Abstract

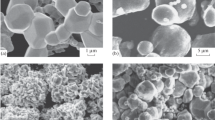

Refractory (melting point Tm = 2100°C), heat-resistant ruthenium monoaluminide RuAl, lighter (ρ = 7.97 g/cm3) than Ni superalloys, is considered as a promising material for operation at a high temperature and under relatively low loads in high-velocity gas oxidizing flows. This alloy can be used not only at a temperature higher than operating temperature tw inherent in both nickel superalloys and nickel and titanium aluminides, but also at a temperature higher than the melting point of the latter. RuAl is also an ideal candidate for potential use in protective coatings. In the first part of the paper, RuAl-based cast alloys have been considered. In the second part of the paper, the potentialities of obtaining alloys based on RuAl directly from the initial powders of ruthenium and aluminum by combining the temperature–time modes of reactive alloying (RA), as well as the sequence and intensity of pressure application in the course of RA, are considered. The third part of the paper is devoted to studying the potentialities of powders doped with RuAl (NiAl, TiAl) with a preset composition obtained by means of mechanical alloying used as a starting material.

Similar content being viewed by others

REFERENCES

Povarova, K.B., Morozov, A.E., and Drozdov, A.A., Heat resistant RuAl-based alloys: Part I. Cast alloys, Inorg. Mater.: Appl. Res., 2020, vol. 11, no. 2, pp. 277–286.

Fleisher, B.L., Miscellaneous novel intermetallics, in Intermetallic Compounds: Principles and Practice, vol. 2: Practice, Westbrook, J.H. and Fleischer R.L., Eds., New York: Wiley, 1994, pp. 237–256.

Guitar, M.A., Moore, E.R., and Mucklich, F., The influence of impurities on the formation of protective aluminium oxides on RuAl thin films, J. Alloys Compd., 2014, vol. 594, pp. 165–170.

Guitar, M.A., Aboulfadl, H., Pauly, C., Leibenguth, P., Migot, S., and Mucklich, F., Production of single-phase intermetallic films from Ru–Al multilayers, Surf. Coat. Technol., 2014, vol. 244, pp. 210–216.

Mucklich, F. and Ilic, N., RuAl and its alloys. Part I. Structure, physical properties, microstructure and processing, Intermetallics, 2005, vol. 13, pp. 5–21.

Mucklich, F., Ilic, N., and Woll, K., RuAl and its alloys. Part II: Mechanical properties, environmental resistance and applications, Intermetallics, 2008, vol. 16, pp. 593–608.

Povarova, K.B., Morozov, A.E., Drozdov, A.A., et al., Heat-resistant RuAl-based alloys: Part II. Powder alloys—preparation via reaction sintering, Inorg. Mater.: Appl. Res., 2021, vol. 12, pp. 1125–1138. https://doi.org/10.1134/S2075113321050312

Dzneladze, Zh.I., Shchegoleva, R.P., Golubeva, L.S., et al., Poroshkovaya metallurgiya stalei i splavov (Powder Metallurgy of Steels and Alloys), Moscow: Metallurgiya, 1978.

Mohamed, K.E., Stover, D., and Buchkremer, H.P., Some reactive processing aspects of high-temperature aluminides Nb3Al and RuAl, J. Mater. Eng. Perform., 1997, vol. 6, pp. 771–779.

Anil, Borah, Robi, P.S., and Srinivasan, A., Synthesis of nanocrystalline RuAl by mechanical alloying, Met. Mater. Int., 2007, vol. 13, no. 4, pp. 293–302.

Povarova, K.B., Tolstobrov, Y.O., Proskyrin, V.B., Kolesnikov, A.A., Levin, V.P., and Borisov, Y.G., The effect of mechanical alloying on the structure and properties of powder mixtures Ti + 48 at %Al and the nature of the formation of intermetallic phases in them during sintering, Metally, 1994, no. 3, pp. 99–107.

Skachkhov, O.A., Povarova, K.B., Drozdov, A.A., Makarevich, O.N., and Morozov, A.E., Effect of the preparation methods of NiAl powders on the structure and properties of NiAl alloys and NiAl–Y2O3 composites, Proc. of PM2010 World Congress, Florence, October 10–14, 2010, Fortezza da Basso Centre, 2010, vol. 5, pp. 344–351.

Drozdov, A.A., Morozov, A.E., and Povarova, K.B., Comparative analysis of the effect of mechanical activation in an attritor on the structure and behavior of β‑RuAl and β-NiAl alloy powder mixtures during reactive sintering, Russ. Metall. (Metally), 2013, vol. 2013, pp. 347–353.

Povarova, K.B., Morozov, A.E., Drozdov, A.A., and Kazanskaya, N.K., Development of RuAl-based cast alloy, Russ. Metall. (Metally), 2011, vol. 2011, pp. 865–874.

Huang, S., Zhang, C.H., Li, R.Z., Shen, J., and Chen, N.X., Site preference and alloying effect on elastic properties of ternary B2 RuAl-based alloys, Intermetallics, 2014, vol. 51, pp. 24–29.

Borisov, Yu.G., Kolesnikov, A.A., and Titovich, E.S., Mechanical alloying of the titanium-aluminum composition, Porosh. Metall., 1992, no. 16, pp. 37–39.

Gobran, H.A., Ilić, N., and Mucklich, F., Effects of particle size and pressure on the reactive sintering of RuAl intermetallic compound, Intermetallics, 2004, vol. 12, no. 5, pp. 555–562.

Liu, K.W., Mucklich, F., and Birringer, R., Synthesis of nano-RuAl by mechanical alloying, Intermetallics, 2001, vol. 9, no. 1, pp. 81–88.

Liu, K.W. and Mucklich, F., Synthesis and thermal stability of nano-RuAl by mechanical alloying, Mater. Sci. Eng., A, 2002, vols. 329–331, pp. 112–117.

Liu, K.W. and Mucklich, F., Thermal stability of nano-RuAl produced by mechanical alloying, Acta Mater., 2001, vol. 49, no. 3, pp. 395–403.

Funding

This work financially supported according to the State Order no. 075-00328-21-00.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by O. Polyakov

Rights and permissions

About this article

Cite this article

Povarova, K.B., Morozov, A.E., Drozdov, A.A. et al. Heat-Resistant RuAl-Based Alloys: III. Powder Alloys—Mechanical Alloying. Inorg. Mater. Appl. Res. 13, 294–305 (2022). https://doi.org/10.1134/S2075113322020344

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113322020344