Abstract

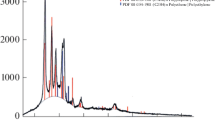

The effect of nanofiller (NF) additives containing zinc oxide nanoparticles stabilized by a polymer matrix of high pressure polyethylene obtained by the mechanochemical method on the structure and properties of metal-containing nanocomposites based on isotactic polypropylene (PP) and high pressure polyethylene (PE) using differential thermal (DTA) and X-ray phase (XRD) analyses was studied. The improvement of strength, deformation, and rheological parameters, as well as thermal-oxidative stability of the obtained nanocomposites, was revealed, which, apparently, is associated with the synergistic effect of interfacial interaction of zinc-containing nanoparticles in the PE matrix with the components of the PP/PE polymer composition. It is shown that nanocomposites based on PP/PE/NF can be processed both by the pressing method and by the injection molding and extrusion methods, which expands the scope of its application.

Similar content being viewed by others

REFERENCES

Ermakov, S.N. and Kravchenko, T.P., Polymer compatibility. Thermodynamic and chemical aspects, Plast. Massy, 2012, no. 4, pp. 32–38.

Novokshonov, V.V., Musin, I.N., and Kimbel’blat, V.I., Dependence of the properties of PP/EPK mixtures on the composition and characteristics of polymers, Plast. Massy, 2009, no. 5, pp. 7–10.

Kuchmenova, L.Kh., Slonov, A.L., Zhansitov, A.A., Shelgaev, V.N., Khashirova, S.Yu., and Mikitaev, A.K., Investigation of the thermal properties of the polymer-polymeric compositions based on polypropylene, Plast. Massy, 2014, nos. 7–8, pp. 7–9.

Nigmatulina, A.I., Vol’fson, S.I., Okhotina, N.A., and Shaldybina, M.S., Properties of dynamic thermoplastic elastomers containing modified polypropylene and layered filler, Vestn. Kazansk. Tekhnol. Univ., 2010, no. 9, pp. 329–331.

Perestoronina, Z.A., Ableev, R.I., Baranets, I.V., and Kurlyand, S.K., Influence of polymer additives on the enhancement of interfacial interaction in mixed thermoplastic elastomers, Kauchuk Rezina, 2012, no. 2, pp. 13–16.

Zaikin, A.E. and Bobrov, G.B., Oil-resistant thermoplastic elastomer based on a mixture of polypropylene and a copolymer of ethylene with vinyl acetate, vulcanized by the hydrosilylation reaction, Vestn. Kazansk. Tekhnol. Univ., 2013, vol. 16, no. 2, pp. 105–108.

Kakhramanov, N.T., Guliev, A.D., and Pesetskii, S.S., Dynamically vulcanized nanocomposites based on random polypropylene, butadiene nitrile rubber and kaolin, Kompoz. Nanostruct., 2019, vol. 11, no. 4, pp. 131–136.

Sevast’yanov, D.V., Doriomedov, M.S., Daskovskii, M.I., and Skripachev, S.Yu., Single-polymer composites—classification, synthesis, mechanical properties and application (review), Tr. VIAM, 2017, no. 4, pp. 104–118.

Suzdalev, I.P. and Suzdalev, P.I., Nanoclusters and nanocluster systems. Assembling, interactions and properties, Russ. Chem. Rev., 2001, vol. 70, no. 3, pp. 177–210. https://doi.org/10.1070/RC2001v070n03ABEH000627

Mikhailin, Yu.A., Polymer nanocomposition materials, Polimer. Mater., 2009, no. 7, pp. 10–13.

Koo, J.H., Polymer Nanocomposites. Processing, Characterization and Applications, New York: McGraw-Hill, 2006.

Tret’yakov, A.O., Polymer nanocomposites – materials of XXI century, Oborud. Instrum. Profession., 2003, no. 2 (37), pp. 18–20.

Foster, L.E., Nanotechnology: Science, Innovation and Opportunity, Prentice Hall, 2005. ISBN 10:0137025750

Pomogailo, A.D., Rozenberg, A.S., and Uflyand, I.E., Nanochastitsy metallov v polimerakh (Nanoparticles of Metals in Polymers), Moscow: Khimiya, 2000.

Gubin, S.P., Yurkov, G.Yu., and Kosobudsky, I.D., Nanomaterials based on metal-containing nanoparticles in polyethylene and other carbon-chain polymers, Int. J. Mat. Prod. Technol., 2005, vol. 23, nos. 1–2, pp. 2–25.

Kurbanova, N.I., Alimirzoeva, N.A., Guseinova, Z.N., and Nurullayeva, D.R., Ecological method of preparation of metal-containing nanoparticles in polyethylene matrix, Proc. 3rd Int. Turkic World Conf. on Chemical Sciences and Technologies, Azerbaijan, Baku, September 10–13, 2017, pp. 22–24.

Kurenkov, V.F., Praktikum po khimii i fizike polimerov (Practical Work on the Chemistry and Physics of Polymers), Moscow: Khimiya, 1990.

Pomogailo, A.D., Molecular polymer–polymer compositions. Synthetic aspects, Russ. Chem. Rev., 2002, vol. 71, no. 1, pp. 1–32. https://doi.org/10.1070/RC2002v071n01ABEH000681

Kuleznev, V.N., Smesi i splavy polimerov (Mixtures and Alloys of Polymers), St. Petersburg: Nauchn. Osnovy Tekhnol., 2013.

Entsiklopediya polimerov (Encyclopedia of Polymers), Moscow: Sov. Entsiklopediya, 1974, vol. 2.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The effect of a zinc oxide nanofiller stabilized by a high-pressure polyethylene matrix, obtained by a mechanochemical method, on the properties of composites based on PP/PE was investigated.

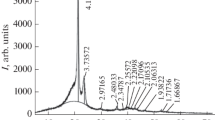

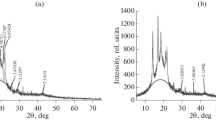

XRD patterns confirm the presence of zinc oxide nanoparticles in the composites based on PP/PE.

An improvement in the strength, deformation, and rheological parameters, as well as the thermal-oxidative stability of the obtained nanocomposites, has been revealed.

It is shown that nanocomposites based on PP/PE/NN can be processed both by pressing and by injection molding and extrusion.

It has been shown that it is promising to use as an additive to PP/PE a nanofiller containing NPs of zinc oxides stabilized by a matrix of high-pressure polyethylene, obtained by a mechanochemical method, which contributes to the creation of a fine-crystalline structure of the composition, in connection with which its properties are improved and, thus, the fields of application of the obtained nanocomposite are expanded.

Additional information

Translated by M. Drozdova

Rights and permissions

About this article

Cite this article

Kurbanova, N.I., Ragimova, S.K., Alimirzoeva, N.A. et al. Composites Based on Isotactic Polypropylene and High-Pressure Polyethylene with Zinc-Containing Nanofillers. Inorg. Mater. Appl. Res. 13, 485–488 (2022). https://doi.org/10.1134/S2075113322020253

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113322020253