. Guidi et al., Investigation on radiation generated by sub-GeV electrons in ultrashort silicon and germanium bent crystals. Eur. Phys. J. C 81(4), 1–9 (2021)

V. Guidi, A. Antonini, S. Baricordi, F. Logallo, C. Malagù, E. Milan, A. Ronzoni, M. Stefancich, G. Martinelli, A. Vomiero, Tailoring of silicon crystals for relativistic-particle channeling. Nucl. Instrum. Methods Phys. Res. Sect. B 234(1–2), 40–46 (2005)

E. Sirtl, A. Adler, Chromic-hydrofluoric acid as a specific system for the development of etch pits on silicon. Z. Metall. 52, 529–534 (1961)

F. Aragona, Dislocation etch for (100) planes in silicon. J. Electrochem. Soc. 119, 948–951 (1972)

B. Tanner, J. Wittge, P. Vagovič, T. Baumbach, D. Allen, P. McNally, R. Bytheway, D. Jacques, M. Fossati, D. Bowen et al., X-ray diffraction imaging for predictive metrology of crack propagation in 450-mm diameter silicon wafers. Powder Diffr. 28(2), 95–99 (2013). https://doi.org/10.1017/S0885715613000122

D. Lietti, A. Berra, M. Prest, E. Vallazza, A microstrip silicon telescope for high performance particle tracking. Nucl. Instrum. Methods Phys. Res. Sect. A 729, 527–536 (2013)

F. Zimmermann, High-energy physics strategies and future large-scale projects. Nucl. Instrum. Methods Phys. Res. Sect. B 355, 4–10 (2015). https://doi.org/10.1016/j.nimb.2015.03.090

Acknowledgements

A special thanks to Stefano Redaelli and Lucio Rossi for the fruitful discussion on the subject of this work. This work has been financially supported by the Istituto Nazionale di Fisica Nucleare (INFN), Italy, Commissione Scientifica Nazionale 5, Ricerca Tecnologica-Bando No. 23246/2021.

Funding

Open access funding provided by Universitá degli Studi di Padova within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Contributions

Primary contributor of the paper is the corresponding author and GALORE PI: Dr. Romagnoni. Dr. Mazzolari, Dr. Bandiera and Prof. Guidi contributed to the writing and revision of the paper. Dr. Sytov and Mr. Soldani contribution belongs to the simulation part of the paper. Dr. Carraro, Prof. De Salvador, Mr. Scatizza, Dr. Sgarbossa and Dr. Tamisari contributed to the experimental details of the paper.

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Romagnoni, M., Bandiera, L., Carraro, C. et al. The GALORE project. Eur. Phys. J. D 76, 135 (2022). https://doi.org/10.1140/epjd/s10053-022-00439-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjd/s10053-022-00439-x